- DL manuals

- FE

- Microcontrollers

- PXR4

- Operation Manual

FE PXR4 Operation Manual

Summary of PXR4

Page 1

Micro-controller x model: pxr4/5/7/9 operation manual c1 c2 al1 al2 al3 pv sv ° c pxr sel ecno:406f www. .Com information@itm.Com 1.800.561.8187.

Page 2: Table of Contents

2 1. Part names and functions ........................................................ 6 2. Operations ................................................................................. 7 2-1 parameter list ..................................................................................... 7 2-2 ba...

Page 3: Information@itm.Com

3 specifying control action and output direction at input burn-out ................................ 53 sv (setting value) lower limiter .................................................................................. 54 sv (setting value) upper limiter ................................................

Page 4: Information@itm.Com

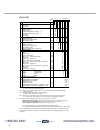

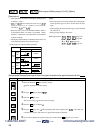

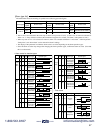

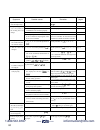

4 specification 4 5 6 7 8 pxr 4 5 6 7 8 9 10 11 12 13 4 7 1 - t r n s a b a c e y a c e r 1 0 1 2 3 4 5 6 7 f g h m d p n v c b 0 m n s t v w 0 0 0 0 0 0 0 0 0 0 0 0 0 0 48 x 48mm 72 x 72mm thermocouple ° c thermocouple ° f resistance bulb pt100 3-wire type ° c resistance bulb pt100 3-wire type ° f ...

Page 5: Information@itm.Com

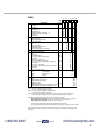

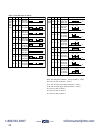

5 specification 4 5 6 7 8 pxr 4 5 6 7 8 9 10 11 12 13 5 9 1 - t r n s a b a c e y a c e r 1 0 1 2 3 4 5 6 7 f g h m d p n v c b 0 m n s t v w 0 0 0 0 0 0 0 0 0 0 0 0 0 0 48 x 96mm 96 x 96mm thermocouple ° c thermocouple ° f resistance bulb pt100 3-wire type ° c resistance bulb pt100 3-wire type ° f ...

Page 6: Part Names and Functions

6 this chapter explains the part names and functions on the face panel. The face panel has the pv and sv displays, the status indicating lamp, and the setting keys, etc. Those functions are explained below. Please read and understand them before using the pxr. For details about the setting of parame...

Page 7: Operations

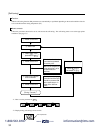

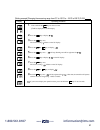

7 2 operations 2-1 parameter list parameters for the pxr are classified into operation parameters, and the first block, the second block and the third block parameters according to the frequency of use. The second and the third block parameters are used at initialization or when they are absolutely ...

Page 8: Information@itm.Com

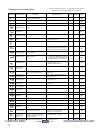

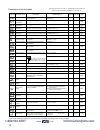

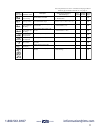

8 parameters of the second block parameter display symbol user’s set value reference page parameter name description proportional band integral time derivative time hysteresis range for on/off control cooling-side proportional band coefficient cooling-side proportional band shift output convergence ...

Page 9: Information@itm.Com

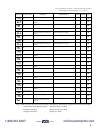

9 1st soak segment time 2nd target sv 2nd ramp segment time 2nd soak segment time 3rd target sv 3rd ramp segment time 3rd soak segment time 4th target sv 4th ramp segment time 4th soak segment time 5th target sv 5th ramp segment time 5th soak segment time 6th target sv 6th ramp segment time 6th soak...

Page 10: Information@itm.Com

10 parameters of the third block control action sv (setting value) lower limiter sv (setting value) upper limiter delay time 1 delay time 2 delay time 3 current transe display hb (set value of heater break alarm) setting alarm 1 hysteresis alarm 2 hysteresis alarm 3 hysteresis alarm 1 options alarm ...

Page 11: Information@itm.Com

11 communication protocol setting re-transmission output type setting re-transmission output scaling base side setting re-transmission output scaling span side setting remote sv input zero adjustment remote sv input span adjustment remote sv input filter constant remote sv input value display parame...

