- DL manuals

- Fairbanks

- Accessories

- FB3000 II Series

- Service Manual

Fairbanks FB3000 II Series Service Manual - 7.2.3.

Section 7: Input/ Output (I/O)

02/10

100

51217 Rev. 1

7.2.3.

Kernel Setup for

VSPD Ports, Continued

4. Open the

Load

tab.

5. Select the

COM Port

to be

configured.

6. Sect the appropriate

Load

Default.

7. Press the button.

8. Open the

Port Settings

tab.

9. Select one of the

COM Ports

configured in the VSPD to be

configured in the Kernel.

10. Select the appropriate

Baud

Rate, Parity Setting, Data

Bits,

and

Stop Bits

rate.

The VSPD Communication Settings for the Kernel are complete The

application or program will utilize the other COM Port configured in

VSPD as the application or programs input COM port.

Summary of FB3000 II Series

Page 1

51217 © 2010 by fairbanks scales, inc. Revision 1 02/10 all rights reserved fb3000 ii series instrument the next generation with intalogix ™ technology service manual.

Page 3

02/10 3 51217 rev. 1 amendment record fb3000 ii document 51217 manufactured by fairbanks scales inc. 821 locust kansas city, missouri 64106 created 12/2009 revision 1 02/2010 documentation release.

Page 4

02/10 4 51217 rev. 1 © copyright 2010 this document contains proprietary information protected by copyright. All rights are reserved; no part of this manual may be reproduced, copied, translated or transmitted in any form or by any means without prior written permission of the manufacturer. Trademar...

Page 5

02/10 5 51217 rev. 1 advanced weighing systems, inc. License agreement for interact® version 4 – 5 advanced weighing systems, inc. ("aws") is willing to license the software identified below to you (either an individual or a single business entity, hereafter "you" or "licensee") only upon the condit...

Page 6

02/10 6 51217 rev. 1 6. Limitation of liability. To the extent not prohibited by law, in no event will aws or its licensors or suppliers be liable for any lost revenue, profit or data, or for special, indirect, consequential, incidental or punitive damages, however caused regardless of the theory of...

Page 7

02/10 7 51217 rev. 1 12. Trademarks and logos. You acknowledge and agree as between you and aws that aws owns the aws and interact trademarks and all aws and interact-related trademarks, service marks, logos and other brand designations ("aws marks"), and you agree to comply with the aws trademark a...

Page 8

02/10 8 51217 rev. 1 table of contents section 1: general information ................................................................ 14 1.1. Introduction.............................................................................................................. 14 1.1.1. The fb3000 ii .............

Page 9

Table of contents 02/10 9 51217 rev. 1 3.5. Option d: conversion of an existing mettler–toledo digitol ™ system.............. 48 3.5.1. Dressing the wires ............................................................................................................ 48 3.5.2. Wiring the connections.......

Page 10

Table of contents 02/10 10 51217 rev. 1 7.3. Configure output ................................................................................................... 101 7.3.1. Introduction .....................................................................................................................

Page 11

Table of contents 02/10 11 51217 rev. 1 9.5. The high speed check mode ............................................................................... 153 9.5.1. High speed check mode configuration .......................................................................... 154 9.6. Service options .....

Page 12

Table of contents 02/10 12 51217 rev. 1 11.9. Memory................................................................................................................. 211 11.8.1. Installing memory............................................................................................................

Page 13

Table of contents 02/10 13 51217 rev. 1 appendix ii: system resource..................................................................... 242 interrupt controller ...................................................................................................................... 242 shared memory ...

Page 14: 1.1.1. The Fb3000 II

02/10 14 51217 rev. 1 section 1: general information 1.1. Introduction the fairbanks fb3000 ii solutions series instrument is a powerful, versatile, indicator which has flexibility, open architecture, and integrated capabilities of many computer functions. With these abilities, the fb3000 ii collect...

Page 15

Section 1: general information 02/10 15 51217 rev. 1 kernel description, continued • intalogix equipped units have load cell diagnostics features for easier troubleshooting capabilities. • an integrated e-mail client is configurable to alert a service organization or individual of a problem prior to...

Page 16

Section 1: general information 02/10 16 51217 rev. 1 1.2. Technical specifications enclosure •painted steel (nema 12) ─ product 30070 •stainless steel (nema 12) ─ product 30079 •stainless steel and aluminum (nema 12) ─ product 30077; 30078 • stainless steel (nema 4x) ─ product 30079 processor 1 ghz ...

Page 17

Section 1: general information 02/10 17 51217 rev. 1 1.2. Technical specifications, continued scale interface options •intalogix technology ─ external qmb interface ( 30433 ) ─ external intalogix communication board ( 28330 ) maximum of twenty (20) 1000 Ω or twelve (12) 350 Ω cells ─ dual external i...

Page 18

Section 1: general information 02/10 18 51217 rev. 1 1.2. Technical specifications, continued accessories continued • external serial port relay kit ( 26727 ) ─ basic traffic light control (interact) • 4-20ma analog and 20ma serial output ( 27104 ) ─ pc140 weight controller power requirements 100 - ...

Page 19

Section 1: general information 02/10 19 51217 rev. 1 1.3. Features, continued email error reporting built-in email client for reporting error conditions such as the following: •calibration change •time and date change •flash memory error •remote access enabled •routine maintenance required •load cel...

Page 20

02/10 20 51217 rev. 1 section 2: pre-installation 2.1. General service policy prior to installation, always verify that the equipment satisfies the customer's requirements as supplied, and as described in this manual. If the equipment cannot satisfy the application and the application cannot be modi...

Page 21

Section 2: installations 02/10 21 51217 rev. 1 2.2. Overview 2.2.1. Physical installation notes • check all devices for proper operation. If any error messages occur, refer to troubleshooting or the proper manual of that device. • only those charges which are incurred as a result of the equipment's ...

Page 22

Section 2: installations 02/10 22 51217 rev. 1 2.2.3. Conferring with our client before the installation is considered complete, the equipment is to be programmed to meet or exceed any applicable weights and measures requirements. • the technician must be prepared to recommend the arrangement of com...

Page 23: 2.3.2. Unpacking

Section 2: installations 02/10 23 51217 rev. 1 2.3.1. Pre-installation checklist the following points should be checked and discussed with the area sales manager and/or customer, if necessary, before the technician goes to the site and installs the equipment. 9 check the customer's application to ma...

Page 24: 2.3.3. Equipment Location

Section 2: installations 02/10 24 51217 rev. 1 2.3.3. Equipment location position the equipment with these points in mind: 9 intense direct sunlight can harm the display. 9 airborne particles can activate the touch screen. 9 work areas should be relatively free from drafts and vibrations. 9 do not l...

Page 25

Section 2: installations 02/10 25 51217 rev. 1 2.3.5. Users’ responsibilities 9 all electronic and mechanical calibrations and/or adjustments required for making this equipment perform to accuracy and operational specifications are considered to be part of the initial installation. ─ they are includ...

Page 26

02/10 26 51217 rev. 1 section 3: scale hardware installation 3.1. Wiring the fb3000 ii the fb3000 ii series instrument is installed in one of three basic configurations. • it is set up as a brand new scale system • the fb3000 ii can be added to pre-existing scales • it is installed to work directly ...

Page 27

Section 3: scale hardware installation 02/10 27 51217 rev. 1 3.2. Option a: installation on a full electronic scale this intalogix ™ technology-equipped indicator uses pit power supplies and smart sectional controllers (sscs) to provide load cell excitation and signal processing on all analog load c...

Page 28

Section 3: scale hardware installation 02/10 28 51217 rev. 1 3.2.3. Load cell wiring connections load cell wire color description tb1 or tb2 black (─) excitation 1 green (+) excitation 2 yellow (bare) shield 6 white (+) signal 7 red (─) signal 8 it is important to note that ssc (acc 2000-1a) connect...

Page 29

Section 3: scale hardware installation 02/10 29 51217 rev. 1 3.2.4. Ssc interfacing connections tb3 or tb4 ssc interface description 1 black (─) 8.0 vdc 2 green (+) 8.0 vdc 5 blue dc return 6 shield shield 7 white (+) rs485 8 red (─) rs485 1 2 3 4 5 6 7 8 tb1 1 2 3 4 5 6 7 8 tb1 1 2 3 4 5 6 7 8 tb1 ...

Page 30: 3.2.5. Switch Setup

Section 3: scale hardware installation 02/10 30 51217 rev. 1 3.2.5. Switch setup in each of the ssc boxes, there is a ten (10) position dip switch labeled s1 . • the switches must be set correctly in order for the scale to operate properly. • switches one (1) sets the ssc for normal or rf operation....

Page 31: 3.2.6. Closing The Ssc

Section 3: scale hardware installation 02/10 31 51217 rev. 1 3.2.6. Closing the ssc • the cable is connected directly to the ssc through a sealed gland fitting which must be tightened with a wrench to prevent any moisture from entering the enclosures. − the load cells are calibrated with the cable a...

Page 32

Section 3: scale hardware installation 02/10 32 51217 rev. 1 3.2.7. Pit power supply installation • all interface cables used in the scale system must be a minimum of 18 awg load cell cable ( 17246 is commonly used ). • feed a cable from the ssc to the pit power supply, and then connect the cables a...

