- DL manuals

- FENDT

- Tractor Accessories

- varioguide

- Operator's Manual

FENDT varioguide Operator's Manual

Summary of varioguide

Page 1

Operator's manual varioguide varioguide novatel varioguide trimble marktoberdorf agco gmbh - johann-georg-fendt-str. 4 - d-87616 marktoberdorf fendt is a worldwide brand of agco © agco 2015 original operator's manual november 2015 438.020.070.012 4832 eame english.

Page 3: Dear Customer

Dear customer please note the following: • before using the tractor, carefully read through this operator’s manual and familiarize yourself with all operating controls and their functions before you begin work. This also applies to the operator's manual for implements. • observe all the operating an...

Page 4

. Varioguide 438.020.070.012.

Page 5: Proper Use of Varioguide

Proper use of varioguide this tractor is designed exclusively for normal agricultural operations or suchlike, e.G. Municipal applications. Any other type of use is considered unauthorized. The manufacturer will not be liable for any damage resulting from such use, which will be entirely at the owner...

Page 6

Up-to-date at the time of going to press the high safety and quality level of the fendt machines is ensured by constant development work on designs, equipment and accessories. We would therefore ask you to bear in mind that changes in form, equipment or technology may be required at any time. The de...

Page 7

Varioguide 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 1.1 delivery of varioguide system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 1.2 operator's manual fendt variog...

Page 8

6 varioguide components and calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 6.1 calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 6.1.1 calibrate steering angle sensor and steering val...

Page 9

7.7.4.1 configure the external mobile modem correction signal . . . . . . . . . . . . . . . 98 7.8 submeter range with trimble receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 7.8.1 autonomous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 10

Table of contents varioguide 438.020.070.012.

Page 11: 1. Introduction

1. Introduction 1.1 delivery of varioguide system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 1.2 operator's manual fendt varioguide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 table of contents varioguide 11 438.020.070.012.

Page 12

Table of contents 12 varioguide 438.020.070.012.

Page 13

1.1 delivery of varioguide system vehicle type chassis no. . . . / . . / . . . . . Service workshop omnistar serial number osn information to be provided at vehicle delivery draw attention to safety instructions in the vehicle operator's manual, on the vehicle itself and in the varioguide operator's...

Page 14: 1.2 Operator'S Manual

1.2 operator's manual fendt varioguide fendt varioguide this operator's manual is only valid in conjunction with the operator's manual for the tractor agco gmbh maschinen und schlepperfabrik 87616 marktoberdorf / bavaria / germany www.Fendt.Com © psd / ap 2015-11 4832 1. Introduction 14 varioguide 4...

Page 15: 2. Safety Instructions

2. Safety instructions 2.1 safety and accident prevention regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 2.1.1 marking of places that affect your safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 2.1.2 advice for the operator . . . . . ...

Page 16

Table of contents 16 varioguide 438.020.070.012.

Page 17

2.1 safety and accident prevention regulations 2.1.1 marking of places that affect your safety make sure that any other users have read all the safety instructions as well. The various levels of safety instructions can be distinguished as follows: danger: this symbol, together with the word danger, ...

Page 18

2.1.3 safe operating environment warning: hazard due to vehicle movements risk of injury and death! Material damage is possible. The automatic way line guidance system may only be used if the tractor is located in an open area away from persons, buildings and other machinery: at a safe distance from...

Page 19

3. Varioguide definitions and specifications 3.1 definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.1.1 gnss and correction signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 20

Table of contents 20 varioguide 438.020.070.012.

Page 21: 3.1 Definitions

3.1 definitions 3.1.1 gnss and correction signal gnss (global navigation satellite system) is a global navigation satellite system designed for position determination and navigation using satellite signals and signals received from pseudolites (terrestrial transmitters which emit signals like those ...

Page 22

• the gnss signal can be obstructed by dense trees, copses, buildings, high-voltage power lines etc. Fig. 3 • varioguide may lose the connection to certain satellites, including the correction signal satellite, if the vehicle is operated on slopes, causing the satellite to be out of the aerial's rec...