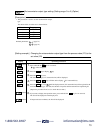

Page 12: 2-2 Basic Operations

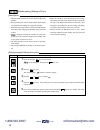

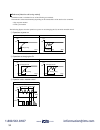

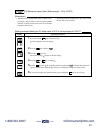

12 2-2 basic operations just after power-on: the display below appears just after power-on. C1 c2 al1 al2 al3 pv sv ° c pxr sel c1 c2 al1 al2 al3 pv sv ° c pxr sel status at delivery how to switch parameters: the figure below shows the basic operations for the pxr. C1 c2 al1 al2 al3 pv sv ° c pxr se...

Page 13: Information@itm.Com

13 how to set values: key: one press increases the value by 1. Press and hold this key to increase the value fast. Key: one press decreases the value by 1. Press and hold this key to decrease the value fast. How to register the set data: by pressing the sel key, the displayed values are registered. ...

Page 14: Information@itm.Com

14 2-3 parameter functions and method of settings method of setting the sv (setting value) [description] • the sv is a target value for control. • any sv that is outside of the range set in the parameters of (lower limit) and (upper limit) of the third block cannot be set. (see page 54.) [setting ex...

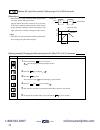

Page 15: Information@itm.Com

15 manual mode setting (settings: off/on) [setting example] switching to manual mode press and hold the sel key for one second, and is displayed. Press the sel key once, and the current set value ( ) on the sv display section starts flickering. Press the or the keys to display . Press the sel key on...

Page 16: Information@itm.Com

16 standby setting (settings: off/on) [description] • this parameter switches the control between run and standby. • during standby, the control output and the alarm output stay off, like the standby for ramp-soak operation. • while the alarm with a hold is selected, the hold function takes effect a...

Page 17: Information@itm.Com

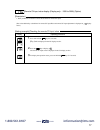

17 local/remote operation setting (setting range: locl/rem) (option) [description] • this parameter is used to switch between local and re- mote operations. [setting example] switching to remote operation press and hold the sel key for one second. Will be displayed on the pv display section. Press t...

Page 18: Information@itm.Com

18 ramp-soak control (settings: off/run/hld) (option) [description] • this function automatically changes the sv (setting value) according to the program pattern set in advance as shown in the right line graph. Up to eight pairs of ramp- soak operation can be programmed. • the first ramp starts at t...

Page 19: Information@itm.Com

19 canceling the alarm latch (setting range: 0/1) (option) [description] • this parameter cancels the alarm latch when it is latching. [setting example] opening up the alarm latch operating procedure display press and hold the sel key for one second. Will be displayed on the pv display. Press the ke...

Page 20: Information@itm.Com

20 auto-tuning function (settings: 0/1/2) [description] [setting example] setting the auto-tuning operation to 1 [note] if the controller is powered off during auto-tuning, this makes the auto-tuning ineffective with each parameter of , , and unchanged. To start the auto-tuning operation, set to “1”...

Page 21: Information@itm.Com

21 , , displaying on-delay alarm or the remaining time of timers (unit: seconds) (option) [setting example] displaying on-delay alarm or the remaining time of timers [description] • these parameters display the remaining time of timers 1, 2 and 3. • the remaining time of the on/off-delay timer is co...

Page 22: Information@itm.Com

22 [setting example] setting the operation value of alarm 2 to -10 ° c press and hold the sel key for one second. Will be displayed on the pv display. Press the key to display . Press the sel key once. The current setting ( ) flashes on the sv display. Press the or keys to display . Press the sel ke...

Page 23: Information@itm.Com

23 [setting example] setting the key lock to “2” key lock (setting range: 0 − 5) [description] • this parameter makes the set values of parameters unchangeable. However, the parameter name and the set values can be displayed. • to reset the key lock, change to . • even when the key lock is set, cont...

Page 24: Information@itm.Com

24 proportional band (setting range: 0.0 to 999.9% of the measured range) [description] • to select the on/off control (two-position control), set to 0.0. It is not necessary to set and . • can be automatically set by the auto-tuning operation. • when is too small, control will be unstable, and when...

Page 25: Information@itm.Com

25 integral time (setting range: 0 to 3200 seconds) [description] • can be set automatically by the auto-tuning operation. • can also be set manually. [setting example] changing the integral time from 240 seconds to 600 seconds • when is set to 0, the integral operation does not start. • when is set...

