- DL manuals

- Faulhaber

- Controller

- MCDC2805 series

- Instruction Manual

Faulhaber MCDC2805 series Instruction Manual

Summary of MCDC2805 series

Page 1

Serie mcdc2805 motion controller with sine wave commutation for ec-motors series mcbl2805 instruction manual.

Page 2: Table of Contents

1 table of contents 2 general information 4 data sheet 6 cables and connections 7 first steps 8 analog velocity control 9 simple possibilities to set command velocity with a potentiometer 10 rs-232 port and the ascii commands 11 default configuration of the rs-232 port 11 the ascii commands 11 savin...

Page 3

3 additional modes 26 stepper motor mode 26 gearing mode 28 position control with a voltage at the analog input 29 using an external encoder to measure actual position 30 voltage regulator mode 32 handling errors and the error output 33 show deviation from command speed as error 33 delayed activatio...

Page 4: General Information

General information 4 the mcbl2805 was designed for faulhaber brushless motors with linear hall sensors. This means that, even without an external encoder, low speed and positioning with a resolution up to 1/1000th of a revolution are possible. The motion controller is based on a powerful 16-bit mic...

Page 5: General Information

5 general information area of application ease of installation, integrated technology, compatability, size, stand-alone capability and the numerous connection possibilities allow this motion controller to perform to the highest standards in a wide range of applications, for example in decentralized ...

Page 6: Data Sheet

Data sheet 6 general specifications supply voltage u b 12 ... 28 v dc pwm switching frequency f pwm 31,25 khz efficiency 95 % max. Continuous current i cont 5 a max. Peak current i max 10 a current consumption in the electronics i el 0,06 a velocity range 10 ... 15000 rpm out put voltage for externa...

Page 7: Cables and Connections

Cables and connections 7 power supply requirements the power supply should deliver at least 5 a. It is important to be careful and connect the controller with the correct polarity. Incorrect polarity will damage the protection fuse and it can only be replaced at the factory. Analog input (analog inp...

Page 8: First Steps

First steps 8 upon delivery the mcbl2805 is configured for the motor type 5 (2444s024b k1155). Important: for successful operation of the motion controller with the motor of choice please read the following chapters carefully: ■ choosing the motor type (page 13) ■ fine tuning the digital filter (pag...

Page 9: Analog Velocity Control

Analog velocity control 9 pi-speed controller mosfet power amplifier ec-motor armature position calculation phase a phase b phase c hall sensor a hall sensor b hall sensor c speed calculation i 2 t - current limiting r s gnd v7 microcontroller rs-232 communication and configurations module + 24v dc ...

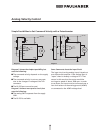

Page 10: Analog Velocity Control

Analog velocity control 10 simple possibilities to set command velocity with a potentiometer m gnd v7 + 24v dc v6 u b 2,7k led v4 v2 v1 rxd txd + _ analog input agnd v5 v3 n com 10k 10k m gnd v7 + 24v dc v6 u b 2,7k led v4 v2 v1 rxd txd + _ analog input agnd v5 v3 n com 1k 10k 20v 4,7k 4,7k diagram ...

Page 11

11 rs-232 port and the ascii commands the rs-232 port allows the mcbl2805 to be connected to a personal computer as well as various digital controllers, like for example an sps or an ipc. Using the rs-232 port ■ to configure the motor ■ online data analysis ■ online communications with the motor dur...

Page 12

Rs-232 port and the ascii commands 12 saving configurations parameters and configurations can be saved in an on board eeprom chip. That means that saved programs and configura- tions are not lost in case of a loss of power. Upon connec- tion to the supply voltage the motor runs under the setup saved...

Page 13

13 rs-232 port and the ascii commands setting the node address with the assistance of the rs-232 multiplexer board it becomes possible to drive multiple motors from one host. Use the ascii addressing command to address the individual motors. Command function description example nodeadr *) define nod...

Page 14

Rs-232 port and the ascii commands 14 optional motor types and parameters no. Motor type p-portion (por) i-portion (i) peak current (ma) continuous current (ma) 1 1628t012b k1155 3 6 3000 770 2 1628t024b k1155 4 10 3000 410 3 2036u012b k1155 5 6 3000 980 4 2036u024b k1155 6 5 3000 480 5 2444s024b k1...

