- DL manuals

- Fagor

- Dishwasher

- FI – 48 W

- Service Manual

Fagor FI – 48 W Service Manual

Summary of FI – 48 W

Page 1

Service manual ********** october 200 7 undercounter & all purpose dishwashers models: fi – 48 w fi – 64 w fi – 72 w.

Page 2: 0 Table of Contents

1 0 table of contents 0 table of contents ________________________________________________________ 1 1 quick start guide _________________________________________________________ 1 2 quick installation _______________________________________________________ 2 3 specifications _______________________...

Page 3

2 12.4 selector switch (ig)__________________________________________________ 35 12.5 safety pressure switch______________________________________________ 35 13 service procedures ______________________________________________________ 38 13.1 tank thermostat _________________________________________...

Page 5: First

All plumb ing and electrical connections mu st be made by a qualifie d installer in accord ance with your state and local codes! Run machine to verify that all electrical, water and drain hookups are correct, chemicals am ount are ade quate and the re are no leaks! Quick installation guide l v c-21w...

Page 6: 3 Specifications

3 3 specifications 3.1 model: fi-48 w performance/capacities capacities heating elements racks per hr.: 22 electric wash tank heater: 2.8 kw dishes per hr.: 550 electric booster heater: 2.8 kw glasses per hr: 792 tank: 6.6gal. / 24.9 liters water consumption / requirements operating cycles gallons p...

Page 7

4 3.2 model: fi-64w performance/capacities capacities heating elements racks per hr.: 35 electric wash tank heater: 2.8 kw dishes per hr.: 875 electric booster heater: 6 kw glasses per hr.: 1260 wash tank: 6.6gal. / 24.9 liters water consumption operating cycles gallons per hr. (max. Use): 36 gal. /...

Page 8

5 3.3 model: fi-72w performance/capacities capacities heating elements racks per hr.: 35 electric wash tank heater: 2.8 kw trays (dishes) / per hr.: 280 (875) electric booster heater: 6 kw glasses per hr.: 1260 wash tank: 6.6gal. / 24.9 liters water consumption operating cycles gallons per hr. (max....

Page 9: 4 Installation

6 4 installation 4.1 visual inspection upon receiving your new fagor dishwasher, check the package and the machine for any damages that may have occurred during transportation. Visually inspect the exterior of the package. If damaged, open and inspect the contents with the carrier. Any damage should...

Page 10

7 4.3 data plate the data plate in located on one side of the machine. Under no circumstances should the data plate be removed from the unit. The data plate is essential to identify the particular features of your machine and is of great benefit to installers, operators and maintenance personnel. It...

Page 11

8 4.5 water installation water installation is carried out as shown in figures 3 and 4. The hot water line to the dishwasher must provide between 20 ±5 psi of water pressure. The hot water heater should be set to deliver ≥140°f water temperature to the dishwasher for best results. Use ¾” copper tubi...

Page 12

9 4.6 water drainage attach the drain hose as shown in fig. 5. It is recommended to affix a siphon pipe to prevent odors. All piping from the machine to the drain must be a minimum 1-1/2” i.P.S. There should also be an air gap between the machine drain line and the drain. For natural overflow effici...

Page 13

10 clear cap yellow / green wire bridge blue cap white wire ground line line note: bridge may have a brown wire fi-64w / fi-72w 208-220 volts / 1 phase 5 4 3 2 1 blue cap red & white wires brown cap white wire gray cap white wire black cap white wire brown cap red & white wires black cap white wire ...

Page 14

11 other wiring configurations used before may 2006:.

Page 15

12 5 installation checklist check off the following items as they are completed before proceeding to operate or service the dishwasher. Has the dishwasher been checked for concealed/hidden damage? Has the dishwasher been properly leveled? Has the service voltage been checked to ensure that it meets ...

Page 16: 6 Operations

13 6 operations 6.1 washing fig. 7 control panel • set selector switch (1) to desired time setting. (fi-48w, 120 or 180 second / fi-64w & fi- 72w, 90 or 180 second) this will turn your machine on. Indicator light (2) will illuminate. Machine will automatically begin to fill and heat the water in the...