Page 26: Information@itm.Com

26 derivative time (setting range: 0.0 to 999.9 seconds) [description] • can be set automatically by the auto-tuning operation. • can also be set manually. [setting example] changing the differential time from 60.0 seconds to 50.0 seconds • when is set to 0, the differential operation does not start...

Page 27: Information@itm.Com

27 hysteresis range for on/off control (setting range: 0 to 50%fs) [description] • to select the on/off control (two-position control), set to 0.0. It is not necessary to set and . • when the hysteresis range (range of on/off control) is too small, the output may switch the on/off frequently. (this ...

Page 28: Information@itm.Com

28 cooling-side proportional band coefficient (option: available for dual output only) (setting range: 0.0 to 100.0) [description] • this parameter is used for setting the cooling-side pro- portional band. (see the figure below.) [setting example] changing the cooling-side proportional band coeffici...

Page 29: Information@itm.Com

29 cooling-side proportional band shift (dead band/overlap band) (option: available for dual output only) (setting range: -50.0 to +50.0) [description] • this parameter is used for shifting the cooling-side pro- portional band from the set value. (see the figure below.) [setting example] shifting th...

Page 30: Information@itm.Com

30 output offset value (setting range: -100.0 to 100.0 %) anti-reset windup (setting range: 0 to 100%fs) [description] • the anti-reset windup ( ) is automatically set to an optimum value by the auto-tuning operation. By setting , the amount of overshoot can be adjusted. [note] by making use of the ...

Page 31: Information@itm.Com

31 control algorithm (settings: pid/fuzy/self) [description] • this parameter is used for selecting pid control, fuzzy- pid control, or pid control with self-tuning. • to select the pid control or fuzzy-pid control, it is necessary to set the parameters of , , , and manually or by the auto-tuning in...

Page 32: Information@itm.Com

32 [self-tuning] 1 function: with the self-tuning function, pid parameters are automatically re-optimised depending on the actual condition of device to be controlled and the setting temperature (sv). 2 how to execute: follow the procedure shown below to set and execute the self-tuning. The self-tun...

Page 33: Information@itm.Com

33 3 conditions under which the self-tuning runs: q at power-on: the self-tuning runs when all of the following conditions are met. • the sv that appears at power-on is not the same one when the , , , and were set previously. (i.E. The , , , and set by the self-tuning, auto-tuning, manual setting, a...

Page 34: Information@itm.Com

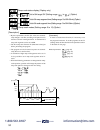

34 7 reference [about the self-tuning method] the pid constant is calculated in one of the following two methods. The method is selected automatically depending on the characteristics of the device to be controlled. • step response method • limit cycle method the following figures show the operation...

Page 35: Information@itm.Com

35 pv (measured value) stable range (setting range: 0 to 100%fs) [description] • self-tuning logic recognizes that control is stable if pv is staying within the sv ± . [setting example] changing the pv stable range from 2 to 3 press and hold the sel key for three seconds. Will be displayed on the pv...

Page 36: Information@itm.Com

36 hys (hysteresis) mode at on/off control (settings: off/on) [description] • this parameter is used for selecting the hysteresis opera- tion mode at on/off control. • default setting: on starts the on/off control at the values of sv+ and sv- . Starts the on/off control at the values of sv and sv+hy...

Page 37: Information@itm.Com

37 cycle time of control output 1 (setting range: 1 to 150 seconds) [description] • this parameter is applicable for to the contact output and ssr-driving output. • while input is within the proportional band, output changes between on and off in cycles. These cycles are called cycle time. For conta...

Page 38: Information@itm.Com

38 cycle time of control output 2 (cooling-side) (setting range: 1 to 150 seconds) (option: available for dual output only) [description] • by this parameter is set, the cycle time of control output 2. • while input is within the proportional band, output changes between on and off in cycles. These ...

Page 39: Information@itm.Com

39 input signal code (setting range: 0 to 16) [description] • this parameter is used for selecting input signals. Input signal varies depending on the sensors (2 types below). Set a code that corresponds to the sensor you use. Type i : thermocouples (9 kinds of signals) resistance bulbs (1 kind of s...

