- DL manuals

- Fairbanks

- Scales

- FB6011

- Service Manual

Fairbanks FB6011 Service Manual

51332

.

Rev. 13 10/2017

© 2014-2017 by Fairbanks Scales, Inc.

All rights reserved

FB6000 Series Instrumentation

FB6011

In/Out/ GTN Intalogix® Desktop Instrument

FB6012

In/Out/ GTN Intalogix® NEMA 4X Wall Mount Instrument

FB6013

IN/OUT/GTN Intalogix® Panel Mount Instrument

For complete wiring information, see

Load Cell-to-Instrument Interfaces Installation Manual,

51326

Service Manual

Service Manual

Service Manual

Service Manual

Summary of FB6011

Page 1

51332 . Rev. 13 10/2017 © 2014-2017 by fairbanks scales, inc. All rights reserved fb6000 series instrumentation fb6011 in/out/ gtn intalogix® desktop instrument fb6012 in/out/ gtn intalogix® nema 4x wall mount instrument fb6013 in/out/gtn intalogix® panel mount instrument for complete wiring informa...

Page 2

Disclaimer every effort has been made to provide complete and accurate information in this manual. However, although this manual may include a specifically identified warranty notice for the product, fairbanks scale makes no representations or warranties with respect to the contents of this manual, ...

Page 3

10/2017 3 rev. 13 51332 public license statement copyright © 2017, fairbanks scales, inc. All rights reserved the fairbanks scales company developed software is provided by the copyright holders and contributors "as is" and any express or implied warranties, including, but not limited to, the implie...

Page 4: Service Manual

10/2017 4 rev. 13 51332 amendment record fb6000 series instrumentation fb6011 in/out/ gtn intalogix desktop instrument ( 32811 ) fb6012 in/out/ gtn intalogix nema 4x wall mount instrument ( 32812 ) fb6013 in/out/gtn intalogix panel mount instrument ( 32813 ) service manual document 51332 manufacture...

Page 5

10/2017 5 rev. 13 51332 table of contents section 1: general information ................................................................. 10 1.1. Instrument description ........................................................................................... 10 1.1.1. Standard features .............

Page 6

Section 1: general information 10/2017 6 rev. 13 51332 6.1.3. Operator menu flow chart .................................................................................. 48 6.2. Audit trail .................................................................................................................

Page 7

Section 1: general information 10/2017 7 rev. 13 51332 10.1. Calibration ............................................................................................................. 76 10.1.1. Data (calibration) ..........................................................................................

Page 8

Section 1: general information 10/2017 8 rev. 13 51332 12.2. Expansion modules (30919, 30920, 30002) ........................................................ 123 12.2.1. Scale interface card (sic) programming ........................................................ 123 12.2.2. Relay pcb assembly (30...

Page 9

Section 1: general information 10/2017 9 rev. 13 51332 appendix i: data string outputs ............................................................... 161 a. Remote display output ..................................................................................... 161 b. Configure output .............

Page 10: 1.1.1. Standard Features

10/2017 10 rev. 13 51332 section 1: general information 1.1. Instrument description the fb6011/6012/6013 instrument is a basic, inbound, outbound, and gtn instrument. The instrument may be enhanced by adding either a 4-20ma or relay module to the unit. – only one (1) module may be added to provide e...

Page 11

Section 1: general information 10/2017 11 rev. 13 51332 1.2. Fb6011/12/13 instrument components each fb6011/12/13 instrument consists of the components listed below. 1 front panel assembly 6 power cable outlet 2 power supply pcb assembly 7 load cell cable gland 3 expansion 8 rj45 network cable port ...

Page 12: 31672

Section 1: general information 10/2017 12 rev. 13 51332 1.2.1. Front panel assembly and led display assembly ( 31672 & 34291c ) the front panel assembly provides power to the keypad. – the usb cable connects to terminal j14 on the base board assembly ( 33143 ) from the led display assembly ( 34291c ...

Page 13: 33143

Section 1: general information 10/2017 13 rev. 13 51332 top-down view side view 1.2.2. Base board pcb assembly ( 33143 ) the base board pcb assembly is the main instrument and graphical interface controller. The weighing application resides on the sbc. • communication between the sbc and the expansi...

Page 14: 30919, 30920

Section 1: general information 10/2017 14 rev. 13 51332 top view side view expansion cards are installed into port j8 . 1.2.4. Expansion modules ( 30919, 30920 ) expansion modules provide the physical connectivity between the fb6011/2/3 and all scale and peripheral input/ output (i/o) devices. • eac...

Page 15

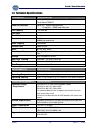

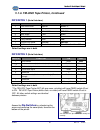

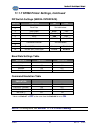

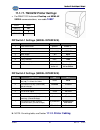

Section 1: general information 10/2017 15 rev. 13 51332 1.3. Technical specifications parameter specification model desktop fb6011; nema 4x wall mount fb6012; panel mount fb6013 load cell interface up to 16 ~ 1000Ω load cells max, or up to 8 ~ 350 Ω load cells max cell capacity 1 thru 999,999 cell u...

Page 16

Section 1: general information 10/2017 16 rev. 13 51332 1.4. Users’ responsibility ✓ all electronic and mechanical calibrations and/or adjustments required for making this equipment perform to accuracy and operational specifications should be performed by trained service personnel. ✓ absolutely no p...

Page 17

10/2017 17 rev. 13 51332 section 2: pre-installation 2.1. Introduction prior to installation, always verify that the equipment satisfies the customer's requirements as supplied, and as described in this manual. If the equipment cannot satisfy the application and the application cannot be modified to...

Page 18

Section 2: pre-installation 10/2017 18 rev. 13 51332 2.2. General service policy prior to installation, always verify that the equipment satisfies the customer's requirements as supplied, and as described in this manual. • if the equipment cannot satisfy the application and the application cannot be...

Page 19

Section 2: pre-installation 10/2017 19 rev. 13 51332 2.3. Pre-installation guidelines the following points should be checked and discussed with the area sales manager and/or customer, if necessary, before the technician goes to the site and installs the equipment. ✓ if the installation process might...

Page 20: W A R N I N G !

10/2017 20 rev. 13 51332 never perform any wiring with the instrument turned on! Damage to the system components is very likely. Never perform any wiring with the instrument turned on! Damage to the system components is very likely. W a r n i n g ! W a r n i n g ! W a r n i n g ! W a r n i n g ! Sec...

Page 21

Section 3: standard installation 10/2017 21 rev. 13 51332 3.2. Power supply wiring, switches and jumpers note: for complete wiring procedures, see load cell-to-instrument interface connections installation manual (51326). 3.2.1. Power supply jp1 jumpers the power supply pcb assembly ( 32388 ) can su...

