- DL manuals

- Fairbanks

- Scales

- FB2250 Series

- Service manual

Fairbanks FB2250 Series Service manual

Summary of FB2250 Series

Page 1

2009-2017 by fairbanks scales, inc. 51213 all rights reserved rev. 19 08/2017 es fb2250 series instrument pc2250 pc software utility program service manual.

Page 3

08/17 3 rev. 19 51213 amendment record fb2250 series instrument document 51213 manufactured by fairbanks scales inc. 821 locust st. Kansas city, missouri 64106 created 3/2009 revision 1 03/2009 released manual revision 2 05/2009 added cc and etl approvals revision 3 06/2009 added mc approval revisio...

Page 4

08/17 4 rev. 19 51213 disclaimer every effort has been made to provide complete and accurate information in this manual. However, although this manual may include a specifically identified warranty notice for the product, fairbanks scales makes no representations or warranties with respect to the co...

Page 5

08/17 5 rev. 19 51213 table of contents section 1: general information ................................................................... 9 1.1. Model descriptions .................................................................................................. 9 1.2. Main product features ..........

Page 6

Table of contents 08/17 6 rev. 19 51213 6.1. 3550 tape printer ................................................................................................. 49 6.2. Tm-u220 tape printer ........................................................................................... 49 6.3. Okidata 18...

Page 7

Table of contents 08/17 7 rev. 19 51213 9.10. Clearing the accumulators .................................................................................. 106 9.11. Piece counting .................................................................................................... 106 9.12. Piece cou...

Page 8

Table of contents 08/17 8 rev. 19 51213 m. Programming the back light timing .................................................................... 138 n. Custom output .................................................................................................... 138 appendix iii: ascii chart......

Page 9

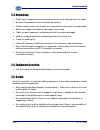

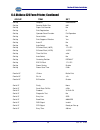

08/17 9 rev. 19 51213 section 1: general information 1.1. Model descriptions the fb2250 is a general purpose weighing instrument that can be used with a wide variety of platforms and load receivers, and is available in nine (9) different configurations. Model part no. • fb2250 series abs, ac power 2...

Page 10

Section 1: general information 08/17 10 rev. 19 51213 1.2. Main product features, continued • the pc2250 software utility program can also upload and modify the instruments set-up, configuration, and calibration. Saved information can be downloaded from a computer to the fb2250 series in the event o...

Page 11

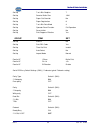

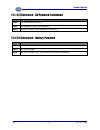

Section 1: general information 08/17 11 rev. 19 51213 1.3. Specifications, continued 1.3.3. Settings • zero range 2 % or 100% • auto zero tracking off, 0.5, 1 or 3 divisions • balance off, 0.5, 1 or 3 divisions • filter slow, cattle, standard, and fast • display update rate 0.2, 0.4, and 0.8 seconds...

Page 12

Section 1: general information 08/17 12 rev. 19 51213 1.3. Specifications, continued 1.3.7. Dc models, continued • internal battery • should be replaced every 12 months using panasonic cr 1220 3v or equivalent. 1.3.8. Out of range warnings • hicap scale input is over capacity • - - - - - - - display...

Page 13

Section 1: general information 08/17 13 rev. 19 51213 1.4. Accessories optional accessories include the following. Fieldbus devices • devicenet ™ • controlnet ™ • profibus ® -dp • modbus® • ethernet/ip 4-20 ma analog current loop output • 16 bit resolution and monotonicity • 0.01% non-linearity • is...

Page 14

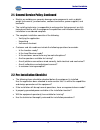

08/17 14 rev. 19 51213 section 2: installation 2.1. General service policy • prior to installation, it must be verified that the equipment will satisfy the customer's requirements as supplied, and as described in this manual. If the equipment cannot satisfy the application and the application cannot...

Page 15

Section 2: installation 08/17 15 rev. 19 51213 2.1. General service policy, continued • electric arc welding can severely damage scale components such as digital weight instruments, junction boxes, sectional controllers, power supplies, and load cells. • the installing technician is responsible to m...

Page 16

Section 2: installation 08/17 16 rev. 19 51213 2.3. Unpacking • check that all components and accessories are on hand, and agree with the order. • remove all components from their packing material. • check to make certain that all parts are accounted for and no parts are damaged. • advise the shippe...

Page 17

Section 2: installation 08/17 17 rev. 19 51213 2.6. Load cell connections 1. Remove the screws to gain access to the main printed circuit board inside the enclosure. – use caution to avoid pulling cables out of their connectors. 2. Bring the dressed end of the load cell cable through the strain reli...

Page 18

Section 2: installation 08/17 18 rev. 19 51213 2.7. Connections chart 4. Connect the platform interface cable wires to the terminal strip according to the following tables. Tb2 – load cell tb3 – ac output* pin description tb3 description 1 ( –) excitation 1 ac ac input 2 ( –) sense 2 acc acc input 3...

Page 19

Section 2: installation 08/17 19 rev. 19 51213 2.8. Cable distances no. Of cells resistance sense leads max distance cable gauge 4 350Ω no 25 feet awg 22 ( 17216 ) 4 350 Ω yes 100 feet awg 18 (17204) 8 350 Ω yes 50 feet awg 18 (17204) 4 1000 Ω no 25 feet awg 22 (17216) 4 1000 Ω yes 150 feet awg 18 (...

Page 20

Section 2: installation 08/17 20 rev. 19 51213 2.10. Battery installation stainless steel instrument 1. Unscrew the black plastic end caps. 2. Insert five (5 ) alkaline “d” cell batteries. Abs instrument 1. Unscrew the two large knurled screws on the back of the instrument 2. Remove the battery cove...

