- DL manuals

- Fedders

- Furnace

- operation and

- Installation, Operation And Maintenance Manual

Fedders operation and Installation, Operation And Maintenance Manual

Installation, Operation and Maintenance

HIGH EFFICIENCY

TWO STAGE VARIABLE SPEED

Please read the operating instructions and safety

precautions carefully and thoroughly before installing

and operating your furnace. Keep this manual in a

safe place for future reference.

USER’S INSTRUCTION GUIDE

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

Model

Serial Number

Date of Purchase

For future reference write down the model, serial

number, and date of purchase. Use these numbers in

any correspondence or service calls concerning your

furnace.

Keep these instructions for future reference.

CATEGORY I NATURAL GAS AND LP GAS

WARM AIR FURNACE

LOCATED AFTER PAGE 43 OF THIS

23-23-0508N-003

MODEL 77FV95A054 FV95A072 <

FV95A090

<

FV95A108

Summary of operation and

Page 1

Installation, operation and maintenance high efficiency two stage variable speed please read the operating instructions and safety precautions carefully and thoroughly before installing and operating your furnace. Keep this manual in a safe place for future reference. User’s instruction guide instal...

Page 2: Table of Contents

S s c case 1: furnace located in an case 2: furnace located in a case 3: furnace located in a confined space, case 4: furnace located in a confined space, sequence of operation if the furnace circulating air blower and field supplied and installed table of contents air conditioning inspection/access...

Page 3

Introduction this 95% efficient gas fired furnace series is cga / aga d vent pressure) non-direct or direct vent central forced air fur- nace. It is an upflow, downflow, horizontal left and right fur- nace suitable for residential and light commercial heating applications from 54,000 to 108,000 btu/...

Page 4

Danger what to do if you smell gas: • do not try to light any appliance • do not touch any electrical switch; do not use any phone in your building • immediately call your gas supplier from a neighbor’s phone, or a cellular phone from a location well away from the building. Follow the gas supplier’s...

Page 5

Codes: this furnace must be installed: • in accordance with all local codes, bylaws and regulations by those authorities having jurisdiction • in the united states, this furnace must be installed in accordance with the current ansi z223.1 (nfpa 54) national fuel gas code • in canada, this furnace mu...

Page 6

Furnace sizing the maximum hourly heat loss for each heated space shall be calculated in accordance with the procedures described in manual j titled, "load calculation" published by the air conditioning contractors of america, or by any other method which is suitable for local conditions, provided t...

Page 7

Other considerations: 1. This furnace is not to be used for temporary heating of buildings or structures under construction. 2. If this furnace is to be used with air conditioning and is to be installed in an area over a finished ceiling or living area, install a field fabricated auxiliary drain pan...

Page 8

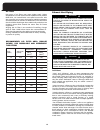

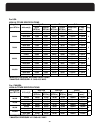

G a c g b f e d j l l k 1 dimensions (inches) model input width depth height supply ab c f x g return side bottom d x e j x k l h 1 vent outlet 4” - use reducer fittings. 2 two return air openings required 54,000 72,000 90,000 108,000 54,000 72,000 90,000 108,000 17.5 20.5 20.5 24.5 14 x 22 16 x 19 ...

Page 9

Ductwork proper airflow is required for the correct operation of this furnace. Insufficient airflow may cause erratic operation, could cause the furnace to cycle on the high temperature limit, and may damage the heat exchanger. Excessive airflow may result in an excessively noisy duct system and may...

Page 10

Warning there must not be any openings between the blower division panel and the combustion compartment. The blower compartment is under greater suction then the combustion compartment and can pull combustion air from the burners and cause incomplete combustion and erratic furnace operation. Warning...

Page 11

Instructions for re-orienting air inducer this furnace comes assembled ready for left side or vertical venting. Rotate the inducer 180 degrees to exit the right hand side. 1. Disconnect inducer wire connections. 2. Remove pressure switch hoses. 3. Remove pressure switches. 4. Remove 4 inducer screws...