Page 22: 3.2.2. Power Supply Leds

Section 3: standard installation 10/2017 22 rev. 13 51332 3.2.2. Power supply leds turn on the fb6011 and observe the three (3) leds on the power supply. • ds1 is located by the board-to-board connector. • ds2 is located near the center of the board. • ds3 is located near the intalogix connector. Ds...

Page 23

Section 3: standard installation 10/2017 23 rev. 13 51332 3.3. Base board pcb wiring, switches & jumpers 3.3.1. Base board jp2 jumpers the jp2 jumper of the pcb assembly base board ( 33143 ) controls the rs485 communications. • for jp2 jumper connections, see the table below. Follow these steps to a...

Page 24: 3.3.4. Sic Connections

Section 3: standard installation 10/2017 24 rev. 13 51332 attach remote display wires to port j4 of the base board. 3.3.3. Remote display 20ma wiring (j4) a.Typical connections – active instrument, passive display note: the fairbanks factory recommendation for the 20ma output is active. B. Typical c...

Page 25

Section 3: standard installation 10/2017 25 rev. 13 51332 3.4. Keypad stickers for basic operating mode when using the basic operating mode , the front panel button configuration is different. Adhere the four (4) replacement button stickers (32765) onto the standard keypad overlay in the following l...

Page 26

10/2017 26 rev. 13 51332 section 4: security 4.1. Levels of security there are three security levels for accessing the fb6011/2/3 programs. • security levels one thru three (1 – 3) configures the hierarchy of the management functions, and limits privilege accesses from unauthorized employees. • when...

Page 27

Section 4: security 10/2017 27 rev. 13 51332 4.2. Factory default service password if the service password is lost or forgotten, follow these steps to input the factory default service password and access the service menu. 1. Press menu . 2. When login displays, press enter . ✓ factory default servi...

Page 28

06/2017 28 rev. 11 51332 section 5: web interface the configuration of all fb60xx series scales with software version 2.0.1 or higher can now be performed through the instrument or through the web interface. Note: scale calibration can only be performed with versions 2.2.0 and higher web interface ....

Page 29

Section 5: web interface 10/2017 29 rev. 13 51332 note : see appendix v for step-by-step details on connecting to the fb60xx via ethernet. 5.2. Logging in to the web interface 1. Locate the ip address of the fb60xx series instrument (see also 5.1.1. To obtain the current ip address of the fb60xx ) n...

Page 30: 5.2.1. Audit Trail

Section 5: web interface 10/2017 30 rev. 13 51332 navigating the web interface after successfully logging into the fb60xx web interface, the additional options of configuration menu, service menu and expansion cards will appear in the left-hand navigation. Additional options also will appear under o...

Page 31: 5.2.2. Operator Menu

Section 5: web interface 10/2017 31 rev. 13 51332 5.2.2. Operator menu new tare : add a new tare from the scale. New keyboard tare : manually enter a new tare. Tare delete : provides the same options of new tare, new keyboard tare and deleting a tare. A drop-down menu of all the existing tares and a...

Page 32: 5.2.3. Configuration Menu

Section 5: web interface 10/2017 32 rev. 13 51332 5.2.3. Configuration menu the following options will appear in the web interface under configuration menu: customer password (configuration menu password) : change the login password of the instrument. This is highly recommended. Prompts : messages t...

Page 33

Section 5: web interface 10/2017 33 rev. 13 51332 threshold weights : initial weight option provides up and down arrows to set the minimum amount the truck must weigh to initiate a weighment. Traffic light control : control (traffic light) either automatic or manual. The event to signal option lets ...

Page 34: 5.2.4. Service Menu

Section 5: web interface 10/2017 34 rev. 13 51332 transaction files : this option allows for file deletion by five different options: all transactions, by ticket number, by date range, by ticket range and incompletes. 5.2.4. Service menu the following options will appear in the web interface under s...

Page 35: 5.2.5. Expansion Cards

Section 5: web interface 10/2017 35 rev. 13 51332 database maintenance : provides the service tech to manually restore instrument defaults and perform backups. See section 9.5. Database maintenance for details. Upgrade : this function checks the micro sd card for any new program revisions. 5.2.5. Ex...

Page 36: 5.2.6. Power Supply

Section 5: web interface 10/2017 36 rev. 13 51332 5.2.6. Power supply the following options will appear in the web interface under power supply: easy config : allows the power supply to be correctly configured after entering the correct avg cell resistance and number of cells. (see how to use easy c...

Page 37

Section 5: web interface 10/2017 37 rev. 13 51332 how to use easy config : important : when using easy config , it is crucial to make sure that the autostart option is set to on before using the easy config option. 1. While in power supply , click adjust 2. Set autostart to on using the drop-down ar...

Page 38

Section 5: web interface 10/2017 38 rev. 13 51332 4. Click power supply , and easy config 5. Enter the avg cell resistance 6. Enter the number of cells. 7. Click configure power supply. The green progress bar will show the following status updates: stopping power supply.

Page 39

Section 5: web interface 10/2017 39 rev. 13 51332 calculating drive level configuring power supply.

Page 40

Section 5: web interface 10/2017 40 rev. 13 51332 restarting power supply scanning for cells.

Page 41: 5.2.7. Scale Diagnostics

Section 5: web interface 10/2017 41 rev. 13 51332 configuration complete 5.2.7. Scale diagnostics scale diagnostics : provides real-time data of the load cell counts and weight. The following screens are available: scale diagnostics – counts with weight.

Page 42

Section 5: web interface 10/2017 42 rev. 13 51332 scale diagnostics shown with an intalogix scale (multiple load cells) and the cell counts selected. Provides the following data: • shows each cell number and zero counts it was calibrated to • shows each cell number and current counts that are distri...

Page 43

Section 5: web interface 10/2017 43 rev. 13 51332 scale diagnostics – with weight scale diagnostics shown with an intalogix scale (multiple load cells) and the weights selected. • shows each cell number and zero counts it was calibrated to • shows each cell number and current weights that are distri...

Page 44

Section 5: web interface 10/2017 44 rev. 13 51332 scale diagnostics – with zero weight scale diagnostics shown with an intalogix scale (multiple load cells) and the weights selected. Provides the following data: • shows each cell number and zero counts it was calibrated to • shows each cell number a...

Page 45

10/2017 45 rev. 13 51332 section 6: standard programming fb60xx instruments upgraded with software v2.0 or higher can now perform internal configuration through an available web interface or through the instrument. This section covers standard programming performed through the instrument. 6.1. Progr...