Page 21

08/17 21 rev. 19 51213 section 3: programming configuration 3.1. Entering program mode stainless steel nema 4x instrument remove the cover plate located at the lower right side of the enclosure and press the internal program switch . Abs instrument unscrew the plastic lockout plug located at the rea...

Page 22

Section 3: programming configuration 08/17 22 rev. 19 51213 3.2. Saving program changes • program changes are automatically saved upon exiting the program mode . • press the program switch to exit to the weigh mode . 3.3. Flow charts dashed line boxes used in the flowchart indicate that the menu ite...

Page 23

Section 3: programming configuration 08/17 23 rev. 19 51213 3.4. Front panel programming parameters follow these steps to program the instrument. 3.4.1. Programming and setting time 1. Press and hold the print key for three (3) seconds. 2. Current time format will display: • 12hr a – 12 hour clock, ...

Page 24

Section 3: programming configuration 08/17 24 rev. 19 51213 3.4.3. Display battery voltage 1. Press and hold the tare key for three (3) seconds. • the battery current or power supply voltage displays – 8.3 vdc nominal 2. When tare key is released, the fb2250 will return to the weight mode. 3.4.4. Pr...

Page 25

Section 3: programming configuration 08/17 25 rev. 19 51213 3.4.6. Display operating mode data note: these options are conditional upon programming the operating mode (see section 3.8 for details) 1. Press and hold the zero key for three (3) seconds. 2. Depending upon how the fb2250 was programmed i...

Page 26

Section 3: programming configuration 08/17 26 rev. 19 51213 3.4.7. Programming the 4-20ma analog output weighing mode setting up the 4-20 ma option depends on how it is enabled and configured. (see section 3.7.2 for details) 1. Press and hold units for three (3) seconds. 2. 4-20 displays, followed b...

Page 27

Section 3: programming configuration 08/17 27 rev. 19 51213 3.5. Setup menu programming parameters – version 2.0+ note: see appendix ii for versions 1.0-1.9 1. Press the internal program switch until setup displays. 2. Press the units key. * rs485 is selected when rs422 output is required. Reference...

Page 28

Section 3: programming configuration 08/17 28 rev. 19 51213 3.5.1. Programming time format 1. The current display format setting will display • 12hr a – 12 hour clock, currently am. • 12hr p – 12 hour clock, currently pm. • 24 hour – military time (1:00 pm = 1300 hours). 2. Press the zero key to edi...

Page 29

Section 3: programming configuration 08/17 29 rev. 19 51213 3.5.3. Programming port 1 1. Port 1 displays, followed by the current protocol setting. • off – com port is not active. • rs232 – using rs232 protocol • rs485 – using rs485 or rs422 protocol 2. Press zero key to edit, or units key to skip. ...

Page 30

Section 3: programming configuration 08/17 30 rev. 19 51213 3.5.5. Programming port 1 baud rate 1. Baud 1 displays, followed by the current baud rate setting. • 2400 • 4800 • 9600 • 19200 • 38400 • 57600 • 115200 2. Press zero key to edit, or units key to skip. • press the units key to scroll throug...

Page 31

Section 3: programming configuration 08/17 31 rev. 19 51213 3.5.8. Programming port 1 stop bits 1. Stop displays, followed by the current stop bits setting: • 1 • 2 2. Press zero key to edit, or units key to skip. • press the units key to scroll through available settings. • press zero key to select...

Page 32

Section 3: programming configuration 08/17 32 rev. 19 51213 3.5.11. Programming port 2 baud rate 1. Baud 2 displays, followed by the current baud rate setting. • 2400 • 4800 • 9600 • 19200 • 38400 • 57600 • 115200 2. Press zero key to edit, or units key to skip. • press the units key to scroll throu...

Page 33

Section 3: programming configuration 08/17 33 rev. 19 51213 3.5.14. Programming port 2 stop bits 1. Stop displays, followed by the current stop bits setting: • 1 • 2 2. Press zero key to edit, or units key to skip. • press the units key to scroll through available settings. • press zero key to selec...

Page 34

Section 3: programming configuration 08/17 34 rev. 19 51213 3.6. Configuration menu programming parameters.

Page 35

Section 3: programming configuration 08/17 35 rev. 19 51213 3.6. Configuration menu programming parameters, continued 1. Press the internal program switch until config is displayed. 2. Press the units key. 3.6.1. Programming the scale capacity 1 . Cap displays, followed by the current scale capacity...

Page 36

Section 3: programming configuration 08/17 36 rev. 19 51213 3.6.3. Programming the primary unit this option sets up the unit parameter for scale capacity, calibration, and the default unit when the instrument is powered up. 1. P-unit displays, and the current primary unit setting with a caret symbol...

Page 37

Section 3: programming configuration 08/17 37 rev. 19 51213 2. Press zero key to edit, or units key to skip. • press the units key to scroll through available settings. • press zero key to select an option. 3. When complete, the program will advance to programming the motion band. 3.6.6. Programming...

Page 38

Section 3: programming configuration 08/17 38 rev. 19 51213 2. Press zero key to edit, or units key to skip. • press the units key to scroll through available settings. • press zero key to select an option. 3. When complete, the program will advance to programming the tare setting. 3.6.9. Programmin...

Page 39

Section 3: programming configuration 08/17 39 rev. 19 51213 3.7. Application menu programming parameters 1. Press the internal program switch until app displays. 2. Press units key. 3.7.1. Microvolts per division x.Xx upd displays where x.Xx is the current microvolts per division for the fb2250. 3.7...