Page 33

Section 3: scale hardware installation 02/10 33 51217 rev. 1 3.2.8. Grounding the system • for proper protection against damage from lightning strikes, all of the components of the system must be properly grounded. • the grounding system contains a minimum of one (1) ground rod for the scale pit loc...

Page 34

Section 3: scale hardware installation 02/10 34 51217 rev. 1 3.2.9. High speed ssc interface 1. Press the f-10 function key to open the hi-speed ssc interface… window. Port settings – these settings can only be changed when the polling mechanism is stopped. 2. Press the stop button. 3. Press the dro...

Page 35

Section 3: scale hardware installation 02/10 35 51217 rev. 1 3.2.9. High speed ssc interface, continued general timer settings 6. Timeout – length of time in ticks (55sm) the kernel program allows before a timeout occurs to a poll request. 7. Interval – the speed of the kernel request timer (in mill...

Page 36

Section 3: scale hardware installation 02/10 36 51217 rev. 1 3.2.9. High speed ssc interface, continued test mode – when enabled , this allows queries to specific sscs that have been found by the kernel. 9. Sections is the number of sections to poll. 10. First is the first section polled. Note: to t...

Page 37: 3.3.1. Introduction

Section 3: scale hardware installation 02/10 37 51217 rev. 1 3.3. Option b: converting an existing analog scale 3.3.1. Introduction with intalogix ™ technology , the rs485 serial communication to each ssc, is based on a switch setting in the ssc which assigns it a digital id number. ─ in the ssc, th...

Page 38

Section 3: scale hardware installation 02/10 38 51217 rev. 1 3.3.3. Installation procedures follow these steps to install the fb3000 ii instrument to an existing analog scale. Note the load cell capacity, resistance, and mv/ v ratings. ─ on mechanical scales, the scale multiple is required. Connect ...

Page 39

Section 3: scale hardware installation 02/10 39 51217 rev. 1 3.3.4. Step 1: input voltage settings and wiring • before applying power, verify the voltage jumper selection at jp1 and the connections at tb2. Input voltage select voltage jumpers installed 117 vac jp1-1 thru jp1-3 jp1-9 thru jp1-11 220 ...

Page 40: S1-1 Thru S1-4 = On

Section 3: scale hardware installation 02/10 40 51217 rev. 1 3.3.5. Step 2: load cell interface • connect the load cell according to the following table. ─ use 18 awg , individually shielded pairs, load cell cable. ─ jumpers jp6 and jp7 must be removed if the load cell cable distance is in excess of...

Page 41: 3.3.8. Cell Capacity

Section 3: scale hardware installation 02/10 41 51217 rev. 1 3.3.7. Step 4: load cell addressing select one of the appropriate address settings from the table below. Load cell address jp2 1 off (1) 3 on (2) (1) first and last cell id must be programmed to 1. (2) first and last cell id must be progra...

Page 42: Cell Capacity, Continued

Section 3: scale hardware installation 02/10 42 51217 rev. 1 cell capacity, continued 3. Open the cell capacity tab. 4. Enter the product amount from one of the two scale types shown in the formulas below. For fe (full electronic): number of cells x load cell capacity = cell capacity or for mechanic...

Page 43: (P/n 27104)

Section 3: scale hardware installation 02/10 43 51217 rev. 1 3.4. Option c: converting an existing analog scale using a pc104 weight controller 3.4.1. Installing the pc104 weight controller kit (p/n 27104) pc 104 weight controller kit installs into the 1 ghz single board computer (sbc) assembly cont...

Page 44: Continued

Section 3: scale hardware installation 02/10 44 51217 rev. 1 installing the pc104 weight controller kit (p/n 27104), continued #3 #4 #1 #2 #5 #5 #4 #1 – 20 ma passive current loop serial port ─ #1 = (+) ─ #2 = (─) #2 – set switch sw3 ─ positions 6 & 7 = on/closed ─ all other switches = off/open #3 –...

Page 45

Section 3: scale hardware installation 02/10 45 51217 rev. 1 3.4.2. Wiring the pc104 card wiring assembly 25768 replaces the existing wiring harness. ─ this provides power to the pc104 card. ─ p3 connector is not used. Used when 2 pc 104 cards are installed.

Page 46

Section 3: scale hardware installation 02/10 46 51217 rev. 1 3.4.3. Programming the high speed a/d interface 1. Press the menu button in the fairbanks weight window, open the service menu , then open the calibration menu. 2. Select the scale id tab. 3. In the type window, select pc104 a/d board 1. 4...

Page 47: 3.4.4. Cell Capacity

Section 3: scale hardware installation 02/10 47 51217 rev. 1 3.4.4. Cell capacity 1. Press the menu key, select service menu from the options menu, then select the calibration menu. 2. Open the cell capacity tab. 3. Enter the cell capacity amount from one of the two scale types shown in the formulas...

Page 48: 3.5.1. Dressing The Wires

Section 3: scale hardware installation 02/10 48 51217 rev. 1 3.5. Option d: conversion of an existing mettler–toledo digitol ™ system fb3000 ii series systems use pit power supplies and digital/analog sscs for load cell excitation and signal processing on all digital and/or analog load cells. • one ...

Page 49

Section 3: scale hardware installation 02/10 49 51217 rev. 1 3.5.2. Wiring the connections cable distance limitations • to ensure adequate power to the system, all wiring between the indicator and the pit power supply, and from the pit power supply to the digital / analog smart sectional controller ...

Page 50

Section 3: scale hardware installation 02/10 50 51217 rev. 1 3.5.2. Wiring the connections, continued digital / analog sscs, continued • one controller will provide an interface for up to four (4) load cells. ─ interfaces can be either digital or analog, or the combination of both. • the outputs are...

Page 51

Section 3: scale hardware installation 02/10 51 51217 rev. 1 3.5.3. Load cell orientation/ numbering the diagram below shows the cell numbering for a seven (7) section scale. Scale house 50711-7 sc1 ps sc2 sc3 sc4 sc5 sc7 sc6 1 3 5 2 4 6 7 9 8 10 11 13 12 14 3.5.4. Load cell connections 9 digital lo...

Page 52

Section 3: scale hardware installation 02/10 52 51217 rev. 1 3.5.4. Load cell connections, continued • in most applications, do not skip load cell input connections. • arrange the cables so drip loops are formed to prevent moisture intrusion. Dssc terminal orientation load cell orientation jp1 jp4 s...

Page 53

Section 3: scale hardware installation 02/10 53 51217 rev. 1 3.5.4. Load cell connections, continued digitol load cell wiring (1) connects to weighbridge ground. (2) not used on cmos digital load cells. Analog load cell wiring (1) connects to the weighbridge ground. ─ connect the outer braided shiel...

Page 54

Section 3: scale hardware installation 02/10 54 51217 rev. 1 3.5.5. Dssc interface connections the two terminal blocks tb6 and tb7 (electrically the same) provide the interconnection to each dssc. • this interface provides a bus for the rs485 communications and the power supply for each dssc. • the ...

Page 55: 3.5.6. Dip Switch Setup

Section 3: scale hardware installation 02/10 55 51217 rev. 1 3.5.6. Dip switch setup in each of the dssc boxes is an 8-position dip switch labeled s1 . • this switch is used to identify the section in a binary code. • the switches must be set properly for the scale to operate. • switches 1 thru 8 se...

Page 56: 3.5.8. Indicator

Section 3: scale hardware installation 02/10 56 51217 rev. 1 3.5.7. Pit power supply connections, continued the fairbanks’ standard cable ( 17246 ) has six (6) conductors, individually shielded pairs. ─ pair 1: green and black ; 18 awg stranded wire. ─ pair 2 and 3: orange and blue; red and white ; ...

Page 57

Section 3: scale hardware installation 02/10 57 51217 rev. 1 3.5.8. Indicator connections, continued note: shields must be connected for the system to communicate. 3.5.9. Linking a second pit power supply when linking a second pit power supply, connect them using this wiring chart..

Page 58

Section 3: scale hardware installation 02/10 58 51217 rev. 1 3.6. Option e: new or conversion of existing scale - qmb this intalogix ™ technology-equipped indicator uses qmb’s ( acc 3000-1a ) to provide load cell excitation and signal processing on light capacity scales using analog load cells. The ...

Page 59

Section 3: scale hardware installation 02/10 59 51217 rev. 1 3.7. System initialization and verification when the wiring connections from the load cell(s) to the analog, qmb, sscs (smart sectional controller) or dsscs (digital smart sectional controller) to the pit power supply (pit power supply)and...

Page 60

Section 3: scale hardware installation 02/10 60 51217 rev. 1 6. If an error is made and the wrong application is selected you can recover the original menu select. At the next reboot, on the first count down, simply press the f4 key and you will be presented with the select new application code entr...

Page 61

Section 3: scale hardware installation 02/10 61 51217 rev. 1 3.7. System initialization and verification, continued this example indicates one or all of the following: ─ an improper address setting in the sscs or dsscs. A value of 31 and 32 is an address for section 16 , which does not exist in this...

Page 62

Section 3: scale hardware installation 02/10 62 51217 rev. 1 3.8. Loading default system settings the following section outlines a procedure for loading default system settings. • this procedure must be done on all new installations or major hardware replacements (i.E. Hard drive). • all customized ...

