- DL manuals

- Fagor

- Oven

- HCG-10/11

- Technical Manual

Fagor HCG-10/11 Technical Manual

Summary of HCG-10/11

Page 1

Technical manual gas ovens hvg and hcg november 2001 fagor industrial s.Coop..

Page 2: Index

2 index no. Description page 1 models and dimensions 3 2 characteristics 7 3 location 9 4 installation 10 electrical water inlet drain gas inlet exhaust gas outlet transformation to different gases 5 control panel 12 6 functional diagrams 14 7 figures 21 8 electrical and assembly diagrams 27 9 preve...

Page 3

3 1 models and dimensions fig 1 fig 2.

Page 4

4 fig 3.

Page 5

5 fig 4 fig 5.

Page 6

6 fig 6 a.- soft water inlet rg ¾”. B.- general drain rg 1”. C.- electrical supply inlet connector. D.- drain cleaning plug. E.- gas inlet rg ¾”..

Page 7

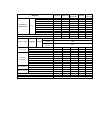

7 2 characteristics model hvg-10/11 hvg-10/21 hvg-2-10/11 hvg-20/11 hvg-20/21 hvg-2-20/11 width x 1060 1180 1060 1180 depth y 965 1170 965 1270 height without chimney w 925 925 1635 1635 height with chimney z 1290 1290 2000 2000 width u 650 770 650 770 depth v 535 740 535 740 external dimensions mm ...

Page 8

8 model hcg-6/11 hcg-10/11 hcg-10/21 hcg-2-10/11 hcg-20/11 hcg-20/21 hcg-2-20/11 width x 900 900 1020 900 1020 depth y 965 965 1170 965 1170 height without chimney w 695 925 925 1635 1635 height with chimney z 1060 1290 1290 2000 2000 width u 650 650 770 650 770 depth v 535 535 740 535 740 depth gas...

Page 9

9 3 location it is recommendable to install the extractor hood to expel fumes to the exterior (see fig 7) on the left- hand side, there must be a minimum space of 50 cm between the oven and the next appliance hvg. (see fig 8) likewise, the over must not be affected by the steam or heat from other ap...

Page 10

10 4 installation before proceeding to install the equipment, make sure that the type of gas set for the oven coincides with the gas supplied in the distribution network. 4.1 electrical connection. − the mains voltage must be the one indicated on the characteristics plate. − remove the left-hand sid...

Page 11

11 fig 9 4.3 drain. The connector hose must be steam resistant (100ºc). 4.4 gas inlet. The connection will be made with a hose fitted with a ½” and ¾” connection in hvg models. A stop cock and pressure regulator must be installed between the appliance and the gas mains. 4.5 exhaust fume outlet. The ...

Page 12

12 5 control panel hvg-10/11 hvg-10/21 hvg-2.10/11 hvg-20/11 hvg-20/21 fig 10 1.- chamber heating indicator. 15.- indefinite time fixed position (manual). 2.- oven on indicator . 16.- real temperature at probe core. 3.- steam generator heating indicator. 17.- core temperature selector. 4.- mode sele...

Page 13

13 hcg- 6/11 hcg-10/11 hcg-10/21 hcg-2.10/11 hcg-20/11 hcg-20/21 fig 11 1.- chamber heating indicator. 2.- oven on indicator. 3.- chamber water inlet indicator. 4.- general switch. 5.- off position (off). 6.- on position (on). 7.- temperature selector. 8.- real chamber temperature. 9.- time selector...

Page 14

14 6 functional diagram (hvg) fig 12 1- steam gas valve 2- convection gas valve 3- gas duct from steam generator. 4 – chamber gas duct. 5- gas duct to main cover. 6 -mixer. 7 -mixer coupling 8 – blower fan. 9 –main cover. 10- chamber burner. 11 – generator burner. 12 –chamber heat exchanger. 13-comp...

Page 15

15 description of the most important components in the convection ignition system (forced air burner): vc: premix centrifugal fan (air blower or supplier) . (fig 28) this is an air supplier motor for combustion. -vf: frequency inverter. (fig-25) this is the electronics that changes and controls the ...

Page 16

16 cn: water level control. Electronics that control the generator water level. (fig 37 ) be: this is the spark plug that generates the spark for ignition.(fig 31) bd: this is the ionisation flame detector. Re1: energy regulator.(fig 34) electro-mechanical component for controlling electrical contac...

Page 17

17 blower fan sequence vc correct ignition. Fig 13 blower fan sequence vc incorrect ignition. Fig 14 ignition control (cec and cev) fig 15 fig 16 connection ignition sequence acronyms pr lr gv si dii lii functions reset button reset light gas valve spark plug flame detector heating indication lamp.

Page 18

18 functional diagram hvg and hcg (convection mode) fig 17 hvg convection mode (30-270ºc) fig 18 convection mode 30º -270ºc convection burner is working. Chimney open..

Page 19

19 functional diagram hvg (steam mode 100º c-adjustable steam mode 30-100º c) fig 19 hvg steam modes 100ºc- adjustable steam 30-100ºc fig 20 steam modes 100ºc-adjustable steam convection burner is working. Chimney closed..

