- DL manuals

- FactoryCat

- Floor Machine

- 390 Series

- Operator's Manual

FactoryCat 390 Series Operator's Manual

Summary of 390 Series

Page 1

A www.Factorycat.Com r.P.S. Corporation phone: 1-800-634-4060 p.O. Box 368 fax: 1-866-901-3335 racine, wisconsin 53401 c actory operator and parts manual 3 9 0 /4 2 0 s e r ie s 4 3 0 /4 9 0 /5 5 0 s e r ie s version 4.0

Page 2: Rider Scrubbers

Factory cats are designed to clean machine shops, food/beverage manufacturing or packaging, distribution -while standing up to the rigors of contract cleaning. With two specialized cleaning systems to choose from, factory cats offer the performance and capacity required to clean your unique applicat...

Page 3: How To Use This Manual

How to use this manual this manual contains the following sections: - how to use this manual - safety - operations - maintenance - parts list the how to use this manual section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized fac...

Page 4: Machine Information

Page 26-27 page 28-29 page 30-31 page 32-33 page 34-35 page 36-37 page 38-39 page 40-43 page 44-45 page 46-47 page 48-49 page 50-51 page 52-53 page 54-55 page 56-57 page 58-59 page 60-61 page 62-63 machine information please fill this area out at the time of installation for future reference. Model ...

Page 5: Page 2

Warranty registration form ***complete form immediately and fax back to (886)901-3335*** distributor:________________________________________________________ serial number:_________________ location (city, state):_________________________________________ install date:____________________ customer:__...

Page 6: Page 3

Page 3 specifications 390 series 430 series body construction frame construction (steel): ½ , ¼ , 7-ga ½ , ¼ , 7-ga drive wheel (diameter x width): 14 x 5 14 x 5 rear wheels (diameter x width): 16 x 7 16 x 7 dimensions (l x w x h) 78 x 38 x 55 84 x 43 x 57 width (squeegee): 48 or 58 58 or 65 weight ...

Page 7: Common Wear Parts

Common wear parts page 4-1 item brush type brushes super-grit tough-grit midi-grit light-grit poly (.028) nylon (.016) pad driver pads super black black brown green blue red white extra pad driver retaining clip: 40-433 brush repair kit: 40-423 replacement locating clip for all disk brushes tough-gr...

Page 8: Scrub Brushes

Fig. 5 brush type disk cylindrical level (10 the highest) color super-grit ##-421ss na very high 10 red/orange tough-grit ##-421s ##-521s high 9 black midi-grit ##-421c ##-521c high 8 blue/grey light-grit ##-421ps ##-521ps moderate 6 grey poly (.028) ##-421p na moderate 5 black nylon (.012) ##-421n ...

Page 9: Safety Messages

Safety messages your safety, and the safety of others, is very important, and operating this unit safely is an important responsibility. To help you make informed decisions about safety, we have provided operating procedures and other safety information in the manual. This information informs you of...

Page 10: !! Safety Precautions!!

!! Safety precautions!! Warning: hazardous voltage. Shock, burns or electrocution can result. Always discon- nect the batteries before servicing machine. Warning: batteries emit hydrogen gases, explosion or fire can result. Keep sparks and open flames away. Warning: charge unit in a well ventilated ...

Page 11: Page 7

Machine controls and features page 7 figure 1. Figure 2. Figure 3. Figure 4. Figure 5. Figure 6a. Figure 6b. 6 5 7 2 1 3 4 8 13 11 14 9 10 12 15 20 16 17 18 21 23 22 26 27 28 25 24 30 29 40 39 38 36 35 31 32 33 34 37 43 46 42 41 44 45 50 48 47 49 19.

Page 12: Page 8

Page 8 controls and functions see figure 1 1. Steering wheel: steers the machine. 2. Adjustable seat with arm rests: your machine is equipped with an adjustable seat with arm rests. 3. Side brooms: (optional) extends the cleaning path up to walls. 4. Dual headlights: helps you see in low light areas...

Page 13: Page 9

Page 9 figures 7-10. 1. Battery level indicator - indicates the energy level remaining in the batteries. (shown on all menu displays) 2. Scrubbing deck down pressure gauge - sets the down pressure on the brushes. (see figure 7.) 3. Vacuum on - indicates the vacuum is "on" . (see figures 7. And 8.) 4...

