- DL manuals

- FarmTek

- Water Heater

- MWH-180

- Installation And Operating Instructions Manual

FarmTek MWH-180 Installation And Operating Instructions Manual

INSTALLATION AND OPERATING

INSTRUCTION

WARNING : If the information in this instruction is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or the

gas supplier.

INSTALLER : Leave this manual with the appliance.

CONSUMER : Retain this manual for future reference.

Model MWH-180

Residential indoor unit,

Manufactured home (mobile home)

Summary of MWH-180

Page 1

Installation and operating instruction warning : if the information in this instruction is not followed exactly, a fire or explosion may result causing property damage, personal injury or death. - do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other...

Page 2: Index

Index specifications ---------------------------------------------------------------------------- 1,2 performance ------------------------------------------------------------------------------ 2 features ------------------------------------------------------------------------------------- 3 for your...

Page 3: Specifications

- 1 - r e b m u n l e d o m 0 8 1 - h w m e c n a il p p a f o e p y t r e t a e h r e t a w w o l f s u o u n i t n o c s a g e p y t s a g d e v o r p p a e n a p o r p r o l a r u t a n n o i t a ll a t s n i g n i g n a h ll a w / y l n o r o o d n i e r u t a r e p m e t t n i o p t e s ) e t o...

Page 4: Specifications

- 2 - safety devices flame failure - flame rod over heat switch 212º f over heat limit 203º f thermal fuse 363º f automatic frost protection fan motor rpm check - pcb over current - fuse (5 amp) remote controller (option) cmr-2250(p/n 3748) main control kitchen / laundry yst-2250(p/n 3749) bathroom ...

Page 5: Features

- 3 - features the mwh-180 is a new advanced technology water heater. It produces hot water, continuously, at the preset temperature of 120ºf. For optimal performance, we recommend the use of the optional remote controllers. The mwh-180 will never run out of hot water. Hot water is available as long...

Page 6: Danger

- 4 - for your safety read before operating for your safety and proper use of the unit. Read and understand the following important symbols before use. The cases shown below are classified by the degree of risk and damage. Be sure to follow the instruction symbols for your safety. "danger" indicates...

Page 7: Danger

- 5 - for your safety read before operating danger unfastening of the vent pipes can cause a shortage of oxygen, fire, or overheating. Check to make sure the flue pipe or vent pipe is properly connected. Leaking exhaust gas indoors poses a danger if the pipes are unfastened during operation. Blockag...

Page 8: Warning

- 6 - for your safety read before operating caution to prevent scalding. Check the water temperature by hand first before using shower or stepping into the bath tub. Do not change the temperature setting while others are running hot water. Gush of hot water may cause scalding or cold water may cause...

Page 9: Warning

- 7 - for your safety read before operating warning pay attention to children. (cause of accident.) do not allow small children to play in the bathroom or to play with the remote controllers. Disassembly, repair or modification of the unit may cause fire, electric shock or other accidents. Do not di...

Page 10: Caution

- 8 - for your safety read before operating caution be sure to electrically ground the unit. Do not touch the exhaust vent pipe and water heater during or immediately after operation. Ho t!! Ground do not touch do not use hair spray or spray detergent in the vicinity. Do not install in locations whe...

Page 11: Caution

- 9 - for your safety read before operating confirm ignition, combustion and extinction. Always check flame logo indicator for combustion and that the unit has shut down by checking the operation lamp on the main or bath remote controller. Caution do not allow the remote controller to get wet. (may ...

Page 12: Caution

- 10 - for your safety read before operating use only genuine factory designated parts, and accessories. Instruction in case the unit is used in lime-rich water (hard water) area. Drain the residual hot water in the unit away. Otherwise the lime may harden and deposit in the pipe, causing lower effi...

Page 13: About Hot Water

- 11 - about hot water hot water heater temperature over 125ºf can cause severe burns instantly or death from scalding. Children, disabled and elderly are at the highest risk of scalding. Feel water temperature before bathing or showering. Scalds - first aid 1. Remove clothing; remove all wet clothi...

Page 14: Remote Controller Operation

- 12 - remote controller operation on/off button power switch to operate this control. Digital monitor indicates the selected water temperature. Error messages flash in the event of a failure. Flame logo indicator indicates that a hot water faucet is open and that control of the temperature is taken...

Page 15: Remote Controller Operation

- 13 - remote controller operation operation of main/bath remote controller. Please read these instructions carefully before using this appliance. 1. Turn on the on/off button. (refer to page 12.) 2. The temperature display will illuminate at 108ºf. 3. The priority indicator will illuminate. 4. Sele...

