- DL manuals

- Farr

- Power Tool

- 80-0420-16

- Technical Manual

Farr 80-0420-16 Technical Manual

TECHNICAL MANUAL

©2011 McCoy Corporation. All rights reserved.

Published by McCoy Corporation, Technical Publications Department

14755 - 121A Avenue • Edmonton, AB, Canada, T5L 2T2

mccoyglobal.com

•Specifications

•Operation

•Maintenance

•Assembly

Model80-0422

Model80-0421-3

KT5500

5-1/2” (13.97cm) 18.7K Lbs.-Ft.

Hydraulic Power Tong & CLINCHER® Backup

Summary of 80-0420-16

Page 1

Technical manual ©2011 mccoy corporation. All rights reserved. Published by mccoy corporation, technical publications department 14755 - 121a avenue • edmonton, ab, canada, t5l 2t2 mccoyglobal.Com •specifications •operation •maintenance •assembly model80-0422 model80-0421-3 kt5500 5-1/2” (13.97cm) 1...

Page 3: III

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents iii t echnical m anual this manual covers the following models: note: some illustrations used in this manual may not exactly match your model of tong. Overall model tong model backup model rev description 80-0420-16 80-0420-3 85-0408 0 5...

Page 4

This page intentionally left blank.

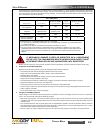

Page 5: Warnings

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents v t echnical m anual warnings any replacement fastener (bolts, nuts, cap screws, machine screws, etc.) used during maintenance or overhaul must be grade 8 or equivalent unless otherwise specified. When re-assembling load-bearing devices ...

Page 6

This page intentionally left blank.

Page 7: Vii

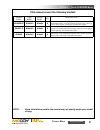

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents vii t echnical m anual summary of revisions date section page description of revision sep2007 n/a n/a initialrelease apr2008 intro iii correctedtableofassembliescoveredbythismanual,addedcompressionlcstyle backup 1 1.3 addedarmlengthspecs...

Page 8: Viii

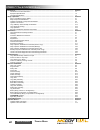

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents viii t echnical m anual introduction ................................................................................................................................................................. Section 1 introduction&contactinformat...

Page 9

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents ix t echnical m anual identification of of warnings and other nomenclature of importance used in this installation guide mccoydrilling&completionsusesthreeindicatorstodescribeitemsofthreedegreesofimportance. A hazard tooperatorsorequipme...

Page 10

This page intentionally left blank.

Page 11: 1.1

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 1.1 t echnical m anual i ntroduction congratulationsonthepurchaseofyourfarr®kt-55005-1/2”tongandclincher®backup.Thisunitwillprovide youwithyearsofoutstandingperformance.Simplemaintenanceandcarewillextenditslifeandensureyearsofexcellent p...

Page 12: 1.2

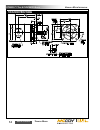

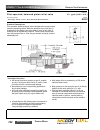

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 1.2 t echnical m anual s pecifications 60” 37” 52” model 80-0421-3 shown.

Page 13: 1.3

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 1.3 t echnical m anual s pecifications ** these are ideal values. Actual achieved torque is highly dependant upon tong efficiency and final position of rotary gear when full torque load is reached. Maximum hydraulic requirements: 60 us g...

Page 14: 1.4

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 1.4 t echnical m anual s pecifications use an ep synthetic grease that meets or exceeds the following specifications: thickener lithiumcomplex nlgiconsistencygrade 2 nlgiperformancegrade gc-lb penetration-astmd217(25°c[77°f] 265-295minim...

Page 15: 2.1

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.1 t echnical m anual s etup & o peration mccoydrilling&completionsrecommendsfollowinganindustry-acceptedstandardsuchasosha,asmeb30.9-2006,ormanu- facturer’sguidelineswhenperforminganyriggingandoverheadlifting.Usebyuntrainedpersonsishaz...

Page 16: 2.2

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.2 t echnical m anual s etup & o peration 1. Inspection of slings mccoy drilling & completions strongly recommends the following practices: acompleteinspectionofnewload-bearingdevicesandattachmentsshallbeperformedbyaqualified,designated...

Page 17: 2.3

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.3 t echnical m anual s etup & o peration unitsdesignedandmanufacturedinaccordancewithen12079anddnv2.7-1shouldbetestedandexaminedinaccordance withthefollowingscheduleofexaminationandtest.Theuseroftheload-bearingdeviceshallplaceapermanen...

Page 18: 2.4

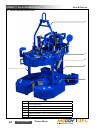

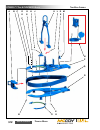

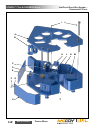

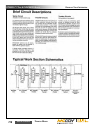

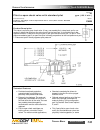

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.4 t echnical m anual s etup & o peration b. Major component identification item description 1 frontlegassembly 2 rigidsling 3 powertong 4 rearbackupspringsupportassembly 5 rearlegassembly-tensionloadcellconfiguration 6 clincher® backup...

Page 19: 2.5

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.5 t echnical m anual s etup & o peration item description 7 rigidslinglevelingdevice 8 cageplateassembly 9 safetydoorswitchguard 10 safetydoorswitch 11 tongdoorlatch 12 torquegaugemountingplate 13 backingpinassembly 14 tongjawswithdiei...