Page 14: Machine Setup

Machine setup uncrating machine carefully check the crate for any signs of damage. Batteries are in the unit. To uncrate the machine, remove banding from around the crate. Take off the top and sides and dispose of properly. Remove banding from machine. Remove the chocks around the drive wheels. Conn...

Page 15: Adjusting Squeegee

Adjusting squeegee 1. Turning adjustment knob clock-wise (tightening) will raise tips & lower center. (see figure 14.) figure 15. Figure 16. Figure 17. Adjusting casters 1. Casters determine the ride height & amount of blade deflection. Note:different squeegee materials (gum, linatex,neoprene) may r...

Page 16: Vac Box System

Vac box system 1. The "high recovery" light (red) will illuminate (a) when the recovery tank is full. Stop immediately and drain recovery tank. (see figure 25.) figure 25. Figure 23. 2. If red light is ignored the vac switch (b) will shut off vac motors and sound horn (c ). (see figure 26.) 3. If va...

Page 17: Solution System

Solution system 1. 3/4" gate valve 2. Stainless steel inline filter 3. Solenoid valve 4. Spray pump (optional) (see figure 29) figure 29. 1 2 3 4 1. To clean filter shutoff 3/4" gate valve (a) . (see figure 30.) figure 30. Figure 31. Figure 32. Page 13 2. Unscrew clear lid (b) , remove stainless ste...

Page 18: Side Broom System

Side broom system 1. Flip side broom switch (yellow toggle) up to lower and engage broom. (see figure 33.) figure 33. 2. To adjust side broom height, open right side door and use 1/2" wrench to loosen locking nut (a) . (see figure 34.) 3. Rotate adjustment knob (b) (figure 34.) counter-clockwise (lo...

Page 19: Page 15

Page 15 6. When both brushes are engaged replace the brush access door and tighten it back down with the thumbscrews. (see figure 44.) *** for correct pad application , call your local dealer*** attaching cylindrical brushes 1. Turn "on" machine power 2. Raise the scrub deck by depressing the brush ...

Page 20: Page 16

Page 16 one pass scrubbing steps: (see figure 46.) 1. Turn machine on with the key switch. 2. Lower squeegee by pressing the switch. 3. Lower scrub head to the floor, use the top half of the brush switch. 4. Adjust the solution lever to the desired setting. (set half way), turn clockwise for less, c...

Page 21: Page 17

Page 17 operating hints 1. Observe the amount of solution the machine is dispensing on the floor and adjust to the desired flow. To increase the solution flow rate, rotate blue knob counter-clockwise. 2. Keep an eye on the "red" recovery full light to make sure there is not foamy buildup in the reco...

Page 22

Recovery tank float shut-off when water is no longer being vacuumed from the floor and the vacuum fan is operating, the ball float has engaged. The vacuum motor will not vacuum water with recovery tank full. The recovery tank must be drained. 1. The float shut-off screen can be cleaned in or out of ...

Page 23: Page 18

Page 18 battery charging caution: the following instructions are intended for the 36v charger supplied with the machine. Do not use any other charger with this machine. Charger specifications output voltage of 36 volts. (standard) output current of 36 amps max. (standard) input voltage of 110 volts/...

Page 24: Page 19-1

Page 19-1 yearly maintenance 1. Call your local dealer for yearly maintenance storing machine 1. Be sure to flush the tanks out completely, and to drain all water from the machine. 2. Open the recovery tank lid to promote air circulation. 3. Raise brushes and squeegee. Daily maintenance 1. Remove an...

Page 25: Page 19-2

Page 19-2 maintenance service schedule maintenance before each work period after each work period 50 hrs 100 hrs 200 hrs check water level of batteries after charging; add distilled water if necessary * check that recovery tank cover seals tightly * visually check for damaged or worn tires * check b...

Page 26: Warning!

To charge the batteries when servicing machine, avoid contact with battery acid. Batteries emit hydrogen gas. Explosion or fire can result. Keep sparks and open flame away. Keep covers open when charging. Wear eye protection and protective clothing when working with batteries. Charge batteries in a ...

