- DL manuals

- Fagor

- Other

- NC-200 PB - V0111

- Installation Manual

Fagor NC-200 PB - V0111 Installation Manual

Summary of NC-200 PB - V0111

Page 1

Installation manual fagor nc-200 pb nc for press brakes manual version: 0111.

Page 2: Index

Page: 2 - installation manual - nc-200 pb index declaration of conformity ................................................................................... 4 safety conditions ............................................................................................... 5 warranty terms ............

Page 3: Warning:

Nc-200 pb - installation manual - page: 3 warning: before starting up the dro, carefully read the instructions of chapter 2 in the installation manual. The dro must not be powered-on until verifying that the machine complies with the "89/392/cee" directive. 4. Operation with the rs-232-c serial line...

Page 4: Declaration of Conformity

Page: 4 - installation manual - nc-200 pb declaration of conformity manufacturer: fagor automation, s. Coop. Barrio de san andrés s/n, c.P. 20500, mondragón -guipúzcoa (espaÑa) we hereby declare, under our responsibility that the product: nc fagor nc-200 pb meets the following directives: safety: en...

Page 5: Safety Conditions

Nc-200 pb - installation manual - page: 5 safety conditions read the following safety measures in order to prevent damage to personnel, to this product and to those products connected to it. Fagor automation shall not be held responsible for any physical or material damage derived from the violation...

Page 6

Page: 6 - installation manual - nc-200 pb working environment this unit is ready to be used in industrial environments complying with the directives and regulations effective in the european community install the unit in the right place it is recommended, whenever possible, to instal the dro so its ...

Page 7: Warranty Terms

Nc-200 pb - installation manual - page: 7 warranty terms warranty all products manufactured or marketed by fagor automation has a warranty period of 12 months from the day they are shipped out of our warehouses. The mentioned warranty covers repair material and labor costs, at fagor facilities, incu...

Page 8: Material Returning Terms

Page: 8 - installation manual - nc-200 pb material returning terms when returning the dro, pack it in its original package and with its original packaging material. If not available, pack it as follows: 1.- get a cardboard box whose three inside dimensions are at least 15 cm (6 inches) larger than t...

Page 9

Nc-200 pb - installation manual - page: 9 description of the different models (they may be selected with par64) a. Controlling only the final position of the bend. The foot switches and the hydraulic circuit are not controlled by this nc. The intermediate positions of the ram are detected by electri...

Page 10

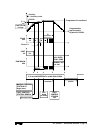

Page: 10 - installation manual - nc-200 pb diagram of a typical press brake y x + - - +.

Page 11: Unit Description

Nc-200 pb - installation manual - page: 11 1. Unit description this unit is especially designed to be used on punch presses. It allows displaying the position of the x and y axes, controlling them as well as the raising device (h), editing and executing part programs etc. The axes may also be moved ...

Page 12: Warning

Page: 12 - installation manual - nc-200 pb x2.- sub-d type 37 pin female connector to connect the digital inputs and outputs as well as the analog outputs. X3.- sub-d hd type 15-pin female connector for x axis feedback device. X4.- sub-d hd type 15-pin female connector for y axis feedback device. X5...

Page 13: 2.1

Nc-200 pb - installation manual - page: 13 2. Connections and characteristics the connection for the rs-232 serial line (optional x1 connector) is not described in this manual; but in a supplement for it. 2.1 connection of the feedback systems the feedback systems (scales or encoders) are connected ...

Page 14

Page: 14 - installation manual - nc-200 pb 2.2 input/output characteristics (x2) a 37-pin female connector is used. Signal characteristics of connector "x2": the supply voltage is at +24v (±25%), thus the threshold between a "0" and a "1" will be about +6v. Characteristics of the inputs at 24v : - m...

Page 15: 2.3

Nc-200 pb - installation manual - page: 15 2.3 input/output connection (x2). 2.3.1 input description. Section 2.3.3 shows the electrical diagrams for the indicated models. The parameters mentioned there are described in chapter 3 of this manual. The inputs are active high at 24v (par21 and par22 = 1...

Page 16

Page: 16 - installation manual - nc-200 pb pin function models a1, b and c 36 16 1 - run 1 0 0 2 - run 2 0 1 3 - set 1 0 4 - jog 1 1 model a external key simulation. Par 31 model a1, b and c footswitch connection models a, a1 next block models a, a1 double function f1 + f2 model a, a1 mode b, c the ...