Page 63

Section 3: scale hardware installation 02/10 63 51217 rev. 1 3.8. Loading default system settings, continued 13. Select the special functions menu . 14. Select the backup / restore tab . 15. Press load default system settings button. 16. Double-click on yes when asked “ are you sure? ” ─ loading the...

Page 64

02/10 64 51217 rev. 1 section 4: key functions and menus 4.1. Key functions on-screen keyboard external keyboard description arrows arrows • navigates through the display. • used also for scrolling. Menu button esc • changes the display to the operation menu. • returns user to the previous menu. Zer...

Page 65

Section 4: key functions and menus 02/10 65 51217 rev. 1 4.1. Key functions, continued the kernel can be set up to operate in one of two modes of operation, depending upon the service programming: ─ gross weighing ─ gtn (gross / tare / net) on-screen keyboard external keyboard description units scro...

Page 66

Section 4: key functions and menus 02/10 66 51217 rev. 1 4.2. General programming menus the programming menus which contain all of the parameters for the system are listed below. Options menu this is the main menu, used to gain access to other system menus for configuration and calibration. • it is ...

Page 67

Section 4: key functions and menus 02/10 67 51217 rev. 1 4.3. Defining the main menus 4.3.1. Options menu descriptions 17. Press the menu button while viewing the weight processing screen. 18. From the kernel options menu, double-click on any menu to access. Window name description return to weighin...

Page 68

Section 4: key functions and menus 02/10 68 51217 rev. 1 4.3.2. Configuration menu descriptions 1. Press the down arrow button while viewing the options menu screen. Scroll down until the configuration menu is highlighted and press the enter button. 2. At the kernel configuration menu screen, double...

Page 69

Section 4: key functions and menus 02/10 69 51217 rev. 1 4.3.3. Service menu descriptions 1. Press the down arrow button while viewing the options menu screen. Scroll down until the service menu is highlighted and press the enter button. 2. At the kernel service menu screen, double-click on any menu...

Page 70

02/10 70 51217 rev. 1 section 5: instrument setup 5.1. Introduction upon successful completion of system verifications on power up and the default system settings loaded, the instrument is ready to be setup and configured for proper operation. The procedure which follows is a recommended method to s...

Page 71

Section 5: instrument setup 02/10 71 51217 rev. 1 5.2. Recommended setup procedures, continued 4. Upon accessing the service options menu, select the number of scales tab. Enter the number of scales the fb3000 ii is controlling. Leave the other parameters at their default condition at this time. 5. ...

Page 72

Section 5: instrument setup 02/10 72 51217 rev. 1 5.2. Recommended setup procedures, continued 6. Select the update rate tab. Enter the update rate desired value. Note(s): use the default setting for most truck scale applications. When using remote displays, do not set below 0.5 seconds. 7. Select t...

Page 73

Section 5: instrument setup 02/10 73 51217 rev. 1 5.2. Recommended setup procedures, continued 8. Select the zero mode tab. Press the appropriate button to enter the desired range of zero operation. Leave the other parameters at their default condition at this time. 9. Press menu one time. Scroll do...

Page 74

Section 5: instrument setup 02/10 74 51217 rev. 1 5.2. Recommended setup procedures, continued 10. Select the scale id tab. Select the scale id drop down menu and choose the desired id for the scale. Select the type drop down menu and choose the type of interface for the scale. Window name descripti...

Page 75

Section 5: instrument setup 02/10 75 51217 rev. 1 5.2. Recommended setup procedures, continued 11. Select the first cell tab. Enter the first cell id numeric value. Select the last cell tab. Enter the last cell id numeric value. Note: for more information regarding the 2500 analog boards , refer to ...

Page 76

Section 5: instrument setup 02/10 76 51217 rev. 1 5.2. Recommended setup procedures, continued 12. Select the division size tab. Select the division size drop down menu and choose the desired value for the scale. 13. Select the units tab. Select the scale units drop down menu and choose the units re...

Page 77

Section 5: instrument setup 02/10 77 51217 rev. 1 5.2. Recommended setup procedures, continued 14. Choose the motion band tab. Select the motion band drop down menu and choose the motion band value required for the scale application. Calibration ─ motion band number of divisions within the motion ba...

Page 78

Section 5: instrument setup 02/10 78 51217 rev. 1 5.2. Recommended setup procedures, continued 15. Choose the azt band tab. Select the azt band drop down menu and choose the azt band value required for the scale application. 16. Choose the filter factor tab. Select the filter factor drop down menu a...

Page 79

Section 5: instrument setup 02/10 79 51217 rev. 1 5.2. Recommended setup procedures, continued 17. Choose the float switch tab. Enter the ssc w/ float switch section number value where the float switch is mounted within the scale pit. 18. Choose the cell capacity tab. Enter the cell capacity value a...

Page 80

Section 5: instrument setup 02/10 80 51217 rev. 1 5.2. Recommended setup procedures, continued 20. Choose the scale capacity tab. Enter the scale capacity value. 21. Choose the calibration wt tab. Enter the calibration wt. Value. Window name description calibration ─ scale capacity the rated capacit...

Page 81

Section 5: instrument setup 02/10 81 51217 rev. 1 5.2. Recommended setup procedures, continued 22. Choose the cell sensitivity tab. Enter each cell, sensitivity, and resistance values as noted on the load cell data sheet and the cells position within the scale. When completed, proceed to section 6 f...

Page 82

02/10 82 51217 rev. 1 section 6: calibration 6.1. Introduction upon successful completion of section 5: instrument setup , the instrument is ready to be calibrated. The procedure which follows is a recommended method calibration of the kernel weight server program. Procedure steps skipped or omitted...

Page 83

Section 6: calibration 02/10 83 51217 rev. 1 5.2. Recommended calibration procedures, continued 4. In the calibration menu, open the scale id tab. 5. Select the desired scale from the drop- down menu box. 6. Open the cell sensitivity tab. ─ enter the sensitivity , if it is incorrect. ─ verify the lo...

Page 84

Section 6: calibration 02/10 84 51217 rev. 1 6.3. Trim calibration after performing the recommended calibration procedure, if the weight value needs adjusting, follow these steps to trim the scale. 1. Open the trim tab, then in the cell / section/ scale drop-down, select the desired method. 2. Place...

Page 85

Section 6: calibration 02/10 85 51217 rev. 1 6.3. Trim calibration, continued 5. Use the up or down arrows to adjust the weight shown on the scale. 6. When the appropriate weight displays, press the enter key. 7. Press the menu button until the weight processing screen is displayed. This completes t...

Page 86: 6.4.1. Span

Section 6: calibration 02/10 86 51217 rev. 1 6.4. Other calibration methods 6.4.1. Span (corners) 8. Press the menu button. 9. From the kernel options menu, double-click on the service menu . 10. Double-click on the special functions option. Window name description special functions enables special ...

Page 87

Section 6: calibration 02/10 87 51217 rev. 1 6.4.1. Span (corners), continued 11. Double-click on the span (corners) menu option. 5. The span (corners) feature is typically utilized to perform corner calibration on small capacity scales. It may also be used to calibrate the course span on large capa...

Page 88: 6.4.2. Span

Section 6: calibration 02/10 88 51217 rev. 1 6.4.2. Span (sections) 12. Press the menu button. 13. From the kernel options menu, double-click on the service menu . 14. Double-click on the special functions option. Window name description special functions enables special features and functions for t...

Page 89

Section 6: calibration 02/10 89 51217 rev. 1 6.4.2. Span (sections), continued 15. Double-click on the span (sections) menu option. 5. The span (sections) feature is typically utilized to perform section calibration adjustments with a concentrated load. 6. Enter the calibration wt value if it is inc...

Page 90: Do Not

Section 6: calibration 02/10 90 51217 rev. 1 6.4.2. Span (sections), continued upon completing this process, press menu repeatedly to exit . 6.5. Legal for trade sealing upon completion of all calibration and programming, the indicator must be sealed in order to be legal for trade. There are two mea...

Page 91

Section 6: calibration 02/10 91 51217 rev. 1 6.5.1. Method 1 – service password, continued window name description write password allows entry of a password. ─ service password is up to twelve (12) alphanumeric characters. ─ write password function secures the service menu. ─ the security is reset a...

Page 92

Section 6: calibration 02/10 92 51217 rev. 1 6.5.1. Method 1 – service password, continued 18. Scroll down and select write password. 19. Enter a password of up to twelve (12) alphanumeric characters 20. Press menu until back to the weight processing screen. The service password is now enabled..

Page 93

Section 6: calibration 02/10 93 51217 rev. 1 6.5.2. Method 2 – calibration switch procedure: 1. Press the menu button. 2. From the kernel options menu, double-click on the service menu . 3. Select special functions ..

Page 94

Section 6: calibration 02/10 94 51217 rev. 1 6.5.2. Method 2 – calibration switch, continued 4. Scroll and select system settings . 5. Click on the system options tab. At calibration switch press the arrow for the drop down menu. A list of options will appear. Select installed (com4) for the externa...

