- DL manuals

- Fantech

- Fan

- SHR 1504

- Operation Manual

Fantech SHR 1504 Operation Manual

Summary of SHR 1504

Page 1

Shr 1504 • shr 1505 r(d) • shr 2004 • shr 2005 r(d) • shr 3005 r • shr 3205rd vhr 1404 • vhr 1405 r • vhr 2004 • vhr 2005 r • vhr 704 *leave with homeowner heat recovery ventilator operation manual for use with models.

Page 2: What Are Hrvs ?

What are hrvs ? To understand these products and their functions, here are a few things to remember. Heat recovery ventilators (hrvs) are recommended for colder areas of the coun- try that have longer heating seasons as well as drier desert areas of the south. Heat recovery ventilators are complete ...

Page 3: Operation

3 operation winter: humidity control is very important during the winter months. This is when problems will be most apparent since condensation on the windows will often occur. The colder the outside temperature, the greater the risk of condensation in the home. The average relative humidity should ...

Page 4: Modes Of Operation

Modes of operation 4 1. Continuous ventilation mode in this mode of operation, both fans are operating and exchang- ing air with the outside. The heat recovery ventilator (hrv) constantly exchanges the air at the rate you select, either at low or medium speed, and switches to high speed when acti- v...

Page 5: Optional Remote Controls

Optional remote controls 5 rts2 - the 20-minute remote timer is typically installed in areas where contaminated such as moisture and odors, are produced. Simply push the button and the hrv will activate to high speed for 20 minutes. Up to 5 electronic timers can be installed throughout the building ...

Page 6: Maintenance

6 maintenance the filters (2) need to be checked and cleaned every three months or when they appear dirty. Wash in warm sudsy water (mild detergent). The filters should be replaced when they can no longer be cleaned properly. Note: • to prevent electrical shock, check that the unit is unplugged befo...

Page 7: Troubleshooting

7 troubleshooting problem causes solutions air is too dry – dehumidistat control is set too low – increase the desired level of humidity. Change ventilation mode from continuous mode to standby. – hrv out of balance – have contractor balance hrv airflows air is too humid – dehumidistat control is se...

Page 8: Hrv Maintenance Chart

Date maintenance performed maintenance required recommended frequency 8 fantech, reserves the right to modify, at any time and without notice, any or all of its products’ features, designs, components and specifi- cations to maintain their technological leadership position. Item #:403704 rev date: 0...

Page 9: Shr & Vhr Models

Shr & vhr models shr 1504 • shr 1505 r • shr 2004 • shr 2005 r • shr 3005 r • shr 3205rd vhr 1404 • vhr 1405 r • vhr 2004 • vhr 2005 r your ventilation system should be installed in conformance with the appropriate provincial or state requirements or, in the absence of such requirements, with the cu...

Page 10: Table Of Contents

2 table of contents determining your airflow requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 technical data shr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 11

3 example for maximum airflow normally required. Hrvs are typically sized to ventilate the whole house at a minimum of 0.35 air changes per hour. To calculate, simply take the square footage of the house (including basement) and multiply by the height of the ceiling to get the cubic volume. Then, di...

Page 12: Technical Data

4 power • volts 120 vac • amperage shr 1504/1505r 1.3 amps shr 2004/2005r 2.1 amps shr 3005r 2.8 amps shr 3205rd 2.5 amps • single phase a b c d f e dimensions airflow path shr1504 shr1505r 280 133 154 320 shr 3205rd fresh air from outside stale air to outside fresh air to inside stale air from insi...

Page 13: Technical Data

5 note: some products may not be exactly as illustrated in the installation manual. Fantech inc. Reserves the right to modify, at any time and without notice, any or all of its products’ features, designs, components and specifications, to maintain their technological leadership position. W o lf r i...

Page 14: Hrv Installation

6 • have a nearby power supply (120 volts, 60hz). • choose a location which allows the possibility of mounting the unit to supporting beams. • the unit should be level in order to allow proper condensate drainage. • to minimize noise, do not install unit in living area. 2 install the drain hose, mak...