Page 20: 2.6

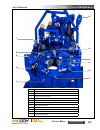

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.6 t echnical m anual s etup & o peration item description 18 hydraulicvalvebankassembly 19 manualshiftassembly 20 accesspanel 21 clincher® cylinderwithwraparoundinsert 22 hydraulicmotor 23 motormount 24 tensionloadcell 24 23 22 18 19 2...

Page 21: 2.7

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.7 t echnical m anual s etup & o peration item description 25 clincher® backup-compressionloadcellconfiguration 26 rearlegassembly-compressionloadcellconfiguration 27 compressionloadcell 25 26 27.

Page 22: 2.8

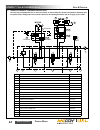

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.8 t echnical m anual c. Hydraulic schematic / component identification your tong may be equipped with one or two control valves, as well as safety door switch and hydraulics, depending upon the specific model. Disregard the control val...

Page 23: 2.9

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.9 t echnical m anual s etup & o peration 7 1 2 6 5 12 3 4 11 9 8.

Page 24: 2.10

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.10 t echnical m anual s etup & o peration 10 13 18 17.

Page 25: 2.11

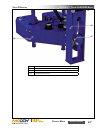

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.11 t echnical m anual s etup & o peration hydraulic return (1-1/4”) hydraulic supply (1”) d. Hydraulic connections apairofhydrauliclines-a1”supplylineanda1-1/4”returnline-connectthetongtothepowerunit(seeillustrationbelow).Ancillary dev...

Page 26: 2.12

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.12 t echnical m anual s etup & o peration thesehosecouplingsareself-sealing,andcareshouldbetakentoensurecompleteengagementtopreventpartialclosureofthe checkvalveinthecoupling.Ensurethatthenut(female)sideiscompletelymadeupontothemalecon...

Page 27: 2.13

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.13 t echnical m anual wraparound jaw die kits (inserts not included) description part number 2-3/8”-3-1/2”wraparoundjawdiekit 1064-wjk-350 4”-5-1/2”wraparoundjawdiekit 1064-wjk-550 2-3/8”wraparoundinsert(forusein1064-wjk-350) 12-2001 2...

Page 28: 2.14

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.14 t echnical m anual 2. Jaw / jaw die removal (continued): 3. Backup jaw availability thefollowingtablelistsallinsertsthatareavailableasstandardsizesforthe5-1/2”clincher®backup.Ifyourdesiredsize isnotlisted,farrcanengineercustomjawsiz...

Page 29: 2.15

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.15 t echnical m anual s etup & o peration 4. Clincher® backup jaw removal/installation i. Extend clincher® cylinders enough so that the hex flat-head cap screws securing the die retainer tabs are well exposed.Turnoffhydraulicpower. Ii....

Page 30: 2.16

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.16 t echnical m anual s etup & o peration toremovethediefromtherearjaw,ensurebothcylindersareretracted.Removethehexboltsecuringtherearjawassembly, thensliderearjawforwardenoughsothattheflat-headcapscrewssecuringthedieretainertabiswelle...

Page 31: 2.17

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.17 t echnical m anual s etup & o peration suspension & restraint (continued): mccoydrilling&completionsrecommendsusingdualbackup(snub)linesofsufficientstrengthtowithstandtheforceimparted bythemaximumratedtorqueofthetongandbackupassembl...

Page 32: 2.18

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.18 t echnical m anual s etup & o peration tong leveling continued: ii. Placealevellengthwise(fronttoback)alongthetong,ensuringthatitisparallelwiththesurfaceofthetong.Loosenthe 3/4”jamnutsontheadjustingboltsonrigidslingbrackets.Complete...

Page 33: 2.19

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.19 t echnical m anual s etup & o peration compression load cell configuration (continued): 4. Tension load cell configuration thebackupiscoupledtotherearlegoftheassemblywithatensionloadcellononeside,andarestraintchainontheother. Tochan...

Page 34

This page intentionally left blank.

Page 35: 2.21

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.21 t echnical m anual s etup & o peration mccoydrilling&completionsrecommendsthatthefollowingpre-operatingtestsbeperformedafterreceiptfromthefactoryor afterextendedstorage,priortoreleasingthetongtooperations: • performacompleteinspecti...

Page 36: 2.22

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.22 t echnical m anual s etup & o peration 3. Valve operation 4-wayproportionalvalvescontroloperationofhydraulicdevicesonthetongassemblysuchashydraulicmotorsandcylinders. Whenanyonevalveis“centered”orinthedetentposition,thereisnohydraul...

Page 37: 2.23

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.23 t echnical m anual lift cylinder thisisadirect-actingvalve.Pushingthevalvehandleforwardwillcausetheliftcylindertoliftthetongvertically.Pullingthe valvehandleintheoppositedirectionwillcausetheliftcylindertolowerthetong. 3. Shifting g...

Page 38: 2.24

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 2.24 t echnical m anual 4. General comments a) positionrotarygearincontactwithbothidlergearswhenbreakingoutjointsorcollarswherehightorquesarerequired. B) whenmaking-upintegral(shouldered)joints,itisessentialtomakeupthelastturnofthethread...

