- DL manuals

- Falcon

- Kitchen Appliances

- E9042

- User, Installation And Servicing Instructions

Falcon E9042 User, Installation And Servicing Instructions - Appliance Information

6

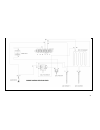

APPLIANCE INFORMATION

This appliance has been CE-marked on the basis of compliance with the relevant EU

directives for the heat inputs, gas pressures and voltages stated on the data plate.

A - Serial No

B - Model No

C - Flue Type

D - Gas Category

E - Gas Pressure

F - Gas Type

G - Gas Rate

H - Total Heat Input

I - Electrical Rating

J - Total Electrical Power

K - Magnetic Field Frequency

L - Electrical Phase Loading

Summary of E9042

Page 1

1 f900 series user, installation and servicing instructions hotplate countertop and oven range e9042, e9084, e9184 read these instructions before use t100944 published: 01-09-2017 date purchased: model number: serial number: dealer: service provider: rev 6.

Page 2

2 falcon foodservice equipment head office wallace view, hillfoots road, stirling. Fk9 5py. Scotland. Weee directive registration no. Wee/dc0059tt/pro at end of appliance life, dispose of appliance and any replacement parts in a safe manner, via a licensed waste handler. Appliances are designed to b...

Page 3

3 symbols. • spanner • screwdriver • cooking oil •grease • spark ignition • flame • warning • viewport • allen key • igniter • c spanner.

Page 4

4 these instructions are only valid if the country code appears on the appliance. If the code does not appear on the appliance, refer to the technical instructions for adapting the appliance to the conditions for use in that country. Installation must meet national or local regulations. Attention mu...

Page 5: Contents

5 contents 1.0 appliance information ..................................................................................... 6 2.0 operation .............................................................................................................. 7 2.1 component parts ...............................

Page 6: Appliance Information

6 appliance information this appliance has been ce-marked on the basis of compliance with the relevant eu directives for the heat inputs, gas pressures and voltages stated on the data plate. A - serial no b - model no c - flue type d - gas category e - gas pressure f - gas type g - gas rate h - tota...

Page 7: 2.0 Operation

7 2.0 operation 2.1 component parts a - hotplate zone control b - oven zone control c - oven temperature control d - hotplate e - flue capper f - drip tray g - door h - shelf.

Page 8

8 2.2 controls a – power neon (red) b – hotplate zone indicator c – hotplate heat neon (amber) d – oven indicator e – oven temperature indicator f – oven heat neon (amber).

Page 9

9 2.3 using the appliance 2.3.1 before use, clean the appliance hob. See section 3. 2.3.2 switch hotplate control to required setting (a). 2.3.3 to switch off hotplates turn control knob to off position. 2.3.4 switch oven zone control knob (b) to required setting. 2.3.5 use temperature control knob ...

Page 10

10 3.0 cleaning and maintenance 3.1 hob 3.1.1 at the end of each day or cooking period, turn off appliance and let it cool down. 3.1.2 remove any trivet plates if used. 3.1.3 clean the hob using soap and water ensuring that no food debris is left on the hob. 3.2 oven 3.2.1 do not stand on oven door....

Page 11

11 3.2.2 turn off and let oven cool down. 3.2.3 remove base tray, base plate and shelf hangers. 3.2.4 clean oven chamber using soap and water. 3.2.5 clean shelves and base tray using soap and water. 3.3 flue capper 3.3.1 the flue capper can be removed for cleaning but must be replaced for use..

Page 12: 4.0 Specification

12 4.0 specification 4.1 technical data for models are shown below: 4.1.1 this unit is suitable for ac supplies only. 4.2.2 the standard terminal arrangement is three phase 400v 3n~. 4.2.3 this appliance must be earthed. Live 1 ( phase 1) brown live 2 ( phase 2) black live 3 ( phase 3) grey neutral ...

Page 13

13 5.0 dimensions / connection locations a = electrical inlet.

Page 14: 6.0 Installation

14 6.0 installation 6.1 siting / clearances where this appliance is to be positioned in close proximity to a wall, partitions, kitchen furniture, decorative finishes, etc., it is recommended that they be made of non-combustible material; if not, they shall be clad with a suitable non-combustible hea...

Page 15

15 6.3 commissioning 6.3.1 remove rear hatch 6.3.2 connect appliance to mains supply 6.3.3 refer to section 2.3 or 2.4 for operation. 6.3.4 this appliance is also provided with a terminal for connection of an external equipotential conductor. This terminal is an effective electrical contact with all...

Page 16

16 6.4 suiting “patent no. Gb 2540131” 6.4.1 before leveling and suiting units ensure the units are fully built, including all accessories and castings. 6.4.2 undo the 4 fixing screws on the control panels and remove. 6.4.3 remove the hob rear infill and replace with rear suiting plate and fixings. ...

Page 17

17 6.4.8 slide suited units into position. 6.4.9 (a) right hand unit: screw the m5 x 40 screw (supplied in the kit) into one of the suiting plates as shown and then insert through the front fixing holes of both units. 6.4.9 (b) left hand unit: slide the penny and lock washer on to the screw and secu...

Page 18: 7.0 Servicing

18 7.0 servicing 7.1 control panel removal 7.1.1 remove as shown. 7.2 operating thermostat removal 7.2.1 remove operating thermostats as shown (only on e9184 model)..

Page 19

19 7.3 safety thermostat removal 7.3.1 undo screws on base access plate (only on e9184 model). 7.2.1 remove safety thermostat as shown (only on e9184 model)..

Page 20

20 7.4 hotplate removal 7.4.1 remove cover plates as required (only on e9184 model). 7.4.2 undo hotplate centre fixing nut(s) and disconnect hotplate wiring at terminal bracket (a) as appropriate. A.

Page 21

21 7.4.3 lift-off hotplate as required. 7.4.4 when re-fitting hotplate, ensure seal has been fitted into groove of spill ring..

Page 22

22 7.4.5 once the hotplate is sitting on the hob and the locating screw is through centre hole in the hotplate support assembly, carefully align and centralise the hotplate. Refit the centre fixing nut and re-tighten. This will pull down the hotplate centrally and equally. Do not adjust the four cor...

Page 23

23 7.6 bottom element removal 7.6.1 remove base shelves as required. 7.6.2 remove screws from element fixing plate as required. 7.6.2 disconnect wires and remove element from oven..

Page 24

24 7.7 circuit diagram ’s:.

Page 25

25.

Page 26

26.

Page 27

27.

Page 28

28 7.8 wiring diagram’s:.

Page 29

29.

Page 30

30

Page 31

31.

Page 32

32 8.0 oven door removal the hinge spring is under tension and no attempt should be made to remove the pins when the door is off. 8.1.1 turn off and cool down. 8.1.2 open the door fully and push an Ø4mm pin into the hole on each hinge. 8.1.3 holding the door with both hands half way down each side, ...

Page 33

33 9 accessories horizontal trivet plate 723410000 10 fault finding fault possible causes remedy unit will not turn on no power to unit check power supply is connected & turned on hotplate will not operate switch at off position change switch to position 1 oven will not operate oven not switched on ...

Page 34

34 12 service information it is recommended to have a maintenance contract with a local service provider. Serviceline contact: (uk only) phone: +441438 363 000 warranty policy shortlist for our warranty policy please go to www.Falconfoodservice.Com.