Page 17

14 6.2 draining and cleaning draining must occur every day and if in a high application; it should be drained after each meal rush! Fig. 7 control panel • switch selector switch (1) to the 0 setting. (off) (fig. 7) • open the door and remove the front right s/s filter. (fig. 8) • remove the overflow...

Page 18

15 6.3 detergent control • use commercial grade, high temperature, low suds liquid detergent. Fagor doesn’t recommend any specific brand name of chemicals. Contact your local chemical distributor for questions concerning your chemical needs. • all machines come equipped with an internal detergent an...

Page 19

16 6.4 preparing the ware - pre rinse all racks prior to placing them in the dishwasher to remove large food particles from the ware. - wash glassware first - put trays in the baskets, making sure is in its separate rack (fig.12). - put plates in the baskets, making sure each is in its separate rack...

Page 20: 7 Troubleshooting

17 7 troubleshooting first be sure that the “installation checklist” in this manual was completed and check out that all the conditions still remains in effect. For support or further service information contact fagor service department toll free at 1-866-go-fagor (46-32467). The diagnosing, testing...

Page 21

18 symptom possible cause action timer faulty (m) verify the programmer is rotating (m1, m2, m3, and m4 & m5). If not, check to see that the motor is receiving power. If so, replace the programmer assembly. Ohm out timer motor leads. Operating t-stat faulty (tc) verify position change if temperature...

Page 22

19 symptom possible cause action tank heater relay (ct) faulty. Verify contacts are close when there is voltage to relay also check for stuck or pitted contacts. Dishwashing machine runs. Wash water not reaching required temperature. Rinse heater (rt) faulty check element for continuity; if open, re...

Page 23: 8 Electrical Diagrams

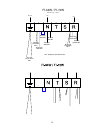

20 8 electrical diagrams b c cc2 m5 3 3a st 7a 7 p2 bd 2a 2 1a 1 6a 5 cp ct cc1 p1 4 4a 8 8a l1 ip tt tc m1 m2 m av.R mbl m r a ve am vi vi na rs n 2 1 3 a rs n na na n vi am ve r vi 2 3 1 6 5a tsc fi - 48 w v m3 m ds det. M m ve b m4 g m rs l2 r rs a g 0 180 x x 1 1a 2 2a 3 3a 4 4a 5 5a 6 6a 7 7a 8...

Page 24

21 b c cc2 m5 3 3a st 7a 7 p2 bd 2a 2 1a 1 6a 5 cp ct cc1 p1 4 4a 8 8a l1 ip tt tc m1 m2 m av.R mbl m r a ve am vi vi na rs n 2 1 3 a rs n na na n vi am ve r vi 2 3 1 6 5a fi-64 w v m3 m ds det. M m ve b m4 g m rs l2 r rs a g 0 180 x x 1 1a 2 2a 3 3a 4 4a 5 5a 6 6a 7 7a 8 8a x x x x 90 x x x x x x x...

Page 25

22 b c cc2 m5 1 1a st eb cp cc1 p1 3 3a 2 2a l1 ip tc m1 m2 m av.R mbl m r a ve vi vi rs n 2 1 3 a rs n na na n ve tsc fi-72w v m3 ds det. M m ve m rs l2 a na am tt ct m tstp b m4 rs z263005000 160s fast got to 90sec.Progr. Rinse wash m5 m3 m2 m1 90sec.Program. Termo-stop m4 180sec 90s 5s 15s 2" x x...

Page 26: 9 Wiring Schematics

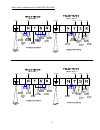

23 9 wiring schematics ip 2 2 2 2 2 1 1 1 1 1 1 1 1 rs 2 1 r z -20 30 2 3 p1 3 1 2 n m vi am r 2 1 3 p2 z-20 300 5 1 g ve m n a b1 a1 cp z-203062 r rs/g ct am a g ve a g a1 a2 z-213007 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 2 1 1 2 1 1 na b ve na rs b rs m rs am vi rs rs n a com com 6 seg. 18...