Page 27: Page 20

Page 20 preventative maintenance records use this form to make copies for your internal records preventative maintenance checked note rotate brushes _____________ ____________________________________ rotate side brooms _____________ ____________________________________ drain solution tank __________...

Page 28: Page 21

Page 21 preventative maintenance records use this form to make copies for your internal records preventative maintenance checked note rotate brushes _____________ ____________________________________ rotate side brooms _____________ ____________________________________ drain solution tank __________...

Page 29: Page 22

Page 22 troubleshooting central command ii (figure 52.) (figure 53.) (figure 54.) (figure 55.) note: this machine is operated by a sophisticated electronic "brain" that has many fail-safes within it. The brain self-analyzes problems and flashes a four-digit numeric code of what is wrong in the lcd w...

Page 30: Page 23

Page 23 9. All other error codes. Turn off the key, and disconnect the positve battery cable from the batteries for more than one minute (the time is needed to drain the brain's on-board capacitor). Reconnect cables, being sure that it is tight. Too loose and you will burn battery. If you overtighte...

Page 31: Page 24

Page 24 problem no power, nothing operates brush motor(s) do not operate drive motor does not operate vacuum motor does not operate drive motor runs incorrectly insufficient solution flow cause faulty key switch batteries need charging faulty battery loose battery cable main circuit breaker tripped ...

Page 32: Trouble Shooting

Trouble shooting page 25 problem no solution flow poor water recovery poor water recovery on turns rear tires noisy poor traction short run time cause no solution in tank solution valve off solution switch off solution screen clogged faulty solution solenoid faulty solution switch recovery tank is f...

Page 33: Model

Model 390/420/430/490/550 machine parts section.

Page 34

7 11 4 6 49 20 9 21 23 52 32 8 19 43 23 51 47 29 23 18 41 50 33 38 46 43 53 48 42 42 48 53 41 47 53 48 42 50 39 3 26 34 15 1 28 13 25 17 51 45 48 44 30 27 10 22 43 frame bottom shown for referance only see door & wiper assembly shown for reference only see cylindrical arm & disk scrubhead assembly's...

Page 35

Item part number title comments qty 1 21-4044 3/4" npt to 3/4" barbed elbow 1 2 290-4179 dbl shut-off hose coupling, 1/4" plug 1 3 290-4550 1/2" npt ball valve 1 4 290-6187 lug nut, 1/2"- 20 12 5 290-8510 1/4" npt dbl end quick disconnect 1 6 390-1100 main frame 1 7 390-1120 rear bumper 1 8 390-1250...

Page 36: Page 28

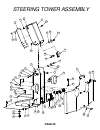

41 18 19 27 25 26 33 23 22 1 2 3 4 5 9 10 7 12 14 15 16 33 43 29 35 17 6 24 23 35 29 32 36 21 20 23 39 42 43 17 40 43 30 35 28 39 42 34 29 35 37 31 44 38 13 11 8 steering tower assembly page 28.

Page 37: Page 29

Item part number title comments qty 1 21-2230 micro switch 1 2 290-1170 lower steering tower 1 3 290-1171 upper steering tower 1 4 290-1172 cover 1 5 290-7050 index plunger 1 6 290-8370 fuse, resettable, 50 amp, 50v dc max 1 7 390-1180 front apron 1 8 390-1610 non skid floor plate 1 9 4-101 serial n...

Page 38: Page 30

47 31 4 41 10 30 33 51 65 74 68 58 67 74 48 62 48 77 67 50 49 34 48 50 32 7 59 36 58 76 76 68 12 6 40 43 55 2 75 76 68 60 73 62 64 69 63 61 72 54 39 17 39 19 seating area assembly 59 67 65 55 5 29 15 44 37 16 54 22 60 71 13 45 35 23 24 14 57 76 3 77 42 27 27 61 70 8 18 38 65 59 67 65 65 67 59 8 11 5...

Page 39: Page 31

Item part number title qty 1 21-1602 3/4 barb elbow 2 2 21-4044 3/4" npt to 3/4" barbed elbow 1 3 21-7040 tank cable 1 4 390-1190 seat pedestal 1 5 390-1195 cover 1 6 390-1205 front upright 1 7 390-1305 seat lid 1 8 390-2328 switch, vacuum shutoff 1 9 390-2328a vacuum switch barb 1 10 390-3010 loade...

