- DL manuals

- Factory Five Racing

- Automobile

- Mk4 Roadster

- Assembly Manual

Factory Five Racing Mk4 Roadster Assembly Manual

Summary of Mk4 Roadster

Page 1

R e v i s i o n 4 l , o c t o b e r 2 0 1 7.

Page 2

2017 factory five racing inc. 9 tow rd wareham, ma 02571 phone 508.291.3443 • fax 508.291.3883.

Page 3

Ii www.Factoryfive.Com 508-291-3443 table of contents general information .................................................................. 8 foreword ......................................................................................... 8 safety notice .............................................

Page 4

Iii www.Factoryfive.Com 508-291-3443 3 link rear suspension torque specs chart .......................................... 79 optional independent rear suspension – standard width ............ 80 parts needed ........................................................................................... ...

Page 5

Iv www.Factoryfive.Com 508-291-3443 fuel filler neck ....................................................................................... 175 fuel tank install ..................................................................................... 177 fuel filter ......................................

Page 6

V www.Factoryfive.Com 508-291-3443 cables ................................................................................................... 273 handle and cable adjustment .............................................................. 276 axle and fuel tank vents .....................................

Page 7

Vi www.Factoryfive.Com 508-291-3443 turn signal ............................................................................................ 379 license plate light ................................................................................. 381 side exhaust .......................................

Page 8

Vii www.Factoryfive.Com 508-291-3443 front wheel ........................................................................................... 488 rear wheel ........................................................................................... 491 finishing touches .................................

Page 9: General Information

8 www.Factoryfive.Com 508-291-3443 general information foreword f you are reading this, you are embarking on a mission to build your own car, or at least considering doing so. I wanted to share with you some of my experiences and lessons learned while working with literally thousands of people who h...

Page 10

9 www.Factoryfive.Com 508-291-3443 part of the very definition of always trying to go faster. The late carroll smith wrote something i really loved that speaks to this point. “there is no magic! The one basic truth of successful racecar preparation bears repeating. There is no magic. There is only l...

Page 11

10 www.Factoryfive.Com 508-291-3443 all the way thru the process, as you build your car, the seasoned guys at factory five in tech support will help you. The larger community of factory five customers will also be there for you, as the one thing that really sets us above the crowd of other companies...

Page 12

11 www.Factoryfive.Com 508-291-3443 the procedures and recommendations contained in this book are to be used as a guide with the ultimate determination of safe construction and race-worthiness to be made by you. If you feel uneasy about whether you have the skills to build your own vehicle, do not p...

Page 13

12 www.Factoryfive.Com 508-291-3443 safety tips read the manual. It is at least a good guide and place to start. Don’t take short cuts. Before starting work, make sure you have the proper tools, the required parts, and sufficient space for the job. If you damage any parts, it will probably be becaus...

Page 14

13 www.Factoryfive.Com 508-291-3443 how to use this book this assembly manual is intended to help you build your factory five kit. This book will not explain such things as engine or transmission building. A secondary purpose of this book is to use it as reference for owners that want to do maintena...

Page 15

14 www.Factoryfive.Com 508-291-3443 driveshaft: select from one of three available driveshaft’s w/fasteners to match the engine/trans of your choice. Select one of the following… 28 spline driveshaft for t-5, aod, or tremec 3550’s 31 spline driveshaft for tremec tko 500 or 600’s 31 spline driveshaft...

Page 16

15 www.Factoryfive.Com 508-291-3443 paint: most customers will send out the body and paint work to a professional body shop. Fuel pump: you are responsible for purchasing an external carbureted or fuel injected inline fuel pump. Battery: we recommend a battery sized for a ford mustang. Wheels and ti...

Page 17

16 www.Factoryfive.Com 508-291-3443 serial number identification factory five racing has included a certificate of origin along with a nameplate for your kit. The serial number from the certificate of origin matches the number engraved on the 2”x 2” tube going across the car at the front of the cock...

Page 18

17 www.Factoryfive.Com 508-291-3443 tools list the following lists detail the tools and supplies that are needed to build your kit. The “helpful” items are not crucial to the assembly but make life easier. Home depot husky®, sears craftsman®, and snap-on tools are all guaranteed for life and we’ve f...

Page 19

18 www.Factoryfive.Com 508-291-3443 required supplies stick with name brand products like eastwood , 3m , and duplicolor . The eastwood brand coatings are great for bringing weathered and oxidized parts up to show quality. Ppg brand and dupont brand paints are excellent. Engine degreaser silicone do...

Page 20: Disassembly Of The Kit

19 www.Factoryfive.Com 508-291-3443 disassembly of the kit chapter 2.

Page 21

20 www.Factoryfive.Com 508-291-3443 unpacking your kit boxes are numbered, when you read your packing list you will see that next to each assembly there is a number circled. This is the box number that the assembly was packaged in. The kit is packaged in the order that you will be using the parts. A...

Page 22

21 www.Factoryfive.Com 508-291-3443 body removal ⅝” socket, ratchet, ⅝” wrench, gloves, 2 friends. Be careful of the raw fiberglass edges, they can splinter into your skin unbolt the door from the hinge leaving the hinge attached to the chassis. Cut the zip ties in the door latch area. Remove the ho...

Page 23

22 www.Factoryfive.Com 508-291-3443 unbolt the body sides from the chassis on the underside of the car. Unbolt the quick jacks and remove the body. Two people can do this but it is much easier with a third person to pull the sides clear of the chassis. When you store the body on the ground (unsuppor...

Page 24

23 www.Factoryfive.Com 508-291-3443 putting two short 2”x 4” braces (24” long) under the windshield holes (running vertically to support the hood cowl area just forward of the doors under the windshield holes). Use these 2”x 4” ’s whenever the body is on the ground, otherwise make a body buck to sup...

Page 25

24 www.Factoryfive.Com 508-291-3443 aluminum removal ¼” nut driver, jack stands, marker. Do one panel at a time. Be careful of the sharp aluminum edges, they can cut you. Using a marker outline the underside of each panel where it contacts the chassis. This is done to locate where to drill rivet hol...

Page 26

25 www.Factoryfive.Com 508-291-3443.

Page 27

26 www.Factoryfive.Com 508-291-3443.

Page 28

27 www.Factoryfive.Com 508-291-3443 use jack-stands to position your frame in your workspace with plenty of room to move things around..

Page 29: Chassis Assembly

28 www.Factoryfive.Com 508-291-3443 chassis assembly chapter 3.

Page 30

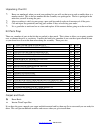

29 www.Factoryfive.Com 508-291-3443 rivet spacing tool packaged aluminum in most cases we use a 3” rivet spacing when mounting aluminum panels to the chassis and a 2” spacing when mounting panel to panel. The rivet spacing tool has this hole spacing marked. The distance from the edge of the tool to ...

Page 31

30 www.Factoryfive.Com 508-291-3443 drill the panels using a 1 / 8 ” bit then clean the marker lines and labeling off using acetone or brake cleaner. Apply silicone to the panel or chassis (whichever is easier) in the areas where they will make contact..

Page 32

31 www.Factoryfive.Com 508-291-3443 use the original #6 screws to remount the panel then drill the 1 / 8 ” rivet holes through the panel holes into the chassis. Rivet the panel in place using 1 / 8 ” short rivets, then remove the screws and replace them with rivets. Repeat for the other side..

Page 33

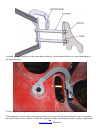

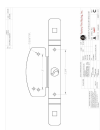

32 www.Factoryfive.Com 508-291-3443 front suspension front lower control arm ⅞” socket, 5 / 16 ”, 15 / 16 ” wrenches, torque wrench front lower control arm assembly unpack the front lower control arms and hardware..

Page 34

33 www.Factoryfive.Com 508-291-3443 screw the grease fittings into the arms using a 5 / 16 ” wrench. Mount the lower control arms using the outer set of holes on the chassis using the supplied hardware..

Page 35

34 www.Factoryfive.Com 508-291-3443 the rear bushing mount on the chassis is wider to be able to accept oem arms so use the large shim washers provided to take up the extra space. While holding the arm parallel to the ground, torque the bolts to 135-149nm (100-110 lbft). Front upper control arm vise...

Page 36

35 www.Factoryfive.Com 508-291-3443 put thread locker on the upper balljoint threads. Screw the upper ball joints into the control arms so that the balljoint angles out on the bottom.

Page 37

36 www.Factoryfive.Com 508-291-3443 tighten the balljoint using the arm for leverage with a vice holding the ball joint. Screw the grease fittings in to the ball joints and tighten with a ⅜” wrench..

Page 38

37 www.Factoryfive.Com 508-291-3443 mount the upper control arms to the chassis with the grease fittings pointed up. Use the mount holes that are vertical on the side of the 2”x 3” tube, not the top horizontal ones. Use a washer with the front locknut..

Page 39

38 www.Factoryfive.Com 508-291-3443 do not use a washer on the rear locknut. Torque the two bolts that hold the arm to the frame to 135-149nm (100-110 lbft). Pivot endplay adjust the locknuts on the ends of the pivot shaft so that there is minimal endplay but so the pivots can still rotate easily on...