Page 16: Caution

- 14 - how to operate. Perform the following steps after the hot water is used. If control switch is not easily accessible : partially open the hot water faucet so that there is less than half gallon flow until the cold water starts to run. 1. Turn the on-off button off. 2. Turn on the hot water fau...

Page 17: Caution

- 15 - the residual water in the unit. Do not drink or cook with any of the water left in the unit or in the pipe for a long time because the quality may have deteriorated. Power failure in winter. Prevent freezing by following steps “ (2) by running water from any faucet. ” or “ (3) by removing wat...

Page 18: Caution

- 16 - 2. Turn on the hot water faucet. Keep water running at about 1/10 gal/min (400cc/min). The unit or pipe is likely to be damaged by freezing, not only in the cold latitudes, but also in the mild-temperature zones in winter season. Pay careful attention to prevent freezing pipes. (1) anti-frost...

Page 19

- 17 - 3. Turn on the hot water faucet. Turn on a shower faucet if any. (3) by removing water in unit as freezing may cause damage to the unit. Close 1. Close the main gas valve. Turn on 4. Remove the drain plug and the water filter. (drain stopper.) 5. Turn off the main power. This is the best meth...

Page 20

- 18 - for your safety read before operating a. This appliance does not have a pilot. It is equipped with an ignition device that automatically lights the burner. Do not try to light the burner by hand. B. Before operating : smell all around the appliance area for gas. Be sure to smell next to the f...

Page 21: Operating Instructions

- 19 - operating instructions 1. Turn off all electric power to the appliance if service is to be performed. 2. Turn the manual valve (installed on the gas supply line) clockwise to the full off position. To turn off gas to appliance. 1. Stop! Read the safety information mentioned previously before ...

Page 22: Caution

- 20 - tips for the inspection. Daily inspection and maintenance inspection. (daily.) exhaust outlet, air intake and the surrounding area. Make sure nothing obstructs the exhaust outlet and air intake. Make sure all clearances are maintained. Gas leakage. Check if gas is leaking from the unit and th...

Page 23

- 21 - maintenance. (as required.) dust. Wipe away dust and stains on the outside surface of the unit with a cloth or a sponge soaked in neutral detergent. How to replace a component. Contact the dealer when you need a component replaced. Make sure to use only factory authorized part(s) for replacem...

Page 24: Fault Monitor

- 22 - fault monitor fault monitor. The mpi water heater has a self diagnosing function for faults. When the unit does not operate correctly an error code is displayed on the main and bath remote controllers digital monitor. The cause of the fault can be determined after checking the fault numbers i...

Page 25: Fault Monitor

- 23 - alarm record monitor mode alarm record can be monitored by special operation of remote controller 1. Start up of alarm record calling mode. While on/off button is off, alarm record calling mode is obtained by simultaneously pushing both up/down buttons ( ) at main or bath remote controller fo...

Page 26

- 24 - trouble shooting and solution the following problems are not a malfunction or defect. Check again before asking for servicing. M e l b o r p n o i t a n a l p x e l a i t i n i e h t t a e t i n g i o t d r a h . S t p m e t t a d n a t e c u a f y l p p u s r e t a w t o h e h t t u h s . E ...

Page 27: Exploded View

- 25 - exploded view h i l k e f c a 21 62 32 19 3 20 17 6 22 31 29 30 28 53 54 50 52 51 47 61 38 55 56 45 45 14 63 23 24 48 49 36 1 7 18 34 25 37 39 35 37 25.

Page 28: Exploded View

- 26 - exploded view 12 60 a l h i 10 8 k j d c f 41 b e j d 26 46 44 25 25 13 16 11 59 56 57 58 40 42 43 42 5 9 15 27 4 2 41 40 18 57.

Page 29: Parts List

- 27 - r e b m u n n / p i p m n o i t p i r c s e d r e b m u n n / p i p m n o i t p i r c s e d 1 1 0 7 3 l e n a p t n o r f 4 3 4 3 7 3 r o t s i m r e h t r e g n a h c x e t a e h 2 2 0 7 3 y l b m e s s a g n i s a c 5 3 5 3 7 3 r e t p a d a t e l n i r i a 3 3 0 7 3 y l b m e s s a r e g n...

Page 30: Installation Instructions

- 28 - installation instructions • the cases shown below are classified by the degree of risk and damage. Be sure to follow the instruction for your safety. "danger" indicates that serious injuries or even death may result from the improper installation due to negligence of following the instruction...