Page 40: Page 32

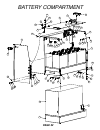

18 2 14 3 4 5 6 7 8 10 9 13 16 15 17 18 22 26 25 23 27 31 20 25 26 22 30 25 23 18 25 26 18 30 25 26 22 22 26 25 26 25 18 19 25 19 20 19 32 12 15 19 19 21 battery compartment page 32 27 29 28 1 28 24 24 11.

Page 41: Page 33

Item part number title comments qty 1 21-4060 6" lanyard 1 2 290-2110 l 16 h battery 6 volt 395 ah 6 3 390-1140 left side panel 1 4 390-1142 lower right side panel 1 5 390-1143 upper right side panel 1 6 390-1165 battery holding bar 1 7 390-1225 11" ss hinge 1 8 390-1300 battery lid 1 9 390-1480 mou...

Page 42: Page 34

12 6 15 35 62 63 39 31 3 17 5 8 9 10 11 26 27 13 29 30 18 19 20 21 22 23 25 32 33 41 35 42 44 61 59 53 45 52 35 42 44 52 52 44 41 51 52 51 37 43 2 34 49 60 44 52 58 38 57 33 50 47 55 64 41 44 52 46 54 tank assemblies 27 63 39 48 page 34 56 15 48 16 a a section a-a 35 24 11 detail b 14 40 28 36 11 4 ...

Page 43: Page 35

Tank assemblies item part number title comments qty 1 21-4086 vac box filter 1 2 21-7205 palm grip knob, 3/8-24 1 3 290-7212 drain hose 1 4 38-712 overfill shutoff ball 1 5 38-738 strainer gasket 2 6 390-1200 rear upright 1 7 390-4100 push-on rubber gasket 67" lg 2 8 390-4112 recovery tank lid 1 9 3...

Page 44: Page 36

22 38 23 8 45 7 8 36 37 27 27 2 4 1 39 15 16 14 12 13 13 12 14 37 36 41 43 44 42 9 40 24 5 24 35 29 10 26 20 19 30 31 28 33 17 34 18 21 32 11 25 25 3 47 48 49 46 390-7310 (does not include wheel) steering/traction assembly page 36.

Page 45: Page 37

46 390-7311 36v, 4hp, motor 1 47 390-7323 electric brake, 36v 1 48 430-7315 430-7320 black tire grey tire 1 49 h-23806 shcs 1/4-28 x 1" grade 8 alloy 10 item part number title comments qty 1 290-7090 steering shaft, upper 1 2 290-7110 u-joint 1 3 290-7111 1/4-28 zerk fitting 1 4 390-7120 steering sh...

Page 46: Page 38

25 1 4 5 6 13 7 8 11 2 24 21 16 2 25 18 20 14 10 22 26 19 3 1 3 19 26 15 12 23 17 (left side shown) lh wiper pn 430-1230 shown rh wiper pn 430-1231 - not shown view below is inside of door assembly fasten this side of hinge to frame & front splash guard 5 8 4 7 10 12 6 13 page 38 side door & wiper a...

Page 47: Page 39

Item part number title comments qty 1 290-1237 fw bronze .75 od x .375 idx .125 thk 4 2 290-1243 3/8" id, 1/2" od, 1/4" lg bearing 6 3 290-1245 3/8" id, 1/2" od, 3/8" lg, flange bearing 6 4 390-1050 wiper arm 3 5 390-1220 door 1 6 390-1221 spring 3 7 430-1225 13" ss hinge 1 8 430-1230 left wiper 1 9...

Page 48

Actuator slide assembly 19 24 30 32 35 18 14 15 15 14 24 3 25 25 27 10 27 36 28 28 38 19 8 9 38 16 21 13 25 25 14 29 22 26 1 23 24 20 15 15 37 25 31 3 6 29 33 12 11 11 37 5 17 39 7 7 25 4 2 34 page 40 setup with serial #390703 & lower 18.

Page 49

Item part number title comments qty 1 21-7690 polyurethane spring 2 2 290-4010 lift bracket 1 3 290-7712 compression spring 8 4 290-7713 scrubhead lift cable 12.25" 3 5 290-7890 squeegee lift cable 2 6 390-4015 lift bracket 1 7 390-8250 .312 od x .25 id x .75 lg 4 8 430-2210 actuator, (20:1) long ba...