Page 40

39 www.Factoryfive.Com 508-291-3443 slightly loosen the three pivot bolts using a ⅝” and 11 / 16 ” wrench. Loosen the jam nuts on both ends of each adjusting tubes using a 1⅛” wrench. Turn the adjusting tubes to lengthen or shorten the arm. After you have adjusted the arm to the desired length, tigh...

Page 41

40 www.Factoryfive.Com 508-291-3443 unpack the front shocks, coil-over’s and hardware. Double check the jam nut under the rod end and bump stop to make sure that it is tight. Screw the spring seat down on the sleeve so it is closer to the unthreaded end. Slide the coil sleeve over the body of the da...

Page 42

41 www.Factoryfive.Com 508-291-3443 the coil-over hats have a snap ring which holds it in place. Remove this snap ring to assemble the coil over shock. Slide the rubber bumper about two inches down on the shaft. Put the spring and hat on the shock and rotate the spring seat back up the sleeve so tha...

Page 43

42 www.Factoryfive.Com 508-291-3443 install the snap ring on the spring hat so that it holds onto the shock end. Make sure that the slot in the snap ring and the slot in the spring hat are not aligned. Pass the shock assembly (with the body of the shock up) through the upper a-arm and attach them to...

Page 44

43 www.Factoryfive.Com 508-291-3443 run zip ties through the holes in the spring hat and around the spring to prevent the spring from becoming unseated. Fasten the shock to the top mount with the fasteners and 0.675” spacers provided and torque both upper and lower mounts to 40 ft-lbs..

Page 45

44 www.Factoryfive.Com 508-291-3443 spindles 13 / 16 ” socket, torque wrench, needle nose pliers, rubber mallet spindle assembly, ifs components. Unpack and lay out the hardware for the spindles assembly. The spindles are marked dss (driver side spindle) and pss (passenger side spindle). These refer...

Page 46

45 www.Factoryfive.Com 508-291-3443 make sure the grease boot is in place on the balljoint then mount the spindle to the lower control arm. Place the spacer under the castle nut to ensure that the cotter pin is at the correct height. Torque to 106-149nm (80-110 lbft) and install the cotter pin..

Page 47

46 www.Factoryfive.Com 508-291-3443 attach the upper ball joint to the spindle and torque to 75 ft-lbs and install the cotter pin. The upper ball joint boot will look crushed and out of shape when the car is in the air, this is ok. The boot will seat when the car is on the ground. Bolt the steering ...

Page 48

47 www.Factoryfive.Com 508-291-3443 the hub is a snug fit on the spindle and may require a light tap with a soft mallet to get in place. Torque the hub nut to 305-338nm (225-250 ft-lbs). Using a large socket or a flat head screwdriver and rubber mallet, hit the dust cap onto the hub. Front suspensio...

Page 49

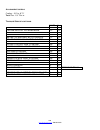

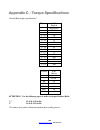

48 www.Factoryfive.Com 508-291-3443 front lower ball joint to spindle 106-163 80-120 upper a-arm to frame 135-162 100-110 upper ball joint to spindle 95-122 70-90 spindle hub nut 305-338 225-250 front brakes 12mm socket, ratchet, 16mm wrench, torque wrench, thread locker front 11” caliper/rotor asse...

Page 50

49 www.Factoryfive.Com 508-291-3443 install the caliper slider pins on the caliper using the supplied bolts and a 16mm wrench and 12mm socket. Torque to 23-26 ft/lbs..

Page 51

50 www.Factoryfive.Com 508-291-3443 install the slider grease boots on the slider pins..

Page 52

51 www.Factoryfive.Com 508-291-3443.

Page 53

52 www.Factoryfive.Com 508-291-3443 in the supplied hardware bag there are six steel clips that are designed to separate the pads from the caliper. These clips allow the pads to slide on a smooth surface and not wear on the caliper. The four clips that go on the ends of the hanger are different end ...

Page 54

53 www.Factoryfive.Com 508-291-3443 the two clips that are left go in the center of the caliper with the tab sticking up through the center hole. Insert the clip from the inside of the caliper through the large center hole with the larger tab on the side facing the pistons then press down on the out...

Page 55

54 www.Factoryfive.Com 508-291-3443 push the rubber boots over the lip on the caliper bracket to seal the slider bolts correctly. Look at the back side of each brake pad to find the inside pads and the outside pads. The difference is the location of the studs that are on the back of each pad. The st...

Page 56

55 www.Factoryfive.Com 508-291-3443.

Page 57

56 www.Factoryfive.Com 508-291-3443 install the brake pads in the caliper. Clean the rotor with brake cleaner and push it onto the hub..

Page 58

57 www.Factoryfive.Com 508-291-3443 install the caliper on the spindle; make sure that the fluid bleeder is at the top of the caliper. Torque the caliper mounting bolts to 130nm (95 ft-lb)..

Page 59

58 www.Factoryfive.Com 508-291-3443 solid axle rear suspension skip to the independent rear suspension if not installing a solid axle. Two bolts are included with the control arms, the other two are included in the kit with the traction lok brackets. Solid axle preparation ¾” sockets, ¾” wrench, ½” ...

Page 60

59 www.Factoryfive.Com 508-291-3443 if not already done, fill the axle with gear oil. See appendix for specifications and capacities. If using a used rear axle, remove the lower shock mounts and the anti vibration weight under the pinion. Drill the lower control arm mount holes with a ½” drill bit..

Page 61

60 www.Factoryfive.Com 508-291-3443 position the traction lok brackets on the rear end with the bolts provided (the two short bolts go on the sides). Axle bracket driver's side.

Page 62

61 www.Factoryfive.Com 508-291-3443 axle bracket passenger side temporarily put the lower shock bolt through the traction lock bracket and stock shock hole on the axle..

Page 63

62 www.Factoryfive.Com 508-291-3443 tighten the two short bolts. Torque to ford specs 75-95 nm (55-70 lbft). Attach the lower control arms to the brackets on the axle using the bolt provided. Torque to 101-111nm (75-82 lb-ft) the lower bolt holes provide more traction than the upper holes..

Page 64

63 www.Factoryfive.Com 508-291-3443 3 link rear suspension 3 / 16 ”, ⅜”, ½” drill bits, ⅝”, ¾”, 15 / 16 ”, 1” wrenches, ⅜”, ⅝”, ¾”, 15 / 16 ” sockets, 5 / 16 ” hex key, ratchet, torque wrench, drill, ruler/tape measure, pliers, flat head screwdriver, tin snips/scissors/razor, marker. 3-link rear sus...

Page 65

64 www.Factoryfive.Com 508-291-3443 test fit the two halves of the upper arm mount together. If it is hard to put all of the bolts in the mount holes, put in as many as you can then use a ½” drill bit through the remaining bolt holes. Attach the upper link bracket onto the axle using the fine hardwa...

Page 66

65 www.Factoryfive.Com 508-291-3443 attach the front of the upper link axle mount to the front axle flange. Upper link install a jam nut on each of the rod ends, remembering that two of them are left hand thread. Insert the rod ends into the swedged tubes (one is right hand thread and one is left ha...

Page 67

66 www.Factoryfive.Com 508-291-3443 attach the short upper link tube to the axle upper link mount using the ¼” spacers on either side of the rod end. Rear axle have someone help with this step, the rear axle is very heavy and mistakes can result in serious injury..

Page 68

67 www.Factoryfive.Com 508-291-3443 use a floor jack to position the rear axle assembly under the frame. Make sure that the rear jack stands are positioned under the 4” round tube as far back as possible to prevent the frame from tipping up once the axle is mounted do not hold the end of the axle fr...

Page 69

68 www.Factoryfive.Com 508-291-3443 with one person holding a side of the axle raise the axle so that the lower control arms can be bolted onto the frame. Attach the lower control arms to the frame mounts..

Page 70

69 www.Factoryfive.Com 508-291-3443 jack the rear axle up and attach the upper link to the frame. Panhard bar frame mount the panhard bar frame mount is mounted to the chassis during shipping.

Page 71

70 www.Factoryfive.Com 508-291-3443 with the axle jacked up, attach the panhard bar frame mount to the inside of the quad shock brackets, the forward leg will attach to the back of the angled 2”x 3” tube. Do not tighten the quad shock bracket bolts yet. For the front mount, use a ½” drill bit and dr...

Page 72

71 www.Factoryfive.Com 508-291-3443 tighten the bolts on the quad shock brackets. Lower the rear axle. With the rear end correctly installed with the 3-link, the rear axle will rest on the 3-link panhard bar mount with the suspension at full droop. Rear coil-over shock assembly snap ring pliers, ¾” ...

Page 73

72 www.Factoryfive.Com 508-291-3443 unpack the rear shocks, coil over’s and hardware. Double check the jam nut under the rod end and bump stop to make sure that it is tight. Screw the spring seat down on the sleeve so it is closer to the unthreaded end. The center high part of the set should be poin...

Page 74

73 www.Factoryfive.Com 508-291-3443 the coil-over hats have a snap ring which holds it in place. Remove this snap ring to assemble the coil over shock. Slide the rubber bumper about two inches down on the shaft. Put the spring on the shock, then install the spring hat on the shaft end of the shock a...

Page 75

74 www.Factoryfive.Com 508-291-3443 install the snap ring on the spring hat so that it holds onto the shock end. Make sure that the slot in the snap ring and the slot in the spring hat are not aligned. Use zip ties to hold the spring to the spring hat. Assembled solid axle koni coil-over shock..