Page 23

3.1.3 signal interruption position determination takes a certain amount of time after activation before reaching the specified level of accuracy. Temporary obstruction may cause the system to lose its connection to the satellite signal. This may result in reduced levels of accuracy, the need to rede...

Page 24

• number of receivable satellites restricted by the inclined position of the tractor on the terrain. • the system will not be able to work in regions where the omnistar satellite is too close to the horizon. This also applies for heavily undulating terrain, particularly in the case of (northern) slo...

Page 25: 3.2 Specification

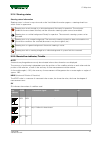

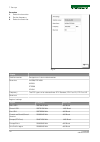

3.2 specification 3.2.1 topcon accuracy specifications varioguide supports the following gnss accuracy options: correction services correction source [1] static accuracy dynamic accuracy autonomous the position is determined without correction signals, using only gps and glonass satellites. Sub-mete...

Page 26

Correction services correction source [1] static accuracy dynamic accuracy rangepoint rtx trimble correction service +/- 50 cm +/- 15 cm centerpoint rtx standard trimble correction service +/- 4 cm +/- 4 cm centerpoint rtx fast trimble correction service +/- 4 cm +/- 4 cm base station rtk correction...

Page 27: 4. Quick Start

4. Quick start 4.1 varioguide menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 4.2 varioguide info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 4.3 vario-guide ma...

Page 28

Table of contents 28 varioguide 438.020.070.012.

Page 29: 4.1 Varioguide Menu Tree

4.1 varioguide menu tree fig. 1 4. Quick start varioguide 29 438.020.070.012.

Page 30

Fig. 2 4. Quick start 30 varioguide 438.020.070.012.

Page 31: 4.2 Varioguide Info

4.2 varioguide info (a) display and input of wayline distance (b) number of gnss satellites used (c) steering behavior for joining wayline (d) current steering status (e) steering behavior on wayline (f) correction signal and accuracy (g) field settings ( h) autoti status press each icon to move dir...

Page 32: 4.3 Vario-Guide Main Menu

4.3 vario-guide main menu softkeys (a) open "field settings" page (b) open "implement selection/settings" page (c) open "steering settings" page (d) open "signal settings" page (e) open "headland settings" page ( f) autoti activation (h) jump back one menu level (i) wayline adjustment (j) manual off...

Page 33

Display (a) current offset display (b) display offset value for manual wayline offset (c) overall offset display fig. 5 4. Quick start varioguide 33 438.020.070.012.

Page 34: 4.4 Implement Selection

4.4 implement selection softkeys (a) create new implement (d) change front-mounted implement settings (f) change rear-mounted implement settings (g) change implement settings on second rear- mounted implement (h) jump back one menu level fig. 6 4. Quick start 34 varioguide 438.020.070.012.

Page 35

Display (a) working width display: actual determined/ measured working width (b) overlap display: required overlap (affects the map display and the wayline distance) (c) calculated wayline distance display (d) symbol: implement determines wayline guidance (e) front-mounted implement selection field ...

Page 36: 4.5 Field Settings

4.5 field settings softkeys (a) add field (c) add boundary (e) create way-line (g) add obstacle (h) jump back one menu level (i) popup wayline information fig. 8 4. Quick start 36 varioguide 438.020.070.012.

Page 37

Display (a) manage fields pull-down menu (b) field boundary available yes/no (c) way-line pull-down menu (d) obstacles pull-down menu fig. 9 4. Quick start varioguide 37 438.020.070.012.

Page 38: 4.6 Steering Behavior

4.6 steering behavior (h) back fig. 10 4. Quick start 38 varioguide 438.020.070.012.

Page 39: 4.7 Signal Settings

4.7 signal settings (a) correction signal (b) system info (c) gyro compass (d) nmea data interface note: press the respective softkey to access the required page. Fig. 11 4. Quick start varioguide 39 438.020.070.012.

Page 40: 4.8 System Info

4.8 system info (a) gnss position: the green tick will appear whenever a valid gnss position has been successfully determined from the gnss data and the correction signal data. The number of gnss satellites is also displayed. (b) correction signal: the green tick will appear whenever a correction si...

Page 41: 5. Map View

5. Map view 5.1 overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 5.1.1 map view menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 5.1.2 map view ....