Page 46: 6.1.1. Login

Section 6: standard programming 10/2017 46 rev. 13 51332 6.1.1. Login 1. Press the menu button to toggle between weight display and menu system. 1. To enter the menu system, when login displays, press the enter button. – the display will be blank. 2. Input the service password , then press enter. – ...

Page 47

Section 6: standard programming 10/2017 47 rev. 13 51332 6.1.2. Defining the programming menus the six (6) programming menus are briefly defined below. Audit trail identifies how many ti mes and when changes have been made to the scale’s calibration or configuration settings. No password required op...

Page 48: 6.2.1. Display

Section 6: standard programming 10/2017 48 rev. 13 51332 6.1.3. Operator menu flow chart the operator menu allows basic operations of the instrument. – allows access to change the time, date, ticket number, and the formatting of the time and date. – allows basic diagnostics of the load cells in the ...

Page 49: 6.2.2. Print

Section 6: standard programming 10/2017 49 rev. 13 51332 6.2.2. Print sets up the print output for the audit report, then prints all configuration and calibration activities that were changed within the instrument. – offers a choice of the available printers configured to a com port. – prints some o...

Page 50

Section 6: standard programming 10/2017 50 rev. 13 51332 • webconfig – displays the current revision level of the web configuration software..

Page 51

10/2017 51 rev. 13 51332 section 7: power supply the power supply pcb assembly ( 32388 ) controls and transfers power to all the instrument components and to the pit power supply (pps). It is then regulated and transported to the smart sectional controller (sscs), which powers the load cells. 7.1. P...

Page 52

Section 7: power supply 10/2017 52 rev. 13 51332 – adjusting this does not automatically enable the power supply. When the elements of this test are incorrect, the instrument will display this message: “level above limits. See manual” note: set the drive level as low as possible. The lower, the bett...

Page 53

Section 7: power supply 10/2017 53 rev. 13 51332 7.3. Status the status function displays the power levels, as well as shows any applicable errors of the scale system. Voltage – displays the applied voltage of the scale. After calibration, these values should display at the following levels. • 5v ra...

Page 54

Section 7: power supply 10/2017 54 rev. 13 51332 7.3. Status, continued errors – displays any errors associated with the scale that may need resolving. Noted below are some of the messages displayed by the fb6011 instrument. • ok and enabled = the pps is powered up. • ok and ready = the pps is in st...

Page 55

Section 7: power supply 10/2017 55 rev. 13 51332 digital/analog sectional controllers (dssc) with digital cells, calculate the resistance of the cells by measuring the dc voltage & current at the vdc to the cell. Voltage / current=resistance) a.Note: this value must be entered here, it does not auto...

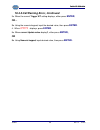

Page 56: Panel:

Section 7: power supply 10/2017 56 rev. 13 51332 7.6.1. To run easy config through the instrument front panel: 1. Login to the fb60xx 2. Use the ▼ to scroll to power supply and press enter . 3. Use the ▼ to scroll to adjust and press enter . 4. Use the ▼ to scroll to power supply and press enter . 5...

Page 57

10/2017 57 rev. 13 51332 section 8: configuration menu 8.1. Change customer pw 1. In the configuration menu, press enter . 2. When change customer password displays, press enter . 3. When enter password displays, enter . 4. Present customer password displays. 5. Input the new customer password, then...

Page 58

Section 8: configuration menu 10/2017 58 rev. 13 51332 8.2. Prompts – programmable, continued 6. Press the down arrow and choose gtn, inbound, outbound, basicin or basicout , then press enter . 7. Press the down arrow to select either disabled or enabled , then press enter to confirm this selection....

Page 59

Section 8: configuration menu 10/2017 59 rev. 13 51332 8.7. Threshold weights threshold weight sets the minimum amount the truck must weigh to initiate a weighment. – this feature is not used when the traffic light control is set to manual . Follow these steps to set the threshold weight. 1. In the ...

Page 60: C A U T I O N

Section 8: configuration menu 10/2017 60 rev. 13 51332 8.9. Reports, continued 7. When delimter displays, using the down arrow, select one of these options, then press enter . – csv ( c omma s eparated v alue) – commas separate data items in the transaction report. – tab – tabs are used to separate ...

Page 61: 9.2.1. Operating Modes

10/2017 61 rev. 13 51332 section 9: service menu the service menu programs the technical parameters of the system, such as scale capacity, span, and load cell data. 9.1. Change service pw 1. In the service menu, when the change service password displays, press enter . 2. When enter password displays...

Page 62

Section 9: service menu 10/2017 62 rev. 13 51332 9.2.1. Operating modes, continued note: with software revision 2.2.0 & lower, loop idinput can only be a numeric value, max 3 characters. Software revision 2.4.2 & higher, supports up to 15 alphanumeric characters. – the loop id number entered for an ...

Page 63

Section 9: service menu 10/2017 63 rev. 13 51332 basic (basicin/basicout) mode weighs the vehicle, then prints a ticket according to the defined ticket format for basicin/basicout. – it weighs either the gross or the tare amount. – this mode does not utilize stored tares. • with a loaded vehicle on ...

Page 64: 9.2.2. Dual Units

Section 9: service menu 10/2017 64 rev. 13 51332 9.2.2. Dual units follow these steps to setup the dual units option. 1. In the service menu, press the down arrow until the options (service) displays, then press enter. 2. When operating mode displays, press enter. 3. Press the down arrow until dual ...

Page 65: 9.2.3. Display Rate

Section 9: service menu 10/2017 65 rev. 13 51332 9.2.3. Display rate follow these steps to program the display [update] rate. 1. In the service menu, press enter. 2. Press the down arrow on 3. Ce and the options (service) will display. 4. Press enter. 5. When display rate displays, press enter. 6. P...

Page 66: 9.2.4. Zero Mode

Section 9: service menu 10/2017 66 rev. 13 51332 9.2.4. Zero mode the zero mode menu programs the functionality of the zero operation. – the ability to disable the zero switch and set the range or limit of the amount which may be zeroed from the scale. – refer to your local weights & measurement reg...

Page 67

Section 9: service menu 10/2017 67 rev. 13 51332 9.2.4. Zero mode, continued 9. Setting the limit (zero) allows either usa (100%) , canada, (2%) or off (use zero range) . Note: if this option is selected, go to range entry (zero) to set the desired percentage amount using the numeric keypad. 10. Usi...

