- DL manuals

- Fagor

- Other

- 8040 MC CNC

- Manual

Fagor 8040 MC CNC Manual

Summary of 8040 MC CNC

Page 1

R ef . 0307 (s oft m: 7. Xx ) (s oft m: 7.1 x ) 8040 cnc n ew f eatures.

Page 2: 40 Cnc

Page 2 of 2 80 40 cnc n ew f eatures (s oft m: 7. Xx ) (s oft m: 7.1 x ).

Page 3: 40 Cnc

N ew f eatures page i of ii 80 40 cnc i ndex version 7.01 1 detected errors ..................................................................................................................1 2 sampling period .............................................................................................

Page 4: 40 Cnc

Page ii of ii 80 40 cnc n ew f eatures version 7.11 1 detected errors ................................................................................................................43 2 new validation codes ...............................................................................................

Page 5: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 1 of 48 80 40 cnc detected errors v ersion 7.01 1 detected errors nbtool variable the installation and programming manuals indicate that this variable is read-only from the cnc, plc and dnc. Actually, it is read-only from the cnc and dnc and it can only be used ...

Page 6: 40 Cnc

Page 2 of 48 80 40 cnc sampling period n ew f eatures (s oft m: 7. Xx ) x1 25-pin female sub-d type (normal density) connector to connect the "central unit + monitor". X2 25-pin female sub-d type (normal density) connector to connect the "alphanumeric keyboard + monitor". X3 25-pin female sub-d type...

Page 7: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 3 of 48 80 40 cnc management of the new sercos board 4 management of the new sercos board this software version is ready to work with the new sercos boards, reference: 902103 and newer. The "hardware diagnosis" function shows these boards as "sercos816" because ...

Page 8: 40 Cnc

Page 4 of 48 80 40 cnc windnc improvements n ew f eatures (s oft m: 7. Xx ) 8 windnc improvements from this cnc version on and having windnc version v2.0 and the following, it is possible: • select the work unit for cnc files option (a). Then indicate the desired work unit: memory (b), hard disk (c)...

Page 9: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 5 of 48 80 40 cnc telediagnosis the remote pc must have the windnc application version 2.00 or later installed in it and the cnc software version must be v07.01 or later. Cnc connection to the telephone line it must be done through the rs232 serial line and usin...

Page 10: 40 Cnc

Page 6 of 48 80 40 cnc improvements to the profile editor n ew f eatures (s oft m: 7. Xx ) 10 improvements to the profile editor the following improvements have been made: it is possible to select the coordinate system of the work plane, axes and their direction. The right window, under "display are...

Page 11: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 7 of 48 80 40 cnc new variables 12 new variables feedrate related variables freal(x-c) actual (real) x-c axis feedrate is read-only from the cnc, dnc and plc. Fteo(x-c) theoretical x-c axis feedrate is read-only from the cnc, dnc and plc. Coordinate related vari...

Page 12: 40 Cnc

Page 8 of 48 80 40 cnc new variables n ew f eatures (s oft m: 7. Xx ) when programming "g92 s" in iso code in mc mode. Variables related to probe cycles tipprb it indicates the probe cycle being executed at the cnc. Is read- only from the cnc, dnc and plc. Tipdig it indicates the digit cycle being e...

Page 13: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 9 of 48 80 40 cnc new range of oem subroutines. 13 new range of oem subroutines. A new range of oem subroutines has now been defined. Although oem subroutines are treated like the general ones, the have the following restrictions: • they can only be defined in o...

Page 14: 40 Cnc

Page 10 of 48 80 40 cnc improved drive parameter management n ew f eatures (s oft m: 7. Xx ) 16 improved drive parameter management from this version on, it also possible to save and load into a peripheral device or pc the drive parameter tables via sercos serial line. For that, select the parameter...

Page 15: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 11 of 48 80 40 cnc functions associated to machine safety bit 16 of g.M.P. “actbakan (p144)” indicates the backlash peak being used. A finer tuning of the leadscrew backlash consists in testing the circle geometry and watch for internal peaks when changing quadr...

Page 16: 40 Cnc

Page 12 of 48 80 40 cnc functions associated to machine safety n ew f eatures (s oft m: 7. Xx ) when the spindle moves with plccntl, the spindle limitation is ignored. 19.2 cycle start disabled by hardware errors if when pressing the cycle-start key, a hardware error is detected (sercos board error,...

Page 17: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 13 of 48 80 40 cnc axes (2) controlled by a drive 20 axes (2) controlled by a drive until this version, when having 2 axes controlled by a single drive, the polarity of the analog output (command sign) always corresponded to that of the main axis. From this vers...

Page 18: 40 Cnc

Page 14 of 48 80 40 cnc change of active tool from the plc n ew f eatures (s oft m: 7. Xx ) • when losing feedback count via sercos due to broken communication. Difference greater than 10 microns (0.00039") or 0.01º • when changing machine parameters that affect the memory distribution, for example:...

Page 19: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 15 of 48 80 40 cnc error register • to execute a special m function at the cnc so the plc executes another m function in the plc channel and activates the general input "synchro". • the m function of the main channel must not end until the plc's m function execu...

Page 20: 40 Cnc

Page 16 of 48 80 40 cnc path jog mode n ew f eatures (s oft m: 7. Xx ) this feature must be managed from the plc. To turn on or off the "path jog" work mode, use cnc logic input “mastrhnd” m5054, to indicate the type of movement, use cnc logic input “hnlinarc” m5053 for a linear path, indicate the p...

Page 21: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 17 of 48 80 40 cnc tool inspection • by setting the general logic input “mastrhnd (m5054)” =0. • setting the general logic input “\stop (m5001)”=0. 26 tool inspection the tool inspection mode now offers a new option: "modify offsets". This window shows (at the t...

Page 22: 40 Cnc

Page 18 of 48 80 40 cnc improvements in tool compensation n ew f eatures (s oft m: 7. Xx ) 28 improvements in tool compensation comptype (p74) from this version on, this g.M.P. Has two digits. The units set the beginning and end of radius compensation applied by the cnc (like it was before). The ten...

Page 23: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 19 of 48 80 40 cnc improvements in high speed machining executed in the upper plane and therefore together with the first block “comptype=00”. At the end of the compensation, the tool should withdraw from the part without penetrating into it. The additional bloc...

Page 24: 40 Cnc

Page 20 of 48 80 40 cnc new graphics option n ew f eatures (s oft m: 7. Xx ) if "jerk control in look ahead" has been selected, the cnc analyzes the a.M.P “jerklim (p67)” of each axis. During look-ahead, the cnc assumes, for the axes with “jerklim (p67)=0”, the value suggested in that parameter. Tlo...

Page 25: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 21 of 48 80 40 cnc improvement in the tool measuring cycle probe1 the programming cycle for the probe1 cycle is: (probe 1, b, i, f, j, k, l, c, d, e, s, m, c, n, x, u, y, v, z, w) parameters x, u, y, v, z, w they are optional parameters that are not usually nece...

Page 26: 40 Cnc

Page 22 of 48 80 40 cnc improvement in the tool measuring cycle probe1 n ew f eatures (s oft m: 7. Xx ) j0 (calibration). L0 (the tool is not rejected due to wear). C0 (interrupts the execution for the user to select another tool) measure or calibrate the tool length on its tip. It may be carried ou...

Page 27: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 23 of 48 80 40 cnc improvement in the tool measuring cycle probe1 if the maximum allowed is exceeded, it issues a "tool rejected" message and acts as follows: if the measuring difference does not exceed the maximum allowed or tool life monitoring is not availabl...

Page 28: 40 Cnc

Page 24 of 48 80 40 cnc improvement in the tool measuring cycle probe1 n ew f eatures (s oft m: 7. Xx ) j0 (calibration). E0. S0 (spindle stopped). M0 (the tool is not rejected due to wear). C0 (interrupts the execution for the user to select another tool). N0 (the cutting edges are not measured sep...

Page 29: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 25 of 48 80 40 cnc improvement in the tool measuring cycle probe1 parameters j, l, d, e, s, m, c, n are optional. If not programmed, the following values are assumed: j0 (calibration). L0 (the tool is not rejected due to length wear). D= tool radius (length prob...

