Operating manual (mco & tco options) ref. 0204-ing.

Iii the information described in this manual may be subject to variations due to technical modifications. Fagor automation, s.Coop. Ltda. Reserves the right to modify the contents of the manual without prior notice..

V index 1. General concepts 1.1 "m/t" and "co" work modes ................................................................................... 1 1.2 keyboard .................................................................................................................. 2 1.3 keyboard customizing ....

Vi 3. Operating with operations or cycles 3.1 associated programs ................................................................................................. 3 3.2 associated routines ................................................................................................... 3 3.3 oem ...

Chapter 1 - page 1 mco-tco work mode 1. General concepts 1.1 "m/t" and "co" work modes the cnc offers all the features of the m/t models plus those specific of the co mode. There are 2 work modes. M/t and co. This manual is for the co mode. The "m" and "t" modes (described in the installation, opera...

Chapter 1 - page 2 mco-tco work mode 1.2 keyboard alphanumeric keyboard and command keys. Selects the x character selects the a character selects the r character jog keyboard to: jog the axes of the machine govern the spindle modify axes feedrate and spindle speed start and stop program execution sp...

Chapter 1 - page 3 mco-tco work mode keys related to the operations or canned cycles. User c1 to access cycle 1, c2 for cycle 2 and son on. Each key may have up to 10 levels or variations which are selected by means of the [level cycle] key. For example: c1 => cycle 1, +level => cycle 21, +level => ...

Chapter 1 - page 4 mco-tco work mode 1.3 keyboard customizing the external devices must be turned on or off by the machine manufacturer by means of a plc program. The cnc will inform the plc on the status of each key. The pertinent register bit will be set to "1" when the key is pressed and "0" when...

Chapter 2 - page 1 mco-tco work mode 2. Operating in jog mode the standard screen for the co operating mode dpends on the model: tco model mco model la forma de operar con ambos modelos es muy parecida. Si algunas de las prestaciones descritas en este capítulo no es común para ambos modelos, se indi...

Chapter 2 - page 2 mco-tco work mode 2.1 introduction the standard screen for the co operating mode may be entirely customized (see "screen customizing" in the installation manual). The one supplied by fagor contains the following information: 1.- clock 2.- this window can display the following data...

Chapter 2 - page 3 mco-tco work mode 6.- this screen may be entirely customized (see "screen customizing" in the installation manual). The one supplied by fagor shows everything about the tool. * the number of the tool currently selected (in large characters). * the graphic representation correspond...

Chapter 2 - page 4 mco-tco work mode the auxiliary screen for the co operating mode may be customized entirely (see "screen customizing" in the installation manual). The one supplied by fagor contains the following information: 1.- clock 2.- this window can display the following data: sbk when the s...

Chapter 2 - page 5 mco-tco work mode 6.- this window shows the status of the «g, f, t, d, m» functions and the value of the variables. Parco states the number of consecutive parts that have been executed with the same program. Whenever a new program is selected, this variable assumes value 0. Cytime...

Chapter 2 - page 6 mco-tco work mode 2.2 axis control 2.2.1 work units whenever the co work mode is accessed, the cnc assumes the work units, «mm or inches», «radii or diameters», «millimeters/minute or millimeters/revolution», etc., that are selected by machine parameter. To modify these values, th...

Chapter 2 - page 7 mco-tco work mode 2.3 home search (machine reference zero) home search can be done in 2 ways: home search on all the axes the cnc will execute the machine reference zero routine defined by the manufacture in the general machine parameter p34 (refpsub). Warning: the cnc saves the p...

Chapter 2 - page 8 mco-tco work mode 2.4 jogging the axes the axes of the machine can be moved in the following ways: - continuous jog - incremental jog - jogging with an electronic handwheel - jogging to a programmed position 2.4.1 jogging to a programmed position the movement is carried out one ax...

Chapter 2 - page 9 mco-tco work mode 2.4.3 continuous jog place the left-hand switch in position and on the right-hand switch select the percentage (0% to 120%) of the feedrate selected to be applied. Continuous movement should be done axis to axis. To do this press the jog key for the direction of ...

