- DL manuals

- FCW

- Welding System

- DYNA MMA 500GTS

- Operating Manual

FCW DYNA MMA 500GTS Operating Manual

Summary of DYNA MMA 500GTS

Page 1

Model • dyna mma 500s • dyna mma 500gts • dyna mma 500(h)s • dyna mma 500(h)gts • dyna mma 630s • dyna mma 630gts operating manual (owner’s manual) important: read these instructions before installing, operating, or servicing this system. Second edition manual no. E0904.

Page 3: Contents

- 1 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual contents symbol legend---------------------------------------------------------------------------------------------------2 statement of warranty----------------------------------------------------------------------------------...

Page 4: Symbol Legend

- 2 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual symbol legend a amperage stick (smaw) v voltage pulse current function (gtaw) hz hertz (frequency) t spot time (gtaw) sec seconds remote outputs control (panel/remote) % percent remote function dc (direct current) arc control ...

Page 5: Statement of Warranty

- 3 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual statement of warranty limited warranty: "fcw" warrants to customers of its authorized distributors hereafter "fcw" that its products will be free of defects in workmanship or material. Should any failure to conform to this war...

Page 6: 1.0 General Information

- 4 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 1.0 general information 1.01 notes, cautions and warnings throughout this manual, notes, cautions, and warnings are used to highlight important information. These highlights are categorized as follows: note an operation, proce...

Page 7

- 5 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual electric shock electric shock can injure or kill. The arc welding process uses and produces high voltage electrical energy. This electric energy can cause severe or fatal shock to the operator or others in the workplace. Z nev...

Page 8

- 6 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 1.03 transporting methods these units are equipped with a handle for carrying purposes. Warning: electric shock can kill. Do not touch live electrical parts. Disconnect input power conductors from de-energized supply line befo...

Page 9

- 7 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 2.0 installation recommendation installation environment dyna mma series is designed for use in hazardous environments. Examples of environments with increased hazardous environments are - in locations in which freedom of move...

Page 10

- 8 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 2.01 electrical input connections warning: electric shock can kill; significant dc voltage is present after removal of input power. Do not touch live electrical parts shut down welding power source, disconnect input power empl...

Page 11

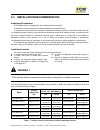

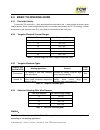

- 9 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 2.02 specifications model mma 500s mma 500gts mma 500(h)s mma 500(h)gts mma 630s mma 630gts input voltage and frequency 380/415v 50/60hz 380/415v 50/60hz 380/415v 50/60hz 380/415v 50/60hz 380/415v 50/60hz 380/415v 50/60hz kva ...

Page 12: 3.0 Operator Controls

- 10 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 3.0 operator controls 3.01 dyna mma controls figure 2 1. Main circuit breaker 2. Arc selection—long arc/ short arc. 3. Current control 4. Stick/ lift tig select switch (dyna mma 500s、500(h)s、630s); stick/ hf tig select switch...

Page 13

- 11 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 17. Ac power indicator 18. Fuse 19. Input gas fitting (dyna mma 500gts, 500(h)gts, 630gts) 20. Fuse 21. Ground screw 22. Input power cable port figure 3 pin function a torch switch b torch switch c remote amp d remote amp e r...

Page 14

- 12 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 3.02 weld parameters description figure 4 dyna mma series front panel with parameter description parameter description welding current this parameter sets the welding current when pulse is off. Arc force this parameter provid...

Page 15

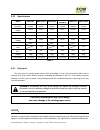

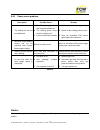

- 13 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 3.03 weld parameter for dyna mma series model mma 500s mma 500gts mma 500(h)s mma 500(h)gts mma 630s mma 630gts peak current 500a 500a 500a 500a 630a 630a tig 10~500a 10~500a 10~500a 10~500a 10~630a 10~630a weld current stick...

Page 16

- 14 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 4.0 set-up for mma (stick) and gtaw (tig) conventional operating procedures apply when using the welding power source, i.E. Connect work lead directly to work piece and welding cable is used to electrode holder. Wide safety m...

Page 17

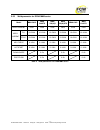

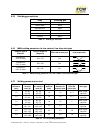

- 15 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 4.01 stick welding z connect work lead to negative terminal. Z connect electrode lead to positive terminal. Z switch machine on. Z set welding current control (see table 7). Workpiece thickness mm 0.5-2.0 2.0-5.0 5.0-7.0 elec...

Page 18

- 16 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 5.0 power supply controls indicators and reatures figure 6 dyna mma series front panel 1. Main circuit breaker 2. Arc selection—long arc/ short arc 3. Current control 4. Stick/ lift tig (hf tig) select switch 5. Remote ampera...