Page 40

Section 3: programming configuration 08/17 40 rev. 19 51213 3.7.3. Programming the piece count feature 1. The current piece count setting displays: • pct n – feature is disabled (no) • pct y – feature is active (yes) 2. Press zero key to edit, or units key to skip. • press the units key to scroll th...

Page 41

Section 3: programming configuration 08/17 41 rev. 19 51213 3.8. Operating mode notes: see section 3.7 for programming settings. See section 9 for operation details..

Page 42

08/17 42 rev. 19 51213 section 4: calibration 4.1. Standard calibration important notes: • in the two following procedures, the fb2250 keypad and the pc2255 utility keyboard operations can be interchanged. • pressing the print key will terminate the calibration process and restore the previous calib...

Page 43

Section 4: calibration 08/17 43 rev. 19 51213 c. The next digit will then blink, operate the units key to increment the number. D. Repeat steps b and c until all digits have been accepted. 8. The display will indicate the test weight value . At this time, you can accept the calibration by pressing t...

Page 44

Section 4: calibration 08/17 44 rev. 19 51213 note: the newly displayed value for the current test weight may not be consistent with the entered value. 7. Press the internal program switch at any point in the process to exit the sequence. • the microvolts per division (i.E. “ 2.91upd ”) will display...

Page 45

Section 4: calibration 08/17 45 rev. 19 51213 4. Replace the access plate , tightening the screws to 18 +/- 2 in-lbs. Torque value. 4.3.3. Ip69k and panel mount instrument 1. Unfasten the four (4) screws and remove the rear cover . 2. Thread the lead seal wire through the hole in the screws. 3. Crim...

Page 46

08/17 46 rev. 19 51213 section 5: serial communication wiring 5.1. Jp3 jumper configuration) * port should be set to rs485. Note: 120 ohm termination resistors are required if the receiver is the last node on the network. Jp3 rs232 rs485 rs422* port 1-2 out 120 ohm resistor 120 ohm resistor com1 3-4...

Page 47

Section 5: serial communication wiring 08/17 47 rev. 19 51213 5.2. Tb2 load cell tb2 load cell 1 ( –)excitation 5v 2 ( –)sense 3 (+) excitation 4 (+) sense 5 shield 6 (+) signal 7 ( –) signal jp7 (+) sense shorting link jp8 ( –) sense shorting link 5.3. Tb3 wiring connections, ac input 1 ac ac input...

Page 48

Section 5: serial communication wiring 08/17 48 rev. 19 51213 5.5. Tb5 remote switch inputs 1 ground 2 ground 3 ground 4 print connect to ground to perform programmed print function 5 tare connect to ground to tare off gross weight 6 b/g net connect to ground to select gross/tare displays 7 zero con...

Page 49

08/17 49 rev. 19 51213 section 6: printer installation 6.1. 3550 tape printer transmission rs232 baud rate 9600 data bits 8 stop bit 1 output “button” for print key 6.2. Tm-u220 tape printer this is the tm-u220 tape printer (non-dat, white case). Transmission rs232 baud rate 9600 data bits 8 stop bi...

Page 50

Section 6: printer installation 08/17 50 rev. 19 51213 6.3. Okidata 186 t form printer follow these steps to change menu settings. 1. To enter menu mode, press and hold select while turning on the printer. – the “12” and “ utility” leds will blink. 2. With the printer in the menu mode , press select...

Page 51

Section 6: printer installation 08/17 51 rev. 19 51213 6.3. Okidata 186 form printer, continued – the settings are the right-hand column on the menu printout . 6. To continue making changes: press line feed for the next group or press form feed for the next item. – repeat as needed until finished ch...

Page 52

Section 6: printer installation 08/17 52 rev. 19 51213 set-up 7 or 8 bits graphics 7 set-up receive buffer size 128k set-up paper out override no set-up paper registration 0 set-up 7 or 8 bits data word 8 set-up operator panel function full operation set-up reset inhibit no set-up print suppress eff...

Page 53

Section 6: printer installation 08/17 53 rev. 19 51213 6.3. Okidata 186 form printer, continued test select switch 5 (sw1) ** circuit on monitor off mode select switch 6 (sw1) ** print mode on test mode off busy line selection switch 7, 8 (sw1) ssd- pin 11 off, on ssd+ pin 11 off, off ** dtr- pin 20...

Page 54

Section 6: printer installation 08/17 54 rev. 19 51213 6.4. Okidata 420 form printer program the fb2250 the following settings. Transmission rs232 baud rate 9600 data bits 8 stop bit 1 output “button” for print key note: always restart the printer after making any switch changes. 1. To enter menu mo...

Page 55

Section 6: printer installation 08/17 55 rev. 19 51213 6.4. Okidata 420 form printer, continued note: if the printer is turned off before exiting the menu mode , all changes will be lost. Group item set (press line feed (press form feed (press tof set to change) to change) to change) printer control...

Page 56

Section 6: printer installation 08/17 56 rev. 19 51213 6.4. Okidata 420 form printer, continued group item set set-up graphics unidirectional set-up receive buffer size 64k set-up paper out override no set-up print registration 0 set-up operator panel function full operation set-up reset inhibit no ...

Page 57

Section 6: printer installation 08/17 57 rev. 19 51213 6.5. Tm-u295 ticket printer transmission rs232 baud rate 9600 data bits 8 stop bit 1 output “button” for print key set the dip switches to the following. • 1 and 3 are on . • the rest are off . Note: always restart the printer after making any s...