Chapter 2 - page 10 mco-tco work mode 2.4.4 jogging with an electronic handwheel the various handwheel configurations are: general handwheel it can be used to jog any axis one by one. Select the axis and turn the handwheel to move it. Individual handwheel: it replaces the mechanical handwheels. Up t...

Chapter 2 - page 11 mco-tco work mode 2.4.4.1 standard handwheel mode with the general handwheel proceed as follows: 1.- select the axis to be jogged. Press one of the jog keys of the axis to be jogged. The selected axis will be highlighted. When using a fagor handwheel with an axis selector button,...

Chapter 2 - page 12 mco-tco work mode 2.4.4.2 path handwheel mode with this feature, it is possible to jog two axes at the same time along a linear path (chamfer) or circular path (rounding) with a single handwheel. The cnc assumes as the path handwheel the general handwheel or, when this one is mis...

Chapter 2 - page 13 mco-tco work mode 2.4.4.3 feed handwheel usually, when making a part for the first time, the machine feedrate is controlled by means of the feedrate override switch. From this version on, it is also possible to use the machine handwheels to control that feedrate. This way, the ma...

Chapter 2 - page 14 mco-tco work mode 2.5 tool control the standard screen for co operating mode displays the following information about the tool. This window may be customized entirely (see "screen customizing" in the installation manual). The one supplied by fagor can display the following inform...

Chapter 2 - page 15 mco-tco work mode 2.5.2 variable tool change point if the manufacturer wishes the user can be allowed to define the tool change point at all times. This feature logically depends on the type of machine and type of changer. This feature allows the tool change to be made beside the...

Chapter 2 - page 16 mco-tco work mode 2.5.3 live tool feature only available at the tco model. When a live tool is selected, the standard screen of the co operating mode shows the following information: to select the rpm "s" of the live tool, take these steps: 1. Press to select the "t" field. 2. Pr...

Chapter 2 - page 17 mco-tco work mode ( ) = cncrd (tool, r101, m1) assigns the number of the active tool to register r101. = cncrd (tof r101, r102, m1) assigns the location code (shape) of the active tool to register r102. Cps r102 eq 10 or cps r102 eq 20 or cps r102 eq 30 = m2 if the active tool is...

Chapter 2 - page 18 mco-tco work mode 2.6 spindle control the standard screen for the co work mode has a window for displaying information about the spindle. This window may be customized entirely. The one supplied by fagor can display the following information depending on the model: css rpm the da...

Chapter 2 - page 19 mco-tco work mode 2.6.1 spindle in rpm the cnc displays the following information: 1.- actual spindle speed in rpm. 2.- theoretical spindle speed in rpm. To select any other speed press value the cnc assumes this value and updates the actual speed of the spindle. 3.- status of th...

Chapter 2 - page 20 mco-tco work mode 2.6.2 constant surface speed feature only available at the tco model. In constant surface speed mode the user sets the tangential speed that there must be at all times between the tool tip and the part. The spindle revolutions therefore depend on the position ta...

Chapter 2 - page 21 mco-tco work mode 2.6.2.1 operating at constant surface speed (css) when constant surface speed operating mode is selected (css), the cnc assumes the spindle range selected at present. In this operating mode, when a new constant surface speed is selected, the following cases may ...

Chapter 2 - page 22 mco-tco work mode 2.7 handling iso code press the iso key once to access the mdi mode. In this mode, a block may be edited and executed. Press the iso key twice to access the iso mode. Up to 6 blocks may be edited, executed and simulated in this mode. In mdi mode (pressing once) ...

Chapter 3 - page 1 mco-tco work mode 3. Operating with operations or cycles the following keys should be used to select the machining operations or cycles: the standard version offers 2 positioning cycles. To access these cycles, press and to change the cycle, press the manufacturer may define up to...