Page 68: 9.2.5. Tare Options

Section 9: service menu 10/2017 68 rev. 13 51332 9.2.5. Tare options follow these steps to program the tare options. 1. In the service menu, press the down arrow until the options ‹service) displays, then press enter. 2. Press the down arrow until the tare options displays, then press enter. 3. When...

Page 69: 9.2.6. Nj Jumper Required

Section 9: service menu 10/2017 69 rev. 13 51332 9.2.6. Nj jumper required the fb6011/2/3 instrument provides a mechanical means of locking out the front panel from accessing the calibration menu. – the jp1 jumper on the base board sbc assembly creates a physical security to the system unmatched in ...

Page 70: 9.3.1. Cell Outputs

Section 9: service menu 10/2017 70 rev. 13 51332 9.2.6. Required nj jumper, continued follow these steps to configure the nj jumper security state . 1. In the service menu, press the down arrow once, and when the options (service) displays, press enter. 2. Press the down arrow until nj jumper requir...

Page 71: 9.3.2. Calibration

Section 9: service menu 10/2017 71 rev. 13 51332 the error message displays in the following format. Error:xxx error date: mm/dd/yyyy ghost: yes/no 6. When finished viewing data, press menu until cell outputs displays. 9.3.2. Calibration see section 10: calibration for complete instructions. 9.3.3. ...

Page 72: 9.4.1. System Settings

Section 9: service menu 10/2017 72 rev. 13 51332 9.4. Special functions 9.4.1. System settings the system settings option stores all the company information where the scale is located. 1. In the service menu, press the down arrow until special functions displays, then press enter . 2. When system se...

Page 73: 9.5.2. Backup

Section 9: service menu 10/2017 73 rev. 13 51332 • sd card is a small removable memory card for storing settings, weighment and other programming data. This card is located in the flash card holder j3 of the base board sbc assembly. • usb drive is available when a usb jump drive is installed in one ...

Page 74: 9.5.3. Restore

Section 9: service menu 10/2017 74 rev. 13 51332 9.5.3. Restore this option restores the previous settings and data, if there is a problem. 1. Restore data from the onboard memory by following these steps. A. In the service menu, select database maintenance . B. Press the down arrow and select enter...

Page 75: C A U T I O N

Section 9: service menu 10/2017 75 rev. 13 51332 9.5.4. Ticket format restore this option restores only ticket format data that was backed up previously, using the backup option. 1. In the service menu, press the down arrow until database maintenance displays, then press enter . 2. Press the down ar...

Page 76: 10.1.1. Data (Calibration)

10/2017 76 rev. 13 51332 section 10: calibration 10.1. Calibration 1. In the service menu, press the down arrow until scales (service) displays, then press enter. 2. When id 1 displays, press enter . 3. Press the down arrow until calibration displays. Press enter. 10.1.1. Data (calibration) 1. While...

Page 77

Section 10: calibration 10/2017 77 rev. 13 51332 10.1.1.Data (calibration), continued g. Auto zero tracking – using the up/down arrows, select the appropriate division. • 0.5d • 1.0d • 3.0d • off • refer to the local weights & measures regulations for the proper setting for legal-for-trade applicati...

Page 78

Section 10: calibration 10/2017 78 rev. 13 51332 10.2. Cell sensitivity there are two (2) ways to pre-calibrate the fb6011. • pre- calibrate the scale as a whole system. • pre-calibrate each load cell individually. 10.2.1. Pre-calibrate all cells together 1. In the calibration menu, press the down a...

Page 79

Section 10: calibration 10/2017 79 rev. 13 51332 3. Press the down arrow and select resistance, press enter, then using the numeric keys, input the cell’s correct ohm value. 4. After all cell data is entered, select cell x and pre-calibrate by pressing the down arrow until calibrate (mv/v/ohm) displ...

Page 80

Section 10: calibration 10/2017 80 rev. 13 51332 10.3. Trim (cell/section/scale), continued 8. Using the up/down arrows, select one of the following units, then press enter . • lb • kg • ton • tonne note : when active units are lbs and span units are kg, the entered trim weight value is converted fr...

Page 81

Section 10: calibration 10/2017 81 rev. 13 51332 i. When current test weight setting is displayed, either press enter or using the numeric keypad enter a new test weight value, then press enter . J. Repeat steps 9c thru 9i above. Or… 11a. When apply load to (cell x, section x, or scale) displays, pr...

Page 82: 10.4.1. Threshold Wt

Section 10: calibration 10/2017 82 rev. 13 51332 10.4. Cell error settings 10.4.1. Threshold wt this setting is used in conjunction with section error and cell motion error settings. ✓ valid values = 0 to 99,999 ✓ default setting = 1000 1. In the calibration menu, press the down arrow until the cell...

Page 83: 10.4.3. Section Error

Section 10: calibration 10/2017 83 rev. 13 51332 10.4.3. Section error the section error checks if both load cells within a section respond by the similar amounts as weight is applied to the section. – it operates when the weight on the scale is above the threshold wt weight setting. – an error flag...

Page 84: 10.4.4. Cell Motion Error

Section 10: calibration 10/2017 84 rev. 13 51332 10.4.4. Cell motion error the cell motion error checks for all load cell weights to change by a specified amount during a weighment, when weight goes above threshold weight value. This feature is used to identify an unresponsive cell. Trigger wt - use...

Page 85: 10.4.5. Cal Warning Error

Section 10: calibration 10/2017 85 rev. 13 51332 10.4.4.Cell motion error, continued follow these steps to format the cell motion error settings. 1. In the calibration menu, press the down arrow until the cell motion error displays, then press enter. 2. When trigger wt displays, press enter . 3. Inp...

Page 86

Section 10: calibration 10/2017 86 rev. 13 51332 10.4.5.Cal warning error, continued 3a. When the current trigger wt setting displays, either press enter , or… 3b. Using the numeric keypad, input the desired value, then press enter . 4. When update displays, press enter . 5a. When current update val...

Page 87: 11.1.2. Printer Cabling

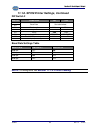

10/2017 87 rev. 13 51332 section 11: serial input / output 11.1. Printers 11.1.1. Printer switch settings roll tape printer sw 1 on sw 2 on sw 3 on switch settings idp3550 (28810) 2, 3, 4, 8 1, 2, 3, 5, 6 — 9600 baud, no parity, 8 data and 1 stop bit. Ticket printer sw 1 on sw 2 on sw 3 on switch se...

Page 88

Section 11: serial input / output 10/2017 88 rev. 13 51332 11.1.3. Idp3550 tape printer settings 11.1.4. Tm-u590 ticket printer settings • for fb6011/2/3 instrument desktop and nema 4x serial communications, use cable 14807. Set the printer dip switches as listed below. Dsw 1: 1, 3, and 7 = on only....