Page 27

24 ip 2 2 2 2 2 1 1 1 1 1 1 1 1 rs 2 1 r z- 20 3 02 3 p1 3 1 2 n m vi am r 2 1 3 p2 z-20 300 5 1 g ve m n a b1 a1 cp z-203062 r rs/g ct am a g ve a g a1 a2 z-213007 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 2 1 1 2 1 1 na b ve na rs b rs m rs am vi rs rs n a com com 6 seg. 180 seg. M5 m4 m3 m2 m...

Page 28

25 rs ve ip z-203014 (ego) 2 4 1 vi na rs tc det. Ds am/ve b.D. Vi ve am/ve a g rt mb c b n am/ve 2 2 2 2 2 1 1 1 1 1 1 1 1 rs 2 1 r z -20 3 023 p1 3 1 2 n m vi am r 2 1 3 p2 z-20 300 5 1 n m g n m cc2 vi ve g a1 a2 z-213007 rs b r n m cc1 vi ve g a1 a2 g ve m n a b1 a1 cp z-203062 r rs/g ct am a g ...

Page 29

26 rs ve ip z-203014 (ego) 2 4 1 vi na rs tc det. Ds am/ve am/ve a g rt mb c b n am/ve 2 2 2 2 2 1 1 1 1 1 n m g n m cc2 vi ve g a1 a2 z-213007 rs b r n m cc1 vi ve g a1 a2 g ve m n a b1 a1 cp z-203062 r rs/g ct am a g ve a g a1 a2 z-213007 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 2 1 1 1 230 v...

Page 30

27 ip 2 1 1 1 1 1 n m g n m cc2 vi ve g a1 a2 z-213007 rs b r n m cc1 vi ve g a1 a2 rs ve m n a b1 a1 cp z-203062 r ct am a g ve a g a1 a2 z-213007 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 1 1 1 230 v - 3 ~ a am /v e n g m a t s r 1 1 1 230 v - 1n ~ a g m n am/ ve n g m a n r 400 v - 3n ~ a g m n a...

Page 31

28 ip 2 1 1 1 1 1 n m g n m cc2 vi ve g a1 a2 z-213007 rs b r n m cc1 vi ve g a1 a2 rs ve m n a b1 a1 cp z-203062 r ct am a g ve a g a1 a2 z-213007 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 1 1 1 230 v - 3 ~ a am/ ve n g m a t s r 1 1 1 230 v - 1n ~ a g m n a m/v e n g m a n r 400 v - 3n ~ a g m n a...

Page 32

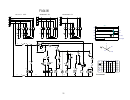

29 10 electrical diagrams (machines before may 2006) eb tl gi x x 12 0 120 c ol our s code -c ode de c oul eu rs -c od igo de col ore s: r = re d- ro uge -r oj o m = br ow n- mar ron- mar ron g = gr ey -gr is -gr is n = bl ac k- no ir-n egr o a = b lue -b le u- az ul b = wh ite- bl an c- bl an co vi...

Page 33

30 c o lou rs co d e- c od e de c o ul e ur s-c od ig o de c ol o re s: r = re d -r o ug e -r o jo m = b ro w n- m a rr on -m ar ro n g = gr e y- g ri s- g ris n = bl a ck- no ir- n eg ro a = bl u e -b le u -a zu l b = wh ite -bla n c- bla n co vi = vio let te -v iole t- vio le ta am = ye llo w- ja ...

Page 34

31 11 schematics (machines before may 2006) am/ve 2 1 na a a no l3 l2 l1 n n n ve n vi cc z-203050 na a a no l3 l2 l1 n n a ve a vi cc z-203050 g ve na na g am llo ri a m a e d r e v tt b1 a1 ve g b r vi rp ct am a r ve a r a1 a2 2s z-203062 m m 2 1 3 2 1 3 p1 p2 z-203023 z-223005 a n am n g rs n vi...

Page 35

32 m m vi rs rs a a na z-229009 z-683087 r rs na a2 a1 ve rs ve g b r vi b1 a1 2s 1n ~ 220v./1n ~ 240v. 3 am rs rs rs 6 seg. Vi r g b rs na am m a m b g b b r r na b e.V. Ve b ve ve vi b.D. N t s r st / lc ve r rs na g g ds det. Vi vi tl n ve lm prg. A m /v e 2 4 1 vi na r a n a r tc rc rt mb c m n ...