Page 58

Section 6: printer installation 08/17 58 rev. 19 51213 6.7. 1600 series remote display using the 20 ma serial current loop output will allow transmission distances up to 1000 cable feet . – interface cable ( 20903 ) is recommended. Port 2 protocol c-loop baud rate 9600 data bits 8 parity none stop b...

Page 59

Section 6: printer installation 08/17 59 rev. 19 51213 6.8. Fb2250 remote display fb2250 (master) fb2250 (remote) port 1 or 2 1 protocol rs232 rs232 baud rate 9600 9600 data bits 8 8 parity none none stop bit 1 1 output type poll rd2250 • see sections starting at 3.5.3 for port 1 configuration progr...

Page 60

08/17 60 rev. 19 51213 section 7: accessories 7.1. 4-20 ma analog output • sixteen (16) bit resolution and monotonicity • 0.01% non-linearity • front panel programmable or using a pc2250 utility software program • passive (does not supply the voltage for the current loop) 7.1.1. Requirements • exter...

Page 61

Section 7: accessories 08/17 61 rev. 19 51213 when the customer’s device is passive, an auxiliary power supply can be used to supply the voltage for the current loop. Output conditions fb2250 condition 4-20 ma analog output weight behind zero 3.5 ma weight below 4.20 lo 3.5 ma weight at 4.20 lo 4.0 ...

Page 62

Section 7: accessories 08/17 62 rev. 19 51213 1. Press and hold the units key for three (3) seconds. 2. The display will show 4-20 , followed by the current setting. A. Gross b. Net 3. (a)to keep the current setting, press the units key. 3. (b) to change the setting: a. Press the zero key b. Then us...

Page 63

Section 7: accessories 08/17 63 rev. 19 51213 7.2. Fieldbus installation fieldbus is a general term that describes an all-digital two-way communications system that interconnects measurement and control equipment such as sensors, actuators and controllers. – fieldbus traces its beginnings in the aut...

Page 64

Section 7: accessories 08/17 64 rev. 19 51213 7.3. Fieldbus connections the term fieldbus usually describes an all-digital two-way communications system that interconnects measurement and control equipment such as sensors, actuators and controllers. 7.3.1. Overview of terms there are currently five ...

Page 65

Section 7: accessories 08/17 65 rev. 19 51213 ethernet/ip can be easily confused as a simple combination of ethernet and the internet protocol. Instead, it is an industrial application layer protocol used for communication between industrial control systems and their components. – such components in...

Page 66

Section 7: accessories 08/17 66 rev. 19 51213 7.3.2. Devicenet ™ ( 29578 ), continued additional information available for devicenet ™ information and eds files: http://www.Anybus.Com/support/support.Asp?Pid=324&producttype=anybus- compactcom network status led module status led state indication off...

Page 67

Section 7: accessories 08/17 67 rev. 19 51213 7.3.3. Controlnet ™ ( 31979 ) controlnet is an open control network running in “real-time”, for high-throughput applications. – it uses a control and information protocol ( cip ), combining the functionality of an i/o network and a peer-to-peer network. ...

Page 68

Section 7: accessories 08/17 68 rev. 19 51213 7.3.3. Controlnet ™ ( 31979 ), continued network status module status led state indication a and b off not online / no power flashing red (1 hz) incorrect node configuration, duplicate mac id etc. Alternating red/green self test of bus controller red fat...

Page 69

Section 7: accessories 08/17 69 rev. 19 51213 7.3.4. Profibus®-dp ( 29576 ) profibus-dp is one of the best-known industrial fieldbus protocols from europe. – it is an established standard, used in a wide range of applications as a multi-application communications link for industrial devices. – the p...

Page 70

Section 7: accessories 08/17 70 rev. 19 51213 7.3.4. Profibus®-dp ( 29576 ), continued operation mode led modular status led additional information available for profibus®-dp information and gsd files: http://www.Anybus.Com/support/support.Asp?Pid=321&producttype=anybus- compactcom led state descrip...

Page 71

Section 7: accessories 08/17 71 rev. 19 51213 7.3.5. Modbus tcp (34032) modbus ( 34032 ) tcp was originally developed in 1978 to exchange information between devices on the factory floor. • it developed into the standard for exchanging data and communication module status information between plc sys...

Page 72

Section 7: accessories 08/17 72 rev. 19 51213 7.3.5. Modbus tcp ( 34032 ), continued device status led modbus-tcp interface additional information available for modbus®-tcp information and gsd files: http://www.Anybus.Com/support/support.Asp?Pid=458&producttype=anybus- compactcom led state indicatio...

Page 73

Section 7: accessories 08/17 73 rev. 19 51213 7.3.6. Ethernet/ip diagnostic leds the ethernet/ip module uses dynamic addressing. – dynamic host configuration protocol ( dhcp ) is used for address requests. – the data is transmitted continuously from this module. – the ip address may be made static b...

Page 74

Section 7: accessories 08/17 74 rev. 19 51213 7.4. Bluetooth ® technology device the bluetooth ® option replaces direct wiring between two devices. – the bluetooth ® interface uses either port 1 or port 2 serial output . – rs232 serial interface to bluetooth ® interface with a range of 100 meters (3...

Page 75

Section 7: accessories 08/17 75 rev. 19 51213 7.4. Bluetooth ® technology device, continued set the 4-position dip switch on each device as shown below. Follow these steps to installing the bluetooth ® devices . 1. Turn on both bluetooth ® devices with the slide switch on their sides. 2. Press the r...

Page 76

Section 7: accessories 08/17 76 rev. 19 51213 7.4. Bluetooth ® technology device, continued 5. Turn device #1 off, and then back on . – the connect led light blinks green twice every three (3) seconds. 8. Turn device #2 off, and then back on . 9. The connect led light blinks green once every second....