Page 31: Installation Instructions

- 29 - installation instructions • make sure the unit to be installed suits the intended use and application. • do not use any gas other than specified on the sticker. • do not operate with any power source (voltage/frequency) other than specified on the sticker. Verification of the unit. Before ins...

Page 32: Installation Instructions

- 30 - installation instructions • reinforce the wall if necessary as this unit weighs about 43lbs. • make sure that there is adequate floor drainage to prevent flooding the floor. Caution installation. 1. Twist 1 screw (for wall hanging) into the wall leaving about 1/8" (4mm) length to hook on. 2. ...

Page 33: Installation Instructions

- 31 - installation instructions • check if adjacent wall or ceiling is fire resistant and allows safe distance for fire prevention. • this water heater is suitable for residential water (potable) heating only. Do not use this water heater for space heating, combination space heating/domestic water ...

Page 34: Dimensions

- 32 - 1 31/32" (50mm) 13/32"~1 13/16" (10~46mm) 4 5/16" (110mm) 24 17/32" (623mm) 24 1/32" (610mm) 8 9/32" (210mm) 3 5/8" (92mm) 1 5/16" (33.5mm) 13 25/32" (350mm) 6 5/8" (168mm) 4 15/32" (113.5mm) 3 13/16" (97mm) 4 1/16" (103mm) 3 13/16" (97mm) φ 5" (φ 127mm) φ 3 1/8" (φ 79mm) 22 27/32" (580mm) 2 ...

Page 35

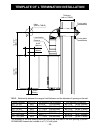

- 33 - template of l termination installation table : relationship between the range of wall thickness and the diameter of opening on the wall. Fft-7u-200 fft-7u-300 fft-7u-500 fft-7u(l)-200 fft-7u(l)-300 fft-7u(l)-500 ø5.7-5.9" ø5.8-5.9" ø6.1-6.9" ø5.7-5.9" ø5.8-5.9" ø6.1-6.9" 3.9-9.8" 9.8-17.7" 17...

Page 36

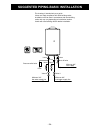

- 34 - suggested piping-basic installation minimum 3/4" hot water supply line minimum 3/4" cold water supply line minimum 3/4" gas supply shut off valve valve 3 valve 4 pressure relief valve drain this drawing is intended only as a guide. It does not imply compliance with local building codes. Insta...

Page 37

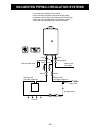

- 35 - hot water return pressure relief valve drain check valve check valve pump storage tank fixtures minimum 3/4" hot water supply line minimum 3/4" cold water supply line minimum 3/4" gas supply union shut off valve union this drawing is intended only as a guide. It does not imply compliance with...

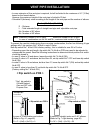

Page 38: Vent Pipe Installation

- 36 - vent pipe installation vent terminal clearances. ; v x vent terminal. Air supply inlet. Area where terminal is not permitted. K ; ; ; ; ; ; v v v v v v v v v x x fixed closed fixed closed operable operable m i b h j a b b c b f b g a b d e l inside corner detail. Clearance above grade, verand...

Page 39: Vent Pipe Installation

- 37 - vent pipe installation • use only designated vent terminal (sold separately). • install correctly in accordance with the installation manual attached. • select the correct switch position depending on the length of the vent pipe. • make sure that the proper distance, within the limitations, i...

Page 40: Vent Pipe Installation

- 38 - vent pipe installation note : maximum number of m 90 is 3pcs. Maximum number of m 45 is 5pcs. In case of combination use for m 90 and m 45 , maximum total number is 5pcs. To prevent the vent/air intake piping from occurring condensation, the fan has following 4 type settings with 2 dip swiche...

Page 41: Vent Pipe Installation

- 39 - vent pipe installation warning : • failure to follow the installation instructions could cause fire, carbon monoxide poisoning, or death. • never change the position of any dip switch other than no.7 & no.8. • unauthorized alteration and use of the unit in a wrong setting may cause material d...

Page 42: High Altitude

- 40 - high altitude note : maximum number of m 90 is 3pcs. Maximum number of m 45 is 5pcs. In case of combination use for m 90 and m 45 , maximum total number is 5pcs. In case of natural gas model ; to prevent poor combustion at higher altitudes, the fan has following 3 type settings with 2 dip swi...

Page 43: Vent Pipe Installation

- 41 - vent pipe installation warning : • failure to follow the installation instructions could cause fire, carbon monoxide poisoning, or death. • never change the position of any dip switch other than no.7 & no.8. • unauthorized alteration and use of the unit in a wrong setting may cause material d...