Page 76

75 www.Factoryfive.Com 508-291-3443 attach the body end of the shock to the upper shock mount using the two equal length (1.09”) spacers. Jack the rear axle up so the rod end of the shocks can be mounted on the axle through the shock mount hole. Passenger side.

Page 77

76 www.Factoryfive.Com 508-291-3443 driver side install the kit ½”x 4” bolts are provided for each lower shock mount. From the rear, the bolt goes through the bracket, ⅛” shim, shock, then the long spacer (1.09”) followed by the bracket and axle. Use a ¾” socket and torque wrench to tighten both upp...

Page 78

77 www.Factoryfive.Com 508-291-3443 run zip ties through the holes in the spring hat and around the spring to prevent the spring from becoming unseated..

Page 79

78 www.Factoryfive.Com 508-291-3443 panhard bar the panhard bar mounts to the car using the ⅝”x 3” bolts and spacers. Install the panhard bar to the passenger side traction lock bracket. Three spacers are used in the front (2) 0.375" (ffr# 14064) and (1) 0.25" (ffr# 14065). The rear uses the thin 0....

Page 80

79 www.Factoryfive.Com 508-291-3443 attach the panhard bar to the frame mount using the spacers provided. There should never be less than ¾” of threads screwed into either the panhard bar or the upper arm. To set the pinion angle, make sure that your ride height is where you want it, and then adjust...

Page 81

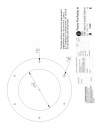

80 www.Factoryfive.Com 508-291-3443 optional independent rear suspension – standard width l&r lower control arms, l&r upper control arms, toe arms, l&r cv axles, koni coil-over shocks, springs, fasteners, driveshaft adapter philips head screwdriver, 5 / 8 ” drill bit, 13 /16 ”, 15 / 16 ” wrenches, 1...

Page 82

81 www.Factoryfive.Com 508-291-3443 mustang irs specifications 2.3l ecoboost 3.7l v6 5.0l coyote housing steel aluminum steel weight 93lb 78lb 93lb gear ratios 3.15:1, 3.31:1, 3.55:1 3.15:1, 3.55:1 3.15:1, 3.55:1 brakes 12.6" (320mm) solid rotor, 45mm single piston aluminum caliper 12.6" (320mm) sol...

Page 83

82 www.Factoryfive.Com 508-291-3443 mark the spindle starting at the top just to the inside of the top inside hole down to the corner of the small boss at the bottom of the ear. Use a saw to cut the ear off the spindle. If using a sawzall or similar, use a wood blade; a 14tpi blade or finer will jus...

Page 84

83 www.Factoryfive.Com 508-291-3443 hubs hammer, vise, ratchet, ½”-20 lugnut, torque wrench. Rear wheel studs. Removal of the hub from the spindle is not necessary but can make things easier. Use a vise to lightly hold the side of the wheel stud head then use a hammer to bang out the mustang studs. ...

Page 85

84 www.Factoryfive.Com 508-291-3443 insert one of the included wheel studs into the hub from the back and use a washer and lug nut on the front side. Use a ratchet to draw the wheel stud into the hub and torque the stud to 135nm (100lb-ft)..

Page 86

85 www.Factoryfive.Com 508-291-3443 repeat for the other wheel studs. If the hub was removed, use loctite on the threads and reattach to the spindle. Torque the bolts to 133nm (98ft-lb)..

Page 87

86 www.Factoryfive.Com 508-291-3443 center section 5 / 8 ” drill bit, drill. Use a 5 / 8 ” drill bit to chase the front mount holes on the center section. Frame rubber/plastic mallet differential mounting components.

Page 88

87 www.Factoryfive.Com 508-291-3443 bushing locations. Use a plastic mallet to install the polyurethane bushings marked 2048 and the longer (3 1 / 16 ”) sleeves where the front of the center section will mount..

Page 89

88 www.Factoryfive.Com 508-291-3443 use a plastic mallet to install the polyurethane bushings marked 2123 and the shorter (2.40”) sleeves where the rear of the center section will mount. Upper control arms upper control arm components grease gun.

Page 90

89 www.Factoryfive.Com 508-291-3443 assemble each of the upper control arms as shown. Grease the control arms using chassis grease until the grease comes out of the flutes in the bushings next to the pivot sleeves. Lower control arms grease gun grease the control arms using chassis grease until the ...

Page 91

90 www.Factoryfive.Com 508-291-3443 toe adjustment arms assemble each of the toe adjustment arms as shown. Installation center section rubber/plastic mallet, torque wrench, 18mm, 13 / 16 ” sockets, 15 / 16 ” wrench. Differential mounting components. Use a friend to help with the heavy center section...

Page 92

91 www.Factoryfive.Com 508-291-3443 use rags to protect between the front center section mount on the frame..

Page 93

92 www.Factoryfive.Com 508-291-3443 with the help of a friend, lift the center section nose up into the frame and over the front mount..

Page 94

93 www.Factoryfive.Com 508-291-3443 flatten the center section out so it is horizontal then back it up so it is above the mount locations and lower it down so the bolts can be installed. The smaller/shorter bolts are used for the rear mounts. The larger/longer bolts and nuts are used for the front m...

Page 95

94 www.Factoryfive.Com 508-291-3443 center section vent pliers, wire cutters, hammer vent hose, vent nipple, insulated clips, secondary body fasteners. Remove the plug at the top of the rear cover..

Page 96

95 www.Factoryfive.Com 508-291-3443 use a hammer on the end of the barb to put the nipple in the rear cover. Push the 12.00” piece of 5 / 16 ” fuel hose onto the barb..

Page 97

96 www.Factoryfive.Com 508-291-3443 run the hose up to the 1” tube that goes across the back of the irs and use one of the kit 5 / 8 ” insulated clips and 3 / 16 ” rivet to hold it in place. Toe adjustment arms irs toe adjustment arm components 13 / 16 ” socket, 15 / 16 ” wrench, torque wrench. If u...

Page 98

97 www.Factoryfive.Com 508-291-3443 attach the toe arms to the frame below the front lower arm mount using the 1 / 8 ” thick spacer in the back and the ¼” spacer on the front side of the rod end. Use the 5 / 8 ” x 2.25” bolts to attach them to the frame. Torque bolts to 135nm (100 ft-lb). Lower cont...

Page 99

98 www.Factoryfive.Com 508-291-3443 attach the control arms to the frame with the shock mount towards the rear and spindle brackets up. Use the longer m16 x 110mm (~4 5 / 16 ”) bolts. Hold the arm horizontal and torque the bolts to 135nm (100 ft-lb). Upper control arms irs upper control arm componen...

Page 100

99 www.Factoryfive.Com 508-291-3443 pass the upper control arm thick tube through the triangular area as shown in between the frame mounts. Use the longer m16 x 110mm (~4 5 / 16 ”) bolts. Hold the arm horizontal and torque the bolts to 135nm (100 ft-lb). Cv axle cv axles, spindles the inside cv join...

Page 101

100 www.Factoryfive.Com 508-291-3443 using the correct axle, push the inner cv joint into the center section. When fully installed there should be an 1 / 8 ” (~3mm) gap between the inside of the cv joint and the center section. If necessary, compress the cv axle and with the cv axle nut on the end h...

Page 102

101 www.Factoryfive.Com 508-291-3443 slide the spindle onto the outer cv joint and start the nut on the end. Spindle to lower arm connect the bottom of the spindle to the lower control arm using the m16 x 90mm bolts and locknuts. Right side shown..

Page 103

102 www.Factoryfive.Com 508-291-3443 wait to torque the bolts until after the other arms are installed. Spindle to upper arm insert the angled mount adapter into the upper arm rod end. Reuse the 5 / 8 ” washer that was on the old bolt and place it on the new 5 / 8 ” x 4.25” bolt along with a misalig...

Page 104

103 www.Factoryfive.Com 508-291-3443 attach the upper control arm to the spindle using the bolt with the misalignment spacer. Use a 15 / 16 ” wrench, 15 / 16 ” socket and ratchet to tighten the locknut. Wait to torque the bolts until after the other arms are installed..

Page 105

104 www.Factoryfive.Com 508-291-3443 check the angle of the upper control arm rod end, make sure that the rod end is not touching the spindle and that it is aligned with the upper control arm. Toe link attach the toe link arm to the spindle using the m14 x 80mm bolt and locknut..

Page 106

105 www.Factoryfive.Com 508-291-3443 repeat for the right hand side. Use the torque specifications page at the back of the instructions to torque the control arm to spindle bolts. Coil-over shock assembly snap ring pliers, ¾” wrench, ¾” socket, ratchet, floor jack shock set, insulated clip hardware....

Page 107

106 www.Factoryfive.Com 508-291-3443 the coil-over hats have a snap ring which holds it in place. Remove this snap ring to assemble the coil over shock. Slide the rubber bumper about two inches down on the shaft. Put the spring and hat on the shock and rotate the spring seat back up the sleeve so th...

Page 108

107 www.Factoryfive.Com 508-291-3443 install the snap ring on the spring hat so that it holds onto the shock end. Make sure that the slot in the snap ring and the slot in the spring hat are not aligned. Attach the rod end of the shock to the upper shock mount using the two equal length 1.09” kit spa...