Page 77

08/17 77 rev. 19 51213 section 8: pc2250 utility software 8.1. Introduction the pc2250 utility software program can be used to set up and configure the fb2250. It is required in order to program certain features such as custom units and custom ticket vector programming. The fb2250 uses port 2 to com...

Page 78

Section 8: pc2250 utility software 08/17 78 rev. 19 51213 8.3. Communication settings, continued 3. Access the com port settings of the computer by pressing f2 . 4. Configure the com port connected to the fb2250 via the pop-up menu to match the settings in table 1 above. 5. Close the pop-up menu whe...

Page 79: Pc2250\saved.

Section 8: pc2250 utility software 08/17 79 rev. 19 51213 8.4. Communication files the default folder for all saved/uploaded parameter files is pc2250\saved. 8.5. Menu bar the pc2250 menu bar is located at the bottom of the display. 1. Press the upload button to retrieve the current fb2250settings t...

Page 80

Section 8: pc2250 utility software 08/17 80 rev. 19 51213 8.5. Menu bar, continued 3. When the process is complete, click ok . 4. Click the download button to retrieve the current pc2250 settings to the fb2250. The fb2250 displays “pc” . 5. Press the internal programming switch. 6. When complete, cl...

Page 81

Section 8: pc2250 utility software 08/17 81 rev. 19 51213 8.6. Configuration 1. Press f4 to enter the parameters editor . Use one of the following methods that apply to programming the features. • click on the data item to highlight it, then type in the replacement data. • click the drop down arrow ...

Page 82

Section 8: pc2250 utility software 08/17 82 rev. 19 51213 8.7. Calibration settings from this window include the following input and drop-down options. • scale capacity • primary units • auto zero tracking (azt) • motion band (bal) • division size • digital filter • auto tare settings actual test we...

Page 83

Section 8: pc2250 utility software 08/17 83 rev. 19 51213 4. Click f4 to open the configuration window. 5. Select the ip connection tab. 6. Click the tcp configuration utility button. 7. The neteon utility will open. 8. The default ip (10.10.50.100 or 10.0.50.100) of the ethernet device should show....

Page 84

Section 8: pc2250 utility software 08/17 84 rev. 19 51213 10. Select the config button. A new dialog box will open. 11. Obtain network setting details from the customer's it personnel and enter the information in the dialog box. A. Note: auto ip sets the card to dhcp 12. Set the user id and password...

Page 85

Section 8: pc2250 utility software 08/17 85 rev. 19 51213 17. The overview window will open showing the current addresses and settings for the ethernet card. 18. If additional network configuration is required, click the networking link. 19. To change the password , click the security link. 20. Do n...

Page 86

Section 8: pc2250 utility software 08/17 86 rev. 19 51213 23. Return to the pc225x utility and select the ip connection tab. 24. If the select button is available, proceed to the next step, if it is not click on the edit button then proceed to the next step. 25. In the configuration field, enter a h...

Page 87

Section 8: pc2250 utility software 08/17 87 rev. 19 51213 8.9. Fieldbus the anybus module is set up using the pc2250 program and configures the following parameters listed below. The fb2250 will automatically detect the anybus module installed. No additional programming is required except the follow...

Page 88

Section 8: pc2250 utility software 08/17 88 rev. 19 51213 8.9. Fieldbus, continued data type data can be setup to output a 32 bit integer word or a 32 bit floating point value . Endian the endianess of a module is determined by the network type, but can be changed from little endian to big endian, o...

Page 89

Section 8: pc2250 utility software 08/17 89 rev. 19 51213 8.9. Fieldbus, continued output data from the fb2250 comprises of three (3) 32-bit words. • gross weight • tare weight • a 32bit status word • gross and tare weights can be selected as either a 32-bit integer or a 32-bit floating point word ....

Page 90

Section 8: pc2250 utility software 08/17 90 rev. 19 51213 8.9. Fieldbus, continued recognized commands command description print steam see custom format pc2250. Print format stream cr, space, stx, enq or defined poll character tare “a” print ticket “p” or “p” zero “z” change gross net weight mode “g...

Page 91

Section 8: pc2250 utility software 08/17 91 rev. 19 51213 8.10. 4-20 ma, continued enable 4-20ma – from the drop down menu, select yes to enable the output. Low weight – enter the weight value which represents the 4ma output signal. High weight – enter the weight value which represents the 20ma outp...

Page 92

Section 8: pc2250 utility software 08/17 92 rev. 19 51213 8.12. Custom output – load a variety of pre-packaged output strings is available. 1. Click the radio button that applies. ✓ default = fairbanks note: plc is no longer used and not a valid selection. 10. Click ok to down load the settings, or ...

Page 93

Section 8: pc2250 utility software 08/17 93 rev. 19 51213 8.14. Custom output – tokens 1. Select from a wide variety of different characters for the polling character. • start • stop • block • primary units • secondary units • weighing mode • motion • capacity characters 12. When entering a characte...

Page 94

Section 8: pc2250 utility software 08/17 94 rev. 19 51213 8.14. Custom output – tokens, continued 1. Make a selection, such as , for example. – this inserts a start of header character… otherwise known as a ctrl/a , or 0x01 hex . 14. When entering a character not listed, select entry . 15. Select en...

Page 95

Section 8: pc2250 utility software 08/17 95 rev. 19 51213 8.16. Formatting tickets • formatting tickets is easily performed with this drag and drop interface. • the blue-dashes indicate the printable area of the ticket based on the ticket size and margins entered (by the user or by default). 1. Clic...