Page 15

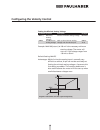

15 configuring the velocity control sources for velocity command function description example sor *) source for sources for the velocity sor1 velocity sor 0: command velocity at the rs-232 port sor 1: command velocity with a voltage at the analog input sor2: command velocity with a pwm signal at the...

Page 16

Configuring the velocity control 16 setting the minimal analog voltage command function description example mav *) minimum sets the minimum analog voltage. Mav500 analog voltage gmav get minimum calls up the minimum analog gmav analog voltage voltage over the rs-232 port. ➔ 25 example: mav100 [retur...

Page 17

17 configuring the velocity control setting the direction of rotation command function description example adl *) analog armature rotates left with positive adl direction voltage at the analog input left adr *) analog armature rotates right with positive adr direction voltage at the analog input rig...

Page 18

Configuring the velocity control 18 setting an acceleration command function description example ac *) load loads a new value for ac100 command acceleration. Acceleration arguement in rev/s 2 gac get calls up current acceleration value gac ➔ 1000 acceleration default setting: 30000 rev/s 2 this acce...

Page 19

19 configuring the velocity control instructions: 1.) set output configuration ■ sor0 [enter] ➔ sets source for command velocity: rs-232 ■ por 8 [enter] ➔ proportional term = 8 (example) ■ i20 [enter] ➔ integral term = 20 (example) ■ v1000 [enter] ➔ sets velocity to 1/3 of maximum appli- cation spee...

Page 20: Position Control

Position control 20 pi-speed controller mosfet power amplifier ec-motor armature position calculation phase a phase b phase c hall sensor a hall sensor b hall sensor c speed calculation i 2 t - current limiting r s gnd v7 microcontroller rs-232 communication and configurations- module + 24v dc v6 u ...

Page 21: Position Control

21 position control standard positioning sequences 1.) enter the acceleration and the maximum velocity (rpm) ac50 [enter] ➔ sets acceleration to 50 rev/s 2 sp3000 [enter] ➔ sets maximum velocity to 3000 rpm these values are set until they are changed or the motor is turned off. 2.) set command posit...

Page 22

Evaluating the homing points and limit switch 22 the following are the available inputs and signals: ■ analog input ■ fault pin (programmed as input) ■ input no. 3 ■ zero index of hall sensor the inputs can be evaluated in varying ways: ■ direct programming with ha, hl, hn commands ■ programmable ho...

Page 23

23 evaluating the homing points and limit switch setting the edge and polarity example circuit diagrams for the fault pin limit switch and the analog input are pictured in diagram 2 and diagram 5. The trigger edge and polarity must be chosen depending on how the limit switch is connected. Command fu...

Page 24

Evaluating the homing points and limit switch 24 programmable homing sequence the programmable homing sequence has the following advantages: ■ when programmed the sequence can be called up at any time with a single command. ■ when upon activation, the limit switch is already active, the motor will f...

Page 25

25 evaluating the homing points and limit switch hard blocking function to ensure that the motor does not run past the limit switch, it is possible to program the limit switch as follows: ■ if the drive system is at a limit switch, one direction of rotation will be blocked, that means the drive syst...

Page 26: Additional Modes

Additional modes 26 additional “special modes” were developed in order to fulfill the requirements of as many different applications as possible. There are also modes programmable, which can work independent of the rs-232 port connection. To increase the resolution of the system it is possible to co...

Page 27: Additional Modes

27 additional modes advantages over a conventional stepper motor: ■ the step count per revolution is programmable and has very high resolution ■ the step width is programmable ■ no torque losses due to cogging ■ the full dynamic capabilities of a brushless motor ■ the motor is very quiet ■ the motor...

Page 28: Additional Modes

Additional modes 28 gearing mode in gearing mode it is possible to connect an external encoder to provide the command position value. Pi-speed controller mosfet power amplifier ec-motor armature position calculation phase a phase b phase c hall sensor a hall sensor b hall sensor c speed calculation ...