Page 95: 6.5.3. Audit

Section 6: calibration 02/10 95 51217 rev. 1 6.5.3. Audit trail 1. From the weighing application window, press the menu button. 2. From the kernel options menu, select audit trail . The screen may viewed or printed. This displays the unique count indicating the calibration or configuration has been ...

Page 96

Section 6: calibration 02/10 96 51217 rev. 1 6.6. Backup changes 6.6.1. Skip back up changes each time a programming change is made to the kernel program, a backup changes popup window appears. In order to skip this process: ─ the normal answer is no . ─ either double-click the or click the . 6.6.2....

Page 97

01/10 97 51217 rev. 1 section 7: input/ output (i/o) 7.1. Introduction connectivity is one of the primary features of the fb3000 ii and kernel weight server program. The fb3000 ii has multiple rs232 ports, usb ports, ethernet port, and a parallel port to name a few. This section will provide steps i...

Page 98

Section 7: input/ output (i/o) 02/10 98 51217 rev. 1 7.2.2. Setup of vspd ports (adding virtual ports) 5. The virtual ports will be indicated on the left side of the pane under serial ports explorer . By default the next open pair of available ports above the physical ports will be selected. Usually...

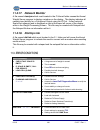

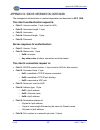

Page 99: 7.2.3.

Section 7: input/ output (i/o) 02/10 99 51217 rev. 1 7.2.3. Kernel setup for vspd ports 1. If it’s not already running, launch the kernel application. By double-clicking on the fb3000 icon on the desk top. 2. From the weight processing screen, press the menu button, from the kernel options menu, sel...

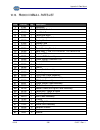

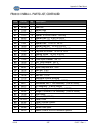

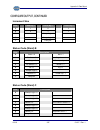

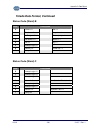

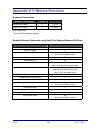

Page 100: 7.2.3.

Section 7: input/ output (i/o) 02/10 100 51217 rev. 1 7.2.3. Kernel setup for vspd ports, continued 4. Open the load tab. 5. Select the com port to be configured. 6. Sect the appropriate load default. 7. Press the button. 8. Open the port settings tab. 9. Select one of the com ports configured in th...

Page 101: 7.3.1. Introduction

Section 7: input/ output (i/o) 02/10 101 51217 rev. 1 7.3. Configure output 7.3.1. Introduction this menu selection provides a means to configure data strings protocols, configuration parameters, and output modes such as continuous, demand, auto, to file, and network. 7.3.2. Configuring an output da...

Page 102

Section 7: input/ output (i/o) 02/10 102 51217 rev. 1 7.3.4. Load default data protocols when programming a output data string, the fairbanks’ fb3000 has five of the most commonly used pre-configurations, known as load defaults . These data strings are listed below: fairbanks toledo cardinal weightr...

Page 103

Section 7: input/ output (i/o) 02/10 103 51217 rev. 1 7.3.5. Load the default com settings 15. Open the load tab. 16. Select the com port to be configured. 17. Sect the appropriate load default. 18. Press the button. 19. Open the port settings tab. 20. Program the baud rate, stop bits , and the pari...

Page 104

Section 7: input/ output (i/o) 02/10 104 51217 rev. 1 7.3.6. Customizing the output data strings the fb3000 ii kernel weight server program can also be customized to support numerous manufacturers software interfaces and peripheral devices. When programming a data string protocol not formatted as on...

Page 105

Section 7: input/ output (i/o) 02/10 105 51217 rev. 1 7.3.7. Steps in customizing, continued 27. Open the build tab. 28. Left-click on the appropriate field to be generated within the specific data string, then select text. ─ this adds a new text box to the output data string. 29. Program a command ...

Page 106

Section 7: input/ output (i/o) 02/10 106 51217 rev. 1 7.3.7. Steps in customizing, continued window name description configure output, ─ build tab • configures the data string protocol order, written in ascii text. • by left-clicking in any item, a drop-down menu offers different parameters, or remo...

Page 107

Section 7: input/ output (i/o) 02/10 107 51217 rev. 1 7.3.8. Ascii and text data character types there are two types of data configuration characters. Both have an important and have a specific function; both are used within the same data string. Both types are defined below. • ascii ( a merican s t...

Page 108

Section 7: input/ output (i/o) 02/10 108 51217 rev. 1 7.3.9. Other data string customization window name description configure output ─ settings tab • rs232 com port drop-down – selects com port with its settings. • data transmission options* ─ continuous [transmission] ─ demand – upon demand as a p...

Page 109

Section 7: input/ output (i/o) 02/10 109 51217 rev. 1 7.3.9. Other data string customization, continued window name description configure output, continued ─ settings tab, continued • hardware hand shake – a means to control data flow using hardware functions for communication between two or more de...

Page 110

Section 7: input/ output (i/o) 02/10 110 51217 rev. 1 7.3.9. Other data string customization, continued window name description configure output, continued ─ [port] settings tab • control signals ─ dsr (data set ready) – a control signal that indicates the device is ready to transmit data. ─ cts (cl...

Page 111

Section 7: input/ output (i/o) 02/10 111 51217 rev. 1 7.3.9. Other data string customization, continued window name description configure output, continued ─ tokens tab • programs the various data string tokens, such as the motion flag. • tokens are setup for the data protocol requirements. Wrappers...

Page 112

Section 7: input/ output (i/o) 02/10 112 51217 rev. 1 7.3.9. Other data string customization, continued window name description configure output, continued ─ tokens tab • status – identifies invalid weight conditions. ─ motion – character(s) used to identify the scale weight is in motion. ─ capacity...

Page 113

Section 7: input/ output (i/o) 02/10 113 51217 rev. 1 7.3.9. Other data string customization, continued window name description configure output, continued ─ status codes tab programs data bits for status words a, b and c within the fairbanks and toledo data streams. ─ status word is eight (8) bits ...

Page 114

Section 7: input/ output (i/o) 02/10 114 51217 rev. 1 7.4. 20 ma serial current loop programming procedure steps skipped or omitted during this process may cause certain features to not operate or function as expected. The 20 ma output is passive. Note: the pc104 weight controller kit (27104) must b...

Page 115

Section 7: input/ output (i/o) 02/10 115 51217 rev. 1 7.4. 20ma serial current loop programming, continued 3. Set the remote display to com 1. 4. Configure the baud , parity , data bits , and stop bits required. 5. Reset the remote display back to off. 6. Select the enable 20ma output check option. ...

Page 116

Section 7: input/ output (i/o) 02/10 116 51217 rev. 1 7.5. 4-20 ma analog output procedure steps skipped or omitted during this process may cause certain features to not operate or function as expected. The 4-20 ma output is passive. Note: the pc104 weight controller kit (27104) must be installed fo...

Page 117

Section 7: input/ output (i/o) 02/10 117 51217 rev. 1 7.5.2. 4-20ma analog output wiring 7.5.2. 4-20ma analog output programming 1. Press the menu button in the fairbanks weight window, open the service menu , then open the calibration menu. 2. Select the 4-20 ma tab. 3. At the maximum wt. Window, e...

Page 118: 7.5.4. Testing The Alarms

Section 7: input/ output (i/o) 02/10 118 51217 rev. 1 7.5.2. 4-20ma analog output programming, continued 7. Select which weight mode the 4-20ma analog output will track in the mode (gross/net) drop-down window. 8. Select which scale the 4-20ma analog output will track in the scale drop-down window. ...

Page 119: 7.6.1. Notifications

Section 7: input/ output (i/o) 02/10 119 51217 rev. 1 7.6. Email notification setup this feature reports errors to operators and supervisory personnel. • . Each of the error notifications can have up to three (3) recipient. • error messages are flagged for the following reasons: ─ calibration change...

Page 120: 7.6.1. Notifications,

Section 7: input/ output (i/o) 02/10 120 51217 rev. 1 7.6.1. Notifications, continued 3. Select special functions. 4. Select system settings. 5. Open the notifications tab. 7.6.2. Setting up recipients 1. Set up the email recipient(s) by clicking the button..

Page 121

Section 7: input/ output (i/o) 02/10 121 51217 rev. 1 7.6.2. Setting up recipients, continued 2. Input all the necessary contact information for each of up to three (3) notification recipients. ─ the mail server must be a dedicated server ( smtp ) type and not a web browser type server ( pop ). ─ th...

Page 122

Section 7: input/ output (i/o) 02/10 122 51217 rev. 1 7.6.3. Setting up each error notification, continued 3. Either enter an email address manually, or select one of the choices, whichever applies. ─ after inputting the email address in this window once, that address automatically appears in the dr...

Page 123

Section 7: input/ output (i/o) 02/10 123 51217 rev. 1 7.7. Ip network output 7.7.1. Ip setup menu overview . Window name description configure output, continued ─ ip setup tab ip port settings • local port – the socket number on the local fb3000 used to transmit and receive data. • remote port – set...

Page 124: Continued

Section 7: input/ output (i/o) 02/10 124 51217 rev. 1 7.7.1. Ip setup menu overview , continued window name description configure output, continued ─ ip setup tab firewall settings • host – the host ip address. • port – the port socket number used. • type 9 default = no firewall. ─ tunnel – set to 8...