Page 39: 3.1

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.1 t echnical m anual m aintenance mccoydrilling&completionsrecognizesthatminoron-siterepairsandmodificationsarerequiredtomaintainpeakoperatingcondition ofyourequipment,ortomatchyourequipmentwiththeoperatingenvironment.Examplesofminorre...

Page 40: 3.2

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.2 t echnical m anual m aintenance d. Lubrication useaqualitymultipurposebearinglubricantthatwillremainwithinitsviscosityrangeatexpectedoperatingtemperatures.Inaddition, farrrecommendsthefollowinglubricationprocedureatthecompletionofeac...

Page 41: 3.3

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.3 t echnical m anual m aintenance 3. Rotary idlers applygreasetotherotaryidlerbearingsthroughthegreasefittingsrecessedintothetopofeachshaftonthetopfaceofthe tong(twolocationstotal). 4. Pinion idler applygreasetothepinionidlerbearingthr...

Page 42: 3.4

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.4 t echnical m anual m aintenance 5. Pinion applygreasetothepinionbearingsthroughthegreasefittingslocatedonthebearingcapsonthetopandbottomfacesofthe tong(twolocationstop,twolocationsbottom). 6. Clutch bearings applygreasetotheclutchbea...

Page 43: 3.5

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.5 t echnical m anual m aintenance 7. Motor mount applygreasetothemotorgear/clutchdrivegearthroughthegreasefittinglocatedonthetopofthemotormount(onelocation only). 8. Shifting shaft applygreasetotheshiftingshaftandtopshiftingshaftbushin...

Page 44: 3.6

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.6 t echnical m anual 9. Door latch applygreasetothedoorlatchthroughthegreasefittinglocatedinthetopoftheadjustmentcam. M aintenance 10. Clincher® cylinders applygreasetotheexternalsurfacesoftheclinchercylindersthroughthegreasefittingsin...

Page 45: 3.7

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.7 t echnical m anual m aintenance 11. Compression load cell (compression load cell style backups only) applygreasetotheflatsurfacesofthecompressionloadcellwherecontactismadewiththerearlegandthepaddleofthe backup. Farrrecommendsthatalib...

Page 46: 3.8

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.8 t echnical m anual m aintenance 2. Door latch adjustment normaloperationofthetongmaycausewearofthedoorlatch,whichwillcausethedoortodevelopaloosefitatthelatch.A latchcamplateislocatedatthetopfaceofthedoor.Thecamplatehaseightpositionin...

Page 47: 3.9

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.9 t echnical m anual m aintenance separation of tong from backup 1. Suspendtongassemblywithcrane.Constructasupportstructurethatwillsupporttheweightofthebackup.Lowerthetong/ backupassemblyontotheconstructedsupportuntilallweightisremoved...

Page 48: 3.10

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.10 t echnical m anual 14. Removedoorassemblybyremovingthedoorrollershaft.Supportdoorassemblyastherollershaftisremoved.Removethe nutfromthetopoftherollershaft,anduseasoftalloymaterial(e.G.Brassrod,etc.)tolightlytaptheshaftdownthroughthe...

Page 49: 3.11

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.11 t echnical m anual m aintenance all fasteners used during reassembly of load-bearing components (chain slings, rigid slings, backup legs) must be tightened to the correct torque. Threaded fasteners used in load-bearing devices must ...

Page 50: 3.12

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.12 t echnical m anual m aintenance note on installation practices: ensure all bearings are liberally greased before installing over a shaft or into gears or bearing caps. When inserting a shaft through a support roller assembly ensure ...

Page 51: 3.13

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.13 t echnical m anual m aintenance mechanical assembly procedure (continued): 5. Installsupportrollerassembliesinthelocationsexposedbytheopeningintherotarygear.Continuetorotatetherotarygear, installingsupportrollerassembliesintherotary...

Page 52: 3.14

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.14 t echnical m anual mechanical assembly procedure (continued): 27. Securethetopplatewithfourteen3/8”uncx1-1/2”hexboltsand3/8”lockwashers,andfive3/8”uncx1”low-headheight hexsocketheadcapscrews.Donotinstallfastenerscoincidentalwithther...

Page 53: 3.15

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.15 t echnical m anual mechanical assembly procedure (continued): 35. Insertthedetentball(pn02-0018)throughtheendofthedetenttubeattachedtothetopshifterbushing,followedbythedetent spring(pn997-0-64)threada7/16”unfjamnutontoa7/16”unfx1-1/...

Page 54: 3.16

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.16 t echnical m anual m aintenance mechanical assembly procedure (continued): 44. Installtheremainingsupportrollershafts(excludingthedoorpivotrollershaft): “stand-alone”tongs(models80-0420-5,80-0420-12) i. Slidea7/8”narrowflatwasherove...

Page 55: 3.17

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.17 t echnical m anual m aintenance vii. Attachthesafetydoorswitchguardplate,pn101-1480,tothesafetydoorswitchguardweldmentusingthree3/8”nc x3/4”hexboltsandlockwashers. 59. Threaddoorcylindermountingpost(pn1050-12-001)intotopplate,justad...

