- DL manuals

- Fedders

- Air Conditioner

- E1FC418N6G

- Service Manual

Fedders E1FC418N6G Service Manual

Summary of E1FC418N6G

Page 1

Issued on 1 april,2003 fedders large split unit (r407c) service manual.

Page 2

Section a: specifications section b: parts list and exploded views section c: installation section d: trouble shooting section e: wiring diagram section f: technical data.

Page 3

Section a: specifications.

Page 4

Fedders large split (r407c) model number indoor unit e1fe418n6d ehfe418n6d e1fe424n6d ehfe424n6d outdoor unit e1fc418n6g ehfc418n6g e1fc424n6g ehfc424n6g performance data volts / hz / phase 220-240 / 50 / 1 220-240 / 50 / 1 220-240 / 50 / 1 220-240 / 50 / 1 cooling - btu/h (kw) 17500 (5.13) 17500 (5...

Page 5

Section b: parts list and exploded views.

Page 6

Specifications : indoor unit dimensions : 1020(40.15")w x 195(7.68")d x 320(12.60")h outdoor unit dimensions : 895(35.2")w x 331(13.0")d x 623(24.6")h refrigerant r charge e eer grams of model v btu/h (kw) mode volt / hz amps watts cool r-407c e1fe418n6d - e1fc418n6g 17500 (5.13) cool 220-240 / 50 9...

Page 7

E e e e 1 h 1 h f f f f e e e e 4 4 4 4 1 1 2 2 8 8 4 4 n n n n item 6 6 6 6 no. Description service part # d d d d -----chassis assembly----- 1 lock plate, blower wheel left 36-08-00010-001 1 1 1 1 2 lock plate, fan motor, right 36-08-00020-001 1 1 1 1 3 lock plate, fan motor, left 36-08-00030-001 ...

Page 8

E e e e 1 h 1 h f f f f e e e e 4 4 4 4 1 1 2 2 8 8 4 4 n n n n item 6 6 6 6 no. Description service part # d d d d indoor evaporator unit (r407c) model number fedders large split -----chassis assembly(cont')----- 24 filter 35-16-00010-001 2 2 2 2 ni 3m purifying filter 35-03-01460-001 1 1 1 1 ni ch...

Page 9

E e e e 1 h 1 h f f f f e e e e 4 4 4 4 1 1 2 2 8 8 4 4 n n n n item 6 6 6 6 no. Description service part # d d d d indoor evaporator unit (r407c) model number fedders large split -----electrical assembly(cont')----- 41 main p.C. Board (c/o) 35-16-04160-012 1 -- 1 -- 41 main p.C. Board kit (h/p) 50-...

Page 13

E e e e 1 h 1 h f f f f c c c c 4 4 4 4 1 1 2 2 8 8 4 4 n n n n item 6 6 6 6 no. Description service part # g g g g -----chassis assembly----- 1 front grille 35-24-05150-001 1 1 1 1 2 front panel (painted),neuter 35-24-05010-083 1 1 1 1 3 fan blade 37-24-01010-001 1 1 1 1 4 fan motor 35-24-90000-001...

Page 14

E e e e 1 h 1 h f f f f c c c c 4 4 4 4 1 1 2 2 8 8 4 4 n n n n item 6 6 6 6 no. Description service part # g g g g model number fedders large split unit outdoor condenser unit (r407c) -----refrigerant assembly(cont')----- 16 capillary tube, 0.064" id x 13" s0-02-c0002-n14 1 1 1 1 17 condenser assem...

Page 15

E e e e 1 h 1 h f f f f c c c c 4 4 4 4 1 1 2 2 8 8 4 4 n n n n item 6 6 6 6 no. Description service part # g g g g model number fedders large split unit outdoor condenser unit (r407c) -----packaging parts----- 34 carton,neuter 35-24-00070-n01 1 1 1 1 35 eps pad, top left 35-24-00030-001 1 1 1 1 36 ...

Page 20

Section c: installation.

Page 21

Split type air conditioner installation manual ® for 18,000 - 24,000 btu c1.

Page 22: Contents

C2 contents safety precaution ........................................................................... C3 part lists ................................................................................................ C4 preparation of piping .............................................................

Page 23: Safety Precaution

C3 safety precaution • we recommend that you ask a qualified technician to install your air condi- tioner in accordance with this installation manual. • read this manual carefully before using your air conditioner. • all wiring must conform to local and national electrical codes. • to avoid possible...

Page 24: Part Lists

C4 part lists a number of small parts have been packed with the indoor unit. Please check the contents of the box with the list below. Indoor to outdoor signal connecting wire (for heat- pump model only) description quantity 1 1 remote control 2 aaa batteries 2 screws for remote control holder 1 rem...

Page 25: Preparation of Piping

C5 preparation of piping pipe length, elevation and refrigerant charge cutting the pipe and the cables. • measure the distance between the indoor and the outdoor units. • cut the pipe length about 10% more than the measured distance. • cut the electrical cable with about 2 metres more than the measu...