Page 125

Section 7: input/ output (i/o) 02/10 125 51217 rev. 1 7.7.2. Ip network output setup instructions the following procedure outlines the setup instructions required to activate the ip network output function. Procedure steps skipped or omitted during this process may cause certain features to not oper...

Page 126

Section 7: input/ output (i/o) 02/10 126 51217 rev. 1 7.7.2. Ip network output setup instructions, continued 3. Select an unused com port to be configured. Example: com 5. 4. Access the load tab and select a default format similar to what is required. 5. Press the button. . 6. Select the build tab a...

Page 127

Section 7: input/ output (i/o) 02/10 127 51217 rev. 1 7.7.2. Ip network output setup instructions, continued 7. Use the mode drop down list to select the network mode. 8. Select the ip setup tab to configure the network parameters. Pointing to each edit box will display a brief help message, to assi...

Page 128

Section 7: input/ output (i/o) 02/10 128 51217 rev. 1 7.7.3. Testing the ip network output test instructions to activate the ip network output function from the fb3000 ii kernel weight server program. 1. Setup the ip network output as described in section 7.6.2. Of this manual. 2. Return the kernel ...

Page 129

Section 7: input/ output (i/o) 02/10 129 51217 rev. 1 7.8. Multicast this output feature will share weights from one fb 3002 instrument to another. Up to eight (8) instruments may be networked together using this method of communications. Full functionality is available to all indicators in this mul...

Page 130

Section 7: input/ output (i/o) 02/10 130 51217 rev. 1 7.8.1. Multicast setup instructions procedure to transmit using multicast: 1. Press the menu button. 2. From the kernel options menu, double-click on the service menu . 3. Double-click on the service options ..

Page 131

Section 7: input/ output (i/o) 02/10 131 51217 rev. 1 7.8.1. Multicast setup instructions, continued 4. Choose special functions and press enter. 5. Select the operating screen tab. Select multi-scale screen . This selection is for ease of multicasting setup where up to 4 scales may be seen at one t...

Page 132

Section 7: input/ output (i/o) 02/10 132 51217 rev. 1 7.8.1. Multicast setup instructions, continued 7. Select the multicast tab. Click the enable multicast scale output box to enable this featured output. Leave the other settings in their default state as indicated on the right. 8. When the multica...

Page 133

Section 7: input/ output (i/o) 02/10 133 51217 rev. 1 7.8.1. Multicast setup instructions, continued 10. Select the scale id tab. Click on the type drop down menu box arrow and choose multicast input . 11. Two additional data programming fields will appear after selecting multicast input. Enter the ...

Page 134

Section 7: input/ output (i/o) 02/10 134 51217 rev. 1 7.8.1. Multicast setup instructions, continued 14. The second method is to start at the desktop and select start > settings > control panel. 15. At the control panel window, select / double click the system icon. 16. Document the full computer na...

Page 135: Fairbanks Logo

01/10 135 51217 rev. 1 section 8: operation 8.1. System boot-up procedure initiate the power up sequence using the power on/off rocker switch located on the bottom-left side of the instrument. Normal indications include the following: ─ lights on the keyboard should blink. ─ after approximately one ...

Page 136

Section 8: operation 02/10 136 51217 rev. 1 8.2. Viewing options when using the kernel program , there are two viewing options for weighing. The gtn screen the gtn screen displays the weighments for only .One scale at a time. Multi-scale screen the multi-scale screen displays all configured scales o...

Page 137

Section 8: operation 02/10 137 51217 rev. 1 8.3.1. Using the display screen function buttons • when in the multi-scale screen, press the f1 button to toggle thru the available scales. • press the display screen’s f6 button to toggle back-and-forth from the gtn screen to the multi-scale screen. F6 to...

Page 138

Section 8: operation 02/10 138 51217 rev. 1 8.4. Application shut-down procedure 1. To close the kernel program, press the exit button on the open weighing application screen. 2. Double-click on the exit application button. C a u t i o n improper shutdown of this instrument can cause damage to the h...

Page 139

Section 8: operation 02/10 139 51217 rev. 1 8.5. System shutdown procedure 1. From the kernel weight processing screen, press the button. 2. Select shutdown and press enter. ─ the instrument turns off. ─ upon shut down, the display turns dark. 3. Turn off the power using the on/off rocker switch. Or...

Page 140

Section 8: operation 02/10 140 51217 rev. 1 8.6. Kernel backup and restore window name description system settings ─ backup/ restore • backup system settings – current parameter settings are saved into the c:\kernel\ backups folder. • backup system setting to flash memory – saves the current configu...

Page 141

Section 8: operation 02/10 141 51217 rev. 1 8.6.1. Kernel backup procedure the following section outlines a procedure for the kernel system backup. 4. If it’s not already running, launch the kernel application. By double-clicking on the fb3000 icon on the desk top. 5. Press the menu button. 6. Selec...

Page 142

Section 8: operation 02/10 142 51217 rev. 1 8.6.1. Kernel backup procedure, continued 7. Select the special functions menu . 8. Open the backup/restore tab. 9. Press the backup system settings button. A. The system automatically names the backup file by date performed (yyymmdd.Bak). B. Backup the fi...

Page 143

Section 8: operation 02/10 143 51217 rev. 1 8.6.2. Kernel restore procedure kernel system restore is an essential function for maintaining the appropriate business-specific settings. If the kernel programs are altered for any reason, this re-establishes their previously saved program settings. 1. Pr...

Page 144

01/10 144 51217 rev. 1 section 9: customizing the fb3000 ii 9.1. Adding an item / icon to the startup folder 1. Right-click on the icon for the program to be copied. ─ either on the desk top or in the program group. 2. Select copy . 3. Right-click on the start button, then select explorer . 4. Navig...

Page 145

Section 7: service & maintenance 02/10 145 51217 rev. 1 9.1. Adding an item / icon to the startup folder, continued 5. Right-click in the startup folder, then select paste . This activates the program at startup of the computer..

Page 146

Section 7: service & maintenance 02/10 146 51217 rev. 1 9.2. The run maximized mode • some software programs are configured to always be the top, or primary window. • this procedure initiates the kernel.Exe directly to a maximized mode. • the weight on the kernel weight screen displays in the taskba...

Page 147

Section 7: service & maintenance 02/10 147 51217 rev. 1 9.2. The run maximized mode, continued 8. Right-click on the start button, then select explorer . 9. Scroll down and double-click on the kernel folder, opening it. 10. Right-click on the file named runmaximized.Not , then select rename. Note: i...

Page 148

Section 7: service & maintenance 02/10 148 51217 rev. 1 9.2. The run maximized mode, continued 13. Close the explorer window by pressing the in the upper right hand corner . 14. If it’s not already running, launch the kernel application. By double-clicking on the fb3000 icon on the desk top. Note: t...

Page 149

Section 7: service & maintenance 02/10 149 51217 rev. 1 9.3. Minimizing to the windows ™ system tray 9.3.1. Minimizing the kernel weight window follow these steps to display the kernel program in the windows ™ minimized tray. 15. Press the menu button. 16. Select the service menu ..

Page 150

Section 7: service & maintenance 02/10 150 51217 rev. 1 9.3.1.Minimizing the kernel weight window, continued 17. Select special functions. 18. Select system settings. 19. Open the system options tab. 20. From the minimized mode drop-down menu, select system tray . 21. Press the menu button four time...

Page 151

Section 7: service & maintenance 02/10 151 51217 rev. 1 9.3.2. Restoring the kernel weight window once the kernel weight screen is minimized, it remains hidden until it is restored. Listed below are the steps to do this. 1. Right-click on the kernel icon in the windows ™ system tray. 2. Left-click r...

Page 152

Section 7: service & maintenance 02/10 152 51217 rev. 1 9.4. Minimizing the remote vnc connection, continued 2. Open the system options tab. 3. From the diagnostics drop-down menu, select show minimized . 4. Return to the weight window by pressing the menu button four times . Note: the diagnostics d...

Page 153: 9.4.2. Additional Tips

Section 7: service & maintenance 02/10 153 51217 rev. 1 9.4.2. Additional tips • once a remote vnc connection is active, an easy way to view the connection ip address is to hover over the program icon in the windows ™ system tray. • for additional options including the program properties, right- cli...

Page 154

Section 7: service & maintenance 02/10 154 51217 rev. 1 9.5. The high speed check mode, continued 9.5.1. High speed check mode configuration follow these steps to enable or disable the high speed check mode . 1. Close the kernel program, press the exit button on the open weighing application window....

Page 155: 9.5.1.

Section 7: service & maintenance 02/10 155 51217 rev. 1 9.5.1. High speed check mode configuration, continued 3. Right-click on the start button, then select explorer . 4. Scroll down and double-click on the kernel folder, opening it. 5. Check the directory for the file for highspeed.Chk. 6. If this...

Page 156

Section 7: service & maintenance 02/10 156 51217 rev. 1 9.6. Service options window name description system settings ─ system options sets up or changes different user interface preferences. ─ hide screen cursor – check box allows the cursor on the display to be viewed or hidden. ─ demo mode – check...

Page 157

Section 7: service & maintenance 02/10 157 51217 rev. 1 9.6. Service options, continued window name description system settings ─ system options ─ threshold weight detect – establishes a weight value that must be met to trigger the weight detect. Weight – the minimum threshold weight programmed to a...

