Fedders F80A Installation, Operation And Maintenance Manual

Installation, Operation and Maintenance

MODEL F80A

CATEGORY I NATURAL GAS AND LP GAS

MID EFFICIENCY WARM AIR FURNACE

Please read the operating instructions and safety

precautions carefully and thoroughly before installing

and operating your furnace. Keep this manual in a

safe place for future reference.

23-23-0427N-006

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . .1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FURNACE SIZING . . . . . . . . . . . . . . . . . . . . . .3

LOCATION of UNIT . . . . . . . . . . . . . . . . . . . .3

INSTALLATION POSITIONS . . . . . . . . . . . . . . .4

AIR CONDITIONING . . . . . . . . . . . . . . . . . . . .4

INSPECTION/ACCESS PANEL . . . . . . . . . . . . .4

CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . .5

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . .5

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . .6

DETERMING COMBUSTION AIR . . . . . . . . . .7

FURNACE VENTING . . . . . . . . . . . . . . . . . . . .8

GAS SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . .12

CONVERSIONS . . . . . . . . . . . . . . . . . . . . . . .13

HIGH ALTITUDE & AIRFLOW

SPECIFICATION TABLES . . . . . . . . . . . . . . . .14

ELECTRICAL SPECIFICATIONS . . . . . . . . . . .15

START UP PROCEDURES/

SEQUENCE OF OPERATION . . . . . . . . . . . . .17

AIR FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . .19

ADJUSTING BLOWER SPEEDS . . . . . . . . . . .19

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . .20

TROUBLESHOOTING . . . . . . . . . . . . . . . . . .21

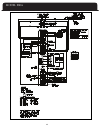

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . .25

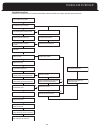

TABLE OF CONTENTS

USER’S INSTRUCTION GUIDE

LOCATED AFTER PAGE 25 OF THIS

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

Model

Serial Number

Date of Purchase

For future reference write down the model, serial

number, and date of purchase. Use these numbers in

any correspondence or service calls concerning your

furnace.

Keep these instructions for future reference.