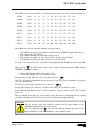

Chapter 3 - page 2 mco-tco work mode the oem cycles accessed via plc by simulating the key whose hex code is indicated below are: $f10c cycles 12 32 52 72 92 112 132 152 172 192 $f10d cycles 13 33 53 73 93 113 133 153 173 193 $f10e cycles 14 34 54 74 94 114 134 154 174 194 $f10f cycles 15 35 55 75 9...

Chapter 3 - page 3 mco-tco work mode 3.1 associated programs in co mode, programs p900000 through p999999 are reserved for the cnc itself and cannot be used as user part-programs. Some have a special meaning and must be defined by the machine manufacturer. P999001 through p999200 configuration files...

Chapter 3 - page 4 mco-tco work mode w1 w2 w3 w4 w5 w6 w7 w8 w9 w10 w12 w11 3.3 oem cycles as mentioned earlier at beginning of this chapter, up to 200 oem cycles may be defined. Every oem cycle has the following elements associated with it: • the oem screen with the same number, created with the wg...

Chapter 3 - page 5 mco-tco work mode 3.3.2 configuration file the configuration file is a cnc program written in high-level language (configuration language) that describes the operating characteristics of the various screen elements. There is a configuration file for each cycle. P999001 for cycle 0...

Chapter 3 - page 6 mco-tco work mode ;(p100=w13) to assign the value of the (w) field to a global parameter, only when calling the routine. When executing a cycle, the cnc calls upon the associated routine indicating, through local parameters, which values have been defined in each field. For exampl...

Chapter 3 - page 7 mco-tco work mode this instruction is for converting coordinates values (decimal) into integers by multiplying them by 10000 examples: to display the % of axis feedrate, the fro variable is used. The fro values are integers (between 0 and 120) thus not requiring ledbardec ;(autore...

Chapter 3 - page 8 mco-tco work mode configuration file (p999001) for cycle 001 %cfgfile,mx, ;(prgscript 1) header and version it begins debugging the configuration file . ;(debug) from this line on, program 999500 starts logging the errors occurred while debugging the configuration file. ;(hotkey w...

Chapter 3 - page 9 mco-tco work mode 3.3.3 associated routine the routine associated with the cycle must be defined by the oem (see programming manual). It must contain all the instructions necessary to execute the canned cycle. There is a routine associated with each cycle. Routine 9001 for cycle 0...

Chapter 3 - page 10 mco-tco work mode routine (9001) associated with cycle 001 %routines,mx, (sub 9001) subroutine definition check machining conditions (if p4 eq 0 p100=97 else p100=96) checks rpm/css and prepares in p100 g97/g96 respectively (if p5 lt p6 p101=p5 else p101=p6) if s>smax, assumes sm...

Chapter 3 - page 11 mco-tco work mode 3.3.4 error log file (p999500) there is a configuration file for each cycle. P999001 for cycle 001, p999002 for cycle 002 and so on up to p999200 which is for cycle 200. The cnc checks these programs the first time they are accessed. If it detects an error, it d...

Chapter 3 - page 12 mco-tco work mode 3.4 access to oem cycles from the plc the oem cycles accessible from the plc, by simulating the key whose hex code is shown here are: $f10c cycles 12 32 52 72 92 112 132 152 172 192 $f10d cycles 13 33 53 73 93 113 133 153 173 193 $f10e cycles 14 34 54 74 94 114 ...

Chapter 3 - page 13 mco-tco work mode 3.5 cycle data entry once the cycle has been selected, the cnc displays the relevant screen. It may have a blue box in the top right hand corner indicating the machine status. Coordinates and machining conditions. One of the data defining the cycle will be highl...

Chapter 3 - page 14 mco-tco work mode 3.6 simulation and execution there are 2 work modes for operations or cycles: editing and execution. Execution mode editing mode to switch from editing mode to execution mode, press to switch from the execution mode to the editing mode, press one of these keys: ...

Chapter 3 - page 15 mco-tco work mode 3.8 positioning cycle to select the positioning cycle press this cycle can be defined in two different ways level 1. The coordinates of the target point have to be defined the way the positioning is to be done the type of feedrate, fast or at the f stated level ...