Page 30: 40 Cnc

Page 26 of 48 80 40 cnc oscilloscope function n ew f eatures (s oft m: 7. Xx ) if the measuring difference does not exceed the maximum allowed or tool life monitoring is not available: • it updates global arithmetic parameter p298, p299 and the length and radius wear values of the tool offset select...

Page 31: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 27 of 48 80 40 cnc oscilloscope function to select another editable data or field, use the [ Ï ] [ Ð ]. It is a rotary selection, if the first element is selected on the screen, when pressing [ Ï ] the focus goes to the last one, whereas if the last element is s...

Page 32: 40 Cnc

Page 28 of 48 80 40 cnc oscilloscope function n ew f eatures (s oft m: 7. Xx ) the parameters defining page shows the definition code on the left column, the parameter name on the center column and the maximum and minimum values on the right column. To add a parameter to the list, select the row for...

Page 33: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 29 of 48 80 40 cnc oscilloscope function cnc variables that may be assigned to a channel examples: anai1, freal, flwex, frealz fagor sercos drive variables that may be assigned to a channel indicate the desired axis and variable, separated by a period. Examples:...

Page 34: 40 Cnc

Page 30 of 48 80 40 cnc oscilloscope function n ew f eatures (s oft m: 7. Xx ) with an up flank, the data capture begins when in a sample the data value is lower than the level and in the next sample the value is greater than or equal to the level. With a down flank, the data capture begins when in ...

Page 35: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 31 of 48 80 40 cnc oscilloscope function cnc machine parameters that may be modified when defining the cnc machine parameters, that could be changed to adjust the machine, use the following nomenclature: machine parameters of an axis: indicate the axis and the p...

Page 36: 40 Cnc

Page 32 of 48 80 40 cnc oscilloscope function n ew f eatures (s oft m: 7. Xx ) indicate the axis and the parameter number and the gear separated by a dot. Examples: [x.Cp1.0], [y.Cp20.2], [z.Sp1.1] save and load the configurations. The system lets you save the current configuration into a program ty...

Page 37: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 33 of 48 80 40 cnc oscilloscope function when auto-scaling a channel, the system sets the right vertical scale and offset so the signal shows as big as possible within its graphic strip. To modify the time base of all the signals, use the [ Ï ] [ Ð ] keys to pla...

Page 38: 40 Cnc

Page 34 of 48 80 40 cnc oscilloscope function n ew f eatures (s oft m: 7. Xx ) the machine parameters of the axis or the spindle are updated according to the criteria defined in the previous tables, the rest of the parameters are updated according to the general criteria: if the password to the mach...

Page 39: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 35 of 48 80 40 cnc mc model. Execute a part-program 33 mc model. Execute a part-program after accessing the list of stored part-programs and selecting the program to be executed from the left column, it is possible to: 1. Execute the whole part-program. Position...

Page 40: 40 Cnc

Page 36 of 48 80 40 cnc mc model. Cycle selection n ew f eatures (s oft m: 7. Xx ) program in execution or interrupted. When editing the active tool, it is possible: to modify the i and k data. Select another tool (t xx recall) and modify its i and k data. When not editing the active tool, it is pos...

Page 41: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 37 of 48 80 40 cnc mc model. Auxiliary m functions in all the cycles cocyf1 (p148) cocyf2 (p149) cocyf3 (p150) cocyf4 (p151) cocyf5 (p152) cocyf6 (p153) cocyf7 (p154) cocyz (p155) cocypos (p156) cocyprof (p157) cocygroo (p158) cocyzpos (p159) each one of these g...

Page 42: 40 Cnc

Page 38 of 48 80 40 cnc mc model. Modifications in the tapping cycle n ew f eatures (s oft m: 7. Xx ) codiset (p147) this parameter has 16 bits counted from left to right. Bit 16 indicates whether the operations or cycles of the mc model have auxiliary m functions associated with roughing and finish...

Page 43: 40 Cnc

N ew f eatures (s oft m: 7. Xx ) page 39 of 48 80 40 cnc mc model. Tool measurement and calibration 42 mc model. Tool measurement and calibration available with the "canned cycles with probe" option and if the parameters that define the tabletop probe position g.M.P. Prbxmin (p40), prbxmax (p41), pr...

Page 44: 40 Cnc

Page 40 of 48 80 40 cnc mc model. Tool measurement and calibration n ew f eatures (s oft m: 7. Xx ) the [s, n, x+, d and h] fields are requested when the calibration/ measurement (a) method so requires. Zone (2) defines whether a measurement or a calibration is to be carried out. To select the desir...

Page 45: 40 Cnc

User notes: n ew f eatures (s oft m: 7. Xx ) page 41 of 48 80 40 cnc.

Page 46: 40 Cnc

User notes: n ew f eatures (s oft m: 7. Xx ) page 42 of 48 80 40 cnc.

Page 47: 40 Cnc

N ew f eatures (s oft m: 7.1 x ) page 43 of 48 80 40 cnc detected errors v ersion 7.11 1 detected errors a.M.P. Dformat (p1) the installation manual shows wrong work units. The right work units are: connector x4. To connect the analog spindle the installation manual shows the wrong function associat...

Page 48: 40 Cnc

Page 44 of 48 80 40 cnc detected errors n ew f eatures (s oft m: 7.1 x ) 48 connector x1. Rs232 serial line (8055i model) from this version on, pin 9 no longer supplies 5v. Variables pos(x-c) and tpos(x-c) the values of variables pos(x-c) and tpos(x-c) are in the following units. • they are read fro...

Page 49: 40 Cnc

N ew f eatures (s oft m: 7.1 x ) page 45 of 48 80 40 cnc new validation codes 2 new validation codes due to new software options, the validation code changes from 16 to 24 characters. The new codes are also valid for the memory cards with software versions older than v7.11 3 smooth stop in probing m...

Page 50: 40 Cnc

Page 46 of 48 80 40 cnc new management of the distance- coded reference mark (i0) n ew f eatures (s oft m: 7.1 x ) 48 5 new management of the distance-coded reference mark (i0) from this version on, the distance-coded i0 via sercos may be managed using the input of the drive's second feedback. • the...

Page 51: 40 Cnc

N ew f eatures (s oft m: 7.1 x ) page 47 of 48 80 40 cnc parameters accessible from the oscilloscope or oem subroutine 8 parameters accessible from the oscilloscope or oem subroutine 8.1 axis parameters that may be modified from the oscilloscope the following axis machine parameters may be modified....

Page 52: 40 Cnc

User notes: n ew f eatures (s oft m: 7.1 x ) page 48 of 48 80 40 cnc.

Page 53: Operating Manual

Operating manual (mc option) ref. 0204-ing.

Page 54

Iii the information described in this manual may be subject to variations due to technical modifications. Fagor automation, s.Coop. Ltda. Reserves the right to modify the contents of the manual without prior notice..

Page 55: Index

V index 1. General concepts 1.1 keyboard ................................................................................................................................1 1.2 general.........................................................................................................................

Page 56

Vi 3.3.2 profile definition (level 2) ......................................................................................................10 3.4 surface and slot milling milling operations .......................................................................11 3.4.1 surface milling data definiti...

Page 57: 1. General Concepts

Chapter 1 - page 1 mc work mode 1. General concepts 1.1 keyboard 1. General concepts 1.1 keyboard alphanumeric keys and command keys. Selects character x selects character a selects character r specific keys for the mc model enable selection and definition of machining operations governing external ...

Page 58

Chapter 1 - page 2 mc work mode 1. General concepts 1.2 general 1.2 general it has all the performance features of the m model plus the specific features of the mc mode. For example, the setting of the numerical control must be done in m mode. In the mc operating mode the programs p900000 to p999999...

Page 59

Chapter 1 - page 3 mc work mode 1. General concepts 1.2 general some of the programs reserved for the cnc itself have the following meaning: p999998 this is a routines program used by the cnc for interpreting the programs edited in mc format and executing these afterwards. Warning no modifications o...

Page 60

Chapter 1 - page 4 mc work mode 1.2.1 management of text program p999997 on power-up, the cnc copies the texts of program p999997 into the system memory. It checks if program p999997 is in the user memory. If it is not, it looks in "card a", if it is not there either, it assumes the ones provided by...