Page 42

Table of contents 42 varioguide 438.020.070.012.

Page 43: 5.1 Overview

5.1 overview 5.1.1 map view menu tree map view menu tree fig. 1 note: depending on the equipment version, the description and images in the operator's manual may differ from the system installed in the tractor. Note: to navigate to the main page, press the softkey in the map view. 5.1.2 map view the...

Page 44

• boundaries note: values from varioguide • background note: only with variableratecontrol varioguide: • mapping the processed area • position of the machine • target way-line • way-line distance • correction signal info • steering status note: set trigger functions and implement width for area mark...

Page 45: 5.2 Display

5.2 display 5.2.1 full screen fig. 2 (c) marker settings (d) worked area settings (f) road/field mode note: in road mode, the implement is not shown. (g) set markers (h) change display size (i) switch between 2d and 3d (k) zoom 5. Map view varioguide 45 438.020.070.012.

Page 46

5.2.2 zoom configure zoom press soft key (k), zoom will change gradually. Note: in 2d mode, 4 levels of magnification are possible. In 3d mode, 3 levels of magnification are possible. Fig. 3 5.2.3 info bar the info bar shows all information which is permanently visible to the operator for safety rea...

Page 47

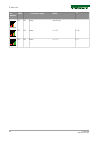

5.2.4 steering status steering status information steering status is shown in map view and on the varioguide information page as a steering wheel icon which varies in appearance. Steering icon struck through on a white background: not ready for operation. The activation conditions have not been sati...

Page 48

Bar indicato r gnss correction signal hdop sv ok ok every over 3 bars ok ok every = >= 6 ok ok every = >= 7 5. Map view 48 varioguide 438.020.070.012.

Page 49: 5.3 Functions

5.3 functions 5.3.1 set markers procedure 1. Press soft key , current position will be saved and the pop-up shown below will appear. Fig. 5 2. Select marker color note: a number id starting at 1 is also assigned for each individual marker color. The name of the marker can be changed in the marker se...

Page 50

5.3.2 marker settings marker selection press the softkey (c) in full-screen mode to open a selection list featuring the markers set for the field. You can change the names of existing markers and delete existing markers in this list. Fig. 7 5.3.3 worked area settings fig. 8 (a) worked areas activate...

Page 51

Procedure 1. Press soft key (d) and a pop-up appears. Fig. 9 color settings for processed area. 2. Press soft key (a) or (b) to activate manual or automatic color selection. (a) man/auto softkey (b) manual color selection softkey (c) delete the area marker in the current field fig. 10 delete the are...

Page 52

4. Press the soft key , the area marker in the current field is deleted and the pop-up closes. Fig. 12 manual color selection 5. Press soft key (b) and a pop-up appears. Fig. 13 6. Select the setting option: ° soft key (a) to change between manual and automatic color display ° (i) is the setting for...

Page 53

6. Varioguide components and calibrations 6.1 calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 6.1.1 calibrate steering angle sensor and steering valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 54

Table of contents 54 varioguide 438.020.070.012.

Page 55: 6.1 Calibrations

6.1 calibrations 6.1.1 calibrate steering angle sensor and steering valve warning: hazard from automatic deflection of the front wheels risk of injury and death! Material damage is possible. During calibration check that there are no people or objects within the steering area! Note: the steering ang...

Page 56

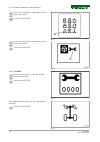

Press one of the buttons repeatedly until the symbol (a) flashes. Confirm with return. Fig. 3 press one of the buttons repeatedly until the symbol (a) flashes. Confirm with return. Fig. 4 input code 2401. Press one of the buttons until the desired number is displayed. Confirm with return. Fig. 5 tur...

Page 57

Turn steering wheel against the right steering lock and hold. Confirm with return. Fig. 7 release hand brake and drive the tractor forwards slowly, keeping the wheels straight. Note: this calibration is an important requirement for ensuring correct way-line guidance. Confirm with return. Fig. 8 if c...