Page 40: Information@itm.Com

40 [description] • these parameters are used for setting the lower and up- per limits of the measured range and unit of temperature. • a decimal point position can be set in the parameter of . • for the current and voltage inputs, , and can be set for , and for other inputs, and can be set for . • s...

Page 41: Information@itm.Com

41 [setting example] changing the measuring range from 0 ° c to 150 ° c to -100 ° c to 200 ° c (pt100) press and hold the sel key for three seconds. Will be displayed on the pv display. Press the key to display . Press the sel key once. The current setting ( ) flashes on the sv display. Press the or...

Page 42: Information@itm.Com

42 [description] • this parameter is used for selecting the number of decimal point positions for the pv (measured value). Decimal point position (settings: 0 / 1 / 2) related parameters: (page 40) (page 40) [setting example] changing the decimal point position setting from 0 to 1 press and hold the...

Page 43: Information@itm.Com

43 [description] • with this function, predetermined value is added to the in- put reading. This parameter is used for adjusting pxr’s indication so that it becomes same as the one of the other instruments like recorder. Pv (measured value) offset (setting range: -10 to 10%fs) [setting example] addi...

Page 44: Information@itm.Com

44 [description] • with this function, predetermined value is added to the origi- nal sv. This parameter is used to eliminate the offset that occurs in performing p control. • the pxr operates based on the sv to which the sv offset value is added. Sv (setting value) offset (setting range: -50 to 50%...

Page 45: Information@itm.Com

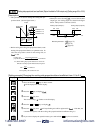

45 [description] • this parameter are used for reducing the fluctuation of input signal (filter function). For example, when the input filter constant is set to 5 seconds, the pv changes as shown in right figure while input changes from 0 to 100% suddenly. It takes 5 sec- onds for the pv to change f...

Page 46: Information@itm.Com

46 [description] • these parameters are used for selecting the operation types of alarms 1, 2 and 3. • or is activated in the same way as except for codes 12 to 15. (codes 12 to 15 cannot be selected for and .) • when any code of 12 to 15 is selected for alarm 2, alarm 2 is activated and alarm 1 or ...

Page 47: Information@itm.Com

47 • alarm codes for standard types • timer codes [alarm type list] the table below shows the meaning of symbols in the following operation figures. • alarm 1 and 3 are activated in the same way as alarm 2 except codes 12 to 15. (codes 12 to 15 cannot be selected for alarm 1 or 3. If any of them is ...

Page 48: Information@itm.Com

48 • alarm codes with dual set values dlyn: the delay time of alarms 1, 2 and 3 or timers 1, 2 and 3 aln: the set value of alarms 1, 2 and 3 an-l: the set value (lower limit) of alarms 1, 2 and 3 an-h: the set value (upper limit) of alarms 1, 2 and 3 al1: the set value of alarm 1 al2: the set value ...

Page 49: Information@itm.Com

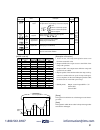

49 selecting ramp-soak patterns (settings: 1 / 2 / 3) (option) [description] • this parameter becomes effective when the ramp-soak operation is changed from to . • setting range : performs 1st to 4th segments. : performs 5th to 8th segments. : performs 1st to 8th segments. Sv time sv-1 sv-2 sv-3 sv-...

Page 50: Information@itm.Com

50 [description] • by these parameters, the sv (set value) are automati- cally changed over time according to the patterns set in advance as shown in the figure below. A maximum of 8 ramp-soak segments can be set in pxr. • the first ramp starts from the pv (measured value) just before performing the...

Page 51: Information@itm.Com

51 current program status description parameter display symbol name remark factory default settings 1st to 8th target sv 1st to 8th ramp segment time 1st to 8th soak segment time ramp-soak mode stat sv-1 to sv-8 tm1r to tm8r tm1s to tm8s mod displays the ramp-soak current status. This parameter is o...

Page 52: Information@itm.Com

52 [setting example] setting the 1st target sv to 400 ° c press and hold the sel key for three seconds. Will be displayed on the pv display. Press the key to display . Press the sel key once. The current setting ( ) flashes on the sv display. Press the key to display . Press the sel key once. Will s...

Page 53: Information@itm.Com

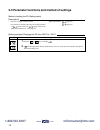

53 specifying control action, and output direction at input burn-out (setting range: 0 to 19) [description] • this parameter specifies action (single/dual and heating/ cooling), and output direction at input burn-out. • the standard model (single output) or the heating/cool- ing control output (dual...

