Fagor Innova 20i-M Installation And Operation Manual - Index

(2/40) - Installation/Operation - 20i-M / 30i-M - V0703

INDEX

1

DRO description ..........................................................................................3

1.1

Front panel ........................................................................................................................ 3

1.2

Turning the unit on and off .............................................................................................. 4

2

DRO operation .............................................................................................5

2.1

Display modes .................................................................................................................. 5

2.2

Incremental, absolute and with respect to Machine Reference Zero .......................... 6

2.2.1

Example .............................................................................................................................. 7

2.2.1.1 Absolute mode .................................................................................................................... 7

2.2.1.2 Incremental mode ............................................................................................................... 8

2.3

Machine Reference selection and search ...................................................................... 9

2.3.1

Home search sequence: ..................................................................................................... 9

2.4

Operating with tools....................................................................................................... 10

2.4.1

Entering tool dimensions .................................................................................................. 10

2.4.2

Tool dimension compensation while machining ............................................................... 10

2.4.3

Datum point (part zero) to work with tool compensation .................................................. 10

2.5

Special operations.......................................................................................................... 11

2.5.1

Scaling factor .................................................................................................................... 11

2.5.2

Part centering ................................................................................................................... 12

2.6

Examples of how to operate with tool compensation................................................. 12

2.6.1

Inside pocket .................................................................................................................... 12

2.6.2

Outside pocket .................................................................................................................. 13

2.7

Access to special modes............................................................................................... 14

2.7.1

Linear and bolt-hole drilling .............................................................................................. 15

2.7.1.1 Work plane selection: ....................................................................................................... 15

2.7.1.2 Bolt-hole drilling ................................................................................................................ 15

2.7.1.3 Execution of bolt-hole drilling ............................................................................................ 16

2.7.1.4 Linear drilling .................................................................................................................... 17

2.7.2

Coordinate freeze (HOLD). ............................................................................................... 17

2.7.3

Calculator ......................................................................................................................... 18

2.7.3.1 Operating with the calculator. ........................................................................................... 18

2.7.3.2 Recall and Reset modes .................................................................................................. 19

2.7.4

Part angle measuring ....................................................................................................... 20

2.7.5

Corner rounding ................................................................................................................ 21

3

DRO installation ........................................................................................22

3.1

Installation of the built-in model ................................................................................... 22

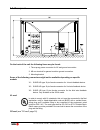

3.2

Rear panel ....................................................................................................................... 23

3.3

General technical characteristics ................................................................................. 24

3.4

Connections.................................................................................................................... 24

3.4.1

Connection of the feedback systems ................................................................................ 24

3.5

Easy setup....................................................................................................................... 25

3.5.1

Accessing the "Easy Setup" mode ................................................................................... 25

3.5.2

Operating mode. ............................................................................................................... 25

3.5.3

Power and machine connection ....................................................................................... 26

3.6

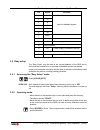

Installation parameters .................................................................................................. 26

3.7

Parameters to configure axis position reading and display....................................... 28

4

Appendix ....................................................................................................35

4.1

UL seal............................................................................................................................. 35

4.2

CE seal............................................................................................................................. 35

4.2.1

Declaration of conformity .................................................................................................. 35

4.2.2

Safety conditions .............................................................................................................. 36

4.2.3

Warranty terms ................................................................................................................. 38

4.2.4

Material returning terms .................................................................................................... 38

4.3

Error codes ..................................................................................................................... 39

4.4

Maintenance.................................................................................................................... 40