Page 17: 2.3.2 Output Description

Nc-200 pb - installation manual - page: 17 2.3.2 output description if any of the outputs is going to be connected to some highly inductive device, a "1n4000" type diode must be installed in antiparallel. It is not required on auxiliary relays of less than 20 ma. The drives are enabled with auxiliar...

Page 18: Nc- 200 Pb

Page: 18 - installation manual - nc-200 pb 2.3.3 input/output connection 2.3.3.1 input/output connection. Model a without footswitch connection or ram controlling outputs. M encoder 24v external motor control 21 3 20 2 4 22 external key simulation 18 27 nc- 200 pb analog x gnda emergency 0v 24v 24v ...

Page 19: Nc- 200 Pb

Nc-200 pb - installation manual - page: 19 2.3.3.2 input/output connection. Model a1 with footswitch connection. Manual control and ram controlling outputs. M encoder 24v external motor control 21 3 20 2 4 22 18 27 nc- 200 pb analog x gnda emergency 0v 24v 24v user x enable x speed x direction m enc...

Page 20: Nc- 200 Pb

Page: 20 - installation manual - nc-200 pb 2.3.3.3 input/output connection. Model b with footswitch connection. Manual control and ram controlling outputs. M encoder 24v external motor control 21 3 20 2 4 22 18 27 nc- 200 pb analog x gnda emergency 0v 24v 24v user x enable x speed x direction m enco...

Page 21: Nc- 200 Pb

Nc-200 pb - installation manual - page: 21 2.3.3.4 input/output connection. Model c with footswitch connection and manual control. M encoder 24v external motor control 21 3 20 2 4 22 18 nc- 200 pb analog x gnda emergency 0v 24v 24v user x enable x speed x direction m encoder motor control valve anal...

Page 22

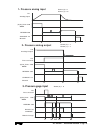

Page: 22 - installation manual - nc-200 pb 2.3.4 block change synchronism. Models a, a1 description of the diagrams according to positions a, b and c. There are three ways to synchronize when going from one block to the next at the end of a bend. If a pressure gage (transducer) is installed, p64.6 =...

Page 23: 3- Pressure Gage Input

Nc-200 pb - installation manual - page: 23 i18 change i13 block analog input (a) in_pos o29 bend return o28 1- pressure analog input par64 (6) = 1 par64 (7) = 0 c b a i18 change i13 block analog output (a) in_pos o29 bend return o28 2- pressure analog output i15 pressure level par64 (6) = 1 par64 (7...

Page 24

Page: 24 - installation manual - nc-200 pb 2.3.5 block change synchronism. Model b description of the diagram according to positions 1 through 6: 1. With x and y axis already in position, the fast approach is activated from the manual control station ie15 or only slow from the "bend" footswitch (i8)...

Page 25

Nc-200 pb - installation manual - page: 25 - position y' - auxiliary scale par33 programmed y coordinate y' = e fast/slow change programmable top dead point by default: par28 slow o29 programmable by default: p29 d ·i8 ·i8 i8 fast 09 retract x ·i15 ram down o28 manual-set ·i35 jog bend footswitch i3...

Page 26: 2.4

Page: 26 - installation manual - nc-200 pb 2.4 machine reference (home) search in this mode, the initial values are preset in a fixed reference position. If par14.4 = 1 on any axis, home search is mandatory on that axis every time the machine is turned on. This unit starts in mode. To quit this mode...

Page 27

Nc-200 pb - installation manual - page: 27 2.4.2 y axis reference (home) search. Models a and a1 a- if the machine has travel limit switches, the home search procedure is the same as the one described for the x axis; but it is only enabled if i13 = 1, ram at top dead position. B- if the machine does...

Page 28

Page: 28 - installation manual - nc-200 pb 2.4.3 y axis home search. Model "b" usually, this axis has home switches on up-stroke models. · position the table or the ram at the far-end position activating the limit switch i13. · press . The led turns on. · select the axis. It displays the word "start...