Page 44: Vent Pipe Installation

- 42 - (1) selecting installation site. • a vent system that exits the structure through a sidewall or the like shall terminate not less than 12" (30.5cm) above the ground. • the termination of the vent system shall be located above the snow line in geographical areas where snow accumulates. • the t...

Page 45: Vent Pipe Installation

- 43 - vent pipe installation straight length model number fftp300 fftp600 fftp900 mpi p/n 3801 3802 3803 l 11.8" (300mm) 23.6" (600mm) 35.4" (900mm) adjustable length drain tee (mpi p/n 3809) l1 : refer to table 2 (page 46) l1 : refer to table 2 (page 46) reducer (mpi p/n 3816) straight termination...

Page 46: Vent Pipe Installation

- 44 - vent pipe installation a vent system and components are the only vent system and components that have been approved by csa to use with this unit. U.L. Listed vent components of similar dimensions may be used. All the air used for combustion shall be supplied from the outside and all the exhau...

Page 47: Vent Pipe Installation

- 45 - vent pipe installation (b) rain cap, air intake pipe, and roof flashing (cap) shall be connected by turning the screw at each end of pipes clockwise as far as they will go, as shown in fig. 3. When connecting between air intake pipe and roof flashing (cap), confirm that the end of air intake ...

Page 48: Vent Pipe Installation

- 46 - vent pipe installation • adjustable lengths adjustable lengths are available to allow for installation where fixed-length sections do not produce the desired dimensions. Also adjustable lengths may be used to compensate for linear thermal expansion/contract between two fixed points. As shown ...

Page 49: Vent Pipe Installation

- 47 - • horizontal installation. Horizontal installation can consist of only horizontal termination (straight termination or l termination), reducer, and 90º elbow. If the distance between an inner wall and the center of the appliance flue outlet is under 5.7" (146mm), use l termination [fft-7u(l)]...

Page 50: Vent Pipe Installation

- 48 - vent pipe installation horizontal installation (see fig. 5). The horizontal termination (straight termination and l termination) consists of two parts (sleeve and termination itself). Separate them before installation. 1. Check the location of appliance and the path for the vent system. 2. Ch...

Page 51: Vent Pipe Installation

- 49 - vent pipe installation end of sleeve end of air intake pipe screw m4 x 10 condensation prevention plate facing plate notch 3 screws 3 plugs stamped letter termination seal between sleeve and wall seal between sleeve and wall seal between inner sleeve pipe and outer pipe sleeve about 0.2" stam...

Page 52: Vent Pipe Installation

- 50 - the straight termination consists of 2 parts (sleeve and termination itself). Separate them before installation. 1. Check the location of appliance and the path for the vent system. And calculate the required number and combination of items (see the dimensions of items in fig.1). 2. Check wal...

Page 53: Vent Pipe Installation

- 51 - vent pipe installation end of sleeve end of air intake pipe screw m4 x 10 condensation prevention plate 4 nuts up label facing plate notch 3 screws 3 plugs stamped letter termination seal between sleeve and wall seal between sleeve and wall seal between inner sleeve pipe and outer pipe sleeve...

Page 54: Vent Pipe Installation

- 52 - vertical installation means installation of vent terminal on flat or angled roofs. It consists of rain cap, reducer, straight lengths, adjustable lengths, and elbows as shown in fig. 7 install drain tee directly on the appliance flue outlet. A continuously upward slope of no less than 2º (1/4...

Page 55: Vent Pipe Installation

- 53 - vertical installation (see fig. 7). 1. Check the location of appliance and the path for the vent system. And calculate the required number and combination of items (see the dimensions of items in fig.1, page 41) of the vent system. Check the pitch of roof where the vent system passes through....

Page 56: Gas Line Sizing Charts

- 54 - gas line sizing charts e z i s e p i p t e e f n i h t g n e l ' 0 1 ' 0 2 ' 0 3 ' 0 4 ' 0 5 ' 0 6 ' 0 7 ' 0 8 ' 0 9 ' 0 0 1 ' 5 2 1 ' 0 5 1 ' 0 0 2 " 2 / 1 5 7 2 9 8 1 2 5 1 9 2 1 4 1 1 3 0 1 6 9 9 8 3 8 8 7 9 6 3 6 5 5 " 4 / 3 7 6 5 3 9 3 5 1 3 7 6 2 7 3 2 7 1 2 6 9 1 5 8 1 3 7 1 2 6 1 6 4 ...

Page 57: Gas Piping

- 55 - gas piping • install the manual gas control valve in the gas inlet connection of mwh-180. • a union should be used to connect the unit and the gas pipe. • check the gas type and the gas inlet pressure before connecting. • remove the screw from the test plug before checking the gas inlet press...