Page 50

Actuator slide assembly page 42 setup with serial #390704 & greater 19 10 10 9 15 18 1 20 8 20 16 24 12 11 30 23 30 4 5 14 14 2 3 22 31 23 23 27 19 7 17 21 31 22 27 23 19 13 6 29 26 25 28.

Page 51

Item part number title comments qty 1 21-7690 polyurethane spring 2 2 290-4010 lift bracket 1 3 290-7890 squeegee lift cable 2 4 430-2240 actuator, (10:1) short barrel 1 5 430-7660 actuator channel 1 6 430-7710 cable trolley 1 7 5-223 limit switch 2 8 5-270 emf supp diode 2 9 5-772 pulley, nylon 2 1...

Page 52: Page 44

11 25 39 46 41 4 34 8 33 45 5 54 32 50 19 9 10 12 13 22 23 14 15 27 21 29 30 31 47 47 16 54 49 26 54 48 50 33 19 19 19 6 37 49 38 38 53 36 37 36 53 29 squeegee assembly 2 55 55 2 51 43 page 44 40 18 12 28 52 56 45 24 1 17 1 3 42 1 35 1 51 45 7 51 44 setup with serial #42473 & greater.

Page 53: Page 45

Item part number title comments qty 1 10436-03660 .1/2" id x 7/16" lg setscrew shaft collar 4 2 21-1127 roller 4 3 250-2210 4 inch stroke 36 volt actuator 1 4 290-1233 3/8" id, 1/2" od, 1/4" lg bearing 2 5 290-1248 fw bronze 1/2" id x 1" od x 1/8" th 1 6 290-5786 star knob 4 7 390-7131 squeegee swin...

Page 54

18 30 17 24 25 32 22 33 22 20 21 19 26 27 3 2 8 9 11 12 13 4 5 7 10 side broom ass'y 31 12 1 13 33 19 16 19 9 27 29 6 20 14 29 22 13 26 23 28 15 21 33 13 page 46.

Page 55

Item part number title comments qty 1 290-4450 side broom drive shaft 2 2 290-8750 side broom motor mount 2 3 390-2210 actuator 1 4 390-4420 side broom lift arm (lh) 1 5 390-4421 side broom lift arm (rh) 1 6 390-4620 side broom suspension axle shaft 1 7 390-4630 axle support bracket 1 8 4-352 bearin...

Page 56

1 5 7 9 11 9 10 3 2 10 8 9 11 9 10 3 8 10 2 8 10 3 2 10 8 4 1 cylindrical arm assembly 6 page 48.

Page 57

Item part number model 390 part number model 420/430 title qty 1 290-1237 fw bronze .75 od x .375 idx .125 thk 4 2 290-1243 3/8" id, 1/2" od, 1/4" lg bearing 4 3 290-1245 3/8" id, 1/2" od, 3/8" lg, flange bearing 8 4 290-1248 fw bronze .500 id x 1.00 od x .125 thk 4 5 390-9586 430-9586 lateral lifti...

Page 58

56 54 55 31 52 58 6 33 41 42 43 45 46 47 48 49 50 1 30 3 4 7 8 11 12 14 17 20 24 32 25 36 35 34 53 44 21 40 51 48 59 59 3 51 2 59 15 5 13 59 10 9 38 18 19 27 49 37 38 49 26 57 23 22 29 28 34 cylindrical assembly 16 page 50 39 note: see disk scrubhead pages 50-51 items 5 & 6 for splash curtain and ba...

Page 59

Item part number model 390 part number model 420/430 title comments qty 1 21-1127 roller 4 2 390-1128 roller bracket 2 3 390-3050 bearing housing 4 4 390-521 430-521 brush 390-521 = 36" cyl, 430-521 = 42" cyl 2 5 390-8009 stud 3/8"- 16 x 2 1/4" ss 6 6 390-8010 5/8" id x 7/8" od x 40" clear tube 1 7 ...

Page 60: Page 52

Disk scrubhead assembly 5 15 8 18 32 23 2 16 35 29 31 22 19 28 12 19 33 6 33 33 28 25 31 26 26 5 26 24 30 3 4 4 3 30 24 30 3 20 9 26 33 26 28 33 33 1 18 18 34 21 7 27 30 3 6 6 6 brush: see common wear parts page 14 10 page 52 11 17 13 13.