Page 89

Section 11: serial input / output 10/2017 89 rev. 13 51332 11.1.5. Tm-u295 ticket printer settings • for fb6011/2/3 instrument desktop and nema 4x serial communications, use cable 14807 . . Set the printer dip switches as listed below. Sw1: 1 and 3 = on remainder = off note: for wiring table, see se...

Page 90

Section 11: serial input / output 10/2017 90 rev. 13 51332 11.1.6. Tm-u220 tape printer – uses serial communication. – use cable 25932 . Wiring cable 25932 wiring for com 1-3 cable 25932 wiring for serial expansion module* * must remove the 9-pin connector. Baud 9600 parity no data bits 8 stop bit 1...

Page 91

Section 11: serial input / output 10/2017 91 rev. 13 51332 11. 1.6. Tm-u220 tape printer, continued dip switch 1 (serial interface) switch function on off 1 data receive error ignored prints “?” 2 receive buffer capacity 40 byes 4kb 3 handshaking xon/xoff dtr/dsr 4 work length 7 bits 8 bits 5 parity...

Page 92

Section 11: serial input / output 10/2017 92 rev. 13 51332 11.1.7. Sp298 printer settings • for fb6011/2/3 instrument desktop and nema 4x serial communications, use cable 14807 . Accessing the dip switches 1. Remove all power from the printer, as well as all network cables from between the printer a...

Page 93

Section 11: serial input / output 10/2017 93 rev. 13 51332 11.1.7 sp298 printer settings, continued dip switch settings (serial interface) switch function on off 1 baud rate see table below. 2 3 data length 8 bits 7 bits 4 parity check disabled enabled 5 parity odd even 6 handshake dtr/dsr xon/xoff ...

Page 94

Section 11: serial input / output 10/2017 94 rev. 13 51332 11.1.8. Sp700 printer settings • for fb6011/2/3 instrument desktop and nema 4x serial communications, use cable 14807 . There are two (2) dip switch locations on the star sp700 printer. – underneath the printer, behind a protective cover is ...

Page 95

Section 11: serial input / output 10/2017 95 rev. 13 51332 11.1.8. Sp700 printer settings, continued dip switch 2 switch function on off 2-1 baud rate see table below. 2-2 2-3 data length 8 bits 7 bits 2-4 parity check disabled enabled 2-5 parity odd even 2-6 handshake dtr/dsr xon/xoff 2-7 pin #6 (d...

Page 96

Section 11: serial input / output 10/2017 96 rev. 13 51332 11.1.9. Sp2000 printer settings the sp2000 is a dot matrix ticket printer. The following switch settings and cable requirements will work with the default format. • for fb6011/2/3 instrument desktop and nema 4x serial communications, use cab...

Page 97

Section 11: serial input / output 10/2017 97 rev. 13 51332 11.1.11. Tm-u230 printer settings • for fb6011/2/3 instrument desktop and nema 4x serial communications, use cable 14807 . Dip switch 1 settings (serial interface) switch function on off 1 data receive error ignored prints “?” 2 receive buff...

Page 98

Section 11: serial input / output 10/2017 98 rev. 13 51332 11.2. Com ports the fb6011/2/3 instrument has numerous ports and outlets allowing different input/ output devices to be utilized. • the back of the instrument has a 120v outlet, but the unit also supports 220v scale input. • the fb6011/2/3 i...

Page 99

Section 11: serial input / output 10/2017 99 rev. 13 51332 11.2.1. Programming com ports note: always configure the printer before formatting the tickets. Follow these steps to program the four (4) com ports. 1. In the configuration menu, press the down arrow until com ports displays. 2. Press enter...

Page 100

Section 11: serial input / output 10/2017 100 rev. 13 51332 11.2.2. Selecting the printer, continued 4. Using the down/up arrows, select the proper communication settings for your remote display, then press enter 5. Select the correct setting for your remote display, then press enter . 6. After chec...

Page 101: 11.2.5. Demandpc

Section 11: serial input / output 10/2017 101 rev. 13 51332 11.2.4. Selecting the pc data string output 1. When device attached displays, press enter . 2. Pressing the down arrow, select pc continuous or pc polled, then press enter . – pc continuous – sends displayed weight continuously. – pc polled...

Page 102: 11.2.5. Demandpc, Continued

Section 11: serial input / output 10/2017 102 rev. 13 51332 11.2.5. Demandpc, continued – all data strings which have a non-zero value in the coordinates will be transmitted. – the order the data strings appear in the data transmission follows the order in which the data is listed in the ticket form...

Page 103

Section 11: serial input / output 10/2017 103 rev. 13 51332 11.3. Formatting tickets 11.3.1. Standard ticket formatting procedures listed below are the standard steps for formatting a ticket. 1. Configure the service menu to the correct mode of operation. – see section 9.2.1. • the mode of operation...

Page 104

Section 11: serial input / output 10/2017 104 rev. 13 51332 11.3.1.Standard ticket formatting steps, continued consider these factors for placement of data when formatting a ticket. A. Top margin the area between the ticket sensor, stop, tear-off and the first line of print is called the top margin....

Page 105: 11.3.2. Programming Tips

Section 11: serial input / output 10/2017 105 rev. 13 51332 keypad formatting buttons units: inserts new format line before. B/g/net: inserts new format line after. Zero: deletes the current format line. Out: prints entire format script. Menu: saves ticket format. – steps back one level . Enter: sav...

Page 106

Section 11: serial input / output 10/2017 106 rev. 13 51332 11.3.2. Programming tips, continued listed below are the write (____) commands. Write (text) commands are programmable text fields, allowing legends or prompts to be altered to suit the application needs. – these text fields can be any char...

Page 107

Section 11: serial input / output 10/2017 107 rev. 13 51332 11.3.3. Ticket format commands the ticket format commands are defined below. Space (__) one (1) movement across (horizontal). Feed (__) one (1) movement downward (vertical). Invert on/off prints the ticket from the bottom-to-the-top, placin...

Page 108: 11.3.4. Ticket Formats

Section 11: serial input / output 10/2017 108 rev. 13 51332 keypad formatting buttons units: inserts new format line before. B/g/net: inserts new format line after. Zero: deletes the current format line. Out: prints entire format script. Menu: saves ticket format. – steps back one level . Enter: sav...

Page 109

Section 11: serial input / output 10/2017 109 rev. 13 51332 11.3.5. G/t/n ticket formatting defined below is the structure and appearance of a gross/tare/net ticket. Example of an actual g/t/n ticket. 14-enhance “on” > is the command for enlarged and bolded print. 32-enhance “off” > restores print s...