Page 61

Chapter 1 - page 5 mc work mode 1.3 power-up both on cnc power-up and after the keystroke sequence: the cnc acts as follows: shows «page 0» if it has been defined by the manufacturer. To access this operating mode, press any key. If there is no «page 0», the cnc will display the standard screen for ...

Page 62

Chapter 1 - page 6 mc work mode 1. General concepts 1.4 operating in m mode with an mc keyboard 1.5 video off 1.4 operating in m mode with an mc keyboard the mc keyboard has been designed to also be able to operate in m mode. The alphanumeric keyboard must be used for the keys replacing softkeys f1 ...

Page 63: 2. Operating In Jog Mode

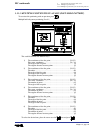

Chapter 2 - page 1 mc work mode 2. Operating in jog mode 2. Operating in jog mode the standard mc operating mode screen is: if one presses key the cnc displays the special mc operating mode screen..

Page 64

Chapter 2 - page 2 mc work mode 2. Operating in jog mode 2.1 introduction 2.1 introduction the standard mc operating mode screen contains the following information: 1.- clock 2.- this window can display the following data: sbk when the single block execution mode is selected. Dnc when the dnc mode i...

Page 65

Chapter 2 - page 3 mc work mode 2. Operating in jog mode 2.1 introduction 6.- this window displays, in large characters, the tool number «m» selected. The offset number «d» associated with the tool. If the tool number and the offset number coincide, the cnc will not display value «d». The coordinate...

Page 66

Chapter 2 - page 4 mc work mode 2. Operating in jog mode 2.1 introduction the special screen for mc operating mode contains the following information: 1.- clock 2.- this window can display the following data: sbk when the single block mode of execution is selected. Dnc when the dnc mode is active. P...

Page 67

Chapter 2 - page 5 mc work mode 2. Operating in jog mode 2.1 introduction 6.- this window shows the state of the «g» functions and the auxiliary functions «m» that are activated. It also displays the value of variables. Parmc states the number of consecutive parts that have been executed with the sa...

Page 68

Chapter 2 - page 6 mc work mode 2. Operating in jog mode 2.2 axis control 2.2 axis control 2.2.1 work units whenever the mc work mode is accessed, the cnc assumes the work units, «mm or inches», «millimeters/minute or millimeters/revolution», etc., that are selected by machine parameter. To modify t...

Page 69

Chapter 2 - page 7 mc work mode 2. Operating in jog mode 2.3 home search 2.3 home search (machine reference zero) home search can be done in 2 ways: - home search on all the axes. - home search on a single axis. Home search on all the axes to carry out a search for machine reference zero for all axe...

Page 70

Chapter 2 - page 8 mc work mode 2. Operating in jog mode 2.4 jogging the axes 2.4.1 continuous jog 2.4 jogging the axes the axes of the machine can be jogged in the following ways: - [x] [target position] [z] [target position] or [z] [target position] - continuous movement - incremental movement - m...

Page 71

Chapter 2 - page 9 mc work mode 2. Operating in jog mode 2.4 joggin the axes 2.4.2 incremental jog 2.4.2 incremental jog place the left-hand switch in one of the positions incremental jog must be done one axis at a time. To do this press the jog key for the direction of the axis to be moved. Each ti...

Page 72

Chapter 2 - page 10 mc work mode 2. Operating in jog mode 2.4 jogging the axes 2.4.3 jogging with an electronic handwheel 2.4.3 jogging with an electronic handwheel this option means the machine movements can be governed by means of an electronic handwheel. To do this the left-hand switch has to be ...

Page 73

Chapter 2 - page 11 mc work mode 2. Operating in jog mode 2.4 jogging the axes 2.4.4 feed handwheel 2.4.4 feed handwheel usually, when making a part for the first time, the machine feedrate is controlled by means of the feedrate override switch. From this version on, it is possible to use the machin...

Page 74

Chapter 2 - page 12 mc work mode 2. Operating in jog mode 2.4 jogging the axes 2.4.5 master handwheel 2.4.5 master handwheel with this feature, it is possible to jog two axes at the same time along a linear or circular path with a single handwheel. More handwheels need not be installed on the machin...

Page 75

Chapter 2 - page 13 mc work mode 2. Operating in jog mode 2.5 tool control 2.5 tool control the standard screen for mc operating mode displays the following information about the tool. This window displays the following information: > in large characters, the number "t" of the selected tool. > the o...

Page 76

Chapter 2 - page 14 mc work mode 2. Operating in jog mode 2.5 tool control 2.5.1 tool change 2.5.1 tool change depending on the type of tool changer, one can have: machine with automatic tool changer machine with manual tool changer in both cases the cnc: executes the routine associated with the too...

Page 77

Chapter 2 - page 15 mc work mode 2.5.1.1 variable tool change point if the manufacturer wishes the user can be allowed to define the tool change point at all times. This feature logically depends on the type of machine and type of changer. This feature allows the tool change to be made beside the pa...

Page 78

Chapter 2 - page 16 mc work mode 2. Operating in jog mode 2.5 tool control 2.5.2 tool calibration 2.5.2 tool calibration to access tool calibration mode press key the cnc displays the following information: 1.- header for the selected operating mode: «tool calibration». 2.- help graphics for the too...

Page 79

Chapter 2 - page 17 mc work mode 2.5.2.1 define the tool in the tool table to define a tool in the tool table take the following steps: select the tool number to be defined press key to select field «t» key in the tool number to be defined and press key if the tool is defined, the cnc will display t...

Page 80

Chapter 2 - page 18 mc work mode 2. Operating in jog mode 2.5 tool control 2.5.2 tool calibration 2.5.2.2 tool measurement there are 2 ways of measuring a tool. A) using a tool calibrating table. Using the window containing the tool dimensions to set that data. B) not using a tool calibrating table....

Page 81

Chapter 2 - page 19 mc work mode 2. Operating in jog mode 2.5 tool control 2.5.2 tool calibration select the bottom left window using the key in the z coordinate of the part used for calibration and press tool measurement. Length only. Approach the tool to the part and touch it with it. Press the to...

Page 82

Chapter 2 - page 20 mc work mode 2. Operating in jog mode 2.6 spindle control 2.6 spindle control the standard mc work mode shows the following information about the spindle. 1.- actual (real) spindle speed in rpm. 2.- theoretical spindle speed in rpm. To select another speed, press the cnc highligh...

Page 83

Chapter 2 - page 21 mc work mode 2. Operating in jog mode 2.7 control of external devices 2.7 control of external devices the cnc allows up to 6 external devices to be activated and deactivated from the keyboard. One of these is the cooling fluid. The activation and deactivation of the devices must ...

Page 84

Chapter 2 - page 22 mc work mode 2. Operation in jog mode 2.8 iso code management 2.8 iso code management the iso key gives access to the mdi mode or to the iso work mode. To access the mdi mode, the jog mode must be selected and then press the cnc displays a window at the bottom of the standard (or...

Page 85

Chapter 3 - page 1 mc work mode 3. Working with operations or cycles 3. Working with operations or cycles the following keys of the cnc must be used to select the machining operations or cycles: when pressing the cnc shows all the user cycles defined by the machine manufacturer using the wgdraw appl...

Page 86

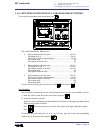

Chapter 3 - page 2 mc work mode 3. Work with operations or cycles 3.1 operation editing mode 3.1 operation editing mode once the operation has been selected, the cnc shows a screen like this: 1.- name of the selected operation or cycle. 2.- help graphics. 3.- when referred to positioning, it indicat...

Page 87

Chapter 3 - page 3 mc work mode 3. Work with operations or cycles 3.1 operation editing mode 3.1.1 definition of machining conditions 3.1.1 definition of the machining conditions some operations keep the same machining condition during the whole execution process (boring, reaming, etc.) other operat...

Page 88

Chapter 3 - page 4 mc work mode 3.1.2 safety plane in all operations, there are four work planes. Starting plane or tool position when calling the cycle. It does not have to be defined. Safety plane . It is used for the first approach and for withdrawing the tool after the machining operation. It is...