Page 15

7 exterior ducting installation weatherhood location • decide where your intake and exhaust hoods will be located. Locating the intake weatherhood • should be located upstream (if there are prevailing winds) from the exhaust outlet • at a minimum distance of 3m (10') away from dryer vents and furnac...

Page 16

8 interior ducting installation general tips to maximize airflow through the ductwork system, all ducts should be kept short and have as few bends or elbows as possible. 45º elbows are preferable to 90º. Use “y” tees instead of 90º elbows whenever possible. All duct joints must be fastened with scre...

Page 17: Installation Examples

9 installation examples bedrooms fresh air exhaust air central control - optional fresh air to living room exhaust cg 4 (4” adjustable grill) fel 4 (4” miter elbow) bathroom 460 mm 3m hrv example diagram only - duct configuration may change depending on model fully dedicated system - recommended (ne...

Page 18: Installation Examples

10 bedrooms fresh air exhaust air furnace thermostat exhaust cg 4 (4” adjustable grill) bathroom 460 mm hrv central control - optional return air hrv connection 3m partially dedicated system direct connection of the supply air stream to the furnace cold air return (stale air drawn from key areas of ...

Page 19: Installation Examples

11 installation examples (cont'd) direct connection of both the hrv supply air stream and exhaust air stream to the furnace cold air return simplified installation option 1 (return/return method) notes: 1. Furnace blower must operate when ventilation from hrv is required. The furnace should be set t...

Page 20: Installation Examples

12 direct connection of both the hrv supply air stream & exhaust air stream to the furnace cold air return & supply air side simplified installation option 2 (supply/return method) notes: 1. Furnace blower must operate when ventilation from hrv is required. The furnace should be set to run continuou...

Page 21: Start Up Procedure

13 start up procedure every time the unit is plugged in, it will go through a 45 second self diagnostic. During this time, the fresh air fans will not turn on. The switch on the side of the unit is used to toggle between standby, low speed and medium speed modes. In order to activate high speed, a j...

Page 22: Airflow Balancing

14 airflow balancing (cont'd) 1 cut hole in duct and insert flow measuring station. Make sure that the flow measuring station’s air direction arrow points in the direction of the airflow. Secure the flow measuring station with duct tape. 2 before taking the reading, make sure that the magnehelic gau...

Page 23

15 low voltage control systems * please see instruction manuals for individual controls for proper wiring and set up of control systems. This 3-speed control (low, med, high) provides 3 modes of operation: • recirculation: allows air to move gently throughout the home without exchanging air to the o...

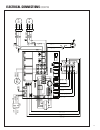

Page 24: Electrical Connections

16 electrical connections air quality sensor - + custom defrost mode jumper selectio n 3 position mode selection switc h diagnostic led u 20-minute timer (up to 5 timers) dehumidistat 2 wires dehumidistat on/off 4 wire s mechanical crank t imer 2 wire s and / or and / or (1 only) cur sw dehu m n.C. ...

Page 25: Electrical Connections

17 electrical connections (cont'd) off j2 white blac k wht/yello w orange yellow wht/green green blue wht/blue + cur sw co m in - - + dehu m n.C. N. O. - + edf timer red furna ce interl ock co m pc sw3 co m no on j7 j5 j6 j4 j3 on off on on orange orange green st and by med brow n brow n gre y tr1 r...

Page 26: Electrical Connections

18 w r g c y w r g y standard furnace interlock wiring thermostat terminals furnace 24-volt terminal block four wire two wire heating only two wire cooling system hrv electronic board w r g c y w r g y alternate furnace interlock wiring thermostat terminals furnace 24-volt terminal block four wire t...

Page 27: Troubleshooting

19 troubleshooting problem causes solutions air is too dry – dehumidistat control is set too low – increase the desired level of humidity. Change ventilation mode from continuous mode to standby. – hrv out of balance – have contractor balance hrv airflows air is too humid – dehumidistat control is s...

Page 28: Hrv Maintenance Chart

20 fantech, reserves the right to modify, at any time and without notice, any or all of its products’ features, designs, components and specifi- cations to maintain their technological leadership position. Item #: 401347 rev date: 042710 united states 10048 industrial blvd. Lenexa, ks 66215 phone: 8...