Page 61: Page 53

Item part number title comments qty 1 21-4044 3/4" npt to 3/4" barbed elbow 2 2 21-5000 brush driver 2 3 290-1245 3/8" id, 1/2" od, 3/8" lg, flange bearing 24 4 290-1248 fw bronze 1/2" id x 1" od x 1/8" th 10 5 390-1310 deck curtain 2 6 390-1320 splash curtain mtg strip 4 7 390-2222 motor 36v 1.0 hp...

Page 62: Page 54

Central command ii 33 33 41 44 43 26 30 32 4 5 10 20 21 25 23 8 9 28 39 35 6 19 1 19 46 11 13 page 54 47 3 2 27 36 38 34 37 24 14 26 26 26 29 26 18 22 7 17 17 16 42 40 31 12 15 45 30 33.

Page 63: Page 55

Item part number part description comments qty 1 21-4510 solution control knob, blue 1 2 290-2001 access cover 1 3 290-2004 access cover gasket 1 4 290-2006 hardware panel 1 5 290-2010 control panel 1 6 290-2015 one touch button 1 7 290-2020 bracket 1 8 290-2300 low solution (amber) low solution 1 9...

Page 64

5 11 6 7 9 27 10 3 4 18 24 15 18 17 22 23 17 13 26 14 19 25 21 23 20 8 16 1 12 2 door/wiper/roller assembly page 56 note hinge, door, arms, & wiper get assembled exactly the same as shown on pages 38-39. *not all parts are shown on this page.

Page 65

Item part number title comments qty 1 21-1127 roller 4 2 290-1126 roller bracket 1 3 390-1050 wiper arm 3 4 390-1220 door 1 5 390-1290 lh pod top support rh pod top support = pn 390-1291 1 6 430-1225 13" ss hinge 1 7 430-1240 left wiper right wiper = pn 430-1241 1 8 430-1270 front lh pod front rh po...

Page 66: Scrubhead Lift Assembly

Page 58 scrubhead lift assembly 22 14 15 12 11 1 13 17 18 25 26 12 19 23 21 2 3 8 6 7 26 14 20 16 17 17 9 21 23 15 8 25 24 4 5 27 9 25 setup for serial #390704 & greater.

Page 67: Scrubhead Lift Assembly

Page 59 scrubhead lift assembly item part number title comments qty 1 290-1243 3/8" id, 1/2" od, 1/4" lg bearing 2 2 32-1083 actuator mtg bracket 1 3 390-1081 actuator anchor 1 4 390-1082 actuator arm 1 5 390-7712 compression spring 6 6 430-2210 actuator, (20:1) long barrel 1 7 430-4021 scrubdeck li...

Page 68: Side Broom Water Option

Side broom water option 21 14 20 17 12 19 18 23 3 4 5 2 11 9 6 14 12 8 18 12 22 24 17 13 17 7 12 25 25 23 19 15 19 1 19 16 19 10 page 60

Page 69: Side Broom Water Option

Item part number part description qty 1 21-4030 clear tube, 1/2" id 1 2 21-4030 clear tube, 1/2" id 1 3 390-4000 recycling system mounting plate 1 4 390-7245 adj solution flow valve, 36v 1 5 390-8500 pump 36v dc (optional) 1 6 b-033 clear tube, 1/4" id 1 7 b-033 clear tube, 1/4" id 1 8 h-014 clear t...

Page 70: Sprayjet System

12 10 13 1 8 9 7 2 3 6 4 5 13 13 1 13 13 13 13 sprayjet system page 62 11 14 note: item 14 is in rear wall of frame..

Page 71: Sprayjet System

Item part number part description qty 1 21-1602 3/4 barb elbow 2 2 390-8500 pump 36v dc (optional) 1 3 390-8960 hose, blue 24' 1 4 430-8910 pump, water jet, 36v 1 5 430-9130 inline filter 1 6 5-895 spray nozzle 1 7 h-015 clear hose, 3/4" id x 4" lg 1 8 h-015 clear hose, 3/4" id x 6" lg 1 9 h-015 cle...