Page 109

108 www.Factoryfive.Com 508-291-3443 jack the spindle up so the body end of the shocks can be mounted on the shock mount on the control arm using the longer 1.09” spacer on the back and 7 / 16 ” spacer in front of the shock. Torque the lower shock bolt to 54nm (40 ft-lb). Remove the floor jack. Driv...

Page 110

109 www.Factoryfive.Com 508-291-3443 apply loctite to the (6) m10 x 25mm socket head screws. Attach the driveshaft adapter to the center section pinion flange and torque the bolts in a star pattern to 55nm (41 ft-lb)..

Page 111

110 www.Factoryfive.Com 508-291-3443 fluids name specification motorcraft® additive friction modifier (u.S.) xl-3 (u.S.) est-m2c118-a motorcraft® sae 75w-85 synthetic hypoid gear lubricant xy-75w85-ql wss-m2c942-a fill the rear axle with fluids. Capacities fluid amount sae 75w-85 synthetic hypoid ge...

Page 112

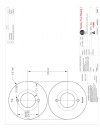

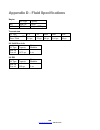

111 www.Factoryfive.Com 508-291-3443 alignment specs camber: -0.5 to -0.75° total toe: 1/8” toe in torque specifications lb-ft nm center section to frame front 129 175 center section to frame rear 129 175 brake caliper to caliper bracket 24 32 brake caliper bracket to spindle 129 175 brake hose banj...

Page 113

112 www.Factoryfive.Com 508-291-3443 once the car has been aligned, use a 1 5 / 8 ” wrench to loosen the upper control arm large jam nut and put some loctite on the threads where the jam nut will sit. Retighten the jam nut. Optional irs brakes download the 2015 irs brake instructions from www.Factor...

Page 114

113 www.Factoryfive.Com 508-291-3443 e-brake cables make sure the ffr cables go through the upper bracket in the transmission tunnel until the sheath end clicks in place..

Page 115

114 www.Factoryfive.Com 508-291-3443 wilwood brake routing run the left e-brake cable over the top of the center section and left rear mount then down and over to the brake caliper. Run the right cable over the center section and right rear mount then down and over to the brake caliper..

Page 116

115 www.Factoryfive.Com 508-291-3443 wilwood e-brake adapter insert the cable end into the bent bracket then bolt the bracket to the e-brake lever..

Page 117

116 www.Factoryfive.Com 508-291-3443 make sure to run the other end of the brake cables under the 4” crossmember and connect them to the e-brake handle and adjust. Firewall & driver front footbox aluminum drill, 1 / 8 ” drill bit, rivet tool, caulk gun, silicone firewall and driver footbox front alu...

Page 118

117 www.Factoryfive.Com 508-291-3443 rivet the firewall in position on the chassis. The footbox front for the wilwood pedal box is packaged with the pedalbox in the kit. The one that is shipped on the chassis is for the oem mustang pedalbox. Mark, drill, and rivet in place the driver’s side footbox ...

Page 119

118 www.Factoryfive.Com 508-291-3443 pedal box ½”, 9 / 16 ” sockets, ¼”, ⅜”, ½” wrenches, ¼” drill bit, drill, philips head screwdriver, 3 / 16 ”, 5 / 16 ” hex key, snap ring pliers pedal components, pedal box hardware. This pedal box is set-up to use either a hydraulic clutch or a cable clutch. The...

Page 120

119 www.Factoryfive.Com 508-291-3443 connect the switch to the switch mount using a hex nut on each side of the mount bracket. See the chassis harness instructions for connecting the switch. Clutch safety switch mount the clutch switch mount attaches the same way as the brake switch mount..

Page 121

120 www.Factoryfive.Com 508-291-3443 place the switch mount between the clutch pedal mount tabs on the side closest to the clutch pedal pivot holes and drill a 3 / 16 ” hole through the switch mount hole and the pedal box. Attach the switch mount to the pedal box using the black #10 screw and locknu...

Page 122

121 www.Factoryfive.Com 508-291-3443 use snap ring pliers to remove the clevis at the top of the clutch pedal..

Page 123

122 www.Factoryfive.Com 508-291-3443 quadrant assembly order for kits older than 6/21/16.

Page 124

123 www.Factoryfive.Com 508-291-3443 quadrant assembly order for kits newer than 6/21/16. Assemble the clutch quadrant to the wilwood clutch pedal as shown above..

Page 125

124 www.Factoryfive.Com 508-291-3443 if necessary use a file to remove the forging centerline so the 3 / 8 ” bolt can go through the clutch pedal hole. Attach the wilwood pedals to the underside of the mounting bracket using four 5 / 16 ” button head screws, locknuts, 3 / 16 ” hex key and ½” wrench..

Page 126

125 www.Factoryfive.Com 508-291-3443 clutch quadrant stop attach the clutch pedal stop mount to the bottom of the pedal box using two ¼” socket head screws, spacers and locknuts. Thread the jam nut onto the ⅜”x 1.25” screw provided in the quadrant box..

Page 127

126 www.Factoryfive.Com 508-291-3443 from the underside, push the screw through the quadrant pedal stop mount plate and hand tighten the locknut on the screw. Frame installation place the pedal box assembly in the driver’s footbox. Make sure that the brake pedal goes in front of the ¾” cross tube on...

Page 128

127 www.Factoryfive.Com 508-291-3443 unpack the pedal box hardware from the secondary chassis components box. Insert three ⅜” x 1” socket head screws from the pedal box hardware assembly and the one included in this pedal assembly through the front of the footbox and through the pedal box mount..

Page 129

128 www.Factoryfive.Com 508-291-3443 push the rear pedal box mount onto the master cylinder mount studs and use a few of the jam nuts from the wilwood pedal assembly to temporarily hold the rear mount in place. Tighten two of the front ⅜” screws then use a marker to mark the locations of the rear mo...

Page 130

129 www.Factoryfive.Com 508-291-3443 loosen the bolts and remove the pedal box assembly from the footbox then use a ¼” drill bit and drill to drill through the ¾” tubes at the locations marked for the rear mount. Reinstall the pedal box assembly in the driver’s footbox; use the ¼”x 1.50” screws from...

Page 131

130 www.Factoryfive.Com 508-291-3443 master cylinders with the jam nut on the threaded shaft, cut 5 / 8 ” off each of the master cylinders. Screw the 90° brake line adapter into the end of the master cylinder making sure that the opening points up when tight..

Page 132

131 www.Factoryfive.Com 508-291-3443 put one of the master cylinders onto one of the brake master cylinder mounts and turn the threaded shaft into the threaded mount on the brake pedal. As a starting point, thread the shaft in until you can see it is flush on the other side of the mount. The brake p...

Page 133

132 www.Factoryfive.Com 508-291-3443 attach and tighten the locknuts using a ½” wrench and ½” deep socket holding the master cylinder to the pedal box then repeat for the other master cylinder. Put the plastic angled inlet adapter with hose clamp on the master cylinders. Use a 6mm socket and ratchet...

Page 134

133 www.Factoryfive.Com 508-291-3443 balance bar adjustment the balance bar is an adjustable lever (usually a threaded rod), that pivots on a spherical bearing and uses two separate master cylinders for the front and rear brakes. Most balance bars are part of a pedal assembly that also provides a mo...

Page 135

134 www.Factoryfive.Com 508-291-3443 make sure that the master cylinder pushrods remain true in relationship to the cylinder during entire pedal travel; pushrods should not be pushing master cylinder pistons at an angle. In its non-depressed position, the pedal and balance bar should allow the pushr...

Page 136

135 www.Factoryfive.Com 508-291-3443 use one ¼”x ¾” screw and locknut from the pedal box hardware position the accelerator pedal using the top hole in the accelerator pedal mount so that the top of the pedal lines up with the accelerator cable hole so the cable will come out straight. Mark the lower...

Page 137

136 www.Factoryfive.Com 508-291-3443 unpack the throttle cable and cut the cylinder end off. Make sure your cutters are very sharp so as not to fray the cable. Thread the inner cable through the cable retaining lock nut from the accelerator cable components assembly..

Page 138

137 www.Factoryfive.Com 508-291-3443 route the cable through the hole in the firewall and slide the sheath back over the cable. Tighten the cable sheath to the firewall with the retaining nut. A piece of tape on the end of the cable will help prevent it from backing out of the sheath. Check the full...

Page 139

138 www.Factoryfive.Com 508-291-3443 steering system steering rack needle nose pliers, ¾” wrench, ¾” socket, ratchet steering rack assembly, steering system hardware the inner tie rod extensions are for stock power steering racks only. The inner tie rod extensions are not for the ffr manual steering...

Page 140

139 www.Factoryfive.Com 508-291-3443 push the bushings and sleeves into the mounting bosses on the rack. Center the steering rack. Line up the steering shaft and adapter and push the rack onto the steering shaft..

Page 141

140 www.Factoryfive.Com 508-291-3443 bolt the rack into the frame. It is easier to do the driver side first then swing the passenger side down into the mount. Screw the grease nipple into the outer tie rod end..

Page 142

141 www.Factoryfive.Com 508-291-3443 thread the outer tie rod and jam nut 1”-2” down onto the steering rack inner tie rod. The outer tie rods may come with either a castle nut and cotter pin or a nylon locknut..