Page 58

Fault code cause f01 preliminary conditions not satisfied f08 calibration taking too long (more than 30 seconds) f09 user terminated calibration with esc f10 plausibility: "center position" signal f11 plausibility: "left stop" signal f12 plausibility: "right stop" signal f13 plausibility: calibrated...

Page 59

Press return; the first main menu level appears on the multiple display. Press one of the buttons repeatedly until symbol (a) flashes. Press return; the second main menu level appears on the multiple display. Fig. 12 press one of the buttons repeatedly until the symbol (a) flashes. Confirm with retu...

Page 60

The image shown opposite is displayed. Note: • the calibration runs automatically (approx. 5 minutes max.) • do not actuate steering. • do not leave operator's seat (seat contact switch). Fig. 16 the image shown opposite is displayed. Fig. 17 if calibration is completed without errors, o.K. Appears ...

Page 61

Fault code cause f01 preliminary conditions not satisfied f02 front wheels are not straight f03 manual steering wheel actuation during calibration f06 no movement in direction "steering to left" f07 no movement in direction "steering to right" f08 calibration taking too long f09 user terminated cali...

Page 62

6. Varioguide components and calibrations 62 varioguide 438.020.070.012.

Page 63: 7. Start-Up

7. Start-up 7.1 load implement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 7.1.1 caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 7.1.2 load im...

Page 64

7.8 submeter range with trimble receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 7.8.1 autonomous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 7.8.2 egnos / waas . . . . . . . . . . . . . . . . ....

Page 65: 7.1 Load Implement

7.1 load implement 7.1.1 caution warning: the tractor should only be operated with the automatic steering system when it is used in an area well away from buildings, other machinery and people. Note: a quick turn of the steering wheel de-activates automatic steering. 7.1.2 load implement settings (7...

Page 66

7.1.3 load implement settings (10.4" terminal) note: this function can be used to load settings for an implement that has already been created, and to add the settings in the varioguide (implement settings and way-line distance). A new implement can also be created. Call up the management main menu ...

Page 67: 7.2 Create Implement

7.2 create implement 7.2.1 call up implement settings on 7" procedure fig. 7 1. Press the positioning button on the external control panel. 2. Under "management info", press the soft key for the on-board computer; "on-board computer" page is displayed. 3. On the "on-board computer" page, press the s...

Page 68

7.2.2 call up implement settings on 10.4" procedure fig. 8 1. On the "tractor info" page, press the softkey for variodoc, and "variodoc info" is displayed in "variodoc info", press the variodoc softkey, and the "variodoc main page" appears. 2. In "variodoc main page", press the soft key for the on-b...

Page 69

7.2.3 front-mounted implement 7.2.3.1 install front-mounted implement procedure 1. Press softkey (a). A pop-up appears. Fig. 9 2. Select front-mounted implement. Geräteanbauposition auswählen heck fig. 10 7. Start-up varioguide 69 438.020.070.012.

Page 70

3. Assign a name and press to confirm. Fig. 11 7.2.3.2 determine the working width, navigation point distance and coupling length working width center navigation point coupling length actual working width of the implement movement of the implement from the center (e.G. For mowers) distance of the ho...

Page 71

7.2.3.3 set the working width of the front-mounted implement procedure 1. Select the working width field (a) by touch or via the external control panel. 2. Set the processed width value via the external control panel. Fig. 12 7. Start-up varioguide 71 438.020.070.012.

Page 72

7.2.3.4 set the navigation point of the front-mounted implement procedure 1. Select the navigation point field (a) by touch or via the external control panel. 2. Set the navigation point distance via the external control panel. Fig. 13 7. Start-up 72 varioguide 438.020.070.012.

Page 73

7.2.3.5 set the coupling length for the front-mounted implement procedure 1. Select the coupling length field (a) by touch or with the external control panel. 2. Set the coupling length distance via the external control panel. Fig. 14 7. Start-up varioguide 73 438.020.070.012.

Page 74

7.2.3.6 set the center of the front-mounted implement procedure 1. Select the center field (a) by touch or via the external control panel. 2. Set the center via the external control panel. Note: only set the center if the mounted implement deviates from the center. Fig. 15 7. Start-up 74 varioguide ...