Page 96

Section 8: pc2250 utility software 08/17 96 rev. 19 51213 8.17. Printed examples accumulation field count1 count2 peak wt gr acc nt acc visible cnt gr cnt nt no yes yes top 14 16 0 20 22 left 2 2 0 2 2 * see 9.8 weight accumulation (in operation) here you see a sample ticket with 4 gross accumulatio...

Page 97

Section 8: pc2250 utility software 08/17 97 rev. 19 51213 piece count field time date gross tare net count1 count2 visible yes yes yes yes yes piece piece top 2 2 6 8 10 14 16 left 2 13 7 7 7 7 7 * see section 9.11. Piece counting (in operation) container weighs 5.0 lb. 5 pieces weigh 1.0 lb pieces ...

Page 98

Section 8: pc2250 utility software 08/17 98 rev. 19 51213 piece count & total field time date gross tare net count1 count2 visible yes yes yes yes yes piece piece top 2 2 6 8 10 14 16 left 2 13 7 7 7 7 7 * see section 9.12. Piece count & total (in operation) container weighs 5.0 lb. 5 pieces weigh 1...

Page 99

08/17 99 rev. 19 51213 section 9: operation 9.1. Front panel key functions note: installing a jumper at j6, located at the upper-right corner of the main pcb assembly, will disable the on/off switch. This is not recommended in battery powered applications. On/off turns the instrument on or off. Unit...

Page 100: Working Example

Section 9: operation 08/17 100 rev. 19 51213 9.2. Operating procedures 1. Press and hold the on / off key for two (2) seconds. – the instrument will display “888888” , followed by “1234567890” character display moving from right-to-left, then the revision of software. – once the warm-up is complete,...

Page 101

Section 9: operation 08/17 101 rev. 19 51213 9.4. Basic weighing follow these steps for basic weighing. 1. Empty the platform. 17. Turn the scale on . 18. Press zero . – when the display indicates “0”, it is ready for use. 9.5. Gross weighing follow these steps for gross weighing. 1. Unload the scal...

Page 102

Section 9: operation 08/17 102 rev. 19 51213 9.7. Gross/tare/net weighing 1. Unload the scale. 2. Press the zero key, if required, to set scale to “0”. 3. Place container/object on scale. 4. Press tare key. 5. Place material in container or add objects. 6. Note the net weight on the display. The car...

Page 103

Section 9: operation 08/17 103 rev. 19 51213 at this point pressing the print key will output the following, assuming you have cnt gr, cnt nt, gr acc and nt acc enabled to print: (see section 8.8: first time connection using the pc225x pc utility and fb225x ethernet tcp/ip option for further instruc...

Page 104

Section 9: operation 08/17 104 rev. 19 51213 7. Press the units key to accept the weight, display will momentarily indicate “ accept ”, and return to the weigh screen. Or press the b/g net key to skip and return to the weigh screen. At this point pressing the print key will output the following, ass...

Page 105

Section 9: operation 08/17 105 rev. 19 51213 9.9. Number of accumulations 1. Press and hold the zero key for three (3) seconds. The display will alternate between the number of gross weight accumulations "n" and the total gross weight accumulated for thirty (30) seconds, then return to the weigh mod...

Page 106

Section 9: operation 08/17 106 rev. 19 51213 9.10. Clearing the accumulators the accumulator(s) to be cleared depend on whether the operating mode is programmed to accumulation, peak weight, or piece count and total . (see section 3.7 for details) • press and hold the bg/net key for three (3) second...

Page 107

Section 9: operation 08/17 107 rev. 19 51213 9.12. Piece count and total note : for the following operation to function: • the piece count parameter “pct” must be set to “y” (see section 3.7.3), the accumulator parameter “acc” must be set to “y” (see section 3.7.4) and the peak hold parameter “p-hol...

Page 108

Section 9: operation 08/17 108 rev. 19 51213 9.13. Peak weight note : for the following operation to function: • peak hold paramete r “p-hold” must be set to “y” (see section 3.7.5), the piece count parameter “pct” must be set to “n” (see section 3.7.3) and the accumulator parameter “acc” must be se...

Page 109

08/17 109 rev. 19 51213 section 10: service and maintenance 10.1. Troubleshooting the instrument display symptom resolution error • possible bad battery or power loss • program error • replace the pcb. • replace battery • see below, 10.2 error reset. No display no power • check ac input • check batt...

Page 110

Section 10: service & maintenance 08/17 110 rev. 19 51213 10.3. Testing the 4-20 ma analog component follow these steps to test the 4-20 ma analog component. 1. Remove the four (4) screws fastening the back of the instrument and open it. 19. Connect the multimeter in series with the 4-20 ma analog o...

Page 111

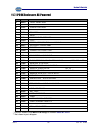

08/17 111 rev. 19 51213 section 11: parts list 11.1. S/s enclosure - ac powered no. Part description 1 28913 enclosure 2 33558 main pcb assy* 3 15131 power cord assy 4 27739 instrument stand 6 15745 instrument stand knobs 7 12621 instrument stand knob washers 8 12103 instrument stand feet 9 11138 sc...

Page 112

Section 11: parts list 08/17 112 rev. 19 51213 11.1. S/s enclosure - ac powered, continued.

Page 113

Section 11: parts list 08/17 113 rev. 19 51213 11.1. S/s enclosure - ac powered, continued part description 16006 program access plate 16007 program access plate gasket 13468 sealing screws (program access plate) 11.2. S/s enclosure - battery powered part description 29265 battery accessory 28914 ba...

