- DL manuals

- Fairbanks

- Scales

- CP Series

- Operator's Manual

Fairbanks CP Series Operator's Manual

Summary of CP Series

Page 1

51412 . Revision 1 12/2017 © 2017 by fairbanks scales, inc. All rights reserved cp series forklift scale with technology carriage plate weighing system operator manual.

Page 2: Amendment Record

12/17 2 rev. 1 51412 amendment record cp series scale document 51412 manufactured by fairbanks scales inc. 821 locust kansas city, missouri 64106 created 12/2017 revision 1 12/2017 released manual.

Page 3: Disclaimer

12/17 3 rev. 1 51412 disclaimer every effort has been made to provide complete and accurate information in this manual. However, although this manual may include a specifically identified warranty notice for the product, fairbanks scales makes no representations or warranties with respect to the con...

Page 4

12/17 4 rev. 1 51412 table of contents section 1: general information ................................................................... 5 1.1 introduction .................................................................................................................. 5 1.2 description .............

Page 5

12/17 5 rev. 1 51412 attention section 1: general information 1.1 introduction the cp (carriage plate) series forklift scales are designed for on-board forklift weighing. The cp series forklift scales are rohs compliant. Its highly accurate design fits into a wide variety of applications. The cp ser...

Page 6

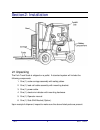

Section 1: general information 12/17 6 rev. 1 51412 1.2 description the cp series forklift scales do not interfere with the forklift’s hydraulic system, instead it utilizes proven load cell technology to capture weight. The forklift operates in its customary manner. When the forks are lifting a load...

Page 7

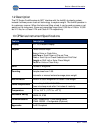

Section 1: general information 12/17 7 rev. 1 51412 1.4 cp series carriage specifications feature description capacities 5,000 lb. Capacity x 5 lb divisions type cleat power rechargeable battery protection ip65 overload 200% fs side loading (single fork) 100% fs construction structural carbon steel ...

Page 8

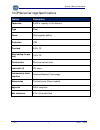

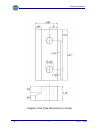

Section 1: general information 12/17 8 rev. 1 51412 1.5 cp series carriage dimensions dimensions (in inches) * class iv cp series scales available through fairbanks scales solutions group. Class ii 5,000 lb capacity class iii 10,000 lb capacity class iv* 15,000 lb capacity a 41.50 44.10 35.10 a 1 35...

Page 9

12/17 9 rev. 1 51412 section 2: installation 2.1 unpacking the fork truck scale is shipped on a pallet. A standard system will include the following components: 1. One (1) scale carriage assembly with safety plates. 2. One (1) load cell cable assembly with mounting bracket. 3. One (1) power cable. 4...

Page 10

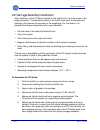

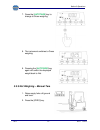

Section 2: installation 12/17 10 rev. 1 51412 2.2 carriage assembly installation after installation of the cp series system on the forklift truck, the truck is part of the weighing system. The mechanical parts of the forklift truck, such as the mast and bearings, will influence the accuracy of the w...

Page 11

Section 2: installation 12/17 11 rev. 1 51412 7. Park mount the eye bolt onto the top side of the weigh carriage back plate. 8. Use a properly rated chain/strap to attach to the eye bolt installed in step 7. And slowly lift the weigh carriage and align with the center of the original forklift carria...

Page 12

Section 2: installation 12/17 12 rev. 1 51412 diagram of the claw dimensions (in inches).

Page 13

Section 2: installation 12/17 13 rev. 1 51412 9. Once the upper claws are attached to the original forklift carriage, proceed with installing the lower blocks (lock blocks) on the lower side of the weigh carriage back plate. Torque to 222 foot pounds for 5,000 lb capacity or 443 foot pounds for 10,0...

Page 14

Section 2: installation 12/17 14 rev. 1 51412 torque to the proper setting: 222 foot pounds for 5,000 lb capacity 443 foot pounds for 10,000 lb capacity. Attaching the lower block and adding the locking bolt.

Page 15

Section 2: installation 12/17 15 rev. 1 51412 10. Remove the chain/strap from the eye bolt then remove the eye bolt. 11. Check: if the original carriage assembly of the forklift is equipped with ‘cut-outs’ at the top side to lock the position of attachments, then the optional side shift bracket can ...