Page 75

7.2.3.7 set the trigger for the front-mounted implement procedure select and activate the trigger by touch or via the external control panel. Note: measurement takes place once all activated trigger conditions are fulfilled simultaneously. (a) toggle switch auto/i (on) note: if toggle switch (a) is ...

Page 76

7.2.4 rear-mounted implement 7.2.4.1 install rear-mounted implement procedure 1. Press softkey (a). A pop-up appears. Fig. 17 2. Select the rear-mounted implement. Geräteanbauposition auswählen heck fig. 18 7. Start-up 76 varioguide 438.020.070.012.

Page 77

3. Select the trailer type. Gezogenes gerät heckkraftheber heckgeräteanbauposition auswählen fig. 19 4. Assign a name and press to confirm. Fig. 20 7.2.4.2 determine the working width, navigation point distance and coupling length working width center navigation point coupling length actual working ...

Page 78

Procedure 1. Start work and drive approx. 10 m. 2. Measure the processed width (working width). 3. Measure the length between the navigation point of the implement and the attachment hook note: the navigation point is the point on the implement that follows the wayline. 4. Measure the length between...

Page 79

7.2.4.4 set the coupling length for the rear-mounted implement procedure 1. Select the coupling length field (a) by touch or with the external control panel. 2. Set the coupling length distance via the external control panel. Fig. 22 7. Start-up varioguide 79 438.020.070.012.

Page 80

7.2.4.5 set the center of the rear-mounted implement procedure 1. Select the center field (a) by touch or via the external control panel. 2. Set the center via the external control panel. Note: only set the center if the mounted implement deviates from the center. Fig. 23 7. Start-up 80 varioguide 4...

Page 81

7.2.4.6 set the trigger for the rear-mounted implement procedure select and activate the trigger by touch or via the external control panel. Note: measurement takes place once all activated trigger conditions are fulfilled simultaneously. (a) toggle switch auto/i (on) note: if toggle switch (a) is s...

Page 82

7.3 save mounted implement data 7.3.1 save implement on stopping note: this function can be used to save the current settings for an implement (incl. The implement settings and the track distance from varioguide). Save the current implement settings with the same name if an implement has been loaded...

Page 83

• the pop-up shown opposite appears. • to save the current implement settings under an existing name, select name and confirm. Fig. 27 • to save the current implement settings with a new name, select a blank line, specify a name using the keyboard and confirm. • the terminal then switches off. Note:...

Page 84

7.4 exchange implement data and field data 7.4.1 plug in the usb stick and call up data exchange implement data and field data can be transferred from tractor to tractor using a usb stick (when using varioguide). The usb stick can also be used to back up the implement data and field data, e.G. Befor...

Page 85

7.4.2 transfer implement data and field data to the usb stick select and transfer individual data procedure 1. Using the soft key, select the data to be transferred: (a) field data (b) implement data 2. Select field data or implement data by touch or with the external control panel. H b a fig. 31 7....

Page 86

3. Press the soft key (i); individual data is transferred to the usb stick. Note: if there is identical data on the usb stick, a popup appears and asks whether the existing file should be replaced or renamed. Note: before the transfer of field data, a popup appears and asks whether processed areas s...

Page 87

2. Press the soft key (k); all data is transferred to the usb stick. Note: if there is identical data on the usb stick, a popup appears and asks whether the existing file should be replaced or renamed. Note: before the transfer of field data, a popup appears and asks whether processed areas should b...

Page 88

Procedure 1. Using the soft key, select the data to be transferred: (a) field data (b) implement data 2. Select field data or implement data by touch or with the external control panel. H b a fig. 35 3. Press the soft key (j), individual data is transferred from the usb stick to the terminal. Note: ...

Page 89

7.4.3.1 select and transfer all data procedure 1. Using the soft key, select the data to be transferred: (a) field data (b) implement data h b a fig. 37 2. Press the soft key (l); all data is transferred from the usb stick to the terminal. Note: if there is identical data on the terminal, a popup ap...

Page 90: 7.5 Correction Signals

7.5 correction signals 7.5.1 overview of correction signals depending on the receiver receiver type accuracy supported correction signal topcon agi-4 sub-meter autonomous egnos / waas omnistar vbs decimetre omnistar hp /g2 / xp centimeter rtk base satel 3as radio modem topcon fh915 radio modem exter...