Page 26: Flaring of Pipe

C6 any bend in the tubing must have a minimum radius of 100mm to any bend in the tubing must have a minimum radius of 100mm to prevent leakage. Prevent leakage. Do not bend any section of the tube repeatedly. Do not bend any section of the tube repeatedly. Do not remove the flare nut from the tubing...

Page 27: Indoor Unit Installation

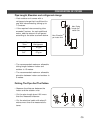

C7 indoor unit installation • do not install the unit near any heat source, steam source or flammable gas source. • locate the unit in a place where it will provide cool air throughout the room. • make sure the minimum distances from the walls and obstructions are main- tained as shown on the right....

Page 28: Indoor Unit Installation

C8 routing the drain hose and tubing • the following illustrate the different piping outlet option. Right back outlet if you are using the following outlet option, you must wire the indoor unit before attaching it to the wall bracket. • remove the decorative front by removing 3 screws. • remove it b...

Page 29: Indoor Unit Installation

C9 sealing the drain hose and tubing • wrap the drain hose, tubing and elec- tric wire together with polyethylene tape. • wrap all exposed tubing with tape except tubing, which will rest inside the unit. Drain hose tubing polyethylene tape use caution when bending piping tape gas pipe insulations dr...

Page 30: Wiring The Indoor Unit

C10 attaching the unit to the wall bracket if you are using right, left or bottom piping outlet (see page 8) you must wire the unit before you attach it to the wall bracket. • hook the unit to the hangers on top of the bracket first and then press the lower left and right side of the unit against th...

Page 31: Indoor Unit Installation

C11 connecting the piping to the indoor unit • align the center of the piping and then sufficiently tighten the flare nut with fingers, tighten the flare nut with torque wrench according to the table as shown below. Flare nut indoor unit tubing torque wrench spanner pipe size diameter torque (n.M) 3...

Page 32: Outdoor Unit Installation

C12 outdoor unit installation at least 10cm at least 60cm at least 60cm at least 40cm at least 60cm locating the outdoor unit • locate the outdoor unit where the air flow around it is not obstructed. • ensure that the base is level and does not exceed the maximum slope of 5 degrees. • secure the uni...

Page 33: Outdoor Unit Installation

C13 outdoor unit installation installing the outdoor unit • attach the base leg damper by sliding the slot into the base of the outdoor unit. • attach the drain gasket and drain adapter to the base pan of the unit before you secure the unit. • fasten the unit down, referred to the mounting dimension...

Page 34: Outdoor Unit Installation

C14 connecting the wires to the outdoor unit • remove the service cover from the unit. • connect the wires to the terminals according to the wiring diagram shown in the wiring diagram section or at the back of the service cover. • clamp the wire to the unit with the wire retainer. • form a drip loop...

Page 35: Checking For Gas Leakage

C15 vacuuming the piping & the indoor unit checking for gas leakage • connect the manifold gauge to the outdoor unit gas line port as shown on the right. • connect the charging cylinder to the manifold gauge and open the valve of the cylinder. • open the low pressure valve of the manifold gauge unti...

Page 36: Restraining The Piping

C16 • unscrew the cap on the 2-way and 3-way valve. • after all lines are installed and leak tested, set both the liquid and gas line valves to fully open position with the allen key for the unit operation, as shown. • reinstall the cap and torque to the specified value under torque table on page 10...

Page 37: Test Run & Check

C17 test run & check switch on the power supply ensure that all the piping and wiring are connected properly and ensure that all the piping and wiring are connected properly and securely, before turning the power on. Securely, before turning the power on. • turn the main switch of the unit to on. • ...

Page 38: Notice to The Consumer

C18 • supply the consumer with the operating manual. • demonstrate the functions of the remote control. • demonstrate how to remove and clean the air filters. • explain the 3 minute delay function. Notice to the consumer checking the unit • check all the control functions. • check all the indicator ...

Page 39

Section d: trouble shooting.

Page 40

D1.

Page 41

D2 symptom diagnosis remedy both fan & compressor not running. Fuse open or breaker tripped. Inspect and repair. Poor power plug connection. Inspect. Power failure. Inspect. Control circuit malfuction. Replace parts. Compressor does not run. Compressor motor windings open. Replace compressor. Compre...

Page 42

Section e: wiring diagram.

Page 43

E1.

Page 44

E2.

Page 45

E3.

Page 46

E4.

Page 47

Section f: technical data.

Page 48

F1 remote control and pc board functional specifications large split unit (18 / 24k) the electronic air-con control system consists of : i. Control system 1) hand-held infra-red transmitter with liquid crystal display panel (hand held unit) 2) receiver module consisting of: a) main receiver board b)...

Page 49

F2 ii. Hand-held transmitter operating voltage : 3.0 vdc. Power source : 2 "aaa" size batteries battery life expectancy : more than 1 year range of transmission : at least 8m from the infrared sensor of the receiver module angle of transmission : 45° about normal medium of transmission : infrared tr...

Page 50

F3 h) clock button starts and stops the setting of time of the day. Deactivates timer function. The accuracy of the time setting must be + / - 15 second per day. I) sleep button activates / deactivates sleep function j) start button activate / deactivate on timer k) stop button activates / deactivat...