Page 110

Section 11: serial input / output 10/2017 110 rev. 13 51332 11.3.6. Inbound ticket formatting defined below is the structure and appearance of an inbound ticket example. Example of an inbound ticket. The image above shows the printed areas and other defined elements of the ticket. – all grey marking...

Page 111

Section 11: serial input / output 10/2017 111 rev. 13 51332 11.3.7. Outbound ticket formatting defined below is the structure and appearance of an outbound ticket example. This image shows the printed areas and other defined elements of the outbound ticket. – all grey markings are for illustration p...

Page 112

Section 11: serial input / output 10/2017 112 rev. 13 51332 keypad formatting buttons units: inserts new format line before. B/g/net: inserts new format line after. Zero: deletes the current format line. Out: prints entire format script. Menu: saves ticket format. – steps back one level . Enter: sav...

Page 113

Section 11: serial input / output 10/2017 113 rev. 13 51332 11.3.9. Basicin and basicout ticket formatting note: tickets programmed in the basicin and basicout formats can be set up as the customer requests, within the boundaries of the ticket size. ‒ the one displayed above is shown as an example o...

Page 114

Section 11: serial input / output 10/2017 114 rev. 13 51332 11.3.10. Deleting a ticket format follow these steps to delete a ticket format, and then reset to the factory default. 1. In the configuration menu , press the down arrow until ticket formats displays, then press enter. 2. When printer disp...

Page 115: 11.4.2. Ticket Format

Section 11: serial input / output 10/2017 115 rev. 13 51332 11.4.1 logging in to the web interface, continued 4. Input the default service password, then press the log in button. Service password = 2 . The web interface home screen appears. After you are logged in successfully, the message “remote c...

Page 116

Section 11: serial input / output 10/2017 116 rev. 13 51332 the image above displays a ticket with the default gtn format using a tm-u295 printer. Drag-and-drop the fields options into their place on the ticket layout area. The printed ticket will appear similar to how it is formatted. To add or del...

Page 117

Section 11: serial input / output 10/2017 117 rev. 13 51332 11.4.3. Standard default formats shown below are images of the standard default formats for each of the ticket modes when using thetm-u295..

Page 118

Section 11: serial input / output 10/2017 118 rev. 13 51332 11.4.4. Exiting without saving there are two warnings that display when the ticket format is closed without being saved. Delete button pressed without saving the format identifies the action. Closing the program without saving offers three ...

Page 119: Recommend Used With

Section 11: serial input / output 10/2017 119 rev. 13 51332 current loop voltage compliance the negative (-) power of the supply must be isolated from chassis ground. A separate power supply must be furnished for each installed passive 4-20. Full scale setting time 8msecs output impedance 25 meg ohm...

Page 120: C A U T I O N

Section 11: serial input / output 10/2017 120 rev. 13 51332 13. Access the fb6000 instrument’s internal configuration to setup the active 4-20ma pcb assembly, in order to test and calibrate the output. 14. Reassemble the instrument, then place it into operation. 11.5.2. Passive 4-20ma kit installati...

Page 121: Dedicated

Section 11: serial input / output 10/2017 121 rev. 13 51332 20. Access the fb6000 instrument’s internal configuration to setup the passive 4- 20ma pcb assembly, in order to test and calibrate the output. 21. Reassemble the instrument, then place it into operation. Failure to use a dedicated and isol...

Page 122

10/2017 122 rev. 13 51332 section 12: accessories 12.1. Installing accessories there are two optional expansion modules for the fb6011/2/3 instrument. ✓ only one of the two kits can be installed on the instrument, and not both. • 4-20ma analog kit ( 30919 ) produces an analog output between 4 and 20...

Page 123

Section 12: accessories 10/2017 123 rev. 13 51332 12.2. Expansion modules ( 30919, 30920, 30002 ) expansion modules provide the physical connectivity between the fb6000 family of instruments and all scale and peripheral input/ output (i/o) devices. Insert the scale interface card (sic) pcb assembly ...

Page 124: 30920

Section 12: accessories 10/2017 124 rev. 13 51332 note : the hex file must be placed on the root of the usb jump drive. 9.Press up or down to scroll through the list and press enter to select from the list. Display will scroll the revision of the selected file, press enter 10. The display will now i...

Page 125: Light (

Section 12: accessories 10/2017 125 rev. 13 51332 12.2.3. Acc 777 led traffic light ( 29001 ) wire the relay pcb assembly kit ( 30920 ) to the acc 777 led traffic light according to the chart shown to the right. – acc 777 ( 29700 ) is a sub-assembly component within the traffic light ( 29001 ). 12.2...

Page 126: 16163

Section 12: accessories 10/2017 126 rev. 13 51332 12.2.4.Wiring the acc 2018 traffic light relay box ( 16163 ), continued relay card connections tb1 color from relay card to acc 2018 #1 from relay card to acc 2018 #2 green pin 1 (gnd) pin 11 (gnd) red pin 2 (+5vdc) pin 12 (+5 vdc) black pin 3 (out 1...

Page 127: Relay Box (

Section 12: accessories 10/2017 127 rev. 13 51332 12.2.5. Wiring the acc 703 relay box ( 13170 ) • the acc 2019 cutoff relay box and acc 703 relay box are wired identically. • the fb6011/2/3 can control up to four (1) traffic lights [two pair (2) per scale] when a relay card ( 30920 ) is interfaced ...

Page 128: Relay Box (

Section 12: accessories 10/2017 128 rev. 13 51332 12.2.5. Wiring the acc 703 relay box ( 13170 ), continued wire color 1 st acc 703/ 2019 – lights 1-2-3-4 2 nd acc 703/ 2019 – lights 5-6-7-8 black pin 1 (gnd) pin 11 (gnd) brown pin 2 (+5vdc) pin 12 (+5 vdc) red pin 3 (out1a) pin 13 (out1b) orange pi...

Page 129

Section 12: accessories 10/2017 129 rev. 13 51332 12.2.6. Relay module [expansion card] follow these steps to program the relay module expansion card. – visible only if relay card is installed. . 1. In the expansion cards menu, press enter. 2. Press the down arrow to select relay module . 3. When de...

Page 130: 12.3.2. Event To Signal

Section 12: accessories 10/2017 130 rev. 13 51332 12.3. Traffic light control the traffic light control sets the operational modes of the traffic light. It is typically controlled automatically by the instrument weighment cycle. • each i/o relay card supports two (2) sets of lights operated in paral...