Page 143

142 www.Factoryfive.Com 508-291-3443 attach the tie rod to the spindle, torque the nut to 25 ft-lbs. If a castle nut is used, torque the nut then install the cotter pin. If the tie rod has a locknut instead of a castle nut, torque to 80nm (59 ft-lb)..

Page 144

143 www.Factoryfive.Com 508-291-3443 steering shaft 1 / 8 ”, 5 / 32 ”, 3 / 16 ”, 5 / 16 ” hex keys, ½”, 9 / 16 ”, 10mm wrenches, marker, drill, 3 / 16 ” drill bit, philips head screwdriver, 15mm deep socket, ratchet. Steering bearings/hardware, steering shaft, manual steering rack and adapter. Unpac...

Page 145

144 www.Factoryfive.Com 508-291-3443 remove the splined adapter from the end of the steering shaft using an 1 / 8 ” hex key. Loosen the set screw, align the set screw with the flat side on the input shaft then slide the new adapter down onto the rack as far as possible..

Page 146

145 www.Factoryfive.Com 508-291-3443 slide the bearing onto the steering shaft so that the locking flange is away from the u-joint loosely mount the top pillow block to the chassis with the set screw toward the rear of the car..

Page 147

146 www.Factoryfive.Com 508-291-3443 slide the steering shaft into the footbox from the engine bay. Insert the lower u-joint into the steering adapter..

Page 148

147 www.Factoryfive.Com 508-291-3443 tighten the adapter set screws using an 1 / 8 ” hex key. Attach the flange bearing to the front of the footbox using the 5 / 16 ” x 1” button head screws, 3 / 16 ” hex key and ½” wrench..

Page 149

148 www.Factoryfive.Com 508-291-3443 tighten the adapter set screw and nut using a 5 / 32 ” hex key and 9 / 16 ” wrench. Upper steering shaft 5 / 32 ”, 3 / 16 ”, 5 / 16 ” hex keys, ½” wrench, rubber mallet steering system hardware use thread locker on all the steering shaft screws that do not have j...

Page 150

149 www.Factoryfive.Com 508-291-3443 slide the steering shaft through the upper bearing and start it in the lower shaft. Turn the steering shaft so the recessed bosses for the spring washers are facing up and set the washers in place. Then tap the upper shaft down until the upper clip just disappear...

Page 151

150 www.Factoryfive.Com 508-291-3443 tighten the upper and lower bearings. Also tighten the set screw on the upper shaft. Cockpit aluminum drill, ⅛” drill bit, rivet tool, silicone, caulking gun, #8 self tapping screws, #8 hex nut driver, ruler, marker, acetone or carburetor cleaner, rags. Packaged ...

Page 152

151 www.Factoryfive.Com 508-291-3443 passenger footbox locate the passenger footbox top and drill and mark the holes in the top flat surface only. Silicone this panel where it meets the chassis and rivet along the bottom of the 2” square frame crossbar only. Use one of the original screws to tempora...

Page 153

152 www.Factoryfive.Com 508-291-3443 drill the tunnel front a-shaped piece where it meets the chassis and silicone and rivet it in place. Mark and drill the two vertical edges of the passenger footbox inside wall..

Page 154

153 www.Factoryfive.Com 508-291-3443 silicone and rivet the panel to the front tunnel “a” and the footbox top. Mark the holes in the passenger footbox front panel upper and outer edges but do not drill yet..

Page 155

154 www.Factoryfive.Com 508-291-3443 silicone the panel and install with the temporary screws then drill through both panels and rivet it in place..

Page 156

155 www.Factoryfive.Com 508-291-3443 mark and drill all three flanges on the passenger outer footbox top. Silicone the flange between the outer top and the outer wall and attach the two pieces together using the temporary screws..

Page 157

156 www.Factoryfive.Com 508-291-3443 silicone the remaining flanges then install the outer wall/top on the footbox with rivets. Make sure the rear edge is flush to the chassis and not caught up on the door hinge before you start riveting. Passenger floor drill the passenger side floor where it was m...

Page 158

157 www.Factoryfive.Com 508-291-3443 silicone the chassis where the aluminum floor will touch. The main chassis rails are not riveted to but still need a bead of silicone run along the tops. The top edge of the tunnel is not riveted yet but gets silicone as well. Drill and rivet the floor in place t...

Page 159

158 www.Factoryfive.Com 508-291-3443 drill, silicone, and rivet the right side under door piece in place. Leave the rivets out of the rear vertical flange for now. Driver floor drill silicone and install the driver’s footbox floor. The outer flange does not get drilled yet..

Page 160

159 www.Factoryfive.Com 508-291-3443 silicone, drill, and install the driver side floor. Install the left side under door aluminum like the right side..

Page 161

160 www.Factoryfive.Com 508-291-3443 drill, silicone and install the inner footbox wall. The front flange tucks in behind the front wall that was left unriveted. Put a little silicone on both sides of this flange. U-joint cover mark the rear tunnel cover where it meets the chassis then silicone and ...

Page 162

161 www.Factoryfive.Com 508-291-3443 transmission tunnel rear corners the inner rear corner pieces tuck behind the tunnel sides and sit on top of the floor. Mark the rivet spacing on the top edge and silicone and rivet the three flanges that make contact..

Page 163

162 www.Factoryfive.Com 508-291-3443 cockpit rear corners the outer cockpit corners get marked on the bottom flange and where they meet the chassis. Drill silicone and rivet these in place. Fuel system 9 / 16 ” and 5 / 16 ” deep sockets, ratchet, 7 / 16 ” wrench, rubber mallet, hammer, marker, punch...

Page 164

163 www.Factoryfive.Com 508-291-3443 unpack the fuel strap fasteners. Unpack the ¾” square plastic end caps from the secondary body fasteners..

Page 165

164 www.Factoryfive.Com 508-291-3443 push the two plastic end caps into the tubes hanging down in front of the gas tank area. Put the fuel tank bolts in the gas tank front frame mounts..

Page 166

165 www.Factoryfive.Com 508-291-3443 hang the fuel tank straps from the rear mount of the chassis using two of the strap fasteners. The longer strap goes on the passenger side. Fuel tank vent ¼”, 5 / 16 ” sockets, ratchet, (2) 1” wrenches, teflon tape, razor knife.

Page 167

166 www.Factoryfive.Com 508-291-3443 unpack the oem fuel tank components including the tank and straps. Screw the vent into the plastic bushing and tighten..

Page 168

167 www.Factoryfive.Com 508-291-3443 insert the small rubber vent gasket in the small hole on the top of the tank. Push the vent into the grommet..

Page 169

168 www.Factoryfive.Com 508-291-3443 fuel pick-up this install shows the set-up for a pick-up with an inline fuel pump. See www.Factoryfiveparts.Com/instructions for in-tank fuel pump set-up. Prep if the car will have a high horsepower fuel injected engine there are a few “tweeks” we recommend get d...

Page 170

169 www.Factoryfive.Com 508-291-3443 starting with a ¼” drill bit drill out the end of the send line then change to a 9 / 32 ” or 19 / 64 ”drill bit, the pressed end is a little restrictive. Starting with a ¼” drill bit drill out the end of the return line then change to a 9 / 32 ” or 19 / 64 ”drill...

Page 171

170 www.Factoryfive.Com 508-291-3443 install set the rubber o-ring gaskets in place for the fuel pump pickup. Slide the pickup down into the tank; you will have to rotate as you go to get the tubes into the sump and line up the tabs on the pick-up and slots on the tank. You can see this looking thro...

Page 172

171 www.Factoryfive.Com 508-291-3443.

Page 173

172 www.Factoryfive.Com 508-291-3443 with the pickup all the way down slide the mounting collar and tap tightly into place with a punch and hammer. Make sure that the lock ring is held by all three locking tabs on the tank or the sender will leak..

Page 174

173 www.Factoryfive.Com 508-291-3443 fuel gauge sender set the rubber o-ring in place for the fuel level sending unit. Insert the fuel level sender into the tank..

Page 175

174 www.Factoryfive.Com 508-291-3443 ] tap the locking ring tightly into place with a punch and hammer. Make sure that the lock ring is held by all three locking tabs on the tank or the sender will leak..

Page 176

175 www.Factoryfive.Com 508-291-3443 fuel filler neck insert the large rubber filler neck gasket in the side of the tank. Slide the filler neck tube into the tank. A little oil or wd40 on the rubber gasket helps..

Page 177

176 www.Factoryfive.Com 508-291-3443 slide the retaining bracket down the filler tube and mark its mounting location on the tank. Move the retainer out of the way and make sure your mark is outside the weld that holds the two tank halves together..

Page 178

177 www.Factoryfive.Com 508-291-3443 drill a ¼” hole through the tank flange on the mark made. Use the ¼”bolt and locknut to attach the retainer to the tank. Fuel tank install at the locations on the tank where the tank straps come near the tank, use a pair of pliers and bend the bent parts flat..

Page 179

178 www.Factoryfive.Com 508-291-3443 put the metal tank in the plastic tank cover. Using a jack, raise the tank up into place on the chassis. Make sure the plastic cover is in position below the tank..

