- DL manuals

- Fagor

- Dishwasher

- Evo CO-402 W

- Instructions For Installation, Use And Maintenance Manual

Fagor Evo CO-402 W Instructions For Installation, Use And Maintenance Manual

Summary of Evo CO-402 W

Page 1

General instructions for installation, use and maintenance w models mod: cop-174w cop-504 w co-502 w co-402 w code: 12119601 rev. : 04 (2015) hood type dishwasher undercounter dishwasher glasswasher.

Page 2: Read First

Read first this manual must be retained for future reference. Read, understand and follow the instructions and warnings contained in this manual. Warning improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operation...

Page 3

3 limited warranty one year parts & labor warranty: fagor commercial, inc. (“fagor”) warrants to the first-end-user purchaser (the “user”) that the fagor brand equipment sold hereunder, except for parts and accessories which carry the warranty of a supplier (the “equipment”) will be free from defect...

Page 4

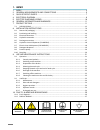

4 1. Index 1. Index ...................................................................................................................................... 4 2. General measurements and connections ............................................................. 5 3. Quick startup guides ..................

Page 5

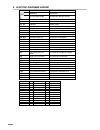

5 2. General measurements and connections hood type dishwasher cop-174w a b c d e f g water inlet drain hose power supply cable strain relief terminal box rinse aid inlet detergent inlet equipotential bond.

Page 6

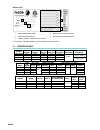

6 undercounter dishwasher co-502 w / cop-504 w glasswasher co-402 w a b c d e f g water inlet drain hose power supply cable strain relief terminal box rinse aid inlet detergent inlet equipotential bond.

Page 7

7 3. Quick startup guides.

Page 8

8.

Page 9

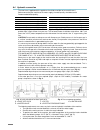

9 4. Electrical diagram.

Page 10

10 5. Electric diagrams legend english franÇais grounding mise à terre terminal block bridge pontage pour bloc de jonction ba rinse pump pompe de rinçage bd drain pump pompe de vidange c1, c2 capacitor condensateur cmb wash pump contactor contacteur pompe de lavage cc boiler heating contactor contac...

Page 11

11 6. General information and warnings this manual has been created to help you understand the operation, installation and maintenance of the machine. It contains all the necessary information and warnings to ensure that the appliance is installed and used correctly, together with information about ...

Page 12

12 data plate 1: appliance model name 4: electrical specifications 2: appliance reference 5: water inlet specifications 3: serial number + manufacture date these details should be quoted when the technical service is called. 7.1 specifications model racks per hr. Dishes per hr. Glasses per hr. Wash ...

Page 13

13 connection voltage total load total power pump load pump power tank power boiler power model type (v) (a) (kw) (a) (kw) (kw) (kw) 208-240v 208v 42,18 14,48 2 x 2,36 2 x 0,49 3,68 9,81 cop-174w 60hz 220v 44,61 16,19 2 x 2,50 2 x 0,55 4,12 10,98 3ph 240v 48,66 19,27 2 x 2,72 2 x 0,65 4,90 13,07 cop...

Page 14

14 cop-504w 208-240v, 60hz 3ph 208-240v, 60hz 1ph 208-240v, 60hz 1ph 208-240v, 60hz 1ph bridge boiler full power boiler full power boiler 2/3 power boiler half power 8. Installation instructions the dishwasher shall be installed in accordance with local codes, or in the absence of local codes, insta...

Page 15

15 8.3 electrical connection an authorised technician should always carry out the appliance’s electrical connection. The dishwasher shall be installed in accordance with local codes, or in the absence of local codes, installed in accordance with the applicable requirements in the national electrical...

Page 16

16 8.4 hydraulic connection the new hoses supplied with the appliance should be used (do not reuse old hoses). Before connecting the machine to the water supply, the water quality should be tested. Recommended water quality: ph: 6.5 to 7.5 alkalinity: less than 50 ppm (mg/l) free chlorine: less than...

Page 17

17 8.5 drainage connection attach the drain hose as shown in fig. 5. It is recommended to affix a siphon pipe to prevent odors. All piping from the machine to the drain must be a minimum 1- 1/2” i.P.S. There should also be an air gap between the machine drain line and the drain. For natural overflow...

Page 18

18 8.6 hydraulic rinse aid dispenser (co models) installation: take the tube located in the back or your machine marked “rinse aid” and place inside rinse container. Tubes are transparent to provide you visible mean that chemicals are being dispensed. Operation: this dispenser absorbs the rinse aid ...

Page 19

19 fill the machine. Add the correct amount of de-liming solutions as recommended by the de- liming solution manufacturer. The water capacity of the tank can be verified on the specification sheet of this manual. Remove detergent and rinsing tubes from containers so no chemicals go to the machine. R...

Page 20

20 it is recommended that the detergent and the dispenser setting are defined by a technician specialised in the use of chemical products in order to ensure a more efficient wash. If you require the installation of an non fagor detergent and/or rinse pump, a form must be fill out prior to installati...

Page 21

21 9. Use and maintenance instructions before starting the appliance, please read the instructions contained in this manual carefully. The appliance is exclusively for professional use, and should only be used by qualified personnel. 9.1 operation the steps required to optimise the operation of your...

Page 22

22 9.1.3 preparation of the dishes before washing the dishes, the preparatory steps below should be followed: remove the largest pieces of waste from the dishes before placing them in the baskets. Wash glassware first. Put the plates in the rack basket. Place the glasses upside down. Place the cutle...

Page 23

23 9.1.6.2 drainage using the drainage pump (optional) the drainage using the drainage pump option is only available on request. The drainage pipe must always be fitted on a siphon to prevent the return of odours.To drain the machine using this method, proceed as follows: open the door and remove th...

Page 24

24 9.2.1 maintenance always clean the machine correctly to prolong the service life of the machine. Remove any waste from the machine at the end of each day. Do not use abrasive, corrosive or acid products, chlorine-based detergents, solvents or petrol derivatives to clean the machine. Do not spray ...

Page 25

25 10. Faults, alarms and breakdowns the steps to be followed in the event of a fault or operating error are described below. The possible causes and possible solutions are listed in the following table. In the event of doubt, or if you are unable to resolve the problem, please contact the technical...

Page 26

26 machine stops during operation. Electrical installation overloaded. Call technical service to modify electrical installation. Machine protection has tripped. Reset safety device and if it trips again, call technical service. Machine stops and fills with water when it is washing. Pressure switch p...

Page 27

27 10.2 display alarms the display may show different alarms for the temperature probes. The alarm is shown on the corresponding display (tank temperature display or boiler temperature display). A4 “temperature probe open” alarm. Verify proper connections at the circuit board and probe sensor. A5 “t...

Page 28

Fagor commercial inc. 13105 nw 47th avenue miami, fl. 33054, usa t. 305 779 0170 fax. 305 779 0173 1-866-go fagor www.Fagorcommercial.Com.