Page 56: 3.18

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.18 t echnical m anual m aintenance mechanical assembly procedure (continued): 61. Attachtherigidslinghangerweldments(lhweldment=pn101-0150,rhweldment=pn101-0151)tothetopplateusing two3/8”ncx1-3/4”bolts(outside),two3/8”ncx1”bolts(inside...

Page 57: 3.19

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.19 t echnical m anual m aintenance mechanical assembly procedure (continued): 71. Useacraneandtemporaryslingtohoistthebackupassemblyontoasupportstructurenexttotheassemblylocationofthe tong.Minimumheightforthebackupsupportsmustbe36”inor...

Page 58: 3.20

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.20 t echnical m anual mechanical assembly procedure (continued): 83. Attachtheoutletcouplingsupportweldment(pn101-0023)totheweldmentmountusingtwo3/8”ncx1”hexboltsand 3/8”lockwashers.Attachtheadjustmentplate(pn101-0277)totheoutletsuppor...

Page 59: 3.21

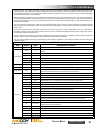

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.21 t echnical m anual i. Daily inspection & maintenance checklist (power tong) farrrecommendsthatthefollowinginspectionandmaintenanceproceduresbeperformedbeforeeachuse,andatleastonceper daywhenthetongisinsteadyuse,intheorderinwhichthey...

Page 60: 3.22

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.22 t echnical m anual m aintenance 23. Whilerotatingthecageplate,ensurethatthejawsproperlycam.Ifthejawsdonotcamproperly,thebrakebands needtobetightened.Incrementallyadjustboththetopandbottombrakebandsequallyuntilpropercamaction isachie...

Page 61: 3.23

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.23 t echnical m anual m aintenance j. Monthly maintenance checklist - power tong thefollowingmaintenancechecklistisintendedasaguidelineratherthanadefinitivemaintenanceschedule.Yourequipmentmay requiremore,orless,maintenancedependingupo...

Page 62: 3.24

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.24 t echnical m anual m aintenance 12. Performavisualinspectionofallliftingpoints-ifvisibledamageisseen,includingcracks,brokenlugs,distortedmetal, etc.Replacedamagedpart(s)beforeplacingtonginservice.Alsoinspectallchains,masterlinks,and...

Page 63: 3.25

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.25 t echnical m anual m aintenance 28. Re-energizepowerunitandextendallhydrauliccylinders.Inspectcylinderrodsforsignsofmechanicaldamage,flak- ing,orrust.Farrrecommendsthatdamagedcylindersbereplaced. 29. Rotatetonginlowgearfor5minuteswh...

Page 64: 3.26

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.26 t echnical m anual m aintenance k. Daily inspection & maintenance checklist (power unit) farrrecommendsthatthefollowinginspectionsandmaintenanceproceduresbeperformedbeforeeachuse,andatleastonceper daywhentheequipmentisinsteadyuse,in...

Page 65: 3.27

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.27 t echnical m anual m aintenance l. Daily inspection & maintenance checklist (backups) farrcanadarecommendsthatthefollowinginspectionandmaintenanceproceduresbeperformedbeforeeachuse,andatleast onceperdaywhenthebackupisinsteadyuse,int...

Page 66: 3.28

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.28 t echnical m anual m aintenance m. Tubular connection equipment de-commissioning procedure performthefollowingdecommissioningprocedureswhenremovingtubularconnectionequipmentfromservice,withtheintentof shorttolong-termstorage.Thesepr...

Page 67: 3.29

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.29 t echnical m anual m aintenance d epressurization p rocedure f or s torage : 1) rotatethetongtothe“openthroat”position. 2) exerciseeachhydrauliccylinderseveraltimes-openthetongandbackupdoors(ifequipped),retractandextendthe remotebac...

Page 68: 3.30

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.30 t echnical m anual m aintenance ifpossible,storeinasealed,climatecontrolledenvironment.Ifisolatedstorageisnotavailable,farrrecommendsstoringyourwrapped equipmentinasecure,out-of-the-waylocation,usingsilicageldesiccanttoreducethehumi...

Page 69: 3.31

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.31 t echnical m anual m aintenance n. Tubular connection equipment re-commissioning procedure performthefollowingrecommissioningprocedureswhenremovingtubularconnectionequipmentfromshortorlong-termstorage backintoregularservice.Thesepro...

Page 70: 3.32

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 3.32 t echnical m anual m aintenance 20. Performafullfunctionaltestoftheequipmentincluding,ifapplicable,backupcomponentsandfloatframecomponents. Reportandcorrectanyhydraulicleaksfromthehydraulicvalvebank,orfromanyhydrauliccylindersthatar...

Page 71: 4.1

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 4.1 t echnical m anual t roubleshooting adequate maintenance and proper fluid selection is essential for minimizing hydraulic-related failures. All troubleshooting must be performedbyatechniciantrainedinhydraulicsystems,andfamiliarwithth...

Page 72: 4.2

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 4.2 t echnical m anual t roubleshooting tong will not develop sufficient torque cont’d: 10. Possibleproblem:loadcellismeasuringincorrectly. Solution:incorrectloadcellisbeingused. Solution:airistrappedintorquemeasuringcircuit(loadcell,hyd...