Page 36

33 12 sequence flow charts (machines before may2006) 12.1 timer wiring schematic (see fig. 9-1 in next page) the cycle timer is comprised of 5 sections (m1 to m5). Each one has a 3 position micro switch (line /normally closed /normally open) and 2 drive motors (run/cycle and rapid advance/start ). M...

Page 37

3 4.

Page 38

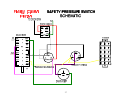

35 12.3 thermo-stop (hot water assurance) (see fig. 9-3 in next page for model fi-64w & fi-72w) the thermo-stop relay (r) works in series with the rinse (booster) heater relay (cc) and is activated through m4 this relay insures the timer will not advance to the rinse cycle until the preset temperatu...

Page 39

3 6.

Page 40

37.

Page 41: 13 Service Procedures

38 13 service procedures 13.1 tank thermostat part number: z718405 (adjusted at 150ºf) – blue and red points / z718441 (adjusted at 160ºf) – yellow and red points. Notes: replace the 150ºf thermostat by the 160ºf if you are having problems reaching washing temperatures. Tools needed: phillips screwd...

Page 42

39 13.3 boiler thermostat part number: z203014 notes: be sure that thermostat is full open, in order to get the proper sanitized rinsing temperature (195ºf) . Turn it clockwise up to the end. Tools needed: phillips screwdriver (#2) 10mm nut driver procedure: 1- remove lower front panel 2- remove the...

Page 43

40 13.5 start button part number: z213033 note: there has been a modification on the start button for fagor dishwashers. The new one is more ergonomic and 1 of terminals (green connection) is in a different position. However they are exchangeable and connections don’t change either, as it is shown o...

Page 44

41 14 detergent pump new location be sure your detergent pump has the position shown below. If not, follow instructions to reverse your pump: tools needed: - drill and ¼” drill bit - 5” nut driver - #2 philips screwdriver procedure: 1- open front bottom panel 2- remove two screws of rinse aid dispen...

Page 45

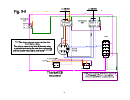

42 15 procedure to install external chemical pump a) electrical connections wiring kit must be supplied from fagor to make the electrical connections. Contact 1 866 - go fagor (463-2467) to be supplied with one. One side of the wiring kit has three caps (white, violet and green) with jumpers. The ot...

Page 46

43 16 themostat configurations (after october 2006) boiler thermostat (z203014) + template 90ºc (z208438000) z748008000 boiler thermostat probe housing bracket p443060000 cap q012073000 bolt m12x20 + q162070000 nut m12 + q306024000 gasket 18x12.5x1.5 hot water assurance themostat (z203014000) + temp...

Page 47

44 z203014000 termostato calderin regulado a 85ºc (termostop) z213014000 limitador tecasa p. Termometro weiss z203014000 termostato calderin (calentamiento) z748008000 tank thermosat probe housing bracket z431701000 tank temp. Gauge probe housing bracket tank thermostat (z203014) with bracket themos...

Page 48

45 17 recommended spare parts part number description z201720 heating element for booster 2800 w. 230v.(fi-48w) z241703 heating element for booster 6000w. 230v.(fi-64 / 72w) z203009 door switch z203014 thermostat z743009 contactor for booster 230v. 50/60 hz. (fi-48w) z683087 contactor 230v. 50/60 hz...

Page 49: 18 Warranty Guidelines

46 18 warranty guidelines 1. Service issues when a service issue occurs, the end user must call fagor to report the problem. Our toll free number: 1-866-go-fagor is located in the front of the machine. If the issue can not be resolved by phone, fagor will contact the closest authorized service agenc...

Page 50

47 documentation: parts breakdown, service manuals, schematics, repair sheets and parts price list. For your convenience this information will be supplied on electronic format. 6. Reasonable times to repair and replace parts 1) from 30 to 45 minutes to diagnose a defective component and/or reason of...

Page 51

48.

Page 52

Fagor commercial, inc. 12800 nw 38th ave miami, fl. 33054-4525 tel: (305) 779 0170 fax: (305) 779 0173 1-866-go-fagor www.Fagorcommercial.Com.