Page 16

Section 2: installation 12/17 16 rev. 1 51412 12. Install each fork by aligning it with the cut-out on the bottom center of the weigh carriage front plate then slide each fork to its permanent position. 13. Install each fork by aligning it with the cut-out on the bottom center of the weigh carriage ...

Page 17

Section 2: installation 12/17 17 rev. 1 51412 2.3 adjusting the tension assembly 1. Load the system with it’s maximum capacity then lift and lower the load (exercise) at least two times. 2. Loosen the upper nuts of each tensioning assembly. 3. Loosen the lower nuts of the tensioning assemblies as we...

Page 18

Section 2: installation 12/17 18 rev. 1 51412 4. Hand tighten the upper nuts. 5. Tighten and lock down the lower nuts with a wrench 6. Load the system with maximum capacity and raise and lower the forks at least two times. The system is now ready for calibration..

Page 19

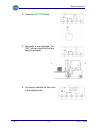

Section 2: installation 12/17 19 rev. 1 51412 2.4 carriage plate battery installation install the carriage plate assembly’s battery pack by lifting the tab, inserting the battery at the bottom first, pressing the battery down and into place, and securing the tab back down. • fairbanks scales inc. Re...

Page 20

Section 2: installation 12/17 20 rev. 1 51412 2.5 instrument installation note: all parts are assembled at the factory. The preferred locations to mount the instrument: a. Near the safety cage roof b. On the right side of the safety cage, mounted onto a side-rail. C. On the dashboard. The cp series ...

Page 21

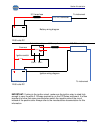

Section 2: installation 12/17 21 rev. 1 51412 3.15 amp fuse to instrument dc-dc converter battery wiring diagram forklift battery 12-80 volts dc automotive relay 3.15 amp fuse dc-dc converter common no nc ignition switch • • • • • coil + coil - ignition wiring diagram forklift battery to instrument ...

Page 22

12/17 22 rev. 1 51412 section 3: operations 3.1 front panel key functions this section examines the functions of the various keyboard operations that can be performed on the cp series forklift scale. There are 5 keys on the keyboard with 5 secondary operational functions. 3.1.1 key functions key sta...

Page 23

Section 3: operations 12/17 23 rev. 1 51412 3.1.2 front panel layout and descriptions descriptions the weighing system (including load) is stable the weight shown is negative the weight shown is within the zero range the display is showing the net weight c 1 displayed weight shown is in range 1 (opt...

Page 24

Section 3: operations 12/17 24 rev. 1 51412 3.2 system power up/shut down 3.2.1 system power up 1. Switch on the forks by pressing the blue button on the battery pack holder. 2. The blue led on the cp series weighing assembly will start blinking automatically. 3. Start up the instrument. Press the o...

Page 25

Section 3: operations 12/17 25 rev. 1 51412 3.3 basic operation 3.3.1 gross weighing 1. Raise empty forks off ground and level 2. Press the [ zero ] key 3. Lower forks and lift load 4. Gross weight displayed 3.3.2 net weighing - autotare 1. Raise empty forks off ground and level. 2. Press the [ zero...

Page 26

Section 3: operations 12/17 26 rev. 1 51412 4. Press the [ autotare ] key. 5. Net weight is now displayed. The “net” pointer shows that the tare weight is activated. 6. The display indicates the net value of the weighed load..

Page 27

Section 3: operations 12/17 27 rev. 1 51412 7. Press the [ autotare ] key to change to gross weighing. 8. The instrument switches to gross weighing. 9. Pressing the [ autotare ] key again will switch the displayed weight back to net. 3.3.3 net weighing – manual tare 1. Raise empty forks off ground a...

Page 28

Section 3: operations 12/17 28 rev. 1 51412 3. Lower forks and lift the tare load. 4. Press the [ pt ] key for three (3) seconds. 5. Press the [ up ] or [ down ] key until the desired value is reached..

Page 29

Section 3: operations 12/17 29 rev. 1 51412 6. In this example, press the [ up ] key five times (5x) until the number 5 is reached. Once the value is reached, press the [ left ] key once (1x). 7. Press the [ up ] or [ down ] key until the desired value is reached. In the example, press the [ up ] ke...

Page 30

Section 3: operations 12/17 30 rev. 1 51412 9. Lower forks and lift load. 10. The net annuciator will light and the net weight will be displayed. 11. Press the [ autotare ] key to change to gross weighing. The instrument switches to gross weighing..

