- DL manuals

- Fairbanks

- Scales

- AEGIS

- Installation Manual

Fairbanks AEGIS Installation Manual

Summary of AEGIS

Page 1

Presented by dallas houston austin ft worth nicolscales.Com 800.225.8181 contact us nicol scales & measurement is an iso accredited calibration company that has provided calibration, repair and sales of all types of weighing and measurement products since 1931..

Page 2

51191 © 2008-2010 by fairbanks scales, inc. Revision 2 04/10 all rights reserved fairbanks transport scale installation manual.

Page 4: Document 51191

04/10 3 51191 rev. 2 amendment record aegis transport scale document 51191 manufactured by fairbanks scales inc. 821 locust kansas city, missouri 64106 created 8/08 created revision 1 8/08 documentation release revision 2 04/10 corrected part number and added load cell, feet and mounting bolts parts...

Page 5

04/10 4 51191 rev. 2 disclaimer every effort has been made to provide complete and accurate information in this manual. However, although this manual may include a specifically identified warranty notice for the product, fairbanks scales makes no representations or warranties with respect to the con...

Page 6

04/10 5 51191 rev. 2 table of contents section 1: general information .................................................................. 7 1.1. Introduction ............................................................................................................. 7 1.1.1. Stainless steel transpor...

Page 8: 1.1.1.

04/10 7 51191 rev. 2 section 1: general information 1.1. Introduction the transport scale is a self-contained portable scale designed for weighing drums in various locations throughout a plant or factory. • it has an extremely low profile of one-and-a-half inch (1½”) for easy on− and off −loading. •...

Page 9: 1.1.3. Specifications

Section 1: general information 04/10 8 51191 rev. 2 1.1.3. Specifications feature description platform size 24” x 30” scale capacities 500, 1000, 2000 and 2500 lbs. Endloading 100% of capacity all models except 2500 lb model which is rated at 80%. Load cell excitation 5 to15 vdc grounding less than ...

Page 10: W A R N I N G !

Section 1: general information 04/10 9 51191 rev. 2 1.2. Conferring with our client prior to installation, always verify that the equipment satisfies the customer's requirements as supplied, and as described in this manual. If the equipment cannot satisfy the customer’s application, the fairbanks tr...

Page 11

Section 1: general information 04/10 10 51191 rev. 2 important installation notice all transport scale interface cables used shall be located a minimum of thirty-six (36”) inches distance away from all single and multiple phase high energy circuits and electric current carrying conductors. • a...

Page 12

Section 1: general information 04/10 11 51191 rev. 2 1.2.1. Service technician’s responsibilities all electronic and mechanical calibrations and/or adjustments required for making this equipment perform to accuracy and operational specifications are considered to be part of the installation. ─ they ...

Page 13: 2.1.1. Unpacking

04/10 12 51191 rev. 2 section 2: operations 2.1. Introduction the installing technician is responsible that all personnel are fully trained and familiar with the equipment's capabilities and limitations before the installation is considered complete. The fairbanks transport scale platform arrives at...

Page 14

Section 2: user operations 04/10 13 51191 rev. 2 2.1.2. Assembling the pillar 5. At the wheel-base side of the platform, remove the four (4) fastening bolts of the cover using the seven-sixteenths inch ( 7/16”) open-ended wrench . 6. Pull out and unwrap the cables, set the instructional cd aside, th...

Page 15

Section 2: user operations 04/10 14 51191 rev. 2 2.1.3. Positioning the equipment position the equipment with the following points in mind. • rest the platform on a smooth surface, within 1/8”, and on a level plane, within ¼” across both the length and width of the platform . • the four corners of t...

Page 16: 2.1.4. Moving The Scale

Section 2: user operations 04/10 15 51191 rev. 2 2.1.4. Moving the scale 1. Remove all objects from the platform. 2. Remove the ac power from the instrument, if applicable. 3. From the back of the scale, hold firmly onto the handle bars, place one foot on the platform base, then pull down on the han...