Page 58: Pressure Relief Valve

- 56 - pressure relief valve • install an approved pressure relief valve with every gas water heater installation. • the pressure relief valve shall conform to the following requirements. Relief valves and automatic gas shutoff devices for hot water supply systems ansi z21, 22. This pressure relief ...

Page 59: Electrical Connection

- 57 - electrical connection • mwh-180 requires 120v ac at 60hz. Disconnect the power supply if the unit is not in use for a long time. • remove residual water in the unit when the power supply is off because the freeze prevention in the unit will not activate, resulting in possible freezing damage....

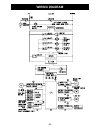

Page 60: Wiring Diagram

- 58 - wiring diagram.

Page 61: Wiring Diagram

- 59 - wiring diagram.

Page 62: Diagnostic Points

- 60 - t n e n o p m o c t n i o p t n e m e r u s a e m e u l a v l a m r o n s e t o n . O n . P m o c r o l o c e r i w r o t c e t o r p e g r u s 2 1 e u l b - n w o r b v 2 3 1 ~ 8 0 1 c a e c i v e d l o r t n o c w o l f r e t a w 0 1 d e r - e u l b v 3 1 ~ 1 1 c d t i n u o t d e il p p u ...

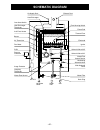

Page 63: Schematic Diagram

- 61 - schematic diagram solenoid valve sv2 electrode anti-frost heater main solenoid valve modulating solenoid valve solenoid valve sv1 burner water filter water flow control device igniter thermal fuse over heat switch outgoing thermistor surge protector pcb fan motor air thermistor flame rod remo...

Page 64: Wiring Remote Controller

- 62 - wiring remote controller the main remote controller model is cmr-2250. (p/n 3748) the bath remote controller model is yst-2250. (p/n 3749) these controllers are to be fitted in the following locations: main remote controller - kitchen or laundry. Bath remote controller - bathroom. Only one of...

Page 65

- 63 - main remote controller cmr-2250 (p/n 3748) detach right-and-left covers of the remote controller and fix them to the wall directly with wood screws. Then attach the covers again. (you can detach the covers by catching the bottom corner’s slot with nail.) in case of installing of the fitting b...

Page 66

- 64 - 1) safety precautions on bath remote controller installation. • before remote controller installation, check the hole position considering wall stud location. • note : do not dismantle the remote controller due to water-proof design. • do not install remote controller where water will contact...

Page 67: Testing Operation

- 65 - testing operation • follow the steps below, to ensure the mwh-180 has been properly installed. 1. Fully open the water supply main valve. 2. Flush out the water supply piping to clean out any installation debris, clean out filter. 3. Turn on power to unit and open gas supply valve. 1. Operate...

Page 68: Instructions For Conversion

- 66 - manifold assembly m4 with washer (3 pcs) manifold assembly m4 with washer (3 pcs) m4 × 7 pcs m4 × 7 pcs instructions for conversion instructions for converting the mwh180 from nat. Gas to lp gas or lp gas to nat. Gas. Danger: serious injury or death can result to individuals who are not licen...

Page 69: Instructions For Conversion

- 67 - instructions for conversion illustration procedure step 2: (1) remove set screws (2pcs) fixing the damper and pull the damper out downward. (2) replace damper with appropriate one stamped lp or nat. Note: damper slides up in between the burner and the front panel, housing the flame rod and el...

Page 70: Instructions For Conversion

- 68 - instructions for conversion step 5: gas pressure checking and setting procedure 1. Preparation (1) it is assumed that the inlet gas pressure coming into the unit is within the min. To max. Allowed, as per the data rating plate, for gas type to be used. The gas inlet pressure can be checked at...

Page 71: Instructions For Conversion

- 69 - instructions for conversion (3) with the unit still running, set "dip switch" no. 6 to on position to set the combustion at a maximum capacity level. At this time, a substantial amount of water should be supplied. "multiple faucets should be opened to prevent water from boiling, as the maximu...

Page 72: Warranty

- 70 - warranty monitor products, inc. Limited warranty mwh-180 instantaneous water heater monitor products, inc. Hereby warrants this gas water heater to be free from defects in materials and workmanship, under the conditions stated below. This warranty is extended to the original purchaser, but on...

Page 73: Warranty

- 71 - warranty this warranty does not apply if the water supply to the water heater does not meet the national secondary drinking water regulations as set forth in the u.S. Code of federal regulations, 40 cfr, chapter 1, part 143. The recommended water quality levels are as follows; procedure for o...