Page 20

20 hvg mixed-refrigeration modes 30º -270ºc fig 21 regeneration mode: - initial phase: both burners simultaneously – chimney open. -temperature maintenance: burners cycle alternatively. 1 st convection –chimney open and 2 nd steam- chimney closed. (steam cycles in turn with the re1 energy regulator ...

Page 21

21 7 figures fig 22 detailed view of burner, ignition spark plug and flame detector fig 23 convection gas valve adjusted according to: -oven size -type of gas convection ignition spark plug convection flame detector spark plug convection burner gas valve sit 830 steam gv3-gv4..

Page 22

22 vr 4605-va 1041b valve (convection gas valve) fig 24 frequency inverter (t-083002) fig 25 fig 26 p.Outlet p.Inlet ignition speed switches maximum operating speed switches detailed view of frequency inverter switches air/gas regulation in ignition. (maximum speed) air/gas regulation in ignition. (...

Page 23

23 detailed view of gas air mixture in the convection ignition system at rear of oven fig 27 detailed view of blower, mixer and burner support fig 28 detailed view of washer fig 29 vc= ebm fan 50/60hz mixer burner air washer diameter 5mm mm.

Page 24

24 steam burner detailed view of steam burner detail of chimney seal mechanism detailed view of chimney seal re1 energy regulator tv steam thermostat tcn condensation thermostat cn level control fig 30 fig 31 fig 32 fig 33 fig 34 fig 35 fig 36 fig 37.

Page 25

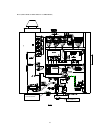

25 hvg (side view of electrical components) fig 38 gas intake ¾” electrical wiring connection inlet.

Page 26

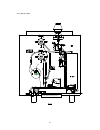

26 hvg (rear view) fig 39 soft water connection ¾”.

Page 27

27 8 electrical diagrams and assembly diagrams acronyms vf: frequency inverter vf2 : contact indicating that the vc blower fan is in operation. Vf1: contact that closes when: -tc = on -blower speed = slow blower ignition speed. Cec: convection ignition control. Cev: steam ignition control. Re1: ener...

Page 28

28.

Page 29

29 fig 40

Page 30

30 fig 41.

Page 31

31 fig 42.

Page 32

32 fig 43.

Page 33

33 9 preventive maintenance in order to guarantee the safe, cost-effective and non contaminating operation of your oven, periodic maintenance is essential. This allows you to keep it in good condition and prolongs its service life. Maintenance must be done by authorised technical personnel, at least...

Page 34

34 2. Steam system 2.1 lime scale indicator lamps. If any of these light up, remove scale in oven as follows: 1 turn off the appliance. 2 turn the water drainage lever "b". When empty, return the lever to the original position. 3 extract plug a and pour in deliming liquid (14 litres) . 4 after 6 hou...

Page 35

35 3 oven door 3.5 seal if this is cracked or damaged, replace. 3.6 steam leaks if there are any steam leaks, adjust the hinge and hooks 3.7 door alignment adjust if necessary. 3.8 handle if this is loose, tighten or replace. 3.9 drain check and clean if necessary. 3.10 light replace lamp if necessa...

Page 36

36 10 trouble shooting effect cause action 1.-oven does not operate in any mode. Green lamp l1 does not come on. Electronic thermostat display on. 1.1.Door switch ip 1.2.Motor thermal switch fm 1.1.Check – change or adjust 1.2.Check motor thermal switch wires (grey motor connection cables) or change...

Page 37

37 7.- oven operates for a time and then stops and starts again. 7.1.Motor thermal switch fm 7.1.Check that the three phases are connected correctly to motor. 7.1.Check whether there is dampness on external surfaces of motor 7.1.Check that the turbine turns in the correct direction 7.1.Change motor ...

Page 38

38 frequency inverter failure modes t-083002: 1. Single pulse of light in red led d21(fig 47). Effect: oven does not ignite. Reset button off. Possible causes: - 1.1 signal cable between frequency inverter and fan (t-083000) is broken. - (check connector wires j2 of frequency inverter) connection 1-...

Page 39

39 - 4.1 blower does not work properly. - 4.2 frequency inverter does not work properly. 5. Five pulses of light on red led. D21 (fig 47) effect: the oven operates, but ignition is abrupt. The blower does not reach the minimum ignition speed. Possible causes: - 5.1 blower does not work properly. 5.2...

Page 40

40 failure modes on display of electronic chamber thermostat: if the following message appears on the electronic thermostat display: _ _ 0 thermocouple or chamber probe cut off. -check connection between thermocouple and electronic thermostat -change chamber probe _ _ 1 ntc open. -change electronic ...

Page 41

41 11 parameters and adjustments the pressure values in ( mbar) are approximate. These are taken with an input pressure of 29 mbar butane , 37 mbar propane and 20 mbar natural gas burner on (v max) burner off model v ignition s1 v maximum s2 Ø air washer gas valve gv1-gv2 p out (mbar) p out (mbar) h...