Page 180

179 www.Factoryfive.Com 508-291-3443 bolt the straps in with the strap fasteners and drop the jack. Tighten only the driver’s side strap as the passenger one will be removed for aluminum fitment later on. Fuel filter tube bender, 3 / 16 ”drill bit, drill, rivet tool, marker, tape measure, flat head ...

Page 181

180 www.Factoryfive.Com 508-291-3443 insulated clip hardware, fuel line components, ¼”, 5 / 16 ” fuel lines, oem fuel tank components. Unpack the fuel filter and mounting hardware. Open the hose clamp and slide it through the slots in the mount and start to tighten it back up into a hoop just bigger...

Page 182

181 www.Factoryfive.Com 508-291-3443 clamp the filter in place on the mount with the filter flange oriented as shown. Attach the short nylon fuel line to the filter and the tank to show where your mounting location must be. The elbow end can attach to either end as shown here; we have attached it to...

Page 183

182 www.Factoryfive.Com 508-291-3443 hold the filter up to the 2”x 3” chassis tube, mark the holes, then drill and rivet the bracket on using 3 / 16 ” rivets. Hard lines unpack the fuel lines and the fuel line assembly which is in the secondary chassis components box..

Page 184

183 www.Factoryfive.Com 508-291-3443 the larger 5 / 16 ” line is the send fuel line to the engine. If you are running a return system then there is ¼” line provided for that as well. There are barbed fittings provided for both sizes. The fuel line routing will depend on your style of fuel pump, whet...

Page 185

184 www.Factoryfive.Com 508-291-3443 from the filter we generally run the lines down the 2”x 3” tube behind the rear cockpit wall and alongside the outside of the main 4” frame tube. Which side you run down may depend on where you are hooking up to your fuel rail, carburetor, or pressure regulator. ...

Page 186

185 www.Factoryfive.Com 508-291-3443 run the lines up the inside of the right footbox. Attach a 25” section of 5 / 16 ” fuel line and fuel line clamp onto the vent..

Page 187

186 www.Factoryfive.Com 508-291-3443 run the vent hose down to the ¾” tube near the battery and attach it to the tube using a zip tie. Brake system tube bender, 3 / 16 ”, ¼”, 7 / 16 ”, ⅝” drill bits, drill, rivet gun, marker, tape measure, razor knife, round file or sand paper, brake fluid. Pedal co...

Page 188

187 www.Factoryfive.Com 508-291-3443 screw in the hose barb. Loosely screw the mounting bracket onto the reservoir. Make sure to mount the reservoir high enough so the top of the reservoir is higher than the master so the master can suck the fluid in to bleed the system..

Page 189

188 www.Factoryfive.Com 508-291-3443 the brake reservoir mounts to the front of the footbox just inside the hood opening. Take the reservoir with cap and line it up so the reservoir can be filled with the body on. Mark the holes. The picture above shows the reservoir hose going through the accelerat...

Page 190

189 www.Factoryfive.Com 508-291-3443 use a 5 / 16 ” hex driver to screw the self-drilling screw into the footbox plate. Drill an 1 / 8 ” hole through the mounting bracket for the second hole location..

Page 191

190 www.Factoryfive.Com 508-291-3443 screw the other mounting screw in. Attach the reservoir to the mounting bracket..

Page 192

191 www.Factoryfive.Com 508-291-3443 if drilling a hole for the reservoir hose, drill a ⅝” hole one inch down from the bottom of the reservoir. Take extra time with a file and round all the edges making sure there are no burrs left or sharp spots. Route the fluid line for the master cylinders throug...

Page 193

192 www.Factoryfive.Com 508-291-3443 connect and split the hose to the two master cylinders using the y provided. Make sure that the line cannot get in the way of moving parts, especially the brake pedal! Attach the master cylinder hose adapter to the master cylinder and use insulated clips from the...

Page 194

193 www.Factoryfive.Com 508-291-3443 front flexible brake lines unpack the hardware from the brake line components. The crossed off parts in the picture above are for the stock mustang master cylinder and flexible brake lines so are not used. The u-nuts, washers and button head screws are for the e-...

Page 195

194 www.Factoryfive.Com 508-291-3443 lay out the various lengths of brake line so you can see what you have to work with. Like the fuel lines, there are many ways to run these lines but you must be very careful to keep them protected from moving parts, heat, or being to close to the bottom of the ca...

Page 196

195 www.Factoryfive.Com 508-291-3443 push the brake line adapters through the brackets from the outside in and install the clips that hold them in place. Attach the front brake line to the caliper making sure there is a crush-washer on either side of the fitting and then screw the other end of the l...

Page 197

196 www.Factoryfive.Com 508-291-3443 screw the brake line t fitting into the end of the drivers side brake adapter and tighten. Make sure that your flex lines will not interfere with anything in the suspension, wheels during travel or turning full lock to lock. Torque the front flexible brake line t...

Page 198

197 www.Factoryfive.Com 508-291-3443 hard brake lines front the ¾” master cylinder is used for front and the 5 / 8 ” master cylinder is used for the rear brakes..

Page 199

198 www.Factoryfive.Com 508-291-3443 run a 60” brake line from the ¾” front master cylinder out the front of the pedalbox along the ¾” tube to the front suspension. Attach the brake line t to the flexible brake line mount and run the brake line into the end of the t..

Page 200

199 www.Factoryfive.Com 508-291-3443 run another 60” brake lines from the t fitting over to the right side flexible mount. The line will bend very easy but be careful not to kink it. When you are happy with the routing use the small insulated line clips and 3 / 16 ” rivets to hold it in place. Mount...

Page 201

200 www.Factoryfive.Com 508-291-3443 use a long 60” brake line and route from the 5 / 8 ” master cylinder out the front and down the front of the footbox. From the front of the footbox angle into the 4” main tube under where the footbox floor would be..

Page 202

201 www.Factoryfive.Com 508-291-3443 use a union to attach the another 60” brake line. Run the brake line up the back of the 2”x 3” tube using line clips and rivets on the 2”x 2” tubes. At this point your routing will depend on your rear brakes. 87-93 mustang solid axles have a single flex line that...

Page 203

202 www.Factoryfive.Com 508-291-3443 solid axle using the ffr rear brakes, we attached the flexible brake line mount to the driver side diagonal ¾” tube with the brake line clip. Attach the “t” adapter to the flexible brake line and route the hard brake line coming from the front to the “t”..

Page 204

203 www.Factoryfive.Com 508-291-3443 run a 60” brake line from the “t” up the ¾” tube to the front fuel tank mount tubes and over to the passenger side ¾” tube. An alternative to running it this way would be to run it across the backside of the 2”x 3” tube. Attach the passenger side flexible brake l...

Page 205

204 www.Factoryfive.Com 508-291-3443 make sure that your flex lines will not interfere with anything in the suspension, wheels during travel or turning full lock to lock. Tighten the banjo bolts on the calipers 2015 irs run the brake line up the 2”x 3” tube and 1” square tube up to the flexible brak...

Page 206

205 www.Factoryfive.Com 508-291-3443 there are a couple of different possibilities for flexible brake line mounts with the irs, on the angled 1” tube as shown above (just make sure to leave enough room for the t junction on the left side) or mount to the 2”x 3” tube near the shock mount as shown in ...

Page 207

206 www.Factoryfive.Com 508-291-3443 banjo bolt torque specs front brake hose to caliper banjo bolt – (39nm) 29lbft rear brake caliper hose to caliper banjo bolt – (43nm) 32lbft when your system is finished being plumbed, go back and check all the fittings for tightness. Fill the system with fluid a...

Page 208

207 www.Factoryfive.Com 508-291-3443 chassis wiring harness the chassis wiring harness routing and instruction are included with the harness. Trunk aluminum 1 / 8 ” drill bit, silicone, rivet gun, caulk gun, 9 / 16 ” wrench, 5 / 16 ” hex key. Mounted aluminum, packaged aluminum, secondary body faste...

Page 209

208 www.Factoryfive.Com 508-291-3443 silicone and rivet in the trunk side panels. Remove the rear bolt of the passenger side gas tank strap. With the rear taillight harness tied up and secure, silicone and install the lower trunk floor. Re-install the gas tank strap and tighten..

Page 210

209 www.Factoryfive.Com 508-291-3443 silicone and install the trunk inner corner pieces. Silicone and rivet the fuel tank strap patch panel from the packaged aluminum assembly..

Page 211

210 www.Factoryfive.Com 508-291-3443 drill and silicone the upper trunk floor. Bend it in the middle to get it into position. Work the corners of the panel down over the roll bar mounts and seat harness tabs a little at a time on each side..

Page 212

211 www.Factoryfive.Com 508-291-3443 once the panel lies flat, finish rivet it into place. The rivets along the front 2”x 3” tube should be close to the back as possible for drill and rivet gun access. Cockpit rear wall mark and drill the rear cockpit wall. Silicone the chassis and aluminum flanges ...

Page 213

212 www.Factoryfive.Com 508-291-3443 battery mounting and cable drill, 1” hole saw, 3 / 16 ”, ¼”, 5 / 16 ” drill bits, rivet gun, marker, 7 / 16 ” deep socket, ratchet, ½” wrench, 3 / 16 ” hex key. Secondary body fasteners, battery mounting kit, insulated clip hardware, misc. Electrical components, ...