Page 54: Information@itm.Com

54 [description] • these parameters set the setting range of the sv (setting value). • both the sv under ramp-soak operation and the sv switched by the di1 function are affected by the sv limiter. • the sv upper and lower limiters ( , ) can be set within the range of the measuring values ( , ). Sv (...

Page 55: Information@itm.Com

55 , , the time of on-delay alarm or timer function [description] on-delay alarm • with this function, the alarm relay is closed after the pre- determined delay time. (see operation q shown in the figure below.) • in case the cause of the alarm is solved within the delay time, the alarm relay is not...

Page 56: Information@itm.Com

56 operating procedure display 1. [setting example] setting the delay time for on-delay alarm to 30 seconds press and hold the sel key for five seconds. Will be displayed on the pv display. Press the key to display . Press the sel key once. The current setting ( ) flashes on the sv display. Press th...

Page 57: Information@itm.Com

57 displaying current detector input (display only) (option) hb (set value of heater break alarm) (setting range: 0.0 to 50.0 a) (option) [description] • when is set to 0.0, the hb alarm is turned off. • the point at which the alarm is activated can be set in the parameter of . • there are two types...

Page 58: Information@itm.Com

58 [setting example] changing the detecting current of heater break from 8.0 a to 9.0a press and hold the sel key for five seconds. Will be displayed on the pv display. Press the key to display . Press the sel key once. The current setting ( ) flashes on the sv display. Press the or keys to display ...

Page 59: Information@itm.Com

59 , , hysteresis of alarm 1, 2 and 3 (setting range: 0 to 50% fs) [description] • the alarm is detected in the two-position operation (on/ off). The hysteresis means the difference between the input at on and the input at off. For example, the hys- teresis of 5 ° c means that the range between on a...

Page 60: Information@itm.Com

60 [description] • these parameters are used to switch on/off of the alarm latch, the error satus alarm, and the de-energized output alarm functions for each of alarm 1, 2 and 3. • each function is set to on by setting the following digit to “1”: , , options of alarm 1, 2 and 3 (setting range: 000 t...

Page 61: Information@itm.Com

61 [setting example] setting the error status alarm function for alarm 2 to on press and hold the sel key for five seconds. Will be displayed on the pv display. Press the key to display . Press the sel key once. The current setting ( ) flashes on the sv display. Press the or keys to display . Press ...

Page 62: Information@itm.Com

62 [description] • these parameters set the limit value of output. , upper and lower limits for control output 1 (setting range: -3.0 to 103.0%) , upper and lower limits for control output 2 (setting range: -3.0 to 103.0%) (option) output (tc= 30 seconds) phc plc 30 (seconds) 100(%) input 0 [setting...

Page 63: Information@itm.Com

63 [description] • this parameter sets whether or not to maintain the value within the limit when the output value increases up to the limit set value. Output limit types (setting range: 0 to 15) [setting example] selecting the operation that outputs 1 and 2 are maintained within the upper and lower...

Page 64: Information@itm.Com

64 , output value display (display only: -3.0 to 103.0%) [description] • these parameters display the output values of outputs 1 and 2 in the unit of %. (since the values are calculated with the software, they may have some error comparing to the actual output.) [setting example] confirming the outp...

Page 65: Information@itm.Com

65 [description] • this parameter sets whether or not to perform the rcj (cold junction compensation) for the thermocouple in- put. Use the factory default setting (on: performs the rcj) under normal conditions. On: performs the rcj (cold junction compensation). Off: does not perform the rcj (cold j...

Page 66: Information@itm.Com

66 [description] • the user-definable functions are independent of the adjust- ment values of the pxr. Setting the parameters of and to can return to the factory default settings. Adjusting the pv (measured value) display (0%) (setting range: -50 to 50% fs) adjusting the pv (measured value) display ...

Page 67: Information@itm.Com

67 • the control can also be switched between run/ standby manually. Select on or off in the parameter for (set- ting standby). • the table below shows the relationship between the run and standby mode switched with a manual op- eration, di 1, and ramp-soak operation. Switching control run/standby (...