Page 73: 4.3

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 4.3 t echnical m anual t roubleshooting b. Failure of jaws to grip pipe 1. Possibleproblem:dieshavebecometoodulltoprovideadequategrip. Solution:replacedies. 2. Possibleproblem:incorrectjawsarebeingused. Solution:double-checkjawsizetoensu...

Page 74: 4.4

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 4.4 t echnical m anual t roubleshooting c. Tong running too slowly 1. Possibleproblem:obstructionintonghydrauliccircuitpreventingadequateflow. Solution:inspectself-sealingcouplingstoensuretheyareproperlyengaged. Solution:themainhydraulic...

Page 75: 4.5

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 4.5 t echnical m anual t roubleshooting d. Failure or difficulty of tong to shift 1. Possibleproblem:bentorbrokenshifterhandle. Solution:replaceshifterhandle. 2. Possibleproblem:bentorbrokenshifteryoke. Solution:inspectandreplaceshiftery...

Page 76: 4.6

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 4.6 t echnical m anual t roubleshooting e. General comments thefollowingfactorsgenerallycontributetopoorhydraulicoperationandprematurewearofequipment: 1. Contaminatedhydraulicfluidduetooveruse,overheating,orinadequatefluidfiltration. 2. ...

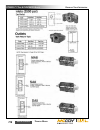

Page 77: 5.1

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.1 t echnical m anual parts and assemblies model80-0422shown model80-0421-3shown.

Page 78: 5.2

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.2 t echnical m anual g ear t rain l ayout j l a b c e f d g h k.

Page 79: 5.3

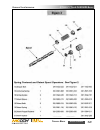

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.3 t echnical m anual g ear t rain l ayout item type description qty partnumber a part hydraulicmotor 1 87-0110 b part motorgear 1 997-a10-149 c assembly clutchassembly(pp.5.14-5.15) 1 d assembly rotaryidlerassembly(pp.5.8-5.9) 2 e asse...

Page 80: 5.4

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.4 t echnical m anual s upport r oller a b c d e f g e d c h.

Page 81: 5.5

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.5 t echnical m anual s upport r oller item type description qty part number a part 1/4”unfstraightgreasefitting 1 02-0097 b part supportrollershaft (1) 1 101-3942 part supportrollershaft(backupreadytongsonly) 1 101-3943 part doorpivotr...

Page 82: 5.6

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.6 t echnical m anual r otary i dler a ssembly a b c d e f g e f d c h j k.

Page 83: 5.7

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.7 t echnical m anual r otary i dler a ssembly item type description qty partnumber a part greasefitting,1/8”npt 1 02-0005 b part 1-1/2”unfnylocknut 2 09-5740 c part rotaryidlerpad 2 997-d20-125 d part idlerbearingspacer 2 997-d20-121 e...

Page 84: 5.8

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.8 t echnical m anual p inion i dler a ssembly a b c d e c j h f g k l.

Page 85: 5.9

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.9 t echnical m anual p inion i dler a ssembly item type description qty part number a part idlerbearingretainer 1 02-0008 b part bearingseal 1 02-0010 c part retainerring 2 02-0009 d part idlergear 1 997-a2-119 e part idlerbearing 1 02...

Page 86: 5.10

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.10 t echnical m anual p inion a ssembly a b c d e j h f g f e d c b a.

Page 87: 5.11

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.11 t echnical m anual p inion a ssembly item type description qty part number a part greasefitting,1/8”nptx90degree 4 02-0093 b part 1/2”uncx1-1/4”hexbolt 8 09-1168 c part 1/2”lockwasher 8 09-5110 d part pinionbearingcap 2 997-d15-89 e...

Page 88: 5.12

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.12 t echnical m anual c lutch a ssembly a b c d e j j k l h f g n p q r s t u m.

Page 89: 5.13

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.13 t echnical m anual c lutch a ssembly item type description qty partnumber a part outsidesnapring 1 02-0001 b part driveshaft/clutchgear 1 997-a3-61 c part #10-24x3/4”hexsocketheadcapscrew 2 09-0001 d part topclutchbearingretainer 1 ...

Page 90: 5.14

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.14 t echnical m anual s hifter a ssembly a b c d e j k m n l h f g p q r s c.

Page 91: 5.15

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.15 t echnical m anual s hifter a ssembly item type description qty partnumber a weldment shifterhandle 1 1037-d-20b b part 5/16”x1-1/2”ansi/asmeb18.8.1clevispin 2 09-0256 c part bs15745/64”x5/8”cotterpin 2 d part shiftingshaft 1 1400-7...

Page 92: 5.16

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.16 t echnical m anual c ageplate a ssembly a b c d e j h f g k l m n p q r s t u.

Page 93: 5.17

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.17 t echnical m anual c ageplate a ssembly item type description qty partnumber a part 1/2”uncx8”hexbolt 1 09-1198 b part 1/2”narrowflatwasher 1 09-5119 c part backingpinspacer 1 101-4093 d part jawpivotbolt 2 1064-28 e part 1/2”ncx6”h...