Page 131: 12.4.1. Display Mode

Section 12: accessories 10/2017 131 rev. 13 51332 12.4. Programming the remote display 12.4.1. Display mode follow these steps to setup the display mode. 1. In the configuration menu, press the down arrow until remote display appears. 2. Press enter . 3. When display mode appears, press enter . 4. W...

Page 132: 12.4.3. Enable 1605T

Section 12: accessories 10/2017 132 rev. 13 51332 12.4.2. Type (output), continued important programming considerations, continued • when display type (output) is set to ticket number , the next ticket number displays until a print occurs and the printed vehicle leaves the scale. – the weight drops ...

Page 133

10/2017 133 rev. 13 51332 section 13: user operations 13.1. Front panel key functions keys function red & green light buttons • activates the traffic light function, if one is installed. • when in the programming mode, pressing the red button returns to the weight display (except when modifying an e...

Page 134

Section 13: user operations 10/2017 134 rev. 13 51332 13.2. Operational procedures 13.2.1. Basic mode weighing basic mode weighs the vehicle, then prints a ticket displaying the time, date and weight amount (either tare or gross). This is its only function. • see section 9.2.1. To configure the inst...

Page 135: Autotare Operation

Section 13: user operations 10/2017 135 rev. 13 51332 13.2.2. Gross-tare-net mode weighing • see section 9.2.1. To configure the instrument for the gtn operating mode. Autotare operation 1a. Press the zero key. B. Drive the empty vehicle to be weighed on the platform. C. Press the tare button. – the...

Page 136: 13.2.4. Inbound Operation

Section 13: user operations 10/2017 136 rev. 13 51332 13.2.3. Inbound/outbound mode weighing noted below are a few tips for the inbound/outbound weighing mode. • with software revision 2.2.0 & lower, loop id input can only be a numeric value, max 3 characters. Software revision 2.4.2 & higher, suppo...

Page 137

Section 13: user operations 10/2017 137 rev. 13 51332 13.2.4 inbound operation, continued 3a. With the scale unloaded, press the zero key. B. Drive the loaded vehicle to be weighed on the platform. C. When the display stabilizes, press the print key. D. When key in tare and press enter display, usin...

Page 138: 13.3.1. Set Time & Date

Section 13: user operations 10/2017 138 rev. 13 51332 4. Using the down arrow, select 12 hour or 24 hour format, then press enter . 5. When date format displays, press enter . 6. Using the up/down arrows, select the best formate for the customer ’s needs, then press enter . 7. When date seperator di...

Page 139: 13.3.2. Ticket Number

Section 13: user operations 10/2017 139 rev. 13 51332 13.3.2. Ticket number follow these steps to access a specific ticket by entering the ticket number. 1. While in the operator menu, select the ticket number option, then press enter . 2a. When number displays press enter . B. Using the numeric key...

Page 140

Section 13: user operations 10/2017 140 rev. 13 51332 13.3.3. Load cell diagnostics load cell diagnostics gives a quick snapshot of how each load cell is performing, used for easier troubleshooting capabilities. Follow these steps to access the load cell diagnostics option. 1. While in the operator ...

Page 141: 13.3.4. New Tare

Section 13: user operations 10/2017 141 rev. 13 51332 13.3.4. Load cell diagnostics, continued the following categories are noted on the counts print-out. Cell num – identifies the load cell in the scale platform. Cal counts – the zero load cell count stored at calibration. Current – the current loa...

Page 142: 13.3.5. New Tare, Continued

Section 13: user operations 10/2017 142 rev. 13 51332 13.3.5. New tare, continued 10. To abort saving the tare, press enter . 11. To overwrite the existing tare data with the new tare data, press the down arrow until overwrite? – yes displays, then press enter • new tare displays. Gross weight – tar...

Page 143: 13.3.6. Tare Delete

Section 13: user operations 10/2017 143 rev. 13 51332 8. When vehicle description displays, press enter . 9. When the current vehicle description displays; input the new vehicle description, then press enter . – this can be the truck drivers’ plate number, the vendor id, or another designated identi...

Page 144: 13.3.8. Utility

Section 13: user operations 10/2017 144 rev. 13 51332 13.3.7. Tare report, continued b. Use the up/down arrows to scroll through the list. C. Press m enu to return to the tare menu. Or… 2a.Use the down arrows to select print , then press enter . B. Press enter when printer displays. C. Select an ava...

Page 145: 13.3.10. Options (Operator)

Section 13: user operations 10/2017 145 rev. 13 51332 13.3.10. Options (operator) 1. While in the operator menu, press the down arrow and select options (operator) , then press enter . 2. Press the down arrow and press enter to select one of these options. • outbound auto suggest – when processing i...

Page 146

10/2017 146 rev. 13 51332 section 14: service & maintenance 14.1. Basic troubleshooting error condition(s) solution(s) check that scale is empty if scale is empty, call for service. Load cell(s) bad. A large amount of weight has zeroed. – press ok and continue weighing. – possible load cell damage, ...

Page 147

Section 14: service & maintenance 10/2017 147 rev. 13 51332 1 14.2. Replacing the sic assembly ( 30997 ) necessary assembly tools ✓ phillips screwdriver ✓ needle nose pliers ✓ anti-static wrist band follow these steps to replace an sic pcb assembly. 1. Unplug the instrument from all external power. ...

Page 148

Section 14: service & maintenance 10/2017 148 rev. 13 51332 14.3. Replacing the keyboard ( 32060 ) and display assembly ( 34291c ) follow these steps to replace the front panel keypad assembly. 1. Remove all external power from the instrument. 2. Remove the fastening screws on the case. 3. Unplug th...

Page 149

Section 14: service & maintenance 10/2017 149 rev. 13 51332 turn switch 2 of sw2 to the on position. 14.4. Replacing the base board pcb assembly ( 33143 ) 1. Remove all external power from the instrument. 2. Unscrew the fasteners on each side of the case. 3. Unscrew the fastening screws from the def...

Page 150

Section 14: service & maintenance 10/2017 150 rev. 13 51332 14.5. Replacing the power supply pcb assembly ( 32388 ) 1. Remove all external power from the instrument. 2. Unscrew the fasteners on each side of the case. 3. Unscrew the mounting fasteners from the power supply pcb assembly, lifting it ou...

Page 151: 15.1.1. Parts List

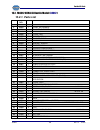

10/2017 151 rev. 13 51332 section 15: parts 15.1. Fb6011 desktop model ( 32811 ) 15.1.1. Parts list item part no. Qty description 1 31671 1 base assy 2 31672 1 front panel assy 3 31673 1 cover 4 34327 1 front panel assembly with keyboard overlay 5 33143 1 pcb assy, base board assy, includes processo...