Page 19

- 17 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 6.0 basic tig welding guide 6.01 electrode polarity connect the tig torch to the - / torch terminal and the work lead to the + / work terminal for direct current straight polarity. Direct current straight polarity is the most...

Page 20

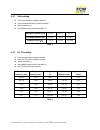

- 18 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 6.05 shielding gas selection alloy shielding gas aluminium & alloys argon carbon steel argon stainless steel argon nickel alloy argon copper argon titanium argon table 12 shield gas selection 6.06 mma welding parameters for l...

Page 21

- 19 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 7.0 basic arc welding guide 7.01 electrode polarity stick electrodes are generally connected to the “+” terminal and the work lend to the “-“ terminal but if in doubt consult the electrode manufacturers literature. 7.02 effec...

Page 22: 8.0 Maintenance

- 20 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 8.0 maintenance if this equipment does not operate properly, stop work immediately and investigate the cause of the malfunction. Maintenance work must be performed by an experienced, qualified person only. Any electrical work...

Page 23

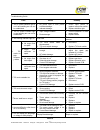

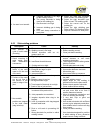

- 21 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual troubleshooting guide fault cause remedy 1. The ac power indicator light is not lit and welding arc can not be established. 1. No power input or main power switches damage. 2. Indicator damage. 1. Check input power or replace...

Page 24

- 22 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 9.02 tig welding problems weld quality is dependent on the selection of the correct consumables, maintenance of equipment and proper welding technique. Description possible cause remedy 1. Excessive bead build-up or poor pene...

Page 25

- 23 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 11. Arc start is not smooth. A tungsten electrode is too large for the welding current. B the wrong electrode is being used for the welding job. C gas flow rate is too high. D incorrect shielding gas is being used. E poor wor...

Page 26

- 24 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 9.04 power source problems description possible cause remedy 1 the welding arc can not be established. A the primary supply voltage has not been switched on. B the welding power source switch is switched off. C loose connecti...

Page 27

- 25 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 10.0 parts list.

Page 28

- 26 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual.

Page 29

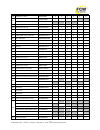

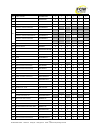

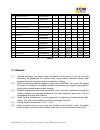

- 27 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual figure 7 qty. 500s 500gts 500hs 500hgts 630s 630gts se qu en ce name order no p/n: 610008999 p/n: 610011999 p/n: 610018999 p/n: 610024999 p/n: 610031999 p/n: 610034999 control pcb fp7.820.041c-03 3kitp002702011 1 1 1 1 contro...

Page 30

- 28 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 19 thermostat sd301 4kncrot85 2 2 2 2 2 2 sensor cs400e 4snocs400e 1 1 1 1 20 sensor cs600e 4snocs600e 1 1 21 capacitance 3kv103 481cc3kv103 15 15 15 15 15 15 22 resistance 15w 10Ω 4rx27d15w10 2 2 2 2 2 2 23 bus bar fp7.725.0...

Page 31

- 29 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 48 label ground 2lam8800003 1 1 1 1 1 1 49 cap protection 2fp8647000 4 2 4 2 4 2 50 panel back fp8.041.018 2fppr8041018 1 1 1 1 1 1 51 overlay control 2lac8807037 1 1 1 1 1 1 overlay control mma500s 2laf8802026 1 overlay cont...

Page 32

- 30 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual 80 resistance 5w 33kΩ 4rx27d5w33k 4 4 4 4 4 4 81 base fp8.031.008 2fpb8031008 1 1 1 1 1 1 82 bus bar fp7.725.022 3bb7725022 1 1 1 1 1 1 83 bus bar fp7.725.024 3bb7725024 2 2 2 2 2 2 84 panel left fp8.048.013 2fpps8048013gj 1 ...

Page 33

- 31 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual appendix: dyna mma 500s, 500(h)s, 630s interconnect diagram 批 准 标准化 审 核 拟 制 标记 数量 更改单号 签名 日期 阶段标记 第 张 共 张 mma 500s mma 500hs 0 0 gn d if - + 1 2 hl2 200a/4v d1 fr300ba50 d2 fr300ba50 zl2 k7 k5 thermostat vr1 5k(4k7) d3 fr300b...

Page 34

- 32 - dyna mma 500s、500gts、500(h)s、500(h)gts、630s、630gts operating manual appendix: dyna mma 500gts, 500(h)gts, 630gts interconnect diagram 批 准 标准化 审 核 拟 制 标记 数量 更改单号 签名 日期 阶段标记 第 张 共 张 mma 500gts mma 500hgts 0 0 gn d if - + 1 2 hl2 200a/4v d1 fr300ba50 d2 fr300ba50 zl2 k7 k5 thermostat vr1 5k(4k7)...