Page 89

Chapter 3 - page 5 mc work mode 3.1.3 cycle level all the cycles have several editing levels. Each level has its own screen and the main window of the cycle indicates (with tabs) the available levels and which one is currently selected. To change levels, use the key or the "page up" and "page down" ...

Page 90

Chapter 3 - page 6 mc work mode 3. Work with operations or cycles 3.2 simulation and execution of the operation 3.2 simulation and execution of the operation there are 2 ways to work with operations or cycles: editing and execution modes. Editing mode execution mode press to switch from the editing ...

Page 91

Chapter 3 - page 7 mc work mode 3. Work with operations or cycles 3.2 simulation and execution of the operation 3.2.1 background cycle editing 3.2.1 background cycle editing while executing a part-program, it is possible to edit an operation or cycle at the same time (background editing). The new op...

Page 92

Chapter 3 - page 8 mc work mode 3. Work with operations or cycles 3.3 profile milling operation 3.3 profile milling operation press to select the profile milling operation this cycle may be defined in two ways: level 1. One must define: the starting point (x1, y1), the intermediate points (p1 throug...

Page 93

Chapter 3 - page 9 mc work mode 3.3.1 data definition coordinates of the starting and end points these coordinates are defined one at a time. Once the cursor is over the coordinates of the axis to be defined, one can: a) enter the value by hand. Key in the desired value and press b) assign the curre...

Page 94

Chapter 3 - page 10 mc work mode 3.3.2 profile definition (level 2) to define the "profile program" one can: key in the "profile program" number directly. If the "profile program" number is known, key it in and press access the "profile program" directory to select one of them press the cycle will s...

Page 95

Chapter 3 - page 11 mc work mode 3.4 surface and slot milling milling operations press to select these operations. Surface milling operation: one must define the type of milling, the starting point (x1, y1), the dimensions of the surface to be milled (l, h, e) and the machining conditions in z (zs, ...

Page 96

Chapter 3 - page 12 mc work mode 3.4.1 surface milling data definition type of surface milling to select the type of surface milling, place the cursor over this icon and press surface to mill (x1, y1, l, h, e, α α ) define one of the corners of the surface to be milled (x1, y1), the length (l) and t...

Page 97

Chapter 3 - page 13 mc work mode 3.4.2 slot milling data definition type of slot milling to select the type of slot milling, place the cursor over this icon and press coordinates of the starting point these coordinates are defined one by one. After placing the cursor over the axis coordinates to be ...

Page 98

Chapter 3 - page 14 mc work mode 3. Work with operations or cycles 3.4 surface and slot milling operations milling the different slot types, clockwise:.

Page 99

Chapter 3 - page 15 mc work mode 3.5 pocket cycle with a profile to select a profile milling operation, press this cycle may be defined in two different ways: pocket with 2d profile pocket with 3d profile a pocket consists of contour or outside profile (1) and a series of contours or profiles intern...

Page 100

Chapter 3 - page 16 mc work mode programming pockets with 3d profiles pocket id number. (3d pocket) it is possible to have several 3d pockets. The cnc associates with each 3d pocket all its data (surface profile, depth profile, machining conditions, etc.) surface profile or profile in the x,y plane....

Page 101

Chapter 3 - page 17 mc work mode to define the values (zs and z), after placing the cursor in the corresponding window, one may: a) enter the value by hand. Key in the desired value and press b) assign the current axis position. Jog the axis to the desired point with the handwheel or the jog keys. T...

Page 102

Chapter 3 - page 18 mc work mode 3.5.2 profile definition to define a profile, after selecting the corresponding window, one can: key in the "profile program" number directly. If the "profile program" number is known, key it in and press access the "profile program" directory to select one of them p...

Page 103

Chapter 3 - page 19 mc work mode 3. Work with operations or cycles 3.5 pocket cycle with a profile 3.5.3 examples of profile definition example of how to define a 2d pocket without islands: 2d pocket profile 1 recall configuration abscissa axis: x ordinate axis: y autozoom: yes validate profile star...

Page 104

Chapter 3 - page 20 mc work mode example of how to define a 3d pocket without islands: 3d pocket= 1 p.Xy= 3 recall configuration abscissa axis: x ordinate axis: y autozoom: yes validate profile (outside profile) starting point x 20 y 0 validate straight x 20 y -40 validate straight x 145 y -40 valid...

Page 105

Chapter 3 - page 21 mc work mode 3.6 rectangular and circular boss cycles to select the boss cycles, press rectangular boss cycle one must define the starting point (x,y), the dimensions of the boss (l,h), the inclination angle (a), the amount of material to be removed (q), the type of corner and th...

Page 106

Chapter 3 - page 22 mc work mode 3.6.1 data definition coordinates of the starting point these coordinates are defined one by one. After placing the cursor over the axis coordinates, one can: a) enter the value by hand. Key in the desired value and press b) assign the position of the axis. Jog the a...

Page 107

Chapter 3 - page 23 mc work mode 3.7 rectangular and circular pocket cycles to select these cycles press rectangular pocket cycle (level 1) one must define the starting point (x, y), the pocket dimensions (l, h) and the machining conditions in z (zs, z, p, i, fz) one must also define the milling pas...

Page 108

Chapter 3 - page 24 mc work mode circular pocket cycle (level 1) one must define the center coordinates (xc, yc), the pocket radius (r) and the machining conditions in z (zs, z, p, i, fz) in the area for roughing data, define the lateral penetration angle ( β ), the milling pass ( ∆ ) and the machin...

Page 109

Chapter 3 - page 25 mc work mode 3.7.1 data definition coordinates of the starting point the coordinates are defined one by one. After placing the cursor over the axis coordinates to be defined, one can: a) enter the value by hand. Key in the desired value and press b) assign the current axis positi...

Page 110

Chapter 3 - page 26 mc work mode 3. Work with operations or cycles 3.7 rectangular and circular pocket cycles milling pass ( ∆ ∆ ) finishing stocks: on walls ( δδ ) and at the bottom ( δδ z) number of finishing passes (n) place the cursor in the window for finishing operation, key in the desired val...

Page 111

Chapter 3 - page 27 mc work mode 3.8 positioning (2 levels) to select the positioning cycle, press this cycle may be defined in two different ways: level 1. One must define the target point (x, y, z), the axes movement sequence and the type of feedrate level 2. One must define the target point (x, y...

Page 112

Chapter 3 - page 28 mc work mode 3.8.1 data definition coordinates of the target point these coordinates are defined one by one. After placing the cursor over the axis coordinates, on can: a) enter the value by hand. Key in the desired value and press b) assign the current axis position. Jog the axi...

Page 113

Chapter 3 - page 29 mc work mode 3.9 boring operation to select the boring operation, press boring operation (level 1) one must define the machining point (x, y), the coordinate of the safety plane (zs), the coordinate of the part surface (z), the total machining depth (p) and the dwell at the botto...

Page 114

Chapter 3 - page 30 mc work mode 3.9.1 data definition coordinates of the machining point these coordinates are defined one by one. After placing the cursor over the axis coordinates, one can: a) enter the value by hand. Key in the desired value and press b) assign the current axis position. Jog the...

Page 115

Chapter 3 - page 31 mc work mode 3.10 reaming operation to select the reaming operation, press one must define the machining point (x, y), the coordinate of the safety plane (zs), the coordinate of the part surface (z), the total machining depth (p) and the dwell at the bottom (t) the reaming operat...

Page 116

Chapter 3 - page 32 mc work mode 3.11 tapping operation to select the tapping operation, press one must define the machining point (x, y), the coordinate of the safety plane (zs), the coordinate of the part surface (z), the total machining depth (p) and the dwell at the bottom (t) and the type of ta...

Page 117

Chapter 3 - page 33 mc work mode 3.11.1 data definition coordinates of the machining point these coordinates are defined one by one. After placing the cursor over the axis coordinates, one can: a) enter the value by hand. Key in the desired value and press b) assign the current axis position. Jog th...

Page 118

Chapter 3 - page 34 mc work mode 3.12 drilling and center punching operations to select the drilling and center punching operations, press center punching operation one must define the punch point (x, y), the coordinate of the safety plane (zs), the coordinate of the part surface (z), the total mach...