Page 31

Section 3: operations 12/17 31 rev. 1 51412 12. Pressing the [ autotare ] key again will switch the displayed weight back to net. When the forklift weighing assemblies are completely unloaded, the tare value is displayed as a negative. 3.3.4 accumulation 1. Raise empty forks off ground and level 2. ...

Page 32

Section 3: operations 12/17 32 rev. 1 51412 4. Press the [ total ] key to accumulate the weight. If a printer is installed, a printout will be made. The gross, tare and net weights are printed. The instrument will indicate the weight has been added to the accumulator by displaying added on the displ...

Page 33

Section 3: operations 12/17 33 rev. 1 51412 = reset total & print 3.3.5 check accumulation subtotal the subtotal can be checked by pressing the [ total ] key for 3 sec. The display will show the number of loads weighed and the subtotal of the accumulated weights. Press the [ c ] key to reset the sub...

Page 34

Section 3: operations 12/17 34 rev. 1 51412 3.3.6 piece counting - sampling 1. Raise empty forks off ground and level 2. Press the [ zero ] key 3. Press the [ sample ] key. 4. The units indication turns off and pcs illuminates..

Page 35

Section 3: operations 12/17 35 rev. 1 51412 5. Press the [ up/down ] key until the desired value is reached. (10 = default) 6. Add 10 pieces. The total weight of the pieces should be > 20 lbs. 7. Press the [enter] key for 2 secondsto save..

Page 36

Section 3: operations 12/17 36 rev. 1 51412 when the sampling is complete, the display will show the total number of pieces. 8. Press the [ c ] key for 1 sec. To return to the normal weighing mode. If the accuracy is too low, the display will show err05. Press any key to return to normal weighing mo...

Page 37

Section 3: operations 12/17 37 rev. 1 51412 2. The last used piece weight will be displayed. To accept the old value press the [ enter ] key or change the value until the required value is reached. 3. Press the [ left arrow ] to change the next digit. 4. Continue to press the [ up/down ] key and [le...

Page 38

Section 3: operations 12/17 38 rev. 1 51412 5. Press the [ enter ] key for 2 seconds. The display will show the total number of pieces. Press the [ ce ] key for 1 sec. To return to the normal weighing mode. 3.3.8 setting time and date on printout 1. Press the [ left arrow ] key for 8 seconds 2. The ...

Page 39

Section 3: operations 12/17 39 rev. 1 51412 3. Press the [ up/down ] key until the desired value is reached. 4. Press the [ left arrow ] key to change the next digit. 5. Press the[ up/down ] key until the desired value is reached..

Page 40

Section 3: operations 12/17 40 rev. 1 51412 6. To accept the new value press the [ enter ] key.. 7. Repeat the procedure to accept or change: • minute setting “m_00” • date of the month setting “da_00” • month setting “m_00” - the year setting “ye_00” 8. To accept the year setting press the [ enter ...

Page 41

Section 3: operations 12/17 41 rev. 1 51412 3.3.9 changing units press the key for 5 sec to toggle the units from lbs to kg and back. 3.3.10 user settings 1. Press the [ total ] key for up to10 sec. Or until “ a_off” appears in order to access the users menu settings..

Page 42

Section 3: operations 12/17 42 rev. 1 51412 this menu will permit setting of the auto shut-off, backlight, and communication ports. 2. Press the [ zero ] key for 3 sec. To save and exit the user menu settings. User settings- auto shut - off set the auto shut-off time (delay time in minutes) 0 min ...

Page 43

Section 3: operations 12/17 43 rev. 1 51412 set the backlight intensity (in %) 0 % = backlight is off • press the[ up/down ] key to select the backlight menu. • press the [ enter ] key to access the menu • press the [ up/down ] key to select the desired choice. • press the [ enter ] key to save th...

Page 44

Section 3: operations 12/17 44 rev. 1 51412 this port is fixed and cannot be disabled as it is tied to the fork weighing assemblies for bluetooth ® communications. User settings – com 2 enable/ disable enable com 2. • press the[ up/down ] key to select the com 2 menu. • press the [ enter ] key to ac...

Page 45

12/17 45 rev. 1 51412 section 4: forklift questionnaire – form 101474.

Page 46

Cp series forklift scale document 51412 manufactured by fairbanks scale, inc . 821 locust street kansas city, mo 64106 www.Fairbanks.Com.