Page 29

Nc-200 pb - installation manual - page: 29 2.4.4 y axis home search. Model "c" an up-stroke or down-stroke model "c" has a linear encoder and controls the actual (real) position of the ram using foot switches. It usually has travel limit switches. If par00 bit 6 = 0, has been set for a linear encode...

Page 30

Page: 30 - installation manual - nc-200 pb 2.4.5 precautions when home searching the software limits set by par12 and par13 will indicate the real values referred to machine zero and they will correspond to the + and - limits slightly short of the positions of the travel limit switches or hard stops...

Page 31: 2.5

Nc-200 pb - installation manual - page: 31 2.5 rs-232-c connection (connector x7) the rs-232-c serial communications line uses a 9-pin male sub-d type connector. Parameter par90 sets the transmission speed through this line. See section 3.5 in this manual. The operating mode for this feature is desc...

Page 32: 2.7

Page: 32 - installation manual - nc-200 pb 2.6 power and machine connection this nc can be connected to an ac voltage anywhere between 100v ac and 264 v ac ±10% at a frequency between 45 hz and 400 hz. Between 120vdc and 300vdc without having to select it depending on the country where they are inst...

Page 33: Installation Parameters

Nc-200 pb - installation manual - page: 33 3. Installation parameters these nc's have a number of installation parameters to configure it for a particular application. These parameters may be saved into a peripheral or uploaded from it through the rs-232-c serial communications line. The format for ...

Page 34: 3.1 Parameter Setting

Page: 34 - installation manual - nc-200 pb 3.1 parameter setting machine parameters par50, par51 and par90 enable special features of this nc. The user may access them directly. In initial mode, press [parameter number] . The rest can only be accessed by installers and technicians. Press and hold fo...

Page 35

Nc-200 pb - installation manual - page: 35 binary values (1/0) are displayed in an 8-digit row identified as 1 through 8 from right to left. X x x x x x x x 8 7 6 5 4 3 2 1 para- meter function par00 feedback configuration, different per axis. Binary type. This parameter sets the specific characteri...

Page 36

Page: 36 - installation manual - nc-200 pb 5 axis units: 0 = mm, 1 = inches these units refer to the feedback and not to the display which may be changed with the key.. 4 not being used at this time. It must be set to "0" 3 not being used at this time. It must be set to "0" 2 type of feedback signal...

Page 37

Nc-200 pb - installation manual - page: 37 par03 external multiplying factor (ex e type) when using linear encoders with distance-coded reference marks and ttl feedback signals. Independent for each axis. Options: 1, 5, 10, 20, 25, 50. Factory setting: 1 these values are selected by pressing for exa...

Page 38

Page: 38 - installation manual - nc-200 pb par10 absolute value set on each axis at the end of the home search. On press brakes, it coincides with (see section 2.4): on the x axis: the distance from the center of the die to the support side of the x carriage. On the y axis: the distance between the ...

Page 39

Nc-200 pb - installation manual - page: 39 1 if = 0, the selected axis moves in rapid in the positive direction up tot home switch and returns at slow speed until detecting the home pulse. If = 1, the home position is floating. When pressing , it requests the password (719200). Par 16 it sets the va...

Page 40

Page: 40 - installation manual - nc-200 pb par21 indicates the active level of the first 8 inputs. By default, they are set to "1" meaning that they are activated with 24v. Digit pin 8 33 bcd 2 7 14 bcd 6 32 retract x axis / feed in forced mode. 5 13 go to next block 4 31 y axis negative travel limi...

Page 41

Nc-200 pb - installation manual - page: 41 par25 in-position zone. It is the distance before and behind the point where the axis is considered to have reached its target position. (model b). On up-stroke machines, it represents the maximum deviation allowed between the y axis position and that of it...

Page 42

Page: 42 - installation manual - nc-200 pb par28 top dead point. Default value of the relative distance between the punch and the die to return ram after each bend. Possible values: from 0.0001mm to 9999.9999 mm (from 0.000005" to 393.700"). It may be forced from the editor. "b" and "c" models. Par2...

Page 43

Nc-200 pb - installation manual - page: 43 par32 configuration of the incremental manual switch positions (pins 14, 33 and 34 of the 37-pin connector x2) to externally select the jog increments. Normally, a 5-position bcd switch is used (positions 1 to 5). Position 1 is used for continuous jog, posi...