Page 12

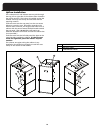

10 c c a b a b a b upflow installation the combustion air and exhaust vent may exit through the top, left or right side of the cabinet when viewed in the upflow position. The inducer is installed so that the exhaust vent may exit the top and left sides without requiring rotation. If exhaust vent exi...

Page 13

11 downflow installation when the furnace is installed in the downflow position the combustion air and exhaust vent may exit through the left or right side of the cabinet (when viewed in the upflow position.). The inducer is installed so that the left side exits require no rotation. If exhaust vent ...

Page 14

12 c a b a a b b b a c c the furnace must be installed level or sloping towards the front to facilitate proper drainage. Important it is not permissible to use a rear of the furnace as a return. Note the furnace must be installed level or sloping towards the front to facilitate proper drainage. Impo...

Page 15

Warning do not allow gas piping to be routed through joist spaces that are used for return air pur- poses. Do not use joist spaces for return air purposes if the joist space already contains plumbing stacks, chimney components, etc. Unless the portion used for return air purpos- es can be completely...

Page 16

Figure 1 danger the following types of installation sites (but not limited to the following) will require outdoor air for combustion because of chemical exposures: commercial buildings, buildings with indoor swimming pools, furnaces installed in laundry rooms, furnaces in hobby or craft rooms, furna...

Page 17

Warning read and follow all instructions in this sec- tion. Failure to properly vent this furnace can cause carbon monoxide poisoning or an explo- sion or fire resulting in property damage, per- sonal injury or loss of life. Definitions "vent" and "chimney" refer to open passageways that convey vent...

Page 18

Guidelines • venting may be vertical or horizontal. • • horizontal piping must slope back towards the furnace at a minimum rate of 1/4” to the foot, so that • horizontal runs must be supported at least every 3 feet. Horizontal sections must not dip or sag • all vent runs through unconditioned space ...

Page 19

Procedure: this guide is intended specifically for pvc pipe; however, the general procedure applies to all plastic piping systems. Materials: pvc cleaner / primer and pvc solvent cement. After cutting pipe, remove all ragged edges and burrs. This will reduce restriction (pressure drop) throughout th...

Page 20

Pipe size number of 90° elbows maximum allowable straight length of exhaust or intake 2 3 2 3 2 3 2 3 01 2 3 4 5 6 s - 24” for service c - combustible floor but not carpet or non-ceramic tile nc - non-combustible floor or use base kit #30476 model 054 072 090 108 all dimensions in inces 70 150 65 14...

Page 21

Concentric venting terminal kits may be used for this series furnace. They provide a means of obtaining combustion air and exhausting products of combustion utilizing a single penetration through the exterior wall. This can be useful when there is limited wall space available. Kits are available in ...

Page 22

If the required clearance to grade or anticipated snow level cannot be obtained with the “straight through” configuration, the exhaust pipe may be “periscoped” up to 24” to gain extra height. (figure 9) in this case, the flue gases may be expelled horizontally. Use the same size pipe as the interior...

Page 23

Combustion air exhaust 8” 12” 2” 12” clearance above grade or highest anticipated snow level. D e f g h i j k l a b c combustion air exhaust 8” 12” 2” 12” clearance above grade or highest anticipated snow level. D e f g h i j k l a b c b c top view interior exterior c d j a b i a b e d c f h a e e d...

Page 24

Danger solvent cements and primers are highly flammable. Provide adequate ventilation and do not assemble near heat source or open flame. Do not smoke. Avoid skin or eye contact. Observe all cautions and warnings printed on material containers. Failure to follow these guidelines may result in fire, ...

Page 25

Canadian installations us installations a = clearance above grade, veranda, 12 in (30 cm) 12 in (30 cm) porch, deck, or balcony b = clearance to window or door that 6 in (15 cm) for appliances 10,000 4 ft (121 cm) below or to side of may be opened btuh (3 kw), 12 in (30 cm) for opening; 1 ft (30 cm)...