Page 152

Section 15: parts 10/2017 152 rev. 13 51332 n/s* 15820 1 lithium battery n/s* 32765 1 labels – blank, gross print, tare print n/s* 34132c 1 250vac 1.6a fuse * n/s means not shown in the parts diagram, on the following page..

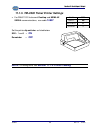

Page 153: 15.1.2. Parts Diagram

Section 15: parts 10/2017 153 rev. 13 51332 15.1.2. Parts diagram.

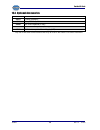

Page 154: 15.2.1. Parts List

Section 15: parts 10/2017 154 rev. 13 51332 15.2. Fb6012 nema 4x hostile model ( 32812 ) 15.2.1. Parts list item part no. Qty description 1 52555 1 box assembly 2 32552 1 stand, instrument 3 32546 1 bracket, support 4 32547 1 bracket, pcb mounting 5 32556 1 cover, usb 6 32557 1 gasket, usb 7 32548 1...

Page 155: 15.2.1.Parts List, Continued

Section 15: parts 10/2017 155 rev. 13 51332 15.2.1.Parts list, continued item part no. Qty description 40 11124 1 washer, plain #6 41 11182 3 nut, stop 6-32 42 11149 2 screw, mach, ph-phil 4-40 x .38 43 11192 washer, lock, ext. Tooth no. 4 44 32562 3 gasket, top 45 32563 2 gasket, side 46 32564 1 ga...

Page 156: 15.2.2. Parts Diagram

Section 15: parts 10/2017 156 rev. 13 51332 15.2.2. Parts diagram.

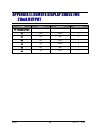

Page 157: 15.3.1. Parts List

Section 15: parts 10/2017 157 rev. 13 51332 15.3. Fb6013 panel mount ( 32813 ) 15.3.1. Parts list item part no. Qty description 1 32659 1 base assy 2 32660 1 front panel assy 3 32658 1 cover 5 33143 1 pcb assy, base board ** 6 32388 1 pcb assy, power supply 7 34291c 1 pcb assy, led display 8 32567 1...

Page 158

Section 15: parts 10/2017 158 rev. 13 51332 15.3.1 parts list, continued * n/s means the item is not shown. * * when replacing 33143 rev. A or b with 33143 rev. C or higher, in a nema 4x or panel mount fb6000, you must also order cable 34332 (not shown).

Page 159: 15.3.2. Parts Diagram

Section 15: parts 10/2017 159 rev. 13 51332 15.3.2. Parts diagram.

Page 160

Section 15: parts 10/2017 160 rev. 13 51332 15.4. Optional accessories part no. Description 30919 4-20ma analog kit * 30920 relay pcb assy kit * 25498 mini usb keyboard (87 key) 31036 standard usb keyboard (104 key) 15892 svp/ uninterruptable power supply (usb) * only one or the other of these acces...

Page 161: –>

10/2017 161 rev. 13 51332 appendix i: data string outputs a. Remote display output data format –> notes: 1. Characters denoted by x are characters 0-9. 2. Leading zeroes are suppressed. 3. Polarity indication for a positive value is a space (sp). negative values are not transmitted. 4. Identifier ...

Page 162

Appendix i: data string outputs 10/2017 162 rev. 13 51332 b. Configure output, continued status code (word) a bit # x00 x0 x x.X x.Xx x.Xxx x.Xxxx x.Xxxxx 0 0 1 0 1 0 1 0 1 1 0 0 1 1 0 0 1 1 2 0 0 0 0 1 1 1 1 fairbanks/toledo data format increment size bit # count by 1 count by 2 count by 5 3 1 0 1 ...

Page 163

Appendix i: data string outputs 10/2017 163 rev. 13 51332 b. Configure output, continued status code (word) c bit # description 0 always logic = 0 1 always logic = 0 2 always logic = 0 3 normal = 0 print switch pushed = 1 4 always logic = 0 5 always logic = 0 6 normal = 0 keyboard tare = 1 7 parity ...

Page 164

Appendix i: data string outputs 10/2017 164 rev. 13 51332 b. Configure output, continued weightronix data format character string description: sp – space g – gross or n = net w – displayed weight •6 characters if the graduation size does not have a decimal point. •5 characters if the graduation size...

Page 165

10/2017 165 rev. 13 51332 appendix ii: remote display codes for 20ma output code units weight scale # 00 – displays all data 40 lbs gross 1 41 lbs net 1 42 lbs tare 1 43 kg gross 1 44 kg net 1 45 kg tare 1.

Page 166

10/2017 166 rev. 13 51332 appendix iii: remote serial communication commands note: commands can not be combined. A carriage return must be peformed after each command, as indicated by the below. Command description a sets the auto tare weight on scale. G turns the traffic light green. ─ used in manu...

Page 167

10/2017 167 rev. 13 51332 appendix iv: drive level adjustment chart.

Page 168

10/2017 168 rev. 13 51332 appendix v: connecting to the fb60xx via ethernet connecting via the web utility using an ethernet crossover cable note : if you are not using a keyboard and mouse on your pc or if you are using a tablet, touch and hold will act as a ‘right click’. To access the current ip ...

Page 169

Appendix v: connecting to the fb60xx via ethernet 10/2017 169 rev. 13 51332 enter the primary dns as: 008.008.008.008 and press enter 12. Scroll down to apply changes scroll down to yes and press enter 13. Press the red traffic light button twice to return to the weigh screen if static is displayed ...

Page 170

Appendix v: connecting to the fb60xx via ethernet 10/2017 170 rev. 13 51332 5. Click on properties 6. Click on internet protocol ver. 4 tcp/ip 4 7. Then click on properties.

Page 171

Appendix v: connecting to the fb60xx via ethernet 10/2017 171 rev. 13 51332 8. Click use the following ip address: 9. Enter the ip address of the instrument here, but make the last number in the ip address at least 1 number higher than the instrument. 10.Click in the subnet mask box and enter 255.25...

Page 172

Appendix v: connecting to the fb60xx via ethernet 10/2017 172 rev. 13 51332 16.Enter the ip address of the instrument in the browser address bar when using certain browsers, you made need to include leading zeros when entering the ip address..

Page 173

Fb6000 series instrumentation fb6011 in/out/gtn intalogix desktop instrument fb6012 in/out/gtn intalogix nema 4x wall mount instrument fb6013 in/out/gtn intalogix panel mount instrument 1.1. Service manual 51332 fairbanks scales, inc. 821 locust kansas city, mo 64106 www.Fairbanks.Com.