Page 29: Additional Modes

29 additional modes position control with a voltage at the analog input in this mode the command position value can be regula- ted with an adjustable resistor (a potentiometer), or any other adjustable analog voltage source. Pi-speed controller mosfet power amplifier ec-motor armature position calcu...

Page 30: Additional Modes

Additional modes 30 the direction of rotation is set with the adr and adl commands. Adr ➔ with a positive voltage the motor rotates in the positive direction (right). Adl ➔ with a negative voltage the motor rotates in the negative direction (left). The ac- and sp-values are also applicable in analog...

Page 31: Additional Modes

31 additional modes pi-speed controller mosfet power amplifier ec-motor armature position calculation phase a phase b phase c hall sensor a hall sensor b hall sensor c speed calculation i 2 t - current limiting r s gnd v7 microcontroller rs-232 communication and configurations module + 24v dc v6 u b...

Page 32: Additional Modes

Additional modes 32 command function description example voltmod*) set voltage mode activates voltage voltmod regulator mode in this mode it is possible to use an external controller. The controller on the motor than functions as a power amplifier. It is important to keep in mind that the sampling f...

Page 33

33 handling errors and the error output show deviation from command speed as error in certain applications a greater degree of deviation from the given command speed is unacceptable. Therefore the unit should be programmed to react by displaying an error. When the actual speed deviates to the given ...

Page 34

Handling errors and the error output 34 the error output as a digital output aside from the ability to function as a limit switch input (refin) and a direction of rotation input (dirin), the error output can also function as a digital output. This makes it possible, for example, to control a valve d...

Page 35

Handling errors and the error output 35 pulse output pulses from the hall sensor are processed and are then sent out at the fault output. Properties of the pulse output: ■ maximum pulse frequency: 2000 pulses per second ■ at speeds in excess of the maximum pulses per second the maximum pulse frequen...

Page 36: Saving and Running Programs

36 saving and running programs important: the handshake control (xon/xoff) must be set in the terminal program. To receive data from the motor (gprogseq), it is best to activate the “return upon receiving” in the terminal program. Note: the faulhaber motion manager program provides a comfortable way...

Page 37: Saving and Running Programs

Saving and running programs 35 37 controlling a program sequence the following are added commands for controlling a program sequence while it is running. These commands are only available while the program sequence is running. When the following commands are used the current program is interrupted u...

Page 38: Saving and Running Programs

38 saving and running programs continuation: additional commands command function description example reti return error jumps back from the error subroutine to the main reti interrupt program. Important: the interrupted command will not repeat upon jumping back to the main program even if it hadn’t ...

Page 39: Saving and Running Programs

Saving and running programs 39 about the eri command at first after entering the eri command nothing happens. The command only takes effect after an error occurs. The program then jumps to the given address. In this way a continuation of the program even after an error occurs is possible. With the r...

Page 40: Technical Information

40 technical information commutation with a sine wave sine wave commutation means that the rotating magnetic field is always ideally positioned to the armature. This minimizes torque variance even when the motor is rotating very slowly. The motor is also very quiet. Current controller and current li...

Page 41: Technical Information

Technical information 41 analog command current ■ the sor3 command can be used to switch to the analog command current input. The current limit is proportional to the voltage at the analog input. The i 2 r current limiting is no longer active. ■ the set current is compared to the maximal current (lp...

Page 42: Appendix

42 appendix electromagnetic compatability (emc) the motion controller mcbl2805 was tested and measured for emc according to the european guideline (89/336/ewg). The system fulfills the following requirements (norms) during operation at nominal values: emc emissions according to the range defined by ...

Page 43: Appendix

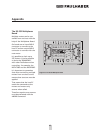

43 appendix the rs-232 multiplexer board multiple motors can be con- trolled from one host with the help of the multiplexer board. On board are an input sub-d connector to connect to the host pc and an output sub-d connector to connect with the next motor. It is possible to chain up to 255 motors. I...

Page 44: Appendix

44 appendix the ascii command set ■ all commands that are marked with a *) will be saved with the eepsav command. Commands for basic settings command function description example di *) disable drive deactivates the motor (power stage) di en *) enable drive activates the motor (power stage) en baud *...