Page 91

7.6 submeter range with novatel receiver 7.6.1 autonomous note: the position is determined without correction signals, using only gps and glonass satellites (for regions in which there is no correction signal or none can be received). Fig. 39 7. Start-up varioguide 91 438.020.070.012.

Page 92

7.6.2 egnos / waas set correction signal select the correction signal via the "signal type" selection field. Fig. 40 display satellite receiver designation of the installed receiver signal type the correction signal source can be selected here accuracy bar indicator and decimal value of static accur...

Page 93

7.7 centimeter range with novatel receiver 7.7.1 fendt base station 7.7.1.1 configure the fendt base station correction signal procedure 1. Select the correction signal via the "signal type" selection field. Note: correction signal activation can only be received if a green tick appears in the conne...

Page 94

Display frequency set the frequency assigned to you by your country's regulatory authority. Channel spacing set the channel spacing here: 25 khz with 6.25 khz spacing/205 khz with 10 khz spacing/12.5 khz with 6.25 khz spacing error correction set the error correction here: on/off signal format selec...

Page 95

7.7.2 external station 7.7.2.1 configure the external station correction signal procedure 1. Select the correction signal via the "signal type" selection field. Note: correction signal activation can only be received if a green tick appears in the connection status. Where applicable, verify channel,...

Page 96

Display baud rate setting data for external radio modem parity setting data for external radio modem signal format setting data for external radio modem 7.7.2.2 external fallback station procedure press toggle switch (a), the fallback option will either be activated or deactivated. Note: enabling th...

Page 97

Set correction signal 1. Select the correction signal via the "signal type" selection field. 2. Select 'internal modem' as the modem type 3. Select "dial connection (gsm)" or "data connection" as the connection type 4. Select signal format fig. 45 display satellite receiver designation of the instal...

Page 98

7.7.3.2 activate/deactivate internal mobile modem fallback procedure press toggle switch (a), the fallback option will either be activated or deactivated note: enabling this function allows wayline guidance to a lower degree of accuracy. Fig. 46 7.7.4 rtk network (external mobile radio modem) 7.7.4....

Page 99

Procedure 1. Select the rtk network correction signal under 'signal type'. 2. Select the modem type "external modem" 3. Enter the baud rate 4. Select parity 5. Select signal format fig. 47 display satellite receiver designation of the installed receiver signal type the correction signal source can b...

Page 100

7.8 submeter range with trimble receiver 7.8.1 autonomous autonomous trimble ag-382 note: the position is determined without correction signals, using only gps and glonass satellites (for regions in which there is no correction signal or none can be received). Fig. 48 7. Start-up 100 varioguide 438....

Page 101

7.8.2 egnos / waas set correction signal select the correction signal via the "signal type" selection field. Fig. 49 display satellite receiver designation of the installed receiver signal type the correction signal source can be selected here accuracy bar indicator and decimal value of static accur...

Page 102

7.8.3 rangepoint rtx set correction signal 1. Select the correction signal via the "signal type" selection field. 2. Set the frequency. 3. Select the service id. 4. Select the baud rate. Fig. 50 display satellite receiver designation of the installed receiver frequency baud rate accuracy bar indicat...

Page 103

7.9 decimeter range with trimble receiver 7.9.1 centerpoint rtx satellite 7.9.1.1 set correction signal for centerpoint rtx satellite set correction signal 1. Select the correction signal via the "signal type" selection field. Note: omnistar correction signal activation can only be received if a gre...

Page 104

Display authorisation level specifies the accuracy level of the gnss receiver (depending on the hardware modules installed in the receiver) serial no. Serial number (6-digit) expiry date expiration date for centerpoint rtx satellite license regional rtx settings region frequency baud rate west usa r...

Page 105

7.10 centimeter range with trimble receiver 7.10.1 fendt base station 7.10.1.1 configure the fendt base station correction signal — trimble ag-715 450 mhz radio modem procedure 1. Select the correction signal via the "signal type" selection field. Note: correction signal activation can only be recei...