Page 158

Section 7: service & maintenance 02/10 158 51217 rev. 1 9.7. Mouse customization 9.8. Taskbar customization due to a limited amount of available space per window, some of the images are cut off at the bottom, and do not display all the information correctly (see example below ). Window name descript...

Page 159

Section 7: service & maintenance 02/10 159 51217 rev. 1 9.8. Taskbar customization, continued this is corrected by changing a parameter on the windows ™ application. Follow these steps to solve this problem. 1. On the external keyboard, click the flying windows key to display the windows ™ task bar ...

Page 160

01/10 160 51217 rev. 1 section 10: programming interact inside 10.1. Introduction interact inside is a database scale transaction software application. • interact inside software installation files are loaded on every fb3000 ii instrument as part of the standard fb3000 ii instrumentation. ─ it is al...

Page 161: 10.2.1. Interact Limited

Section 6: programming interact software 02/10 161 51217 rev. 1 10.2. Defining the different interact versions interact inside the version loaded on every fb3000 ii instrument as part of the standard fb3000 ii at no additional charge. It has tables for vehicles, material and pricing, and customers. ...

Page 162

Section 6: programming interact software 02/10 162 51217 rev. 1 10.2.4. Initial setup for the interact program files 1. From the desktop, double-click on my computer icon. 2. Double click on the c:\ drive, open the 3000_drivers folder, open the interact_install folder, then double-click on the setup...

Page 163: Continued

Section 6: programming interact software 02/10 163 51217 rev. 1 10.2.4. Initial setup for the interact program files, continued 6. In the set scale 1 port parameters window, make the following selections: ─ baud rate: 9600 ─ data bits: 8 ─ stop bits: 2 ─ parity: none ─ flow control: none ─ device ty...

Page 164: Continued

Section 6: programming interact software 02/10 164 51217 rev. 1 10.2.4. Initial setup for the interact program files, continued 8. Click the done button, then the to exit. ─ this returns to the interact application screen. 9. Select the weigh... Button. The basic setups for the interact program are ...

Page 165

01/10 165 51217 rev. 1 section 11: service & maintenance 11.1. Important precautions before handling the fb3000 ii boards or other system components, a service technician must always use esd precautions. • electrostatic discharge (esd) can easily damage the fb3000 board assemblies. • remove the anti...

Page 166

Section 11: service and maintenance 02/10 166 51217 rev. 1 11.2.1. Service information and error logging, continued 1. From the weight processing screen, press the menu button. 2. Select the service menu . 3. Select special functions..

Page 167

Section 11: service and maintenance 02/10 167 51217 rev. 1 11.2.1. Service information and error logging, continued 4. Select system settings. 5. Select service info. Enter the scale or facility identifier under site id. Complete the other data fields for the customer name, address, city, state, and...

Page 168

Section 11: service and maintenance 02/10 168 51217 rev. 1 11.2.2. Error logging errors and reporting 1. When error logging is programmed to display errors, the screen shown is typical of what the operator will observe. 2. The error must be repaired before the error display screen will be able to be...

Page 169

Section 11: service and maintenance 02/10 169 51217 rev. 1 11.2.2. Error logging errors and reporting, continued • weighing kernel errors list error condition file name file contents calibration change, span wt ccs_val [type] (val = weight used) code=ccs [parms] calwt=val note: calibration change to...

Page 170

Section 11: service and maintenance 02/10 170 51217 rev. 1 11.2.2. Error logging errors and reporting, continued error condition file name file contents scale behind zero sbz_#_# [type] (# is the cell number) code=sbz [parms] scale=# range=# where range = 'l' 400 lbs below zero note: scale is behind...

Page 171: 11.2.3. Routine Maintenance

Section 11: service and maintenance 02/10 171 51217 rev. 1 11.2.3. Routine maintenance this service tool provides a means to prompt the operator or a supervisor that a regular scheduled maintenance checkup is due for the scale. Procedure: 1. Enter the maintenance performed date in which service was ...

Page 172: 11.2.4. Load Cell Ghosting

Section 11: service and maintenance 02/10 172 51217 rev. 1 11.2.4. Load cell ghosting the ghosting feature allows a scale with a load cell problem to operate normally until qualified service personnel can repair the problem. The scale is not legal for trade when ghosting is enabled. The f6 key will ...

Page 173

Section 11: service and maintenance 02/10 173 51217 rev. 1 11.2.5. Cell output (counts) the cell output (counts) provides a way to view all of the counts from each load cell. Observing the counts upon each load cell will assist in determining if each load cell is loaded evenly. It will also assist i...

Page 174

Section 11: service and maintenance 02/10 174 51217 rev. 1 11.2.6. Clear cell error flags load cell errors are flagged in the cell output (counts) display by an asterisk under the errors column. Each error is date stamped as to the errors occurrence. This feature will assist with the problems which ...

Page 175

Section 11: service and maintenance 02/10 175 51217 rev. 1 11.2.6 clear cell error flags, continued 9. Select special functions. 10. Highlight clear cell error flags and press enter. After 1-3 seconds the word cleared will appear. All error flags have now been cleared. 11. Press menu repeatedly unti...

Page 176: 11.2.7. Peak Weights

Section 11: service and maintenance 02/10 176 51217 rev. 1 11.2.7. Peak weights this feature, peak weights , captures the highest eight (8) sectional weights which driven across the scale. These weight are time and date stamped. The benefit for this service tool is to be able to diagnose whether or ...

Page 177

Section 11: service and maintenance 02/10 177 51217 rev. 1 11.2.7. Peak weights, continued procedure: 12. From the weight processing screen, press the menu button. 13. Select the service menu . 14. Select special functions..

Page 178

Section 11: service and maintenance 02/10 178 51217 rev. 1 11.2.7. Peak weights, continued 4. Select peakweights . 5. The peak weights may be viewed or printed..

Page 179: 11.2.8. Reset Section Peaks

Section 11: service and maintenance 02/10 179 51217 rev. 1 11.2.8. Reset section peaks this service utility resets the peak weights back to zero window name description reset section peaks • resets the peak weights recorded which have gone across the scale. • reset all values to zero . Procedure: 15...

Page 180

Section 11: service and maintenance 02/10 180 51217 rev. 1 11.2.8. Reset section peaks, continued 17. Select special functions. 18. Select reset section peaks. 19. Press enter and reset section peaks menu will indicate the peak weights have been reset ..

Page 181: 11.2.9. Vnc Settings

Section 11: service and maintenance 02/10 181 51217 rev. 1 11.2.9. Vnc settings ultr@vnc is the remote diagnostics utility program which gives the fairbanks service center and customer numerous functions including file transfers, remote operation, troubleshooting capabilities and other remote servic...

Page 182: 11.2.10. Vnc

Section 11: service and maintenance 02/10 182 51217 rev. 1 11.2.10. Vnc setup procedure: 20. From the weight processing screen, press the menu button. 21. Select the service menu . 22. Highlight vnc settings and press enter..

Page 183

Section 11: service and maintenance 02/10 183 51217 rev. 1 11.2.10 . Vnc setup, continued 12 enter in a new password . The remainder of the settings are recommended to be left at their default values. See section 11.2.11. Saving the vnc password as a method of recording this value..

Page 184

Section 11: service and maintenance 02/10 184 51217 rev. 1 11.2.11. Saving the vnc password 1. On the external keyboard, click the flying windows key to minimize the weight application window. 2. Right-click on the start button, then select explore . 3. In the c-drive, select the kernel folder. 4. W...

Page 185: The Vnc Connection

Section 11: service and maintenance 02/10 185 51217 rev. 1 11.2.11. Saving the vnc password, continued 6. Write ultr@vnc password as the name for the new wordpad document. 7. In the open document, write the password. 8. Close the program by clicking the . 9. When prompted to save, select yes. 11.2.1...

Page 186

Section 11: service and maintenance 02/10 186 51217 rev. 1 11.2.12. Vnc remote service and diagnostics, continued 3. The ip address is listed within the remote diagnostic mode window. 4. The instrument is ready to have diagnostics remotely. Note: for additional information, please see section 9: cus...

Page 187: 11.2.13. Float Switch

Section 11: service and maintenance 02/10 187 51217 rev. 1 11.2.13. Float switch 11.2.14. Updater settings window name description ─ float switch an optional deviceconnected to the ssc which activates an alert when water is in the pit. ─ recommended part is purchased from www.Grainger.Com . ─ part n...

Page 188

Section 11: service and maintenance 02/10 188 51217 rev. 1 11.2.15. Print calibration report this service tool will compile all of the instrument programming and calibration data which may be viewed or printed. The report utilizes a form printer only for printed reports. It is recommended one copy b...

Page 189

Section 11: service and maintenance 02/10 189 51217 rev. 1 11.2.15. Print calibration report, continued procedure: 1. From the weight processing screen, press the menu button. 2. Select the service menu . 3. Select print calibration report..

Page 190: 11.2.16. Hyperterminal

Section 11: service and maintenance 02/10 190 51217 rev. 1 11.2.15. Print calibration report, continued 4. View or print report as required. 11.2.16. Hyperterminal it is always good to test the data strings being set up. Because of this, the best first step is opening a hyperterminal window to test ...