Page 26

Canadian installations us installations a = clearance above grade, veranda, 12 in (30 cm) 12 in ( 30cm ) porch, deck, or balcony b = clearance to window or door that 6 in (15 cm) for appliances 10,000 6 in (15 cm) for appliances 10,000 may be opened btuh (3 kw),12 in (30 cm) for btuh (3 kw), 9 in (2...

Page 27

Condensate drains the furnace will condense as much as a half pound of water per hour (approximately 2 imperial quarts, 2 1 / 2 u.S. Quarts or 2 1 / 4 liters). It is necessary to make provisions for draining the condensate away. The furnace is supplied with a drain trap assembly. See the drain coupl...

Page 28

Horizontal flow right condensate trap condensate trap horizontal flow left upflow downflow condensate condensate trap trap figure 11 figure 12 figure 13 figure 14 26.

Page 29

D e a b c condensate neutralizers some local codes may require the use of a condensate neu- tralizer. If the furnace condensate is to be routed to a sep- tic system, it may be advisable to use a condensate neutral- izer. Condensate neutralizers such as the ward industries 90+ neutralizer are availab...

Page 30

Warning this furnace is factory equipped to burn natural gas only. Conversion to l.P. Gas requires special kit no. Failure to use the proper conversion kit can cause fire, explosion, carbon monoxide poisoning, property damage, personal injury or loss of life. Caution conversion of this furnace requi...

Page 31

Conversions high altitude in the united states, the modifications for high altitude are based on a 4 percent reduction of input capacity for every the impact of altitude for selected elevations. Ratings shown apply to the highest elevation in range. Consult with local fuel suppliers or authorities t...

Page 32

For usa high altitude specifications rating plate *manifold pressure natural gas=3.5 inwc **manifold pressure l.P. Gas=10.5 inwc for- canada high altitude specifications rating plate *manifold pressure natural gas=3.5 inwc **manifold pressure l.P. Gas=10.5 inwc 6 54,000 72,000 108,000 high fire 3 4 ...

Page 33

Setting the manifold (outlet) gas pressure (f92-1003 36g valve pressure check kit) the manifold outlet pressure is specified on the rating plate. 1. Shut off the gas upstream of valve and move valve switch to off. 2. Using the 3/32 inch hex wrench that is included in the valve pressure check kit, ro...

Page 34

Danger the furnace cabinet must have an uninterrupted ground. A ground wire is provided in the electrical junction box. Do not use gas piping as a ground. Failing to ground the furnace properly can result in electric shock resulting in personal injury or death. Warning this furnace is equipped with ...

Page 35

Thermostat cooling contactor fan relay heating relay 24v 115v r g y w y g w isolation relay thermostat location the thermostat should be located approximately 5 feet above the floor, on an inside wall where there is good natural air circulation, and where the thermostat will be exposed to average ro...

Page 36

6. The circulating fan begins 30 seconds after flame is sensed. 7. Furnace continues to run in this state until a call for second stage heat (w1 and w2) after a call for first stage heat will energize the inducer at high speed and the circulator high heat. The second stage pressure switch contacts w...

Page 37

Meter test dial is: where: input is expressed in btu/hr. Heating value of the gas is expressed in btu/ ft 3 time means time required for the test dial to indicate 1 ft 3 /sec. If using a gas meter with si (metric) units: 1 ft 3 = 0.0283 m 3 1 m 3 = 35.315 ft 3 0.01 m 3 = 0.3531 ft 3 0.5 m 3 = 1.766 ...

Page 38

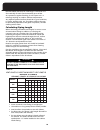

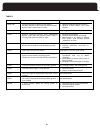

Rating plate input btu/hr rating plate input btu/hr switch description cool jumper ac tonnage rise heating jumper 54,000 72,000 90,000 108,000 54,000 72,000 90,000 108,000 dip switch configurations to obtain the correct airflow for the cooling mode, please refer to the table above. Note the position...