Page 114

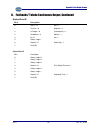

Section 11: parts list 08/17 114 rev. 19 51213 11.3. Abs enclosure - ac powered no. Part description 1 29267 enclosure , front 2 29268 enclosure, middle 3 33558 main pcb assy, fb2250* 4 13475 power cord 5 29244 bracket, instrument 6 20324 knob 7 12621 washer, retainer 8 20190 foot, rubber 10 29236 k...

Page 115

Section 11: parts list 08/17 115 rev. 19 51213 11.4. Abs enclosure, parts diagram.

Page 116

Section 11: parts list 08/17 116 rev. 19 51213 11.5. Abs enclosure - battery powered no. Part description 1 29269 battery compartment cover 2 29397 battery holder – 2 “d” cell – factory wired 3 29396 battery holder – 3 “d” cell – factory wired 5 29218 cable assy 6 29219 cable assy 7 11286 4 in. Tubi...

Page 117

Section 11: parts list 08/17 117 rev. 19 51213 11.6. Accessories part description 31979 controlnet ® acc complete 28697 pcb assy, anybus ® 29864 controlnet ® module 29576 profibus ® -dp complete 28697 pcb assy, anybus ® 29575 profibus ® -dp module 29578 devicenet ™ acc complete 28697 pcb assy, anybu...

Page 118

Section 11: parts list 08/17 118 rev. 19 51213 11.7. Ip69k enclosure ac powered no. Part description 1 29010 front panel assy 2 33558 pcb assy, fb2250 * 3 15131 power cord assy 4 27739 bracket, instrument 5 29009 box assy 6 15745 knob 7 12621 knob washer, retainer 8 12103 foot 9 11138 screw, mach, p...

Page 119

Section 11: parts list 08/17 119 rev. 19 51213 11.7. Ip69k enclosure ac powered, continued.

Page 120

Section 11: parts list 08/17 120 rev. 19 51213 11.8. Panel mount enclosure ac powered part description 29802 panel mounting fb2250 15718 outer gasket, 1.00 wide x .19 thick 29011 keyboard, fb2250 ip69k 29007 inner gasket 14083 screw, sealing 25355 vent, membrane 25356 nut, vent.

Page 121

08/17 121 rev. 19 51213 appendix i: data output formats a. General notes = means carriage return character = line feed character = space character = end of transmission character …> = used to indicate individual characters for clarity only (not present in data stream) power must be cycled after each...

Page 122

Appendix i: data output formats 08/17 122 rev. 19 51213 b. Fairbanks/ toledo continuous output, continued character string description stx start of text character : (02 hex) a status word a b status word b c status word c xxxxxx displayed weight : x = weight (6 characters if grad size does not have ...

Page 123

Appendix i: data output formats 08/17 123 rev. 19 51213 b. Fairbanks/ toledo continuous output, continued status word b bit # description 0 gross = 0 net = 1 1 positive = 0 negative = 1 2 in range = 0 overcapacity = 1 3 no motion = 0 motion = 1 4 lb = 0 kg = 1 5 always logic 1 6 normal = 0 power up ...

Page 124

Appendix i: data output formats 08/17 124 rev. 19 51213 c. Cardinal 738 continuous scoreboard output w = displayed weight p = polarity + = positive weight - = negative weight u = units lb = pounds kg = kilograms m = motion or o = overload g = gross; n = net sp = space leading zeroes are not suppress...

Page 125

Appendix i: data output formats 08/17 125 rev. 19 51213 e. Condec continuous output p = polarity space = positive weight - = negative weight w = displayed weight u = units l = pounds k = kilograms g = gross; n = net m = motion leading zeroes are suppressed f. Demand output - default activated by the...

Page 126

Appendix i: data output formats 08/17 126 rev. 19 51213 g. Continuous output - default outputs once every display update rate cycle. Continuous output formatted output. Same for poll and auto gross weight – no motion – decimal points included gross weight – motion – decimal points included net weigh...

Page 127

Appendix i: data output formats 08/17 127 rev. 19 51213 h. Plc (do not use) the plc selection is no longer functional within the pc2250 software and should not be used or selected. General information the information below is automatically configured by the fb2250 and is provided as supplemental inf...

Page 128

Appendix i: data output formats 08/17 128 rev. 19 51213 i. Ups • serial data output format for ups worldship software . The instrument will transmit the following string of data. Character number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 string 1 gross weight: x x x x . X x sp l/k b/g sp g/g r/r ...

Page 129

Appendix i: data output formats 08/17 129 rev. 19 51213 j. P ship • serial data output format for p ship, used to interface to fedex shipping programs. All computer commands and scale responses are ascii character strings , where: is an ascii carriage return (hexadecimal 0d) is an ascii line feed (h...

Page 130

Appendix i: data output formats 08/17 130 rev. 19 51213 j. P ship, continued 3. Uu = a two character weight identifier. If the scale is configured to weigh kilograms, a "kg" (uppercase letters) will be returned, if configured for pounds, "lb" (uppercase letters) will be returned. 4. The decimal poin...

Page 131

08/17 131 rev. 19 51213 appendix ii: setup menu programming – ver. 1.0 – 1.9 1. Press the internal program switch until setup displays. 1. Press the units key. * rs485 is selected when rs422 output is required. Reference wiring and jumper connections in section 5: serial communication wiring ..

Page 132

Appendix ii: setup menu programming – ver. 1.0 – 1.9 08/17 132 rev. 19 51213 a. Programming time format follow these steps to program the instrument. 1. Press and hold the print key for three (3) seconds. 2. Press the zero key. 3. Press the units key to toggle through the available selections. 4. Pr...