Page 191: 11.2.16. Hyperterminal,

Section 11: service and maintenance 02/10 191 51217 rev. 1 11.2.16. Hyperterminal, continued 3. Click the start button, select programs , select accessories , select communications , select hyperterminal . 4. Enter a name for the connection. Example = test.

Page 192: 11.2.16. Hyperterminal,

Section 11: service and maintenance 02/10 192 51217 rev. 1 11.2.16. Hyperterminal, continued 5. Press the drop down menu arrow in the connect using box. Select the com port required. 6. Enter the correct port settings and set the flow control to none. Click apply and then select ok..

Page 193: 11.2.16. Hyperterminal,

Section 11: service and maintenance 02/10 193 51217 rev. 1 11.2.16. Hyperterminal, continued 7. The hyperterminal display screen will indicate the data which is being transmitted by the indicator. 4. Minimize this window by clicking the button in the upper-right corner of the screen, until the hyper...

Page 194: 11.2.17. Network

Section 11: service and maintenance 02/10 194 51217 rev. 1 11.2.17. Network monitor a file named view.Ipm which must located in the c:\kernel folder causes the kernel weight server program to display a window on the display. The display indicates all network input activity for a configured output us...

Page 195

Section 11: service and maintenance 02/10 195 51217 rev. 1 11.4. Boot-up troubleshooting 1. If the above indications are not observed in a reasonable length of time, set the dvm (digital volt meter) to measure dc volts. 2. Connect the test leads to the cn21 connector on the sbc. ─ red lead to pin 1;...

Page 196: 11.5.1. Com Port Locations

Section 11: service and maintenance 02/10 196 51217 rev. 1 11.5. Loopback test 11.5.1. Com port locations the kernel application can perform a simple com port loopback pass/fail test to confirm com port function. The three available com ports are located in the following places: • com port 1 is loca...

Page 197: 11.5.3. Steps to Building A

Section 11: service and maintenance 02/10 197 51217 rev. 1 11.5.2. Loopback test connector in order to perform a loopback test, a test connector will need to be used one can also be built with a rs-2332 db-9 female plug, a short jumper wire, some solder and a soldering tool. 11.5.3. Steps to buildin...

Page 198

Section 11: service and maintenance 02/10 198 51217 rev. 1 11.5.4. Loopback test procedure 1. Insert the rs-232 db-9 pin loopback test connector into com port 1, or com port 3, or com port 4. Com 2 is a rs485 port dedicated to the scale communications. 2. While in the main weight window, press the m...

Page 199

Section 11: service and maintenance 02/10 199 51217 rev. 1 11.6. Touch panel (usb) 11.6.1. Touch panel software installation 1. If the fairbanks weighing application boots up from power-on, press alt + f4 to close the application. ─ the ms windows ™ desktop appears. ─ fb weighing application should ...

Page 200

Section 11: service and maintenance 02/10 200 51217 rev. 1 11.6.1. Touch panel software installation, continued 7a. If the installation is correct, press save & exit . The software installation is complete 7b. If the installation needs to be redone, press cancel & exit and start over on step 1 again...

Page 201

Section 11: service and maintenance 02/10 201 51217 rev. 1 11.7. Sbc connector and jumper locations 11.7.1. Sbc connector and jumper definitions.

Page 202

Section 11: service and maintenance 02/10 202 51217 rev. 1 11.7.2. Sbc connector and jumper pin outs.

Page 203

Section 11: service and maintenance 02/10 203 51217 rev. 1 11.7.2. Sbc connector and jumper pin outs, continued.

Page 204

Section 11: service and maintenance 02/10 204 51217 rev. 1 11.7.2. Sbc connector and jumper pin outs, continued.

Page 205

Section 11: service and maintenance 02/10 205 51217 rev. 1 11.7.2. Sbc connector and jumper pin outs, continued.

Page 206

Section 11: service and maintenance 02/10 206 51217 rev. 1 11.7.2. Sbc connector and jumper pin outs continued.

Page 207

Section 11: service and maintenance 02/10 207 51217 rev. 1 11.7.2. Sbc connector and jumper pin outs.

Page 208

Section 11: service and maintenance 02/10 208 51217 rev. 1 11.7.2. Sbc connector and jumper pin outs, continued.

Page 209

Section 11: service and maintenance 02/10 209 51217 rev. 1 11.7.3. Sbc connector and jumper pin outs continued.

Page 210

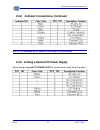

Section 11: service and maintenance 02/10 210 51217 rev. 1 11.8. Com 2 scale port jumper settings all equipment is fully tested for basic operations at the factory. 1. Ensure that the optional components and kernel internal wirings are connected properly. 2. Connect required scale equipment to the a...

Page 211: 11.8.1. Installing Memory

Section 11: service and maintenance 02/10 211 51217 rev. 1 11.9. Memory 11.8.1. Installing memory the fb3000 ii has one 144-pin ddr so-dimm socket, supporting memory up to 1gb. To insert so-dimm memory , align the module with the socket key, pressing down until the levers at each end of the socket s...

Page 212

Section 11: service and maintenance 02/10 212 51217 rev. 1 11.10. Bios setup the rom chip of your fb3000 ii is configured with a customized basic input/output system (bios) from phoenix-award bios . • the bios is a set of permanently recorded program routines that give the system its fundamental ope...

Page 213: 11.10.1. Bios

Section 11: service and maintenance 02/10 213 51217 rev. 1 11.10.1. Bios quick setup in most cases, configuring the system is done quickly by choosing the following main menu options. 1. Select load optimized defaults from the main menu. ─ this loads the setup default values from the bios features s...

Page 214

Section 11: service and maintenance 02/10 214 51217 rev. 1 11.10.2. Accessing the bios’ main menu enter the program's main menu by following these steps: 6. Turn on or reboot the system. ─ after the bios performs a series of diagnostic checks, the following message appears: “press del to enter setup...

Page 215

Section 11: service and maintenance 02/10 215 51217 rev. 1 11.10.3. Cmos setup menu options cmos setting description standard cmos features configures the date and time, hard disk drive type, floppy disk drive type, primary display type and more. Advanced bios features configures advanced system opt...

Page 216: 11.10.4. Fb3000

Section 11: service and maintenance 02/10 216 51217 rev. 1 11.10.4. Fb3000 ii bios settings setup utility main menu • phoenix - award bios cmos setup utility • standard cmos features • frequency/voltage control • advanced bios features • load fail-safe defaults • advanced chipset features • load opt...

Page 217: 11.10.6. Navigation

Section 11: service and maintenance 02/10 217 51217 rev. 1 11.10.6. Navigation keys • arrow keys move • enter select • +/-pu/pd value • f10 save & exit setup • esc exit • f1 general help • f5 previous values • f6 fail-safe defaults • f7 optimized defaults 11.10.7. Advanced bios features • cpu featur...

Page 218

Section 11: service and maintenance 02/10 218 51217 rev. 1 • c8000-cbfff shadow disabled • cc000-cffff shadow disabled • d0000-d3fff shadow enabled • d4000-d7fff shadow enabled • d8000-dbfff shadow enabled • dc000-dffff shadow enabled • full screen logo show disabled • small logo (epa) show disabled...

Page 219: 11.10.9. Integrated

Section 11: service and maintenance 02/10 219 51217 rev. 1 11.10.9. Integrated peripherals • onchip ide device (press enter) (1) onchip primary pci ide enabled (2) ide primary master pio auto (3) ide primary slave pio auto (4) ide primary master udma auto (5) ide primary slave udma auto (6) onchip s...

Page 220

Section 11: service and maintenance 02/10 220 51217 rev. 1 (4) uart mode select normal (5) onboard parallel port 378/irq7 (6) parallel port mode normal • watch dog timer select disabled • onboard serial port 3 3e8 • serial port 3 use irq irq9 • onboard serial port 4 2e8 • serial port 4 use irq irq10...

Page 221

Section 11: service and maintenance 02/10 221 51217 rev. 1 11.10.11. Pnp/pci configurations • pnp os installed yes • reset configuration data disabled • resources controlled by manual • irq resources (press enter) (1) irq3 assigned to pci/isa pnp (2) irq4 assigned to pci/isa pnp (3) irq5 assigned to...

Page 222: 11.10.12. Pc Health Status

Section 11: service and maintenance 02/10 222 51217 rev. 1 replacing the hard drive for a fb3000 ii • the microsoft ® product key label is located directly under the nomenclature label on the side of the fb3000. • it is a 25-digit product key (5 groups of 5 alphanumeric characters ). 11.10.12. Pc he...

Page 223

Section 11: service and maintenance 02/10 223 51217 rev. 1 11.12. Additional service information there are additional service tools within the fb3000 ii instrument. Windows control panel permits setting time, date, add and remove programs, as well as other windows features. A service manual is also ...

Page 224

Section 11: service and maintenance 02/10 224 51217 rev. 1 11.13. Additional reference information for other fb3000 ii software-specific configurations, refer to the following manuals: • interact installation / operation manual ( 50772 ) ─ data collection software configurations • in/out service man...