Page 119

Chapter 3 - page 35 mc work mode drilling operation. (level 2) it is possible to set the withdrawal distance (b) after each penetration. One must define the machining point (x, y), the coordinate of the safety plane (zs), the coordinate of the part surface (z), the total machining depth (p), the dri...

Page 120

Chapter 3 - page 36 mc work mode 3. Work with operations or cycles 3.12 drilling (2 levels) and center punching operations 3.12.1 data definition coordinates of the machining point these coordinates are defined one by one. After placing the cursor over the axis coordinates, one can: a) enter the val...

Page 121

Chapter 3 - page 37 mc work mode 3.13 multiple positioning with this cnc, it is possible to associate multiple positioning with boring, reaming, tapping, drilling and center punching operations. The following keys must be used to select this feature. When pressing one of these keys, the cnc selects ...

Page 122

Chapter 3 - page 38 mc work mode 3.13.1 multiple positioning at random points to associate this positioning with an operation, press up to 12 points can be defined. Coordinates (x1, y1) .... (x12, y12) when not using all 12 points, the first unused point must be defined with the same coordinates as ...

Page 123

Chapter 3 - page 39 mc work mode 3.13.2 multiple positioning in a straight line to associate this positioning with an operation, press this may be defined in 5 different ways: 1) the coordinates of the first point .......................................... (x1, y1) the coordinates of the last point ...

Page 124

Chapter 3 - page 40 mc work mode 3. Work with operations and cycles 3.13 multiple positioning 3.13.2 multiple positioning in a straight line the coordinates are defined one by one. After placing the cursor over the axis coordinates, one can: a) enter the value by hand. Key in the desired value and p...

Page 125

Chapter 3 - page 41 mc work mode 3.13.3 multiple positioning in an arc (bolt-hole pattern) to associate this positioning with an operation, press multiple bolt-hole pattern positioning (level 1) this could be defined in 6 different ways: 1) the coordinates of the first point ...........................

Page 126

Chapter 3 - page 42 mc work mode multiple bolt-hole pattern positioning (level 2) one must define: the center coordinates ........................................................(xc, yc) the starting point in polar coordinates:......... Radius (r) and angle ( α ) 2 of the following data must be defi...

Page 127

Chapter 3 - page 43 mc work mode 3.13.4 multiple positioning in a parallelogram pattern to associate this positioning with an operation, press this could be defined in 3 different ways: 1) the coordinates of the first point .......................................... (x1, y1) the lengths in x, y .......

Page 128

Chapter 3 - page 44 mc work mode 3.13.5 multiple positioning in a grid pattern to associate this positioning with an operation, press this could be defined in 3 different ways: 1) the coordinates of the first point ..........................................(x1, y1) the lengths in x, y .................

Page 129: 4. Storage of Programs

Chapter 4 - page 1 mc work mode 4. Storage of programs 4. Storage of programs this cnc allows the editing, simulating and executing of part-programs. Each of these programs consists of the interlinking of elementary operations or cycles and/or blocks edited in iso code. The form of editing or defini...

Page 130

Chapter 4 - page 2 mc work mode 4. Storage of programs 4.1 list of stored programs 4.1 list of stored programs to access the list of part-programs stored press note: if the «tool calibration» mode is selected you cannot directly access the list of part-programs. This mode must first be left, that is...

Page 131

Chapter 4 - page 3 mc work mode 4.2 see content of a program to see the content of a part-program, select this with the pointer from the left-hand column. To do this use and if the part-program is formed on an mc mode cycle basis, the right -hand column will display the cycles which said part consis...

Page 132

Chapter 4 - page 4 mc work mode 4. Storage of programs 4.3 edit a new part-program 4.3.1 storage of an operation of cycles 4.3 edit a new part-program to edit a new part-program the following steps should be taken: * press to access the list of part-programs stored. * use the pointer to select the o...

Page 133

Chapter 4 - page 5 mc work mode 4. Storage of programs 4.4 erasing a part-program 4.5 copy a part-program in another 4.4 erasing a part-program to erase a part-program follow these steps: * press to access the list of part-programs stored. * use the pointer to select from the left-hand column the pa...

Page 134

Chapter 4 - page 6 mc work mode 4. Storage of programs 4.6 modifying a part-program 4.6 modifying a part-program to modify a part-program the following steps must be taken: * press to access the list of part-programs stored. * use the pointer to select from the left-hand column the part-program you ...

Page 135

Chapter 4 - page 7 mc work mode 4. Storage of programs 4.6 modifying a part-program 4.6.3 adding or inserting a new operation to add or insert an operation take the same steps as to store an operation. * define the operation or cycle required, assigning this the relevant data. * press to access the ...

Page 136

Chapter 5 - page 1 mc work mode 5. Execution and simulation 5. Execution and simulation simulation allows graphic reproduction of a part-program or an operation with the data that has been defined. By means of simulation, one can thus check the part-program or the operation before executing or stori...

Page 137

Chapter 5 - page 2 mc work mode 5. Execution and simulation 5.1 simulating or executing an operation or cycle 5.1 simulating or executing an operation or cycle all the operations or cycles have 2 operating modes: execution mode and edition mode editing mode execution mode simulation the operation or...

Page 138

Chapter 5 - page 3 mc work mode 5.2 simulating or executing a part-program whenever you wish to simulate or execute a part-program do the following: * press to access the list of part-programs stored. * select the program to be simulated or executed from the left-hand column. To simulate the part-pr...

Page 139

Chapter 5 - page 4 mc work mode 5.4 execution mode when you press to execute an operation or part-program, the cnc displays the standard mc operating mode screen. If you press the cnc displays the special mc operating mode screen. After selection, the operation or part can be executed as many times ...

Page 140

Chapter 5 - page 5 mc work mode 5.4.1 tool inspection the plc mark m5050, general cnc logic input "toolinsp", determines when tool inspection is enabled. Toolinsp=0 tool inspection is possible after pressing toolinsp=1 when pressing program execution is interrupted. Once program execution is interru...

Page 141

Chapter 5 - page 6 mc work mode 5.5 graphic representation when you press the cnc displays the m mode graphic representation page. To leave the graphic representation mode press or in the operation manual, m -mc models, section «graphics» in the «execution / simulation» chapter, there is an explanat...

Page 142

Chapter 5 - page 7 mc work mode graphic parameters simulation speed. In the top right-hand of the screen select the percentage of the simulation speed to be applied. To select the percentage use , for the cnc to assume said value, press colors of the path. This only applies in line graphics (not sol...

Page 143: Self-Teaching Manual

Self-teaching manual (mc option) ref. 0112-ing.

Page 144: Index

Index chapter 1 theory on cnc machines 1.1.- machine axes ……………………………………………………………………….3 1.2.- machine reference zero and part zero……………………………...…………….…5 1.3.- home search………... ……………………………………………………….….….6 1.4.- travel limits ……………………………………………………………………….. 7 1.5.- part zero setting …………………………………...………...

Page 145

Chapter 4 automatic operations 4.1.- operation keys ………….………………………………….……..…………...…... 3 4.2.- work modes .……………………………………………..…………..…………..... 5 4.3.- example of an automatic operation. ……………………..….……….………..……6 4.3.1.- edit an operation .………………………………………….……….…...………6 4.3.1.1.- rectangular pocket …………...

Page 146

Appendix i programming example step 0: part to be machined ...…………………………………...…..….………..………2 step 1: surface milling ……...………………………..……………...…………..………3 step 2: machining the profile ………………………………………....………...……….4 step 3: rectangular boss ………………………………………………………...……… 5 step 4: circular pocket .…..…………...

Page 147: Theory On Cnc Machines

Chapter 1 theory on cnc machines.

Page 148: Mc Model

Self-teaching manual chapter 1 page 2 mc model theory on cnc machines this chapter describes: • how to name the axes of the machine. • what machine reference zero and part zero are. • what “home search” is. • what travel limits are. • how to preset a part zero. • which are the work units. > programm...