Page 68: Information@itm.Com

68 starting the auto-tuning (di functions 3, 4) • these functions can switch the start/stop of the auto- tuning. Cancel the alarm latch (di functions 5 to 8) • these functions can cancel the alarm latch while alarms are latched by setting the alarm latch function to on. Timer operation (di functions...

Page 69: Information@itm.Com

69 [setting example] changing the sv (front sv) to sv1 if you want to display the operation status, press and hold the key for two seconds. The sv value and sv no. Will appear alternately. The switched sv or will be displayed alternately on the display area. Press the key once. Will be displayed and...

Page 70: Information@itm.Com

70 [description] • do not set the same number as other micro-controllers. • see communication function instruction manual for details. Station no. For communication (setting range: 0 to 255) [setting example] setting the station no. To “123” press and hold the sel key for five seconds. Will be displ...

Page 71: Information@itm.Com

71 [description] • this parameter sets the parity for communications. The baud rate is fixed at 9600bps. : odd parity : even parity : no parity parity for communication (setting range: 0 to 2) [setting example] setting the even parity press and hold the sel key for five seconds. Will be displayed on...

Page 72: Information@itm.Com

72 communication protocol setting (setting range: 0 to 1) (option) [description] • this parameter is used to switch communication protocols. * see the following communication specifications for details of each protocol. • instruction manual for micro controller x communication functions (rs485 modbu...

Page 73: Information@itm.Com

73 re-transmission output type setting (setting range: 0 to 3) (option) [description] • this parameter is used to set the retransmission output type. The means of the set values are as shown below. Related parameters: (page 74) (page 74) [setting example] changing the retransmission output type from...

Page 74: Information@itm.Com

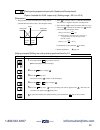

74 re-transmission base scale (setting range: -100.0 to 100.0%) (option) re-transmission span scale (setting range: -100.0 to 100.0%) (option) [description] • the retransmission base scale and span scale can be set as shown below. Unit for the setting is %. Output type description of percentage pv/s...

Page 75: Information@itm.Com

75 [setting example] setting zero adjustment +1 ° c press and hold the sel key for 5 seconds. Will be displayed in the pv display section. Press the key to display . Press the sel key once. The current set value ( ) in the sv section flickers. Press the and keys to display . Press the sel key once. ...

Page 76: Information@itm.Com

76 [setting example] changing the filter constant from 0.0 (filter off) to 5.0 (5 seconds) display remote sv input 100 63 (%) y control output input filter pid ° c remote sv input y t 5 seconds press and hold the sel key for 5 seconds. Will be displayed in the pv display section. Press the key to di...

Page 77: Information@itm.Com

77 remote sv input value display (display only: -1999 to 9999) (option) [description] • these parameters are used to correct the deviation of remote sv input. (the value obtained by calculations for remote sv input filter and remote sv input adjustment is displayed as display value.) [setting exampl...

Page 78: Information@itm.Com

78 [description] • this parameter skips the parameter display by items. • this parameter is used not to display the items that are not used, or not to change the settings mistakenly. To to parameter display mask (setting range: 0 to 255) • “parameter mask dsp” in “2-1 parameter list” (pages 7 to 11)...

Page 79: Troubleshooting

79 3 troubleshooting remedies set the parameter of correctly. Correct the polarity of the sensor and the pxr. Set the parameter of to 3, and check if the tem- perature around an ordinary temperature is displayed. (thermocouples b and r have a large error around ordi- nary temperatures. However, this...

Page 80: Information@itm.Com

80 remedies decrease the set value of the parameter of . Remove the short-circuited terminals. Connect it properly. Power it on. Prepare the micro-controller to be suitable for the device to be controlled. Or select the device to be controlled to be suitable for the micro-controller. Set the paramet...

Page 81: Index

81 index a b p r c d e h i k l m o s t u adjusting the pv display (0%) ..................................................... 66 adjusting the pv display (100%) ................................................. 66 alarm codes ..............................................................................

Page 82: Memo

82 memo www. .Com information@itm.Com 1.800.561.8187.

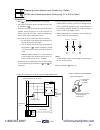

Page 83: Over-Temperature Protection

Consult on the pxr with the following: [note] modbus™ is a trademark of modicon. Ciltect ™ is a trade mark of ci technology. Over-temperature protection any control system design should take into account that any part of the system has the potential to fail. For temperature control systems, continue...