Page 94: 5.18

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.18 t echnical m anual t ong b ody a ssembly a b c d e f g e j s b h k l d e e g n p q r m.

Page 95: 5.19

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.19 t echnical m anual t ong b ody a ssembly item type description qty part number a assembly doorassembly(seepp.7.30-7.31) 1 b part 3/8”ncx1-3/4”hexsocketcap(flatheadheight) 5 09-2052 c assembly doorcylinderassembly 1 101-0069 d part 3...

Page 96: 5.20

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.20 t echnical m anual b rakeband a ssembly a b c d e f g.

Page 97: 5.21

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.21 t echnical m anual b rakeband a ssembly item type description qty part number a part 3/8”ncx3/4”hexbolt 2 09-1044 b part 3/8”carbonsteellockwasher 2 09-5106 c part brakebandretainer 1 101-0140 d assembly brakeband,lined 1 1064-d4-29...

Page 98: 5.22

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.22 t echnical m anual m otor m ount a ssembly a b c d e j f g k n m p q h l.

Page 99: 5.23

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.23 t echnical m anual m otor m ount a ssembly item type description qty part number a weldment torquegaugemountweldment 1 1500-09-03a b part 1/2”ncx1-1/4”hexsocketheadcapscrew 2 09-2168 c part 1/2”ncx1”hexsocketheadcapscrew 2 09-2166 d...

Page 100: 5.24

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.24 t echnical m anual h ydraulic a ssembly c r s q a v w d b f g l j k u n p t e m h x x.

Page 101: 5.25

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.25 t echnical m anual h ydraulic a ssembly item type description qty part number a part m-npt/f-npt90d1”fitting 1 02-9221 b part 1”longnipple 1 101-0079 c assembly m-orb/f-npt90d1”fitting(includesseals) 1 02-9206 d part hydraulicinlet,...

Page 102: 5.26

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.26 t echnical m anual t ong d oor a ssembly a b c d e f g h j k l m n p q p r.

Page 103: 5.27

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.27 t echnical m anual t ong d oor a ssembly item type description qty part number a part 5/16”x3/4”uncshoulderbolt 2 09-0227 b assembly doorcylinder 1 101-0069 c part 3/8”ncx1”hexbolt 1 09-1046 d part 3/8”carbonsteellockwasher 3 09-510...

Page 104: 5.28

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.28 t echnical m anual s afety d oor a ssembly a b c a d h g e f j d l k d m n p q r.

Page 105: 5.29

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.29 t echnical m anual s afety d oor a ssembly item type description qty partnumber a part 3/8”ncx3/4”hexbolt 4 09-1044 b part switchguardtopplate 1 101-1480 c part 3/8”ncx2-1/4”hexbolt 3 09-1055 d part 3/8”carbonsteellockwasher 9 09-51...

Page 106: 5.30

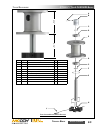

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.30 t echnical m anual l eg a ssemblies a b d e f h q c l p m l p g n j k.

Page 107: 5.31

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.31 t echnical m anual l eg a ssemblies item type description qty part number a part 1-1/4”ncx8”hexbolt 2 09-0222 b part 1”ncx7”hexbolt 2 09-9165 c weldment rearlegweldment-tensionloadcellconfiguration 1 1010-1987 weldment rearlegweldme...

Page 108: 5.32

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.32 t echnical m anual l eg a ssemblies a q o r s p t u m n j l w v k i b c h d e f g b.

Page 109: 5.33

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.33 t echnical m anual item type description qty part number a weldment lhfrontlegmount 1 101-0787 b part 7/16”ncx31/2”hexbolt 4 c part 7/8”nfthinnylocknut 4 09-5722 d part supportleg 2 1364-909 e part frontlegspringtopcap 2 101-4489 f ...

Page 110: 5.34

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.34 t echnical m anual b ackup b ody a ssembly - t ension lc c onfig a b d e j k h c g l m b q n p g f.

Page 111: 5.35

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.35 t echnical m anual item type description qty part number a part rearbodyplate 1 1391-7-3 b part 1-1/4”unchexnut 3 09-5832 c part 1-1/4”uncx8”threadedrod 1 101-1993 d part suspensionspringv-bracket 1 1483-500-00-04 e part suspensions...

Page 112: 5.36

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.36 t echnical m anual b ackup b ody a ssembly - c ompression lc c onfig a b e f k l j c d h g r q t m s n m p u v.

Page 113: 5.37

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.37 t echnical m anual b ackup b ody a ssembly - c ompression lc c onfig item type description qty part number a weldment loadcellholderweldment 1 01-9116d b part 3/8”regularflatwasher 1 09-5006 c part 3/8”ncx1-1/4”hexbolt 1 09-1048 d p...

Page 114: 5.38

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.38 t echnical m anual l ow -p rofile b ackup b ody a ssembly - c ompression lc c onfig a i j b k e g h f c l m n d.

Page 115: 5.39

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.39 t echnical m anual l ow -p rofile b ackup b ody a ssembly - c ompression lc c onfig item type description qty part number a weldment backupbody 1 1421-500-lp b weldment 2”loadcellholder 1 01-9116d c part reliefvalvebody 1 08-1839 d ...