Page 149: Mc Model

Self-teaching manual chapter 1 page 3 mc model theory on cnc machines the orientation of the axes depends on the type of machine and are established by the “rule of the right hand”. 1.1 machine axes. Axes orientation. Rotary axes..

Page 150: Mc Model

Self-teaching manual chapter 1 page 4 mc model theory on cnc machines this manual uses the following axes configuration. Two types of movements can be distinguished on a machine, those of the machine (x, y) and that of the tool itself (z). But for programming them, let us assume the movements of the...

Page 151: Mc Model

Self-teaching manual chapter 1 page 5 mc model theory on cnc machines 1.2 machine reference zero and part zero. O m o m o p o p they are the references the machine needs in order to work: machine ref. Zero (o m ) it is set by the manufacturer and it is the origin point for the axes. Part zero (o p )...

Page 152: Mc Model

Self-teaching manual chapter 1 page 6 mc model theory on cnc machines 1.3 home search. When the cnc is off, the axes may be moved by hand or by accident. In these situations, the cnc no longer keeps track of the real position of the axes. That is why a “home search” should be carried out on power-up...

Page 153: Mc Model

Self-teaching manual chapter 1 page 7 mc model theory on cnc machines 1.4 travel limits. Physical limits there are two types of limits: – hard limits: mechanical limits set on the machine to prevent the carriage from moving beyond the ways (cams and hardstops). – cnc limits: set at the cnc by the ma...

Page 154: Mc Model

Self-teaching manual chapter 1 page 8 mc model theory on cnc machines 1.5 part zero setting. The part zero is set on all three axes. When machining several parts, the distance from machine ref. Zero ( o m ) to the part is different for each one. A different program would be needed for each part. By ...

Page 155: Mc Model

Self-teaching manual chapter 1 page 9 mc model theory on cnc machines 1.6 work units. Programming units they are set by the manufacturer and may be in millimeters or inches. Sindle speed the spindle turning speed is programmed in rpm. Axis feedrate the feedrate of the axes (f) is programmed in m/min...

Page 156: Theory On Tools

Chapter 2 theory on tools.

Page 157: Mc Model

Self-teaching manual chapter 2 page 2 mc model theory on tools this chapter describes: • what the tool turret is. • what the tool table is and what information it contains. • what tool presetting is. • defects due to errors in the tool table. > due to wrong tool calibration. > due to wrong tool radi...

Page 158: Mc Model

Self-teaching manual chapter 2 page 3 mc model theory on tools 2.1 tool management. The tools to be used with this cnc may be placed in a tool magazine. Depending on whether the machine has or not a tool magazine, the tool change may be carried out as follows: – if the machine does not have a tool m...

Page 159: Mc Model

Self-teaching manual chapter 2 page 4 mc model theory on tools 2.2 tool table. The tool data is stored in the tool table. When a tool change takes place, the cnc assumes the data set for that tool. The data shown in the table is: t: tool number d: offset associated with the tool it defines the tool ...

Page 160: Mc Model

Self-teaching manual chapter 2 page 5 mc model theory on tools nominal life machining time or number of operations that could be carried out with the tool. Real life machining time or number of operations carried out. Family tools with similar characteristics. Status tool type: •n: normal. •s: speci...

Page 161: Mc Model

Self-teaching manual chapter 2 page 6 mc model theory on tools 2.3 tool calibration. Tool calibration refers to the operation used to indicate to the cnc the length of the tool. This operation must be carried out properly so the parts come out with the right dimensions and the same point is controll...

Page 162: Mc Model

Self-teaching manual chapter 2 page 7 mc model theory on tools z1: real dim. Z2: wrong dim. Z2 > real dim. Right part dimensions wrong machining tools calibrated wrong proper machining tools calibrated right part to be machined tools defects due to wrong length calibration wrong part dimensions.

Page 163: Mc Model

Self-teaching manual chapter 2 page 8 mc model theory on tools defects due to wrong radius values wrong radius. Residual stock there is a residual stock due to different radii. Real radius. Real profile desired profile part tool.

Page 164: Hands-On Training

Chapter 3 hands-on training.

Page 165: Mc Model

Self-teaching manual chapter 3 page 2 mc model hands-on training this chapter describes: • the keyboard and the screen. • how to carry out a “home search”. > maintaining the part zero. > without maintaining the part zero. • how to operate with the spindle. > what the speed ranges (gears) are. • how ...

Page 166: Mc Model

Self-teaching manual chapter 3 page 3 mc model hands-on training 3.1 screen and keyboard description. 3.1.1 power-up. On power-up, the cnc will display the following screen. Screen for the mc mode. Note: refer to the operation manual chapter 2 section 2.3 if this screen is not displayed, it is becau...

Page 167: Mc Model

Self-teaching manual chapter 3 page 4 mc model hands-on training 3.1.2 keyboard description. 1.- keys to define the machining operations. 2.- keys for external devices. 3.- alphanumeric keyboard and command keys. 4.-operator panel. Note: refer to the operation manual chapter 2 section 2.1.

Page 168: Mc Model

Self-teaching manual chapter 3 page 5 mc model hands-on training description of the operator panel. 1.- axes jogging keys. 2.- work mode selector. (continuous jog ( ), incremental jog ( ) or with handwheel ( )). 3.- selection of spindle turning direction ( ) and start-up. Spindle speed override perc...

Page 169: Mc Model

Self-teaching manual chapter 3 page 6 mc model hands-on training 3.1.3 description of the standard screen. 1.- time, single-block/continuous execution, program number, execution status. (in position, execution, interrupted or reset) and plc messages. 2.- cnc messages. 3.- tool position referred to p...

Page 170: Mc Model

Self-teaching manual chapter 3 page 7 mc model hands-on training 3.1.4 description of the auxiliary screen. 1.- time, single block/continuous execution, program number, execution status. (in position, execution, interrupted or reset) and plc messages. 2.- cnc messages. 3.- lines of the selected prog...

Page 171: Mc Model

Self-teaching manual chapter 3 page 8 mc model hands-on training 3.2 home search. After powering the machine up, carry out the “home search” just in case the axes of the machine have moved while the cnc was off. A “home search” can be carried out in two ways. 3.2.1 maintaining the part zero. The “ho...

Page 172: Mc Model

Self-teaching manual chapter 3 page 9 mc model hands-on training 3.2.2 without maintaining the part zero. The “home search” is carried out on one axis at a time. The cnc does not know the position of the axes. Home search on the z axis press + + home search on the x and y axes. Press + + press + + t...

Page 173: Mc Model

Self-teaching manual chapter 3 page 10 mc model hands-on training 3.3 spindle. 3.3.1 speed ranges (gears) with this cnc, the machine can have a gear box. By means of ranges, we can choose the best gear ratio for the programmed spindle speed. Range 1 range 2 constant power constant power power if the...

Page 174: Mc Model

Self-teaching manual chapter 3 page 11 mc model hands-on training 3.3.2 spindle control. To select the work speed (in rpm), press: + (turning speed) + the cnc shows the following information: start the spindle clockwise. Stop the spindle. Start the spindle counter-clockwise. Increase or decrease the...

Page 175: Mc Model

Self-teaching manual chapter 3 page 12 mc model hands-on training 3.4 axis jog. To select the jog mode, use the selector switch: jog keys each key is used for moving the axis in one direction according to the axes of the machine. (section 1.1) handwheel it can have one, two or three handwheels. The ...

Page 176: Mc Model

Self-teaching manual chapter 3 page 13 mc model hands-on training 3.4.1 handwheels. – select the jog mode with the selector switch. ( position). Jog table handwheel selector switch – jog the axes with the handwheels. • if the machine has 1 handwheel: select an axis with the jog keys. The machine mov...

Page 177: Mc Model

Self-teaching manual chapter 3 page 14 mc model hands-on training incremental jog. Every time a jog key is pressed, the axis will move the selected increment at the programmed feedrate. (in rapid, if f=0). – select the distance to move at the selector. ( position). 3.4.2 jog. Continuous jog when pre...

Page 178: Mc Model

Self-teaching manual chapter 3 page 15 mc model hands-on training 3.4.3 automatic axis movement to a particular position. By means of the key, an axis may be moved to a particular coordinate. Follow these steps: – select the axis to be moved at the stantard screen. – enter the value of the destinati...