Page 42

42 steam generator burner on burner off models v ignition s1 v maximum s2 Ø air washer gas valve gv1-gv2 nozzles. (qty=12) p out (mbar) p out (mbar) hvg 10/11 b.P. Ve=2000 rpm v=4000 rpm Ø18: t-115082 t-115097 z-955899 0,3:1,1 -0,8:-0´3 hvg 10/11 prop. Usa-60 hz " v=4500 rpm " t-115100 " hvg 10/11 b...

Page 43

43 speed selectors s1-s2 of frequency inverter : 0 0000 800 r.P.M. 8 1000 2500 r.P.M. 1 0001 1000 r.P.M. 9 1001 3000 r.P.M. 2 0010 1200 r.P.M. 10 1010 3500 r.P.M. 3 0011 1400 r.P.M. 11 1011 4000 r.P.M. 4 0100 1600 r.P.M. 12 1100 4500 r.P.M. 5 0101 1800 r.P.M. 13 1101 5000 r.P.M. 6 0110 2000 r.P.M. 1...

Page 44: Position of

44 adjusting amount of steam in mixed and regeneration mode. The oven is adjusted for an optimum amount of steam, but if for any reason the user wants more, do the following: 1. Locate the energy regulator re 1. This is regulated approximately to give 15 seconds of steam and 15 seconds without steam...

Page 45

45 - with set held down, press “up” to choose “cr” parameter on display for k-type thermocouple. (fig 54) note: if, instead of “cr” we select “fe” this corresponds to the black j-type core thermostat (iron – costanta). Core probe thermostat fig 52 fig 53 electronic chamber thermostat adjustment 1/ a...

Page 46

46 electronic thermostat (r743013) fig 54 parameters for distance between ignition spark plug . Bd flame detector with convection burner fig 55 blue switch p2 p5 p3 the burner seal must not coincide with the be and bd position convection burner.

Page 47

47 12 recommended spares list of recommended spares in hvg and hcg convection ovens z953004 combustion control s333001 energy regulator r343072 level detector r253049 motor 230-240v 50/60hz t113030 function selector switch r743013 electronic thermostat t113010 50/60hz chimney motor z100522 door magn...

Page 48

48 anexo: transformaciÓn a diferentes gases proceso transformaciÓn tipo gas importante: para transformar el tipo de gas del horno se requiere cambiar y modificar las siguientes piezas : -1/ válvula gas convección gv1-gv2. -2/ arandela de aire. -3/ posicionar los interruptores s1 y s2 del variador de...

Page 49

49 piezas a cambiar para conversion a diferentes gases cambiar arandela aire (2) cambiar válvula gas convección (1)gv1-gv2 cambiar inyectores gas quemador del generador vapor (4) modificar posición en s1 y s2 los interruptores del variador de frecuencia vf (3).

Page 50

50 1º cambiar válvula de gas convección. 2º cambiar arandela aire según indica detalle. Ubicacion de la arandela de aire válvula gas convección gv1- gv2 regulada según: -tamaño horno -tipo de gas válvula gas vapor gv3-gv4. Arandela de aire.

Page 51

51 3º posicionar los interruptores del variador de frecuencia según modelo corresponda tanto en s1 y s2 según tablas. Variador encendido hvg (t-083002) 4º cambiar inyectores gas quemador del generador de vapor (solo hvg) quemador vapor detalle quemador vapor inyectores vapor conmutadores velocidad e...

Page 52

52 parametros y regulaciones los valores de presión en ( mbar) son orientativos. Estos estan tomados con una presión de entrada de 29 mbar butano , 37 mbar propano y 20 mbar gas natural quemador on (v max) quemador off modelo vencendido s1 vmáxima s2 Ø arandela aire válvula de gas gv1-gv2 p out (mba...

Page 53

53 generador vapor quemador on quemador off modelos vencendido s1 vmáxima s2 Ø arandela de aire válvula de gas gv1-gv2 toberas. (cant=12) p out (mbar) p out (mbar) hvg 10/11 b.P. Ve=2000 rpm v=4000 rpm Ø18: t-115082 t-115097 z-955899 0,3:1,1 -0,8:-0´3 hvg 10/11 prop. Usa-60 hz " v=4500 rpm " t-11510...

Page 54

54 generador vapor quemador on quemador off modelos vencendido s1 vmáxima s2 Ø arandela de aire válvula de gas gv1-gv2 toberas. (cant=12) p out (mbar) p out (mbar) hvg 20/11 b.P. Ve=3000 rpm v=6000 rpm Ø22: t-135035 t-135037 z-955899 hvg 20/11 prop. Usa-60 hz " " " t-135040 " hvg 20/11 b.P. Australi...

Page 55

55 selectores de velocidad s1-s2 del variador de frecuencia : 0 0000 800 r.P.M. 8 1000 2500 r.P.M. 1 0001 1000 r.P.M. 9 1001 3000 r.P.M. 2 0010 1200 r.P.M. 10 1010 3500 r.P.M. 3 0011 1400 r.P.M. 11 1011 4000 r.P.M. 4 0100 1600 r.P.M. 12 1100 4500 r.P.M. 5 0101 1800 r.P.M. 13 1101 5000 r.P.M. 6 0110 ...

Page 57

57.