Page 116: 5.40

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.40 t echnical m anual clincher® c ylinders a k d g j l h c b p q e f m n r s t.

Page 117: 5.41

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.41 t echnical m anual clincher® c ylinders item type description qty part number a part 3/8”unfx1”hexsocketflatheadcapscrew 4 09-4046 b part dieretainer(top) 2 101-2981 part dieretainer(bottom) 2 101-2290 c part wraparoundinsert(seepp....

Page 118: 5.42

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.42 t echnical m anual r igid s ling a ssembly a f c b a g h j d k l e m n p q j.

Page 119: 5.43

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 5.43 t echnical m anual r igid s ling a ssembly item type description qty part number assembly chainslingassembly 1 101-2211 a part 3/4”nchexnut 3 09-5818 b part liftlink 1 02-0516 c part adjustinghelix 1 1053-1-h d part 3/4”ncx9”hexbolt...

Page 120

This page intentionally left blank.

Page 121: 6.1

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 6.1 t echnical m anual a. Basic torque measurement basictorquemeasurementsareperformedusingasimplehydraulicmeasurementsystem.Ahydraulicloadcellconnectstoacali- bratedtorquegaugethroughareinforcedflexiblehydraulichose.Thetorquegaugeisfact...

Page 122: 6.2

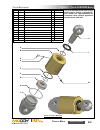

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 6.2 t echnical m anual item type description qty part # assembly 30”arm-20ktensionloadcellandgauge 1 10-0028t a part 4.08in2tensionloadcell 1 10-0008t b part torquegauge,20,000ft.-lbs.36”arm 1 10-0028g c part hydraulichose 1 02-0069 item...

Page 123: 6.3

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 6.3 t echnical m anual item type description qty part number assembly tensionloadcell,4.08in 2 1 10-0008t a part o-ring 1 02-0800 b part loadcellbody 1 lc99-104 c part 1/4”ncx1/2”bindingheadmachinescrew 1 09-0045a d part stat-o-seal 1 02...

Page 124: 6.4

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 6.4 t echnical m anual t orque m easurement item type description qty part number assembly compressionloadcell,8in 2 1 10-0008c a part 5/16”uncx1”hexsocketheadcapscrew 1 09-2026 b part loadplate 1 e360-a c part 5/16”uncx3/4”hexsockethead...

Page 125: 6.5

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 6.5 t echnical m anual t orque m easurement item type description qty part number assembly standardturncounterencodermount 1 60-0001 a part 6-32x3/8”hexsocketheadsetscrew 4 b part helicalflexibleencodershaftcoupling 1 60-0130n c part int...

Page 126: 6.6

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 6.6 t echnical m anual t orque m easurement b. Troubleshooting undernormaloperatingconditions,andwithpropermaintenance,thetorquegaugeandloadcellsystemaredesignedtogivelasting trouble-freeperformance.Faultyindicationonthegaugewillveryofte...

Page 127: 6.7

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 6.7 t echnical m anual t orque m easurement c. Periodic inspection and maintenance 1. Inspection thetorquemeasurementsystemsuppliedwithyourequipmentisdesignedandbuilttoprovideyearsoftrouble-freeservice withminimummaintenance.Periodicinsp...

Page 128

This page intentionally left blank.

Page 129: 7.1

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.1 t echnical m anual h ydraulic m otor i nformation section 7: hydraulic component information the manufacturer information contained in this section has been obtained from publicly available web sites and has been provided for informa...

Page 130

This page intentionally left blank.

Page 131: 7.3

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.3 t echnical m anual eight fixed displacement motors ranging from 6 in 3 to 15 in 3 . Starting and stall torques equal to 90-94% of theoretical torque. Speed to 2,000 rpm continuous. Up to 75 hp continuous. Conforms to sa e 'c' mountin...

Page 132: 7.4

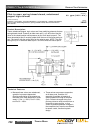

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.4 t echnical m anual h ydraulic m otor i nformation 1.38 sa e 14t 12/24 pitch f lat root side fit invo lute spline optiona l shaft 6.81 3.41 4.51 5.70 9/16" dia., 4 ho les 17° 17° c enter line cas e drain c enter line cas e drain 5.91 ...

Page 133: 7.5

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.5 t echnical m anual h ydraulic m otor i nformation technical information - all styles v ane crossing vane the rineer patented vane crossing vane design produces much higher volumetric and mechanical efficiencies than is possible with ...

Page 134: 7.6

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.6 t echnical m anual h ydraulic m otor i nformation performance data - selected displacements the above performance data was obtained at 140 o f with iso 46(dte 25). These values must be maintained to obtain the performance indicated. ...

Page 135: 7.7

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.7 t echnical m anual h ydraulic m otor i nformation for durable hydraulic motors that meet your demands, specify rineer. For over 35 years, we have specialized in only one thing - engineering the right motor for your needs. Rineer deli...

Page 136: 7.8

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.8 t echnical m anual h ydraulic m otor i nformation standard motor two speed motor hydraulics, inc. Hydraulics, inc. R m a n u f a c t u r e r o f h y d r a u l ic m o t o r s 15 series repair manual 331 breesport * san antonio, tx 782...