Page 179: Mc Model

Self-teaching manual chapter 3 page 16 mc model hands-on training 3.5 tools. 3.5.1 tool selection. Depending on the machine, there are two possibilities: machine with manual tool changer. The tool change is carried out like on a conventional machine: – change the tool on the machine. – press . – ent...

Page 180: Mc Model

Self-teaching manual chapter 3 page 17 mc model hands-on training 3.5.2 tool calibration. – just before calibrating the tools, a “home search” must be carried out on all axes. Home search on the z axis. Home search on the x and y axes. – a flat surface is needed for calibrating the tools. Use contin...

Page 181: Mc Model

Self-teaching manual chapter 3 page 18 mc model hands-on training – enter in the calibration mode. Press . The cnc displays the tool calibration screen. Height of the part used for tool calibration. Data on current tool status. Actual position of the axes and cutting conditions. Work mode. Help grap...

Page 182: Mc Model

Self-teaching manual chapter 3 page 19 mc model hands-on training the cnc calculates the length and assigns it to the tool. Part dimensions 1.- measure the part. – go to the tool calibration window. – enter the z value. 2.- start the spindle. 3.- select the tool to be calibrated. The cnc will assign...

Page 183: Mc Model

Self-teaching manual chapter 3 page 20 mc model hands-on training 3.5.3 how to change any data on the tool table. To change the values (t, d, r, l, i, k, nominal life, real life or family), enter in the calibration mode and press: + (tool number) + the cnc shows the data for that tool. To change it,...

Page 184: Mc Model

Self-teaching manual chapter 3 page 21 mc model hands-on training 3.5.4 tool change point. The machine manufacturer may allow selecting the tool change position. Tool change position referred to home. Enter the x, y and z values of the point chosen as the tool change position. • + + (x value) + • + ...

Page 185: Mc Model

Self-teaching manual chapter 3 page 22 mc model hands-on training approach the tool along z. Press + + 3.6 checking for proper calibration. – preset the part zero. Approach the tool along y. Press + + withdraw the tool. Part zero position. – start the spindle, touch the part surface with several too...

Page 186: Automatic Operations

Chapter 4 automatic operations.

Page 187: Mc Model

Self-teaching manual chapter 4 page 2 mc model automatic operations this chapter describes: • which are the keys associated with the automatic operations. • which are the various work modes. • example of an operation and a positioning cycle. > how to edit the parameters of the operation and what the...

Page 188: Mc Model

Self-teaching manual chapter 4 page 3 mc model automatic operations 4.1 operation keys. Layout of the automatic function keys..

Page 189: Mc Model

Self-teaching manual chapter 4 page 4 mc model automatic operations positioning. Rectangular and circular pocket. Rectangular and circular boss. Pocket with profile. Surface milling. Profile milling. Operation keys: selection of the cycle level within an operation used to associate a positioning cyc...

Page 190: Mc Model

Self-teaching manual chapter 4 page 5 mc model automatic operations 4.2 work modes. There are 2 work modes: edit mode editing the parameters of the operation or cycle. Simulation of an operation or cycle.( ) execution mode simulation of an operation or cycle. ( ) execution of an operation or cycle. ...

Page 191: Mc Model

Self-teaching manual chapter 4 page 6 mc model automatic operations 4.3 example of an automatic operation. Help graphics. Machining conditions of the cycle. Actual axes position. Cutting conditions. Cycle geometry definition. 4.3.1 edit an operation. 4.3.1.1 rectangular pocket. – select the rectangu...

Page 192: Mc Model

Self-teaching manual chapter 4 page 7 mc model automatic operations – set the operation data. To select an icon (symbol), data or coordinate: • use the keys to move the cursor. • press or . The cnc selects the first coordinate of the axis. Press it again to select the second coordinate. • press . Th...

Page 193: Mc Model

Self-teaching manual chapter 4 page 8 mc model automatic operations 4.3.1.2 associate a positioning with an operation. If it is a boring, reaming, threading, drilling or center punching operation, a positioning cycle may be associated with it. After setting the operation, choose the type of position...

Page 194: Mc Model

Self-teaching manual chapter 4 page 9 mc model automatic operations 4.3.2 simulate an operation. It is used for checking the tool path on the screen. – press . The cnc will display the graphics menu. To access the various options, press their corresponding keys: function: f1 f2 f3 f4 f5 f6 f7 key: t...

Page 195: Mc Model

Self-teaching manual chapter 4 page 10 mc model automatic operations •type of graphics. – “3d” graphics. The three-dimensional tool path is represented by color lines. – “xy, xz, yz” graphics. Color lines represent the tool path in the selected plane. – “combined” graphics. The screen is divided int...

Page 196: Mc Model

Self-teaching manual chapter 4 page 11 mc model automatic operations •display area. It is possible to define the display area by setting the maximum and minimum axis coordinates. –to set the coordinates, use . –once the data has been set, press . •zoom. It is used for enlarging or reducing the drawi...

Page 197: Mc Model

Self-teaching manual chapter 4 page 12 mc model automatic operations •graphic parameters. Simulation speed: for selecting the % override of the simulation speed being applied. Tool path colors: for changing the tool path colors on “3d”, “xy, xz, yz” and “top view” graphics. Colors for solid graphics...

Page 198: Mc Model

Self-teaching manual chapter 4 page 13 mc model automatic operations 4.3.3 execute an operation. The operations can be executed from beginning to end or a pass at a time. This choice is made with . Once the data has been entered, press . The cnc screen shows the cycle start key ( ) and lets execute ...

Page 199: Mc Model

Self-teaching manual chapter 4 page 14 mc model automatic operations tool inspection. With this option, the operation may be interrupted for inspecting and replacing the tool or for modifying the tool wear value. – press . – depending on the machine manufacturer, on some machines will also have to b...

Page 200: Mc Model

Self-teaching manual chapter 4 page 15 mc model automatic operations modifying the tool wear value. With this option, the i, k values may be changed. The entered values are incremental and will be added to those stored previously. This option may be executed during tool inspection or while the machi...

Page 201: Summary of Work Cycles

Chapter 5 summary of work cycles.

Page 202: Mc Model

Self-teaching manual chapter 5 page 2 mc model summary of work cycles 5.1 profile milling operation. At this cycle level, the profile is defined by points. (up to a maximum of 12 points). At this cycle level, the profile is defined by the profile editor. (section 5.16). Note: refer to the operation ...

Page 203: Mc Model

Self-teaching manual chapter 5 page 3 mc model summary of work cycles 5.2 surface milling operation. Note: refer to the operation manual chapter 4 section 4.4.

Page 204: Mc Model

Self-teaching manual chapter 5 page 4 mc model summary of work cycles 5.3 pocket cycle with profile. Note: refer to the operation manual chapter 4 section 4.5 the profile is generated with the profile editor (section 5.16)..

Page 205: Mc Model

Self-teaching manual chapter 5 page 5 mc model summary of work cycles 5.4 rectangular and circular boss milling cycles. Rectangular boss circular boss note: refer to the operation manual chapter 4 section 4.6.

Page 206: Mc Model

Self-teaching manual chapter 5 page 6 mc model summary of work cycles 5.5 rectangular and circular pocket milling cycles. Rectangular pocket at this cycle level, the type of pocket corner may be chosen as well as the inclination angle of the pocket. Note: refer to the operation manual chapter 4 sect...

Page 207: Mc Model

Self-teaching manual chapter 5 page 7 mc model summary of work cycles note: refer to the operation manual chapter 4 section 4.7 circular pocket.

Page 208: Mc Model

Self-teaching manual chapter 5 page 8 mc model summary of work cycles 5.6 positioning. At this cycle level, auxiliary functions may be defined to be executed before or after the movement. Note: refer to the operation manual chapter 4 section 4.8.

Page 209: Mc Model

Self-teaching manual chapter 5 page 9 mc model summary of work cycles 5.7 boring operation. Note: refer to the operation manual chapter 4 section 4.9 this operation may be carried out at the indicated position (x,y) or may be repeated at different positions using the keys..