Page 133

Appendix ii: setup menu programming – ver. 1.0 – 1.9 08/17 133 rev. 19 51213 b. Programming the date • set-da displays , followed by the current date setting. • date is entered in the mm-dd-yy format. 1. Press zero . 2. The first two digits will blink. 3. Press the units key to increment to the desi...

Page 134

Appendix ii: setup menu programming – ver. 1.0 – 1.9 08/17 134 rev. 19 51213 d. Programming the output type output displays, followed by the current setting. 1. Press zero , then the units key to scroll through available output type settings, 2. Press zero to enter the selection. Available selection...

Page 135

Appendix ii: setup menu programming – ver. 1.0 – 1.9 08/17 135 rev. 19 51213 e. Programming the port 1 baud rate baud 1 displays, followed by the current setting. 1. Press zero . 2. Press units to scroll through available settings. 3. Press zero to enter the selection. Available selections include t...

Page 136

Appendix ii: setup menu programming – ver. 1.0 – 1.9 08/17 136 rev. 19 51213 h. Programming port 2 port 2 displays, followed by the current setting. 1. Press zero . 2. Press units to scroll through available settings. 3. Press zero to enter the selection. Available selections include the following. ...

Page 137

Appendix ii: setup menu programming – ver. 1.0 – 1.9 08/17 137 rev. 19 51213 k. Programming port 2 stop bits stop displays, followed by the current setting. 1. Press zero . 2. Press units to scroll through available settings. 3. Press zero to enter the selection. Available selections include the fol...

Page 138

Appendix ii: setup menu programming – ver. 1.0 – 1.9 08/17 138 rev. 19 51213 m. Programming the back light timing blt x displays, followed by the current setting. – this is the time (in seconds) that the back light remains illuminated . 1. Press zero . 2. Press units to scroll through available sett...

Page 139

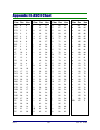

08/17 139 rev. 19 51213 appendix iii: ascii chart char dec hex nul 0 0 soh 1 1 stx 2 2 etx 3 3 eot 4 4 enq 5 5 ack 6 6 bel 7 7 bs 8 8 ht 9 9 lf 10 a vt 11 b ff 12 c cr 13 d so 14 e si 15 f dle 16 10 dc1 17 11 dc2 18 12 dc3 19 13 dc4 20 14 nak 21 15 syn 22 16 etb 23 17 can 24 17 em 25 19 sub 26 1a es...

Page 140

08/17 140 rev. 19 51213 appendix iv: keypad schematic.

Page 141

08/17 141 rev. 19 51213 appendix v: battery conversion kit the battery accessory for the fb2250 stainless steel models come completely assembled at the factory. To install, replace the back cover with the battery accessory and connect the cable assembly header to j4-j5 on the main pcb assembly . Abs...

Page 142

08/17 142 rev. 19 51213 appendix vi: remote pc commands transmitting certain ascii characters to the fb2250 will duplicate a key-press from a remote location via the rs232 serial connection to port 1. The baud rate, parity, and stop bits must match. The data bit length is 8 bits. Ascii character fun...

Page 143

Appendix vi: remote pc commands 08/17 143 rev. 19 51213 example "12345 lb gr" or "12345 lb nt". C (lower case) active in the polled or continuous modes if the instrument is in the polled mode the output will be the same as if a carriage return was received. The output will be transmitted when the di...

Page 144

08/17 144 rev. 19 51213 appendix vii: wiring for main pcb (24800) a. Jp3 jumper configuration jp3 rs232 rs485 rs422* port 1-2 out 120 Ω resistor 120 Ω resistor com1 3-4 out in out com1 5-6 out in out com1 7-8 out in out com2 9-10 out in out com2 11-12 out 120 Ω resistor 120 Ω resistor com2 120 ohm t...

Page 145

Appendix viii: fb2250 remote display wiring 08/17 145 rev. 19 51213 rs232 interface wiring (master) fb2250/55 remote display fb2250* remote display model com connect com connect com connect fb2200 (abs) 1 3 tx 1 tb4(a)-1 rx 1 tb4-1 rx 1 5 gnd 1 tb4(a)-4 gnd 1 tb4-4 gnd fb2200 (ss) 1 3 tx 1 tb4(a)-1 ...

Page 146

08/17 146 rev. 19 51213 appendix ix: calibration (28600) early models a. Single point calibration single point calibration is the basic, standard technique. Shown below is a flow chart that highlights this process..

Page 147

Appendix ix: calibration early models 08/17 147 rev. 19 51213 b. Multi-point calibration the fb2250 includes a multi-point calibration procedure which can correct linearity errors. – calibration can selectively be performed using one, two, three, or all four calibration points. – the multipoint cali...

Page 148

Appendix ix: calibration early models 08/17 148 rev. 19 51213 b. Multi-point calibration, continued.

Page 149

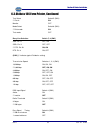

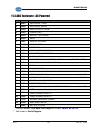

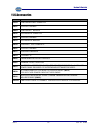

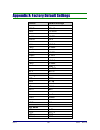

08/17 149 51213 rev. 19 appendix x: factory default settings fb2250 default settings setup menu setup 12hr p set-ti 12:00:00 set-da 01.01.13 port 1 rs 232 output ups baud 1 9600 d-bits data 7 parity p none stop bits stop 2 port 2 rs 232 output p ship baud 2 9600 d-bits data 8 parity p none stop bits...

Page 150

Fb2250 series instrument fb2250/ pc 2250 document 51213 fairbanks scales inc. 821 locust st. Kansas city, mo 64106 www.Fairbanks.Com.