Page 51

F4 1.1. Operation / filter reset button. Operation by pushing this button, one of the following two air-con operations are selected. A) automatic operation selecting this operation is equivalent to selecting auto mode, auto fan speed control and auto vane function in manual operation. The set temper...

Page 52

F5 c) filter dirty/system fault (red) lights up after 500 hours of operation, to led indicate that the filter requires cleansing. The operation/filter reset switch should be pressed by the user to switch this led indication off after cleansing and replacing the filter. When indoor air thermistor (th...

Page 53

F6 3. 3-min. Compressor switch on delay the compressor is not switched on again immediately after being switched off. The air-con controller waits for 3 minutes before turning it on again to protect it. This protective measure applies throughout the operation of the air-con except on power-up. 4. 60...

Page 54

F7 v. Modes of operation 1. Cool mode the air-con controller lowers the room temperature in this mode. In cool mode, the indoor fan is always turned on, allowing it to run at the set speed. To stop the cool mode cycle, the compressor, outdoor fan are turned off, the 4-way valve which serves no funct...

Page 55

F8 if the room temperature >=31 ° c, compressor off, outdoor fan off and 4-way valve remains on, indoor fan runs according to following table: id room temp., tr tr ° c 31 ° c ° c tr>=32 ° c id fan set * low * maintain current state the heating cycle starts and stops according to the result of set te...

Page 56

F9 vi. Temperature control and measurement 1. Temperature measurement accuracy the temperature measurement range of the air-con controller is from -10ºc to 60ºc. Measurement accuracy is given in the following table: ºc + - ºc + - ºc + - ºc + - ºc + - -10 1 1 5 1 1 20 1 1 35 1 1 50 1 1 -9 1 1 6 1 1 2...

Page 57

F10 when the indoor fan control is set to auto, the fan speed is automatically selected according to the mode of operation, set temperature and room temperature. In cool mode, choosing auto fan will result in the following automatic fan speed selection: room temperature = set pt+3°c > set pt+3°c ind...

Page 58

F11 viii. Vane function 1. Vane position home the vane will be at this position whenever the air-con is off. Its exact angle is 115 ° counter-clockwise from position 3. Position 1 the vane plane is positioned 70 ° counter-clockwise from position 3. Cool, dry and fan modes default vane position. Posi...

Page 59

F12 ix. Sleep function sleep function is only selectable in manual operation, but it is not available in dry and fan modes. When this function is selected, the indoor fan immediately runs at low speed, all timer functions will be overridden and disabled at the same time. In cool or auto-cool mode, o...

Page 60

F13 x. Timer function the start timer will switch the air conditioner on at the start time set in the hand-held transmitter, while the stop timer will switch the air-con off at the specified stop time. Both timers can be activated together to perform "on-off-on" or "off-on-off" operation. The settin...

Page 61

F14 xi. Device protection measures 1. 3-minutes compressor switch on delay the compressor is not switched on again for 3-minutes every time after it is switched off to protect it. This restriction applies throughout the operation of the air-con except on power- up. 2. Cool mode protection (low-press...

Page 62

F15 for example, if the temperature set point is 20°c when cool mode is entered at a room temperature of 21°c, the controller will start the cool mode cycle to cool the room. The cycle still continues when the room temperature later lowers to 20°c. It finally stops when the room temperature lowers f...

Page 63

F16 when the indoor coil temperature reaches 10ºc or higher for 2 minutes de-icing will be terminated and normal cool mode operation resumes. However, if the coil temperature is still below 10ºc after 10 minutes, de-icing operation will still be terminated to resume normal cool mode operation. 40 mi...

Page 64

F17 6. Defrosting in heat mode (applicable on heat pump unit only) a) defrost starting conditions when all conditions of i) ~ iii) are satisfied, defrosting operation starts. I) the indoor coil thermistor read ≤ 42 ° c ii) the outdoor coil thermistor reads -4 ° c or below. Iii) the difference betwee...

Page 65

F18 7. Outdoor coil de-icing in heat mode (applicable on heat pump unit only) the air-con controller heats up the outdoor coil to melt the ice formed at outdoor coil. To achieve this, the compressor must be turned on, while the 4-way valve must be turned off. During this period, the indoor fan must ...

Page 66: Large-Split Heatpump

F19 xii. Thermistor fault indication the electronic controller flashes the filter led when a thermistor fault is detected. The filter led blinking according to the time specified until the thermistor fault is rectified. 1. Heat overload protection algorithm large-split heatpump large split heat mode...

Page 67

F20 xiii. Self test main pcb self-test to initiate the self-testsequence, execute the following: a) turn on the ac. Supply to the air-con. B) press and hold the operation / filter reset button for 6 seconds after which you can hear 2 beep sound to indicate activation of self-test sequence. (note : w...

Page 68

F21.

Page 69

F22.

Page 70

F23.

Page 71

F24.

Page 72

F25.

Page 73

F26.

Page 74

F27.

Page 75

F28.