- DL manuals

- Fancor

- Scales

- 50612

- Service Manual

Fancor 50612 Service Manual - Document #50612

03/08

3

50612 Rev. 9

Amendment Record

FLOOR SCALE

Document #50612

Manufactured by Fancor, Inc.

821 Locust

Kansas City, Missouri 64106

Issue 1

Issue 2

11/97

Issue 3

08/01

Update the procedures.

Issue 4

10/01

Update the Electrical Schematic on page 6.

Issue 5

11/01

Removed brand name references.

Issue

6

01/02

Updated

manual.

Issue 7

05/02

Added note on page 16.

Issue 8

12/02

Corrected part number on analog series parts list.

Updated note callouts.

Revision 9

03/08

Revised date of load cell(s).

Removed references to stainless steel model.

Altered image: 21896 MS.

Summary of 50612

Page 1

50612 © 1997, 2002, 2008 by fancor, inc. Revision 9 03/08 all rights reserved floor scale service manual.

Page 3: Document #50612

03/08 3 50612 rev. 9 amendment record floor scale document #50612 manufactured by fancor, inc. 821 locust kansas city, missouri 64106 issue 1 issue 2 11/97 issue 3 08/01 update the procedures. Issue 4 10/01 update the electrical schematic on page 6. Issue 5 11/01 removed brand name references. Issue...

Page 4

03/08 4 50612 rev. 9 disclaimer every effort has been made to provide complete and accurate information in this manual. However, although this manual may include a specifically identified warranty notice for the product, fancor, inc. Makes no representations or warranties with respect to the content...

Page 5

03/08 5 50612 rev. 9 table of contents section 1: general information .................................................................. 7 introduction.......................................................................................................................... 7 description................

Page 7

03/08 7 50612 rev. 9 section 1: general information introduction the floor scale is available in two series. • the analog series using a standard junction box for interfacing to most analog indicators • the intalogix™ series using a quad multiplexer box (qmb) for interfacing to an intalogix™ technol...

Page 8

03/08 8 50612 rev. 9 section 2: company service information general service policy prior to installation, always verify that the equipment satisfies the customer's requirements as supplied, and as described in this manual. If the equipment cannot satisfy the application and the application cannot be...

Page 9: Physical Installation Notes

Section 2: company service information 03/08 9 50612 rev. 9 overview physical installation notes • check all devices for proper operation. If any error messages occur, refer to troubleshooting or the proper manual of that device. • only those charges which are incurred as a result of the equipment's...

Page 10: Pre-Installation Checklist

Section 2: company service information 03/08 10 50612 rev. 9 pre-installation checklist the following points should be checked and discussed with the area sales manager and/or customer , if necessary, before the technician goes to the site and installs the equipment. 9 check the customer's applicati...

Page 11: Equipment Checkout

Section 2: company service information 03/08 11 50612 rev. 9 equipment checkout position the equipment with these points in mind: 9 intense direct sunlight can harm the display. 9 do not locate near magnetic material or equipment/indicators which use magnets in their design. 9 avoid areas which have...

Page 12: In Personal Injury.

03/08 12 50612 rev. 9 section 3: scale installation 1. Select a location that is flat, solid, level, and one that fully supports the weight of the platform plus a full capacity load. 2. Remove the top of the crate and all packing material. 3. Screw the two (2) eyebolts into the threaded adapters in ...

Page 13: Technology

Section 3: scale installation 03/08 13 50612 rev. 9 installation, continued 7. Wire the scale cable to the proper type indicator, as shown in the chart below. 8. Once the scale platform is completely wired to the indicator, calibrate the unit. ─ follow the appropriate indicator service manual to ens...

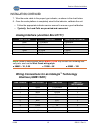

Page 14: Calibration Steps

Section 3: scale installation 03/08 14 50612 rev. 9 calibration steps adjust the analog interface indicator to the platform. • install all the corners to within one (1) division of each other at 25% of rated capacity. • follow the appropriate indicator service manual to ensure a proper calibration. ...

Page 15

Section 3: scale installation 03/08 15 50612 rev. 9 if corners do require adjustment, complete the following steps: 1. Place the concentrated weight on the corner displaying the lowest weight. 2. Turn the adjustment on the potentiometer clockwise ( cw ) to the displayed weight so it reads the same a...

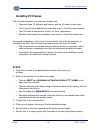

Page 16: Installing Bolt-Down Plates

03/08 16 50612 rev. 9 section 4: installing accessories installing bolt-down plates bolt down plates are used to keep the scale from sliding or moving when loads are applied. The plates are bolted using anchors at each of the scales feet. Steps 1. Place the platform into the correct position. 2. Pla...