Page 106

Display mode set here: tt450s 4800 bps or tt450s 9600bps frequency set the frequency assigned to you by your country's regulatory authority. Signal format the signal format is displayed 7.10.1.2 configure the fendt base station correction signal (trimble 900 mhz) procedure 1. Select the correction s...

Page 107

Display distance to base distance in m network id signal format the signal format is displayed 7.10.2 rtk network (internal gsm/gprs modem) 7.10.2.1 configure the internal mobile modem correction signal (gsm/gprs) note: after the ignition has been switched off/on, the system connects to the gsm/gprs...

Page 108

Display signal lag specifies the time in s taken to receive the correction signal update. If 999 is shown here, the correction signal cannot be currently received. Connection status specifies the connection status of the gnss receiver to the source of the correction data (e.G. Connected, update requ...

Page 109

Display satellite receiver designation of the installed receiver signal type the correction signal source can be selected here modem type external modem signal strength mobile communications signal strength accuracy bar indicator and decimal value of static accuracy signal lag specifies the time in ...

Page 110

Procedure 1. Select the base data. 2. Set the frequency. 3. Select the baud rate. Fig. 57 display satellite receiver designation of the installed receiver base data wgs84/itrf2008 nad83 etrs89 gda94 frequency the rtx type can be selected here: rtx standard, rtx fast eu, rtx fast us baud rate regiona...

Page 111: 7.11 Field Settings

7.11 field settings 7.11.1 add field procedure 1. Press the soft key (a), the pop-up for inputting the field name appears fig. 58 2. Input the field name and confirm with , the pop-up will then close fig. 59 7. Start-up varioguide 111 438.020.070.012.

Page 112

7.11.2 record field boundary add boundary 1. Press soft key (c) note: if a field boundary is detected within the selected field, the pop-up below will appear: fig. 60 2. Overwrite field boundary or abandon operation: ° press soft key , current field boundary will be overwritten ° press soft key , po...

Page 113

3. Select recording page 4. Confirm using , pop-up will close fig. 62 start boundary recording 5. Press soft key (c), boundary recording will be activated fig. 63 7. Start-up varioguide 113 438.020.070.012.

Page 114

Stop boundary recording 6. Press soft key (c), boundary recording will be paused note: in order to be able to position the tractor differently in the corners for a more accurate approximation of the boundaries, recording may be paused and later restarted. 7. Press soft key (c) once more, boundary re...

Page 115

9. Select field name and confirm with . Fig. 66 7.11.3 record/manage obstacles small obstacle the obstacle is created once "small obstacle" has been selected in the pop-up above. In addition, a field can be selected and the obstacle name assigned. Fig. 67 large obstacle select the recording page the...

Page 116

Start area recording to start area recording, press softkey (g). The image shown opposite appears with modified softkey (g); drive around the large obstacle. Note: large obstacles are recorded in the same way as boundaries. Fig. 69 end and save the area recording to end the area recording, press sof...

Page 117

A field can be selected and the obstacle name assigned. Manage obstacles the pop-up shown opposite appears once softkey (k) has been pressed. Fig. 71 7. Start-up varioguide 117 438.020.070.012.

Page 118

From this pop-up, obstacles can be selected, renamed and deleted. 7. Start-up 118 varioguide 438.020.070.012.

Page 119: 7.12 Way-Line

7.12 way-line 7.12.1 create and save way line way line type selection can be accessed from the varioguide information page, the varioguide main page and the field settings page, see chapter 4.1 varioguide menu tree, page 29. Note: before creating a wayline, specify a field name and record a boundary...

Page 120

A/b line after you have selected way line a/b, straight way lines will be created between two points a and b. Button a will appear in the terminal. If you press this, a value will appear indicating the minimum distance that must be driven before button b appears and can be pressed. The wayline can b...

Page 121

A+ angle after you have entered and confirmed the angle, the page shown opposite appears. Press the softkey (e) to specify the position of the starting point. (e) softkey to specify starting point a fig. 78 contour after you have selected contour, the start button will appear in the terminal, follow...

Page 122

Fig. 80 fig. 81 7. Start-up 122 varioguide 438.020.070.012.