Page 39

T c 8 s 1 o d m 70-4 cool cool 1 b 1150 1on 1000 3 a a 2 off 810 1 off 650 2.5 b 2 on 1 on 2c 2 on 1 on 1.5 d a b b c d a b c c d 1550 4 1350 1150 3.5 1000 810 3 a 2.5 2 s3 2 1 2 1 2 1 2 1 2 1 2 on off off on off off on on on on on s3 85-4 all delay 5 5 off 6 on 5 on 6 on 5 on t no delay no delay 1 ...

Page 40

Do not operate the furnace without an air filter. Holes in the exhaust piping or furnace heat exchanger can allow toxic fumes to enter the home and circulate through the duct system resulting in carbon monoxide poisoning or death. If leaks are found in the furnace heat exchanger, it must be replaced...

Page 41

Disconnect the electrical power supply to the furnace before attempting this maintenance procedure. Failure to do so can cause electrical shock resulting in personal injury or loss of life. All electrical connections should be examined to ensure that they are tight and corrosion free. Repair any con...

Page 43

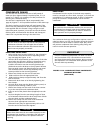

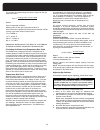

Led flash(es) green off 1 red 2 red 3 red 4 red 5 red 6 red 7 red 8 red 9 red 10 red i internal controller or room air fan failure. Do not operate on heat until fan failure cleared. Roll-out open. Cycle power to reset. Flame sensed with gas valve de-energized. Pressure switch(es) remains open. Combu...

Page 44

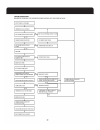

If and check or repair induced blower does not energize 3 flash code does not come on 1. Induced blower wiring. 2. Induced blower. Induced blower does not energize 3 flash code does come on 1. Pressure switch stuck closed. 2. Pressure switch is mis-wired or jumpered. Induced blower is energized 2 fl...

Page 45

67$*,1*0,187($1'0,187(67$*,1* e-803(5$70,187(67$*,1*&21752/:,//$8720$7,&$// d-803(5$70,187(67$*,1*&21752/:,//$8720$7,&$// +,*++($7$)7(50,187(62)&217,18286/2:+($723(5$7,21 +,*++($7$)7(50,187(62)&217,18286/2:+($723(5$7,21 250,187(67$*,1* )256,1*/(67$*(7+(50267$7-803(51(('672%(6(7720,187( )$&725 7+(&21...

Page 46

Furnace components . . . . . . . . . . . . . . . . . .1 regulator vent . . . . . . . . . . . . . . . . . . . . . . .1 general safety rules . . . . . . . . . . . . . . . . . .1 furnace operation information to start the furnace . . . . . . . . . . . . . .2 furnace shutdown procedure . . . . .2 mainte...

Page 47

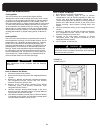

1 furnace components regulator vent most natural gas systems and all lp gas systems have a service regulator located near the point where the gas piping enters the building. The propane tank will normally have an additional first stage regulator located at the tank outlet valve. All of these regulat...

Page 48

2 warning improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or death for assistance or additional information, consult a qualified installer, service agency, or your gas supplier. Warning devices attached to either the vent or combustion...

Page 49

Caution the furnace should be operated with all panels in place. Never operate the furnace with the blower door removed except for service purposes. Warning always disconnect the electrical supply to the furnace before removing the burner compartment access door. 3 maintenance lubrication minimal lu...

Page 50

4 sequence of operation 1. Thermostat, responding to cool room, calls for heat. 2. Combustion air blower begins. 3. After 15 second prepurge, hot surface igniter warms up. 4. After approximately 5 seconds, the gas valve will open, and the burners ignite. 5. Thirty seconds after the burners ignite an...