Page 214

213 www.Factoryfive.Com 508-291-3443 position the battery with mounting bracket in the trunk for mounting. It is centered side to side with just enough room for the mounting bracket between it and the front of the trunk. Drop the j-bolts in the mounting holes and mark where they hit the trunk floor..

Page 215

214 www.Factoryfive.Com 508-291-3443 drill the ¼” mounting holes in the floor. Hook the j-bolts through the floor and bolt the battery down. Hold the j-bolts with a vice grip and be careful not to over tighten and crack or distort the battery..

Page 216

215 www.Factoryfive.Com 508-291-3443 remove any coating from the small circle in the trunk closer to the ground terminal of your battery. Drill through the center of the circle and put a washer down in the cut out..

Page 217

216 www.Factoryfive.Com 508-291-3443 bolt the ground strap to the chassis, the battery terminal is left off for now while the rest of the system is being routed. Drill out the hole you didn’t use for the ground with a 1” hole saw..

Page 218

217 www.Factoryfive.Com 508-291-3443 install one of the grommets in the hole. Route the small end of the batter cable from through the floor from the top and hook to the battery terminal..

Page 219

218 www.Factoryfive.Com 508-291-3443 attach the battery positive terminal and leave enough slack to be able to remove the terminal easily. Cover the remaining positive cable that runs underneath the car with the provided conduit to protect it from the elements..

Page 220

219 www.Factoryfive.Com 508-291-3443 on the right engine mount there is a 5 / 16 ” hole for the engine ground cable. Grind any coating from in and around the hole to give a good engine ground. Drivetrain install if installing a coyote engine, call or check our parts catalog online for install instru...

Page 221

220 www.Factoryfive.Com 508-291-3443 trim it flush or just below the pad for the transmission mount. Engine prep engine hoist, chain, ¾”, 15 / 16 ” sockets, ratchet, extension engine, polyurethane engine/transmission mount kit the easiest method to install the drivetrain is with the engine and trans...

Page 222

221 www.Factoryfive.Com 508-291-3443 unpack the engine mounts and attach to the engine. Don’t forget to attach the engine ground strap to a right side engine mount bolt. 87-95 oil filter relocator ⅞” wrench, razor knife, teflon tape, chassis grease, ⅜” hex key oil filter relocating kit, oil, oil fil...

Page 223

222 www.Factoryfive.Com 508-291-3443 place the o-ring in the adapter groove. If the o-ring will not seat properly, put it in the freezer for 15 minutes and use a small amount of chassis grease to hold it in place while spinning on the adapter. Tighten ½ turn after solid resistance is felt. The outle...

Page 224

223 www.Factoryfive.Com 508-291-3443 use teflon tape on the threaded barbs and thread them into the oil filter relocator. Thread the short end of the threaded nipple into the relocator..

Page 225

224 www.Factoryfive.Com 508-291-3443 mark the hole locations for the oil filter relocator on the old ac bracket or on the front frame x member (preferred location). If you’re going to mount the relocate bracket on the x member. Drill the mounting holes for the relocator. Make sure to drill this befo...

Page 226

225 www.Factoryfive.Com 508-291-3443 engine/transmission installation lower the engine and transmission into place. The more hands you have to help the better. Go very slowly and make sure the transmission tail-shaft is above the rear cross-member..

Page 227

226 www.Factoryfive.Com 508-291-3443 install the engine mount to chassis nuts and tighten down all the engine mount hardware. Make sure the alignment pins on the mounts are in the holes on the chassis pads. Engine ground sand paper or grinder bit, ½” socket, ratchet, 3 / 16 ” hex key electrical syst...

Page 228

227 www.Factoryfive.Com 508-291-3443 bolt the ground strap to the hole on the frame engine mount. Transmission mount 5 / 16 ” hex key, 9 / 16 ”, ¾” socket, ratchet, ¾” wrench, floor jack transmission mount/hardware.

Page 229

228 www.Factoryfive.Com 508-291-3443 unpack the a-frame transmission mount and hardware. Jack the transmission up and mount the a-frame underneath it. Normally this mounts above the frame tabs but can be mounted underneath if extra clearance is needed..

Page 230

229 www.Factoryfive.Com 508-291-3443 install the bolts that hold the transmission to the mount and tighten all the hardware on the mount and a-frame. Driveshaft 14mm wrench, thread locker driveshaft unpack the driveshaft and slip it up into the rear of the transmission. The most room to do this is u...

Page 231

230 www.Factoryfive.Com 508-291-3443 solid axle the driveshaft bolts are in the box with the driveshaft and should have thread locker on them already. If thread locker is not there, put a small bead on each bolt. Fit the driveshaft snug against the yoke and install the bolts and tighten. You can put...

Page 232

231 www.Factoryfive.Com 508-291-3443 2015 irs insert the driveshaft into the transmission, bolt the rear flange to the driveshaft adapter and torque the bolts to 109nm (80 ft-lb). Headers and j-pipes 7 / 16 ”, 9 / 16 ” wrenches, 7 / 16 ” socket, ratchet, extension, 5 / 16 ” hex key headers or straig...

Page 233

232 www.Factoryfive.Com 508-291-3443 mount up your headers to the engine. If you are using full length headers they bolt in place with the gaskets and hardware provided. Thread locker is recommended. If you are using shorty headers or stock manifolds bolt them back on. On a small block (302 or 351) ...

Page 234

233 www.Factoryfive.Com 508-291-3443 if you are using the cats or j-pipes bolt them to the headers. The shorter pipe will go on the passenger side. Fuel line to engine flat head screwdriver fuel line components, external fuel pressure regulator (if used).

Page 235

234 www.Factoryfive.Com 508-291-3443 finish running your fuel system by hooking up either to your carburetor or fuel rail. Here we mounted a pressure regulator on the firewall and ran a single line over to the rail. Oil filter relocator razor knife, flathead screwdriver oil filter relocating kit, oi...

Page 236

235 www.Factoryfive.Com 508-291-3443 hook the oil lines up to the oil filter relocator and the adapter on the engine. Make sure that the lines go to the correct ports or the engine will be starved for oil. The out on the engine goes to the in on the relocator and the out on the relocator goes to the...

Page 237

236 www.Factoryfive.Com 508-291-3443 route the clutch cable down to the bellhousing. Using zip ties or insulated clips tie the cable safely away from the headers and the moving steering components. It can be fastened to the engine using the bracket on the cable to the front lower bolt that holds the...

Page 238

237 www.Factoryfive.Com 508-291-3443 thread the cable end adjuster nut on so that the cable has no play in it. Adjust the pedal closer or further away as desired by screwing the pedal stop screw up or down. Check the full range of travel for the clutch pedal. Accelerator cable accelerator cable comp...

Page 239

238 www.Factoryfive.Com 508-291-3443 cut the barrel fitting off the end of the cable. Push and twist the ball stud retainer onto the end of the cable and attach the ball stud retainer using a 5 / 64 ” hex key..

Page 240

239 www.Factoryfive.Com 508-291-3443 push the ball stud retainer onto the ball on the bottom of the throttle body. Make sure the accelerator cable is tied up and out of the way of moving or hot parts as well. Check the idle screw underneath the throttle body to see if the throttle arm is hitting it....

Page 241

240 www.Factoryfive.Com 508-291-3443 using a pair of wire cutters, cut the barrel fitting off the cable. Push and twist the ball stud retainer onto the end of the cable and attach the ball stud retainer using a 5 / 64 ” hex key. Attach the engine end of the cable sheath to the cable mount on the eng...

Page 242

241 www.Factoryfive.Com 508-291-3443 thread the inner cable through the cable retaining lock nut from the accelerator cable components assembly. Tighten the accelerator cable locknut. Push the ball stud retainer onto the throttle pedal. While pulling the cable tight, push the accelerator pedal up un...

Page 243

242 www.Factoryfive.Com 508-291-3443 the hole in the firewall extension can be used to pass wires through from the engine to behind the dash and we often mount the computer inside the cockpit with the wires running through here. There is a cover plate that can be drilled to a smaller hole as well..

Page 244

243 www.Factoryfive.Com 508-291-3443 silicone and rivet the dash extension in position. Cooling system marker, hack saw, insulated clip hardware, drill, ¼” drill bit, 3 / 16 ” hex key, 7 / 16 ”, ½” wrenches, ruler, flathead screwdriver. Fan mounting components, stainless radiator hose kit, roadster ...

Page 245

244 www.Factoryfive.Com 508-291-3443 fan mounting unpack the fan and push the four mounting brackets into the angled tab mounts. Center the fan on the radiator and mark the brackets to trim off the excess..

Page 246

245 www.Factoryfive.Com 508-291-3443 remove and trim the brackets then bolt the assembly together using the hardware provided. Make sure and tighten the hardware that came pre-installed on the mounts. Radiator mounting zip tie the radiator in place on the chassis. The bottom section can just hang by...

Page 247

246 www.Factoryfive.Com 508-291-3443 mark the center of the radiator and the center of the chassis and offset the radiator by ⅝”. Drill the holes to mount the radiator top flange to the two small mounting tubes on the chassis..

Page 248

247 www.Factoryfive.Com 508-291-3443 mount the radiator top to the flange with the hardware provided. The bottom stays zip tied for now. Stainless radiator hoses unpack the stainless radiator hose kit and remove the hose connectors from the boxes..