Page 44

Page: 44 - installation manual - nc-200 pb on the model a. Set the upper negative value for the maximum bending depth. Par35 indicates the duration of the "in-position" output o29 that enables the "bend" foot switch. Possible values: between 0.1 seconds and 9.9 seconds. If = 0, the signal stays acti...

Page 45

Nc-200 pb - installation manual - page: 45 par40 proportional gain kv of the position loop in the positive direction if par46(5) = 1. Axis controlled in closed loop. (see section 5.2). Possible values: between 0 and 255. Par41 proportional gain kv of the position loop in the negative direction if pa...

Page 46

Page: 46 - installation manual - nc-200 pb par47 analog voltage for slow axis feedrate in the positive direction. Value range: between 0 and 10v. Par48 analog voltage for slow axis feedrate in the negative direction. Value range: between 0 and 10v. Par49 analog voltage for fast axis feedrate in both...

Page 47

Nc-200 pb - installation manual - page: 47 par64 press brake model definition digit 8 not being used at this time. It must be set to "0". 7 if = 0, pin 18 of connector x2 is selected as the analog input for the pressure/voltage gage or potentiometric scale. Both options are incompatible. This operat...

Page 48

Page: 48 - installation manual - nc-200 pb par65 special configurations. Digit 8 to 5 not being used at this time. They must be set to "0". 4 only for the "b" model. If = 0, the feedback device for the ram/table position is a linear encoder. If = 1, the feedback device for the ram/table position is ...

Page 49: 4.1.

Nc-200 pb - installation manual - page: 49 4. Operation with the rs-232-c serial line 4.1. Saving and restoring data with this nc, it is possible to save data into a pc or peripheral device and later restore it by using the rs-232-c serial communications line. This data is sent out in the following ...

Page 50: Setup

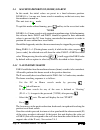

Page: 50 - installation manual - nc-200 pb 5 setup 5.1 test mode a special mode has been created in order to make machine setup easier. This mode is accessed from the main menu. Special care must be taken since software and hardware limits are ignored in this mode. Section 3.1, par21 through par24 d...

Page 51

Nc-200 pb - installation manual - page: 51 analog input / outputs ana> in this mode, it is possible to force a value to the analog outputs in order to move the axes and set reference values in parameters par44 through par48. · select the or axis the enable signal of the relevant axis is activated. ·...

Page 52

Page: 52 - installation manual - nc-200 pb kv> to set the gain with automatic back-and-forth movements. · select the or axis. Indicate the coordinate of the positive limit, indicate the coordinate for the negative limit, a back-and-forth movement is generated to analyze the dynamic response on rever...

Page 53

Nc-200 pb - installation manual - page: 53 5.1.1 direct access to the parameters in order to get better acquainted with the operation of this unit without having to connect the 24v input, there is a special way to access the installation parameters on power-up: · while the unit is off, hold the keys...

Page 54: 5.2

Page: 54 - installation manual - nc-200 pb 5.2 axis setting these sections describe the most common criteria to achieve a good response when positioning the axes with the proper accuracy and repeatability in the three ways to close the loop. Each one refers to the affected parameters. 5.2.1 open loo...

Page 55: Par46(3)=1, Par46(5)=0

Nc-200 pb - installation manual - page: 55 5.2.2 open loop with analog voltage output. Par46(3)=1, par46(5)=0 method recommended in low range drive systems: unipolar drive [par45(1)=0], proportional valves, etc. Par27 sets the distance before the end point where the analog voltage is canceled. On dr...

Page 56

Page: 56 - installation manual - nc-200 pb figure 2 - drain active the fast approach movements are carried out in open loop with the analog voltage set in par49. Par26 sets the anticipation distance for the slow speed (par47-par48) and it positions in closed loop. The braking response depends on the...

Page 57: Appendix

Nc-200 pb - installation manual - page: 57 appendix error codes message description fagor dro power outage or turned off by main switch after saving the data. Error 02 power outage or turned off by main switch without having saved the data. The unit has been turned off without previously pushing the...

Page 58: Maintenance

Page: 58 - installation manual - nc-200 pb if any message other than the first two from the table were to come up, the equipment should be switched off and on again until one of the first two are seen. After pressing to access the counting mode, check the parameters. If any of the errors shown as (s...