Page 225

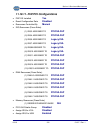

02/10 225 51217 rev. 1 section 12: parts 12.1. Fb3000 ii parts - parts list item part no. Qty description 1 30067 1 base, fb3002 2 30071 1 bracket, electronics rack fb3002 3 30075 1 base, stand fb3002 instrument 4 30069 1 box, display fb3002 5 6 29477 1 pcb assy, embedded sbc 1 ghz 7 27801 1 pcb ass...

Page 226

Appendix iii: data output 02/10 226 51217 rev. 1 fb3000 ii parts - parts list (continued) item part no. Qty description 41 10893 2 screw-mach-pan head 6-32 x .25 42 13176 5 screw-mach-pan head, phil m3 x 5 43 10104 1 nut, hex 8-32 44 14083 2 screw, sealing ss 10-32 45 11075 2 screw-cap-hex head ss 1...

Page 227

Appendix iii: data output 02/10 227 51217 rev. 1 fb3000 ii parts – diagrams (continued).

Page 228

Appendix iii: data output 02/10 228 51217 rev. 1 12.2. 1 ghz rtu rack assembly – parts list / diagram item part no. Qty description 1 25340 1 bracket 5 25617 1 hard drive assembly 8 24885 1 power supply pcb assembly 9 24886 1 embedded sbc pcb assembly 400 mhz * 25768 1 dc power cable assembly * 2780...

Page 229

Appendix iii: data output 02/10 229 51217 rev. 1 12.3. Fb3000 ii wiring diagram.

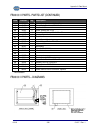

Page 230: Parts List & Diagram

Appendix iii: data output 02/10 230 51217 rev. 1 12.4. Fb3000 ii t desktop display – parts list / diagram parts list & diagram item part no. Qty description 51 26485 1 screen assy 52 26087 1 screen stand 53 26785 1 spring pin, retractable .25-20 threads 54 26786 2 shoulder screw, hex socket head 10-...

Page 231: Parts List & Diagram

Appendix iii: data output 02/10 231 51217 rev. 1 12.5. Fb 3000 t desktop display – parts list / diagram parts list & diagram item part no. Qty description 61 26485 1 screen assy 62 26495 1 wall mount bracket 63 26785 1 spring pin, retractable .25-20 threads 64 26786 2 shoulder screw, hex socket head...

Page 232

Appendix iii: data output 02/10 232 51217 rev. 1 12.6. Fb3000 ii t instrument assembly – parts list item part no. Qty description 1 30081 1 rack assembly 2 26489 2 main box side 3 26491 1 main box 1 wrap 4 26492 1 main box 2 wrap 5 25369 1 rocker switch 6 27040 1 power cord assembly 7 25312 2 fuse h...

Page 233

Appendix iii: data output 02/10 233 51217 rev. 1 12.7. Fb3000 ii t instrument assembly - diagram.

Page 234

Appendix iii: data output 02/10 234 51217 rev. 1 12.8. Fb3000 ii t rack assembly - parts list item part no. Qty description 1 26097 1 pcb base rack 2* 26099 1 pc mount 2 rack 3 17602 4 hex spacer m/f 6-32 x 0.31 long sst 4* 22610 1 analog interface pcb assembly 5* 15056 1 communications pcb assembly...

Page 235

Appendix iii: data output 02/10 235 51217 rev. 1 12.9. Fb3000 ii t rack assembly - diagram.

Page 236

Appendix iii: data output 02/10 236 51217 rev. 1 12.10. Fb3000 ii nema 4 - parts list item part no. Qty description 1 27981 1 enclosure 2 27992 1 fb3000ss gasket 3 27998 1 heat sink cover 4 27997 1 cable seal block 5 28001 1 cable clamp bracket 6 27977 1 display seal 7 27802 1 display plate 8 27983 ...

Page 237

Appendix iii: data output 02/10 237 51217 rev. 1 fb3000 ii nema 4 - parts list, continued item part no. Qty description 43 25355 1 membrane vent 44 25356 1 vent nut 46 11224 1 name plate 50 25271 31in adhesive tape 51 11272 10 spacer 0.25 dia. Delrin .125 long 52 25553 4 spacer-hex-.19 4-40 x 0.25 l...

Page 238

Appendix iii: data output 02/10 238 51217 rev. 1 66 12 4 57 67 back view 5 cn2 ;; ;; ;; ;; ;; ;; cn6 cn3 cn9 37 70 53 57 67 6 50 34 33 46 9 to 4-6 in. Lbs to be torqued 60 64 ;; ;; 8 cn1 1 c j4 j2 j1 1 j3 1 c a a 58 64 3 2 1 51 69 ref 15 69 ref 62 52 14 69 51 7 13 53 18 57 67 39 41 75 97 40 41 43 44...

Page 239

Appendix iii: data output 02/10 239 51217 rev. 1 12.12. Fb3000 ii nema 4 - system wiring diagram.

Page 240: Programming The Gpio Port

02/10 240 51217 rev. 1 appendix i: gpio port programming the gpio port the fb3000 ii provides an 8-bit gpi port and an 8-bit gpo port that you can use to read and write data through. Reading the gpio data • 2e,87 • 2e,87 • 2e,2a //configuration register(cr2a) • 2f,fc //set gpio ,not game port • 2e,0...

Page 241: Writing The Gpio Data

Appendix iii: data output 02/10 241 51217 rev. 1 writing the gpio data • 4e,87 • 4e,87 • 4e,2a //configuration register(cr2a) • 4f,fc //set gpio ,not game port • 4e,07 //point to logical device number reg. • 4f,07 //select logical device 7 • 4e,30 //configuration register(cr30) • 4f,1 //open logical...

Page 242: Interrupt Controller

02/10 242 51217 rev. 1 appendix ii: system resource interrupt controller the fb3000 embedded pcb is a fully pc compatible control board. It consists of 16 isa interrupt request lines. Most of them are already in use by other parts of the board. Both isa and pci expansion cards may need to use irqs, ...

Page 243

Appendix iii: data output 02/10 243 51217 rev. 1 shared memory (kernel mapped output) //*********************************** // sample code to read kernel mapped output (shared memory) //*********************************** // filemap memory structure struct filemapstruct { unsigned char data[256]; //...

Page 244

Appendix iii: data output 02/10 244 51217 rev. 1 shared memory (kernel mapped output), continued mappedoutputhandle = createfilemapping((handle)0xffffffff, null, page_readwrite, 0, sizeof(struct filemapstruct), “output1”); if( mappedoutputhandle == null ) { closehandle(rsemaphore); rsemaphore = null...

Page 245

Appendix iii: data output 02/10 245 51217 rev. 1 shared memory (kernel mapped output), continued { lastcounter = mapoutputdata->counter; int len = mapoutputdata->length; if( len > sizeof(mapoutputdata->data)-1 ) len = sizeof(mapoutputdata->data)-1; scalestatus_text->caption = (string)mapoutputdata->...

Page 246

02/10 246 51217 rev. 1 appendix iii: data output remote display output data format note(s): 1. Characters denoted by x are characters 0-9. 2. Leading zeroes are suppressed. 3. Polarity indication for a positive value is a space ( sp ). − negative values are not transmitted. 4. Identifier code = gros...

Page 247

Appendix iii: data output 02/10 247 51217 rev. 1 configure output, continued increment size bit # count by 1 count by 2 count by 5 3 1 0 1 4 0 1 1 5 always logic 1 6 always logic 0 7 parity bit status code (word) b status code (word) c bit # description 0 gross = 0 net = 1 1 positive = 0 negative = ...

Page 248: Toledo Data Format

Appendix iii: data output 02/10 248 51217 rev. 1 toledo data format note(s): 1. Characters denoted by g and t are characters 0-9 . 2. Leading zeroes are not suppressed. 3. Gross weight data = g tare weight data = t status code (word) a increment size bit # count by 1 count by 2 count by 5 3 1 0 1 4 ...

Page 249

Appendix iii: data output 02/10 249 51217 rev. 1 toledo data format, continued status code (word) b status code (word) c bit # description 0 gross = 0 net = 1 1 positive = 0 negative = 1 2 in range = 0 overcapacity = 1 3 no motion = 0 motion = 1 4 lb = 0 kg = 1 5 always logic = 0 6 normal = 0 power ...

Page 250: Weightronix Data Format

Appendix iii: data output 02/10 250 51217 rev. 1 cardinal 738 continuous scoreboard data format note(s): 1. W = displayed weight p = polarity + = positive weight - = negative weight u = units lb = pounds kg = kilograms m = motion or o = overload g = gross; n = net sp = space 2. Leading zeros are not...

Page 251: Build Tab Definitions

Appendix iii: data output 02/10 251 51217 rev. 1 condec continuous data format note(s): 1. P = polarity space = positive weight - = negative weight w = displayed weight u = units l = pounds k = kilograms g = gross; n = net m = motion 2. Leading zeros are suppressed. Build tab definitions load cell s...

Page 252

02/10 252 51217 rev. 1 appendix iv: network command functions command structure: [sender],[command],command,[end][lf] where sender is: the computer name of the pc which is sending the command. Where command is: lowercase z = zeroes all scales. Uppercase z1, z2, etc = zero a specific scale. Uppercase...

Page 253