Page 249

248 www.Factoryfive.Com 508-291-3443 use the smaller sections of tube inside the adapters to fit them to smaller fittings on the radiator and intake..

Page 250

249 www.Factoryfive.Com 508-291-3443 then fit the larger adapters over them. Upper radiator hose start at the engine and route the tube above the “x” and to the upper radiator hose location. The inline filler neck goes in the upper hose. Mark the tube where it needs to be cut so that the tube will j...

Page 251

250 www.Factoryfive.Com 508-291-3443 mount the inline filler neck where it is both accessible and as high as possible. Lower radiator hose connect the lower radiator tube to the engine. Run the tube next to the 4” main rail and under the steering rack to the radiator. Route the lower tube with enoug...

Page 252

251 www.Factoryfive.Com 508-291-3443 make sure that the lower hose is not hanging down. If necessary, zip tie the hose to the frame. Mark the tube where it needs to be cut so that the tube will just touch the attaching location. Remove the tube/hose assembly from the vehicle. Cut the tube using a ha...

Page 253

252 www.Factoryfive.Com 508-291-3443 overflow tank unpack the overflow assembly. Bolt the mounting tabs loosely onto the tank so they can be slid around to fit..

Page 254

253 www.Factoryfive.Com 508-291-3443 pick the mounting location for the tank and mark the holes. Make sure the tank is accessible and visible inside to check the level on the finished car then bolt it in place. Mount the overflow tank to the frame/aluminum. Route the overflow hose from the filler to...

Page 255

254 www.Factoryfive.Com 508-291-3443 make sure you attach the hose to the tube that runs off the bottom of the tank and not the one that extends up into the tank. Put the radiator cap in place on the filler for now so it doesn’t get lost..

Page 256

255 www.Factoryfive.Com 508-291-3443 if you did not use the hole in the f-panel for your hose routing then silicone and rivet the cover panel in place. For a cleaner look run the rivets you can get to from the engine bay out. There is a thermostatic fan switch provided to activate the fan. In your e...

Page 257

256 www.Factoryfive.Com 508-291-3443 fan wiring wire crimp tool misc. Electrical components. Attach the cooling fan wires according to the wiring harness manual. Speedometer sending unit 11mm deep socket, ratchet, wire crimping tool speedometer sending unit components, misc. Electrical components th...

Page 258

257 www.Factoryfive.Com 508-291-3443 install the gear on the end of the sender and hold it in place with the clip. Put a little oil on the o-ring and install the sender in your transmission. Use the original bolt to hold the sending unit in place..

Page 259

258 www.Factoryfive.Com 508-291-3443 connect the plug and plug it into the sender. If you are running fuel injection you may also need to send this signal to the computer as well depending on your system. Emergency brake e-brake handle 5 / 32 ”, 3 / 16 ” hex keys, 7 / 16 ”, ½” wrenches, channel lock...

Page 260

259 www.Factoryfive.Com 508-291-3443.

Page 261

260 www.Factoryfive.Com 508-291-3443 unpack the emergency brake handle components. Push a nylon bushing into one side of the fixedgear..

Page 262

261 www.Factoryfive.Com 508-291-3443 push the other bushing into the other side of the fixed gear. From the right side of one of the handle to ratchet mounts, insert the shoulder bolt through the ratchet mount and then the fixed gear..

Page 263

262 www.Factoryfive.Com 508-291-3443 put the other ratchet to handle mount on shoulder bolt from the other side of the fixed gear. Using a 3 / 16 ” hex key and ½” wrench, tighten the shoulder bolt lock nut so that the ratchet to handle mount plates are against the bushings but they can still move up...

Page 264

263 www.Factoryfive.Com 508-291-3443 slide the lower handle between the ratchet to handle mount plates and bolt the three pieces together using the two 5 / 16 ”x 1” button head screws. Put the ratchet tooth on the long anchor bolt as shown in the picture below..

Page 265

264 www.Factoryfive.Com 508-291-3443 rotate the fixed gear out of the way and pass the anchor bolt up through the lower handle. Rotate the ratchet tooth between the handle to ratchet mount plates and align the mount holes..

Page 266

265 www.Factoryfive.Com 508-291-3443 push the included spring pin through the ratchet mount plates and the ratchet tooth using a pair of channel lock pliers. Slide the 1” nylon spacer onto the end of the anchor bolt. There are two nylon spacers included. They provide preload on the spring so there i...

Page 267

266 www.Factoryfive.Com 508-291-3443 spray a little wd-40 on the lower handle threads and screw the upper handle onto the lower handle. Insert the spring into the upper handle over the anchor bolt..

Page 268

267 www.Factoryfive.Com 508-291-3443 screw the button onto the end of the anchor bolt. Screw the male and female rod ends together..

Page 269

268 www.Factoryfive.Com 508-291-3443 use a wrench to spread the ears of the ratchet to handle mounts so that the rod end can just slide between them. Slide the male rod end between the ratchet to handle mount plates and attach it using the ¼” flange head bolt and locknut..

Page 270

269 www.Factoryfive.Com 508-291-3443 insert a 5 / 16 ” carriage bolt into one of the bent mount brackets so the square shoulder is in the square hole. Attach the mount brackets to the fixed gear using a ½” wrench. Leave the locknut slightly loose so positioning can be done on the frame later..

Page 271

270 www.Factoryfive.Com 508-291-3443 check the fit of the emergency brake cable end in the brake cable clevis..

Page 272

271 www.Factoryfive.Com 508-291-3443 if necessary, use a drill bit and drill or a dremel tool to open up the slot slightly..

Page 273

272 www.Factoryfive.Com 508-291-3443 facing the cable slots towards each other, attach one of the cable clevises to each side of the female rod end using the ¼”x 1.50” socket head bolt and locknut. Just start the nut for now, do not tighten it. Attach the handle to the frame using the 5 / 16 ” carri...

Page 274

273 www.Factoryfive.Com 508-291-3443 this picture is shown without aluminum for easier viewing. Tighten the mount bracket to fixed gear carriage bolts. Cables solid axle your e-brake cables should be from the same car as your rear brakes. 87-92 mustang cables or the ffr cables mount to the bracket u...

Page 275

274 www.Factoryfive.Com 508-291-3443 for 87-92 and ffr cables route them through the upper bracket in the transmission tunnel until the sheath end clicks in place. The following picture is shown without aluminum for easier viewing. For 87-92 and ffr cables route the inner cable down under the chassi...

Page 276

275 www.Factoryfive.Com 508-291-3443 solid axle route the cables back to the calipers and attach. Make sure your routing is out of the way of any moving parts and the cable has slack to move with the axle. Emergency brake cable in caliper bracket..

Page 277

276 www.Factoryfive.Com 508-291-3443 handle and cable adjustment if using wilwood brakes attach the two spacer brackets included with the brakes between the clevises and rod end. Remove the cable clevises from the rod end and attach them to the cable ends..

Page 278

277 www.Factoryfive.Com 508-291-3443 adjust the rod end so that the ¼” bolt goes through the rod end and both clevises and the cable is tight. Put the locknut back on the ¼” bolt hand tight..

Page 279

278 www.Factoryfive.Com 508-291-3443 slowly pull up on the handle to set the brake pads and remove any slack from the brake cables. Release the brake and if necessary remove the ¼” clevis bolt and readjust the rod end so that the cable is tight..

Page 280

279 www.Factoryfive.Com 508-291-3443 reinstall the clevises and ¼” bolt then tighten the bolt so that the clevis ends are closed, this will prevent the cable ends from coming out. Axle and fuel tank vents razor knife oem fuel tank components, insulated clip hardware.

Page 281

280 www.Factoryfive.Com 508-291-3443 if using the ffr rear axle, attach the ¼” rubber fuel line to the vent tube on the rear axle or center section. Tie the top of the tube up high under the trunk allowing room for the axle to move. Attach the two foot section of ¼” rubber fuel line attach to the fu...

Page 282

281 www.Factoryfive.Com 508-291-3443 aluminum panels transmission tunnel cover drill, 1 / 8 ” drill bit, silicone, caulking gun, rivet gun roadster secondary body fasteners components, packaged aluminum, mounted aluminum silicone and install the transmission tunnel top. Silicone and install the shif...

Page 283

282 www.Factoryfive.Com 508-291-3443 silicone and install the tunnel plug patch panel. Driver footbox side aluminum 1 / 8 ” drill bit, drill, rivet gun, caulking gun, silicone mounted aluminum, packaged aluminum, secondary body fasteners silicone and install the drivers side footbox outer wall. The ...

Page 284

283 www.Factoryfive.Com 508-291-3443 silicone and install the front patch panel. Seats 5 / 16 ” drill bit, drill, 3 / 16 ” hex key, ½” deep socket, marker seat mount hardware, seats unpack the seats and set them in the cockpit. Sit in the seats and locate them in the position you are most comfortabl...

Page 285

284 www.Factoryfive.Com 508-291-3443 lift up the bottom of the cushion to reveal the seat frame. Using the rivet heads as a guide mark where the rails of the seat frame are above the seat mounting plates..

Page 286

285 www.Factoryfive.Com 508-291-3443 drill the first hole for the seat mounting and install the bolt. Drill the remaining holes for mounting the seats and install the bolts. Nameplate 1 / 8 ” drill bit, rivet gun, drill.

Page 287