Page 17: Installing Ramps

Section 4: installing accessories 03/08 17 50612 rev. 9 installing ramps each mild steel ramp accessory comes with two integral bolt-down plates and four anchors. Steps 1. Place the ramp in position, then lift and set the platform feet into the bolt-down plate holes. 2. Drill the two (2) 7/16” holes...

Page 18: Installing Pit Frames

Section 4: installing accessories 03/08 18 50612 rev. 9 installing pit frames the pit frame accessory is a one-piece welded unit. ─ there are three (3) different type frames with six (6) sizes for each type. ─ two (2) are for the standard duty scale and one (1) is for the heavy capacity. ─ the pit f...

Page 19

Section 4: installing accessories 03/08 19 50612 rev. 9 installing pit frames, continued 7. Use soft wire and make two (2) loops by twisting wire around each 2x4 and the frame. 8. With the frame supported by the wire and 2x4's, use a level to set the frame flush with the surrounding floor, level, an...

Page 20: Load Cell Replacement Steps

03/08 20 50612 rev. 9 section 5: parts replacement load cell replacement steps 1. Cycle-down the power to the indicator, then unplug the unit. 2. Remove the platform and junction box access covers. 3. Disconnect the failed load cell cable(s) at the junction box. 4. Loosen the gland bushing, and tie ...

Page 21: Load Cell Specifications

Section 5: parts replacement 03/08 21 50612 rev. 9 load cell specifications description specification material mild steel resistance 350 ohm rated output 3mv/v safe overload 150% compensated temperature range -10° c to 40° c safe operating temperature range -10° c to 40° c junction box replacement s...

Page 22

Section 5: parts replacement 03/08 22 50612 rev. 9 foot assembly replacement steps 1. Lift the platform end with a forklift or heavy pry bar using wood blocks for safety. 2. Remove the hole plug over the foot to be replaced. 3. Using a standard screwdriver, unscrew the foot assembly. 4. Replace with...

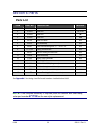

Page 23: Parts List

03/08 23 50612 rev. 9 section 6: parts parts list item part no. Description models 1 - - - - platform weldment - - - - 2 107003 load cell 1k, 2.5k 2 107004 load cell 5k 2 107005 load cell 10k 3 66754 load cell shim all 4 63913 foot assembly all 5 54501 load cell mounting bolt, ½” – 20 x 1-3/4” all 6...

Page 24: Parts Diagram

03/08 24 50612 rev. 9 parts diagram 50612-2 corner 4 corner 1 corner 2 corner 3.

Page 25

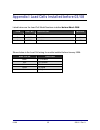

03/08 25 50612 rev. 9 appendix i: load cells installed before 03/08 listed below are the load cell model numbers installed before march 2008: item part no. Description models 2 58925 load cell 1k, 2.5k 2 12896 load cell 5k 2 63593 load cell 10k shown below is the load cell wiring for models installe...

Page 26

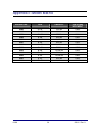

03/08 26 50612 rev. 9 appendix ii: model matrix product no. Size capacity platform weldment 63606 3’ x 3” 1000 lbs 63489 63607 3’ x 3’ 2500 lbs 63489 63608 4’ x 4’ 2500 lbs 63491 63609 4’ x 4’ 5000 lbs 63491 63610 4’ x 4’ 10,000 lbs 63491 63611 4’ x 5’ 5000 lbs 63523 63612 4’ x 5’ 10,000 lbs 63523 6...

Page 27

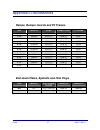

03/08 27 50612 rev. 9 appendix iii: accessories ramps, bumper guards and pit frames size capacity ramp bumper guard pit frame 3’ x 3” 1000 lbs 63751 (3’) 72198 (3’) 63757 3’ x 3’ 2500 lbs 63751 (3’) 72198 (3’) 63757 4’ x 4’ 2500 lbs 63753 (4’) 72194 (4’) 63759 4’ x 4’ 5000lbs 63753 (4’) 72194 (4’) 6...

Page 28

03/08 28 50612 rev. 9 appendix iv: pit frame installation a (narrow side) b 8" 8" 11" 8/11/00 1 jsh released 3 7/16" 11" 2 gal 10/23/02 chg’d scale foot locators a poured concrete based on the size installation of pit frame a-a view 1k-10k 4 3 b b typ typ 2 with the scale in the place, the clearance...

Page 30

Floor scale service manual document 50612 manufactured by fancor, inc ..