Page 17

04/10 16 51191 rev. 2 section 3: service and maintenance 3.1. Scale assembly maintenance follow these points to keep the transport scale well maintained. • clear all debris from between the spaces of the platform sides, ramps, edges, and the surface beneath the platform. • at the end of each day, wi...

Page 18

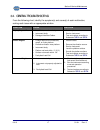

Section 3: service & maintenance 04/10 17 51191 rev. 2 3.2. General troubleshooting from the following chart, identify the symptom(s) and cause(s) of each malfunction, solving each issue with an appropriate solution. Symptom cause solution display stays at zero 1. Load cell connections faulty. 2. In...

Page 19: C A U T I O N

Section 3: service & maintenance 04/10 18 51191 rev. 2 3.2.1. Disassembling the platform 1. Cycle-down the power to the indicator, then unplug the unit, if applicable. 2. Lay down the scale on its back. 3. At the wheel-base end of the platform, remove the four (4) fastening bolts of the cover using ...

Page 20

Section 3: service & maintenance 04/10 19 51191 rev. 2 3.2.2. Pillar replacement steps 1. Unplug/remove the cable to the indicator (or battery pack unit) from the scale platform connection. 2. If it is present, remove the fastening screws on the battery pack, pulling it away and setting it aside. 3....

Page 21: Continued

Section 3: service & maintenance 04/10 20 51191 rev. 2 3.2.2. Pillar replacement steps, continued 7. Use two 9/16” open-ended wrenches on the 3/8” x 3-1/2” bolts through the pillar and on the fastening nuts. 8. Remove the (2) ¼” x .50” bolts using a 7/16” open-ended wrench to loosen the pillar from ...

Page 22: 3.2.3. Load Cell Testing

Section 3: service & maintenance 04/10 21 51191 rev. 2 3.2.3. Load cell testing when corners do not match the correct tolerances, disconnect/cut each load cell cable at the wheel base access area, then test each load cell for the settings on the following chart. Test reading remarks green to black (...

Page 23

Section 3: service & maintenance 04/10 22 51191 rev. 2 3.2.4. Load cell replacement, continued 4a. For a stainless steel scale, remove the six (6) phillips-head screws securing the junction box cover. 4b. Open the junction box cover, identifying the correct cable. 5. Cut the five (5) load cell cable...

Page 24

Section 3: service & maintenance 04/10 23 51191 rev. 2 3.2.4. Load cell replacement, continued 13. Strip away all the insulation from the four (4) load cell to a minimum of ¾”. 14. Using crimp connectors , fasten all five (5) green wires together, all five (5) black wires together, all five (5) whit...

Page 25

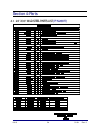

04/10 24 51191 rev. 2 section 4: parts 4.1. 24” x 30” mild steel parts list (p/n 28877).

Page 26

Section 4: parts 04/10 25 51191 rev. 2 4.2. 24” x 30” mild steel parts diagram (p/n 28877).

Page 27

Section 4: parts 04/10 26 51191 rev. 2 4.3. 24” x 30” mild steel sub-assembly (p/n 28792, 28793).

Page 28

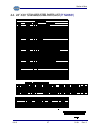

Section 4: parts 04/10 27 51191 rev. 2 4.4. 24” x 30” stainless steel parts list (p/n 28881).

Page 29

Section 4: parts 04/10 28 51191 rev. 2 4.5. 24” x 30” stainless steel parts diagram (p/n 28881).

Page 30

Section 4: parts 04/10 29 51191 rev. 2 4.6. 24” x 30” stainless steel sub-assembly (p/n 28794, 28795).

Page 33

Fairbanks transport scale installation manual document 51191 manufactured by fairbanks scales, inc . 821 locust kansas city, mo 64106 www.Fairbanks.Com.