Page 45: Appendix

45 appendix commands for motion control command function description example m *) initiate motion activates positioning mode and starts positioning m la load absolute position loads new absolute position. La100000 arguement: 1000 is one rotation. Lr load relative postion loads a new relative positio...

Page 46: Appendix

46 appendix commands for evaluating homing points and limit switches command function description example ho define home position with no arguement: sets the actual position to 0 ho with arguement: sets actual position to the given value hp *) hard polarity sets the trigger edge and the polarity for...

Page 47: Appendix

47 appendix continuation: commands for evaluating homing points and limit switches command function description example gahs get actual 5 numbers with values between 0 and 7 are sent to gahs ➔ 33300 homing status the host over the rs-232. They indicate the status of the homing switches. 1. Ha value ...

Page 48: Appendix

48 appendix commands for additional modes command function description example contmod *) continuous mode switches from the present further mode back to contmod continuous operating mode. (hall sensor gives actual position. Communication over the rs-232) stepmod *) steppermotor mode switches to step...

Page 49: Appendix

49 appendix commands for configuration of the error functions and error output: command function description example dirin *) direction input programs the fault output as a direction of dirin rotation input. (the limiter switch is also thereby activated) refin *) reference input programs the fault p...

Page 50: Appendix

50 appendix more request commands command function description example pos get actual position calls up the actual position pos ➔ 500000 gn get n calls up the actual speed gn ➔ 4000 gcl get current limit calls up the actual current limit value gcl ➔ 2800 grc get real current calls up the actual curr...

Page 51: Appendix

51 appendix continuation: more request commands command function description example gscs get special calls up configuration at the host rs-232 (8 bits) gscs ➔ 00000001 configuration set from left to right: bit 0: 1 ... Power on homing sequence is active 0 ... Power on homing sequence is inactive bi...

Page 52: Appendix

52 appendix example configurations and programs the following examples are programmed from the basis of the factory settings. Velocity control: command value received as a pwm signal at the analog input. Goals: ■ velocity control with a pwm signal at the analog input. ■ limit acceleration to 500 rev...

Page 53: Appendix

53 appendix position control goals: ■ position control ■ limit acceleration to 300 rev/s 2 ■ reference point at falling edge ■ controller parameters: proportional 25 and integral 8 ascii command form: ac300 hp0 por25 i8 sor0 ➔ switches to receive commands at the rs-232 la0 ➔ loads new position m ➔ a...

Page 54: Appendix

54 appendix program sequence: calling up various positioning routines at the rs-232 this program makes it possible to call up various programs at the rs-232 port. ■ homing: the motor first runs to a limiter switch then to the hall index zero. This type of homing sequence is repeatable with a high de...

Page 55: Appendix

55 appendix commentary: ■ the homing sequence is called up by sending the jmp2 command from the rs-232. The other routines are called up in a similar manner. ■ the np command without an arguement makes sure that the sequence stops at the m command until the command position has been achieved. Progra...

Page 56: Appendix

56 appendix hosp-200 ➔ loads homing speed (backward) hp1 ➔ rising edge will be registered at the limit switch enprog ➔ program will activate after power on answ0 ➔ no asynchronus answering eepsav ➔ saves configuration program: gohix ➔ homing with the hall index zero a1 hp3 ➔ logic level high is regi...

Page 57: Appendix

57 appendix factory configuration the commands in the factory configuration are as follows: en ➔ drive is active v0 ➔ command speed 0 sor1 ➔ source for velocity is the analog input adr ➔ positive voltage means direction of rotation right hp7 ➔ rising edge registered at all limit switches errout ➔ fa...

Page 58: Notes

58 notes.

Page 59: Notes

59 notes.

Page 60

Dr. Fritz faulhaber gmbh & co. Kg antriebssysteme daimlerstraße 23 71101 schönaich · germany tel. +49(0)70 31/638-0 fax +49(0)70 31/638-100 info@faulhaber.De www.Faulhaber.De from software version 305010a and upwards © dr. Fritz faulhaber gmbh & co. Kg ma05002, english, 1. Edition, 13. 06. 01.