Page 137: 7.9

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.9 t echnical m anual h ydraulic m otor i nformation.

Page 138: 7.10

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.10 t echnical m anual h ydraulic m otor i nformation warning: rineer recommends following all standard shop safety practices specifically including wearing of eye protection. 1 2 3 4 5 6 7 8 5 1) remove snap ring warning: use caution w...

Page 139: 7.11

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.11 t echnical m anual h ydraulic m otor i nformation warning: rineer recommends following all standard shop safety practices specifically including wearing of eye protection. 9 10 11 12 13 14 15 16 6 1) remove front housing 2) note: tw...

Page 140: 7.12

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.12 t echnical m anual h ydraulic m otor i nformation warning: rineer recommends following all standard shop safety practices specifically including wearing of eye protection. 17 21 22 23 24 18 19 20 7 1) remove the rotor. 2) remove bot...

Page 141: 7.13

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.13 t echnical m anual h ydraulic m otor i nformation warning: rineer recommends following all standard shop safety practices specifically including wearing of eye protection. 25 26 27 28 29 30 31 32 8 1) reverse the procedures in steps...

Page 142: 7.14

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.14 t echnical m anual h ydraulic m otor i nformation warning: rineer recommends following all standard shop safety practices specifically including wearing of eye protection. 33 34 35 36 b a 9 1) install dowel pins into rotor/stator ca...

Page 143: 7.15

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.15 t echnical m anual h ydraulic m otor i nformation information: bolt torque - main bolts (5/8-11): 190 ft. Lbs. Seal plate (3/8-16) (wheel motor only): 45 ft. Lbs. Grease used for bolt threads and o-ring retention: pennzoil 707l red ...

Page 144: 7.16

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.16 t echnical m anual h ydraulic v alve i nformation.

Page 145: 7.17

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.17 t echnical m anual h ydraulic v alve i nformation.

Page 146: 7.18

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.18 t echnical m anual h ydraulic v alve i nformation.

Page 147: 7.19

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.19 t echnical m anual h ydraulic v alve i nformation.

Page 148: 7.20

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.20 t echnical m anual h ydraulic v alve i nformation.

Page 149: 7.21

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.21 t echnical m anual h ydraulic v alve i nformation.

Page 150: 7.22

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.22 t echnical m anual h ydraulic v alve i nformation.

Page 151: 7.23

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.23 t echnical m anual h ydraulic v alve i nformation.

Page 152: 7.24

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.24 t echnical m anual h ydraulic v alve i nformation.

Page 153: 7.25

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.25 t echnical m anual h ydraulic v alve i nformation.

Page 154: 7.26

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.26 t echnical m anual h ydraulic v alve i nformation.

Page 155: 7.27

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.27 t echnical m anual h ydraulic v alve i nformation.

Page 156: 7.28

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.28 t echnical m anual h ydraulic v alve i nformation.

Page 157: 7.29

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.29 t echnical m anual h ydraulic v alve i nformation.

Page 158: 7.30

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.30 t echnical m anual h ydraulic v alve i nformation pilot-to-open, spring biased closed, unbalanced poppet logic element capacity: 60 gpm (240 l/min.) functional group: products : cartridges : corrosion resistant : logic element : unb...

Page 159: 7.31

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.31 t echnical m anual h ydraulic v alve i nformation these valves have positive seals between port 3 and port 2. Stainless steel cartridge options p or w are intended for use within corrosive environments with all external components m...

Page 160: 7.32

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.32 t echnical m anual h ydraulic v alve i nformation pilot operated, balanced piston relief valve capacity: 50 gpm (200 l/min.) functional group: : cartridges : relief : 2 port : pilot operated, balanced piston model: rpgc product desc...

Page 161: 7.33

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.33 t echnical m anual h ydraulic v alve i nformation technical data u.S. Units metric units cavity t-3a capacity 50 gpm 200 l/min. Adjustment - number of clockwise turns to increase setting 5 5 factory pressure settings established at ...

Page 162: 7.34

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.34 t echnical m anual h ydraulic v alve i nformation control adjustment range external material/seal material l standard screw adjustment a 100 - 3000 psi (7 - 210 bar), 1000 psi (70 bar) standard setting w 150 - 4500 psi (10,5 - 315 b...

Page 163: 7.35

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.35 t echnical m anual h ydraulic v alve i nformation pilot-to-open check valve with standard pilot capacity: 30 gpm (120 l/min.) functional group: products : cartridges : pilot-to-open check valve : 3-port, non-vented : standard pilot,...

Page 164: 7.36

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.36 t echnical m anual h ydraulic v alve i nformation use counterbalance valves. Cavities, same flow path for a given frame size). However, cartridge extension dimensions from the mounting surface may vary. Stainless steel cartridge opt...

Page 165: 7.37

Kt5500 5- 1 / 2 ” t ong & clincher® b ackup s ection c ontents 7.37 t echnical m anual h ydraulic v alve i nformation standard options l manual load release a 4 psi (0,3 bar) b 15 psi (1 bar) d 50 psi (3,5 bar) e 75 psi (5 bar) f 100 psi (7 bar) p stainless/buna- n v viton w stainless/viton customer...