Page 210: Mc Model

Self-teaching manual chapter 5 page 10 mc model summary of work cycles 5.8 reaming operation. Note: refer to the operation manual chapter 4 section 4.10 this operation may be carried out at the indicated position (x,y) or may be repeated at different positions using the keys..

Page 211: Mc Model

Self-teaching manual chapter 5 page 11 mc model summary of work cycles 5.9 threading operation. Note: refer to the operation manual chapter 4 section 4.11 this operation may be carried out at the indicated position (x,y) or may be repeated at different positions using the keys..

Page 212: Mc Model

Self-teaching manual chapter 5 page 12 mc model summary of work cycles 5.10 drilling and center punching operations. Note: refer to the operation manual chapter 4 section 4.12 drilling. At this cycle level, one programs the distance the tool withdraws after each penetration (drilling peck). These op...

Page 213: Mc Model

Self-teaching manual chapter 5 page 13 mc model summary of work cycles note: refer to the operation manual chapter 4 section 4.12 center punching..

Page 214: Mc Model

Self-teaching manual chapter 5 page 14 mc model summary of work cycles 5.11 multiple positioning at several points. Note: refer to the operation manual chapter 4 section 4.13.1 only for boring, reaming, drilling and center punching operations..

Page 215: Mc Model

Self-teaching manual chapter 5 page 15 mc model summary of work cycles 5.12 multiple positioning in a straight line. Note: refer to the operation manual chapter 4 section 4.13.2 only for boring, reaming, drilling and center punching operations..

Page 216: Mc Model

Self-teaching manual chapter 5 page 16 mc model summary of work cycles 5.13 multiple positioning in an arc. Note: refer to the operation manual chapter 4 section 4.13.3 only for boring, reaming, drilling and center punching operations..

Page 217: Mc Model

Self-teaching manual chapter 5 page 17 mc model summary of work cycles 5.14 multiple positioning in a parallelogram pattern. Note: refer to the operation manual chapter 4 section 4.13.4 only for boring, reaming, drilling and center punching operations..

Page 218: Mc Model

Self-teaching manual chapter 5 page 18 mc model summary of work cycles 5.15 multiple positioning in a grid pattern. Note: refer to the operation manual chapter 4 section 4.13.5 only for boring, reaming, drilling and center punching operations..

Page 219: Mc Model

Self-teaching manual chapter 5 page 19 mc model summary of work cycles 5.16 profile editor. It is used to define the “profile milling” cycle and the “pocket with profile” cycle. With the profile editor it is possible to define straight and circular sections of the profile (the editor solves the inte...

Page 220: Conversational Part-Programs

Chapter 6 conversational part-programs.

Page 221: Mc Model

Self-teaching manual chapter 6 page 2 mc model conversational part-programs this chapter describes: • what a conversational part-program is. • how to edit it. • how to change it. (inserting or deleting operations). • simulate/execute an operation. • simulate/execute starting at a particular operatio...

Page 222: Mc Model

Self-teaching manual chapter 6 page 3 mc model conversational part-programs 6.1 what is a conversational part-program? It is a set of operations ordered secuentially. Each operation is defined separately and they are then stored one after the other in a program. The name of the part-program can be a...

Page 223: Mc Model

Self-teaching manual chapter 6 page 4 mc model conversational part-programs 6.2 edit a part-program. To edit a part-program, we first choose the operations needed to execute the part. A part may be executed in various ways. Drilling +posit. In a straight line surface milling simple pocket profile.

Page 224: Mc Model

Self-teaching manual chapter 6 page 5 mc model conversational part-programs once the sequence of operations has been chosen, the part-program is built by editing the operations one by one. Standard screen (enter number) + + (comment) + e.G. : + + + note: the following keys are used: : to move up and...

Page 225: Mc Model

Self-teaching manual chapter 6 page 6 mc model conversational part-programs choose the operation and define the parameters. Repeat these steps with the other operations. In our case, the finished part-program will be: program number.

Page 226: Mc Model

Self-teaching manual chapter 6 page 7 mc model conversational part-programs 6.3 modify a part-program. The cnc shows the cycle with all its data. Modify the operation parameters like in the editing mode. The cnc requests an option. Choose replace. The new operation replaces the previous one. The ope...

Page 227: Mc Model

Self-teaching manual chapter 6 page 8 mc model conversational part-programs note: refer to the operation manual chapter 5 section 5.6.3 choose operation new operations can also be inserted into a part-program. Define the parameters and cutting conditions of the operation to be inserted. Press choose...

Page 228: Mc Model

Self-teaching manual chapter 6 page 9 mc model conversational part-programs the cnc requests confirmation operations can be deleted from a part-program. Note: refer to the operation manual chapter 5 section 5.6.1 select, on the right column, the operation to be deleted. Delete an operation.

Page 229: Mc Model

Self-teaching manual chapter 6 page 10 mc model conversational part-programs the position of an operation can also be changed. Note: refer to the operation manual chapter 5 section 5.6.2 select the new position. Select, on the right column, the operation to be moved. The operation is inserted behind...

Page 230: Mc Model

Self-teaching manual chapter 6 page 11 mc model conversational part-programs 6.4 simulate/execute an operation. Note: refer to the operation manual chapter 6 section 6.3 graphics screen. More information about the graphics screen in chapter 4.3.2 of this manual. Select, on the right column, the oper...

Page 231: Mc Model

Self-teaching manual chapter 6 page 12 mc model conversational part-programs 6.5 simulate/execute a part-program. Note: refer to the operation manual chapter 6 section 6.2 graphics screen more information about the graphics screen in chapter 4.3.2 of this manual. Select, on the left column, the part...

Page 232: Mc Model

Self-teaching manual chapter 6 page 13 mc model conversational part-programs 6.6 simulate/execute starting at a particular operation. Note: refer to the operation manual chapter 6 section 6.2.1 graphics screen more information about the graphics screen in chapter 4.3.2 of this manual. Select, on the...

Page 233: Mc Model

Self-teaching manual chapter 6 page 14 mc model conversational part-programs 6.7 copy a part-program into another one. Select, on the left column, the part-program to be copied: key in the number and comment of the new program. Note: refer to the operation manual chapter 5 section 5.5.

Page 234: Mc Model

Self-teaching manual chapter 6 page 15 mc model conversational part-programs 6.8 delete a part-program. Select, on the left column, the part-program to be deleted: note: refer to the operation manual chapter 5 section 5.4 the cnc requests confirmation..

Page 235: Programming Example

Appendix i programming example.

Page 236: Mc Model

Self-teaching manual appendix i. Page 2 mc model programming example step 0: part to be machined. Initial considerations this chapter shows an example of how to create a part-program. Remember that the tool number may be different depending on the machine. The tool used in this example are: t1: ? 40...

Page 237: Mc Model

Self-teaching manual appendix i. Page 3 mc model programming example step 1: surface milling. 1.

Page 238: Mc Model

Self-teaching manual appendix i. Page 4 mc model programming example step 2: machining the profile. 2 other data.

Page 239: Mc Model

Self-teaching manual appendix i. Page 5 mc model programming example step 3: rectangular boss. 3.

Page 240: Mc Model

Self-teaching manual appendix i. Page 6 mc model programming example step 4: circular pocket. 4.

Page 241: Mc Model

Self-teaching manual appendix i. Page 7 mc model programming example step 5: rectangular pocket. 5.

Page 242: Mc Model

Self-teaching manual appendix i. Page 8 mc model programming example step 6: center punching + multiple positioning at several points. 6.

Page 243: Mc Model

Self-teaching manual appendix i. Page 9 mc model programming example step 7: center punching + multiple positioning in parallelogram pattern. 7.

Page 244: Mc Model

Self-teaching manual appendix i. Page 10 mc model programming example step 8: drilling + multiple positioning at several points. 8.

Page 245: Mc Model

Self-teaching manual appendix i. Page 11 mc model programming example step 9: drilling + multiple positioning in parallelogram pattern. 9.

Page 246: Mc Model

Self-teaching manual appendix i. Page 12 mc model programming example step 10: tapping + multiple positioning in parallelogram pattern. 10

Page 247: Mc Model

Self-teaching manual appendix i. Page 13 mc model programming example step 11: part-program. Once the operations have been entered, the part program will be like this:.