Chapter 3 - page 16 mco-tco work mode 3.8.1 definition of data type of positioning to select the type of positioning move onto this icon and press the icon changes and the help graphics are updated. Type of feedrate feedrate at the selected f in rapid traverse to select the type of feedrate move ont...

Chapter 3 - page 17 mco-tco work mode 3.8.2 definition of spindle conditions work mode (rpm) or (css) move over the "rpm" or "css" icon and press spindle range move over this item, key in the desired value and press maximum spindle turning speed in rpm (s) move onto this item, type in the required v...

Chapter 4 - page 1 mco-tco work mode 4. Program storage a part-program is the set of operations to be executed to make a particular part or workpiece. It is extremely easy to create a part, just define each basic operation and store them in the right sequence. Iso-coded block editing makes it possib...

Chapter 4 - page 2 mco-tco work mode 4.1 list of stored programs to access the list of part-programs stored press on the left there is a list of part-programs that are stored in the cnc’s memory. When there are more programs than those displayed in the window, use and to move the pointer over the li...

Chapter 4 - page 3 mco-tco work mode 4.2 see content of a program to see the content of a part-program, select this with the pointer from the left-hand column. To do this use and . The right -hand column will display the cycles which said part consists of: if you press or or the pointer goes on to t...

Chapter 4 - page 4 mco-tco work mode 4.3 edit a new part-program to edit a new part-program the following steps should be taken: * press to access the list of part-programs stored. * use the pointer to select the option "--create new part --2" in the left-hand column. * press . The cnc will ask at t...

Chapter 4 - page 5 mco-tco work mode 4.4 erasing a part-program to erase a part-program follow these steps: * press to access the list of part-programs stored. * use the pointer to select from the left-hand column the part-program to be erased. * press at the bottom the cnc will display a message re...

Chapter 4 - page 6 mco-tco work mode 4.6 modifying a part-program to modify a part-program the following steps must be taken: * press to access the list of part-programs stored. * use the pointer to select from the left-hand column the part-program you wish to modify. After selecting the program, th...

Chapter 4 - page 7 mco-tco work mode 4.6.3 adding or inserting a new operation to add or insert an operation take the same steps as to store an operation. * define the desired block or cycle, assigning this the relevant data. * press to access the list of part-programs stored. * move over the operat...

Chapter 5 - page 1 mco-tco work mode 5. Execution and simulation simulation allows graphic reproduction of a part-program or an operation with the data that has been defined. By means of simulation, one can thus check the part-program or the operation before executing or storing it and consequently ...

Chaper 5 - page 2 mco-tco work mode 5.1 simulating or executing an operation or cycle all the operations or cycles have 2 operating modes: execution mode and edition mode execution mode editing mode simulation the operation or cycle can be simulated in both operating modes. To do this press the cnc ...

Chapter 5 - page 3 mco-tco work mode 5.2 simulating or executing a part-program whenever you wish to simulate or execute a part-program do the following: * press to access the list of part-programs stored. * select the program to be simulated or executed from the left-hand column. To simulate the pa...

Chaper 5 - page 4 mco-tco work mode 5.4 execution mode when pressing to execute an operation or part-program, the cnc displays the standard screen for the co mode. Tco model mco model if you press the cnc displays the special screen for the co mode. After selection, the operation or part can be exec...

Chapter 5 - page 5 mco-tco work mode 5.4.1 tool inspection depending on how the toolinsp mark has been set at the plc, the tool inspection mode will be available after interrupting the execution without pressing any key or after pressing once tool inspection has been selected, one can: jog the axes ...

Chaper 5 - page 6 mco-tco work mode 5.5 graphics when you press the cnc displays the graphics screen. To leave the graphics m ode press or in the operation manual, m-mc or t-tc models, section «graphics» in the «execution / simulation» chapter, there is an explanation of how to operate during graphi...

Chapter 5 - page 7 mco-tco work mode graphic parameters simulation speed. In the top right-hand of the screen select the percentage of the simulation speed to be applied. To select the percentage use the keys and for the cnc to assume said value, press colors of the path. This only applies in line g...