Page 123

Pivot the circuit way line is created in the same manner as the contour. The circular arc driven is used to calculate the theoretical accuracy of the center of the circle. If this is less than 10.00 m, the stop button will appear. (e) start softkey fig. 83 fig. 84 7. Start-up varioguide 123 438.020....

Page 124

7.12.2 path to path distance the way line distance can be set on the implement settings page. Set the way line distance procedure 1. Set working width of the implement in (a). 2. Set overlap (b). Note: way line distance (c) is calculated: way line distance = implement width minus overlap fig. 86 (a)...

Page 125: 7.13 Check System

7.13 check system 7.13.1 check system info/system status note: to activate automatic way line guidance, a way line must be created and a green tick displayed in every system info box. (a) gnss position: the green tick will appear whenever a valid gnss position has been successfully determined from t...

Page 126

Note: if the ignition is switched off while working (e.G. To perform maintenance and adjustments on the implement) and no stand-by time has been set (thus resulting in the receiver being switched off), a short distance must be driven at a speed exceeding 1.5 km/h (until the green tick appears at c) ...

Page 127

7.14 activate varioguide system 7.14.1 switch on automatic way line guidance (k) button with on/off led, steering pre- activation (ehl) • press button: the led will light up if the self-test was successful. (j) button with on/off led, automatic wayline guidance • press button briefly: if all activat...

Page 128: 7.15 Adjust Way Line

7.15 adjust way line 7.15.1 way line offset display (a) way line distance input field (b) auto offset (c) way-line deviation display (d) manual way line offset input field (e) overall offset display (f) overall offset reset button auto offset (b): if the overlap/under lap becomes too great while wor...

Page 129: 7.16 Headland Settings

7.16 headland settings 7.16.1 headland settings note: due to satellite drift, a field boundary recording and therefore the headland settings are only appropriate from decimetre (dm) accuracy or with rtk (cm) accuracy. Softkeys (e) headland settings (f) autoti pre-activation (only possible within a f...

Page 130

Headland settings softkeys (a) headland alarm on/off note: when you use autoti, the alarm automatically switches on. Fig. 91 select variotronic ti sequence fig. 92 7. Start-up 130 varioguide 438.020.070.012.

Page 131

Functions and displays (c) headland length in meters (d) calculated number of headland way-lines, dependent on the way-line distance (no setting!) (e) setting (in meters) for "driving into the field": distance to the headland boundary, where the autoti/headland alarm is triggered (f) setting (in met...

Page 132

Softkeys (e) headland settings (f) autoti pre-activation (only possible within a field boundary) note: the autoti headland management starts a ti sequence dependent on the distance between the tractor and the headland boundary. Fig. 94 preliminary conditions 1. A field boundary is recorded, see chap...

Page 133

7.17 operation with the base station 7.17.1 brief description the varioguide system can be used with a reference station for centimeter accuracy. The operation of the system is identical, irrespective of whether the correction is received from a reference station or from a satellite. This section gi...

Page 134

Mains cable fig. 97 power supply unit fig. 98 sae connecting cable - current supply to base station fig. 99 sae connecting cable - alligator clips fig. 100 7. Start-up 134 varioguide 438.020.070.012.

Page 135

Sae connecting cable - cigarette lighter fig. 101 sae extension cord fig. 102 serial connecting cable fig. 103 null modem db9 m-m adapter fig. 104 7. Start-up varioguide 135 438.020.070.012.

Page 136

Tripod fig. 105 carrying case fig. 106 7.17.3 led and keys on the base station base station with radio module (a) on/off button (b) function button (c) rs 232 communication interface a (d) rs 232 communication interface d (e) usb communication interface (f) current supply connector input: operation:...

Page 137

(l) aerial port for radio modem (m) port for external gnss aerial fig. 108 led functions battery status led (h): • green: > 85% • orange: medium • red: the led also indicates the following: • flashing once a second: external current supply is connected, internal battery is being charged. • flashing ...

Page 138

Note: to minimize battery discharge, store the base station in "off" mode. 7.17.5 operating modes • "off" mode: the base station is switched off completely. No leds are lit up, and the internal battery cannot be charged in this mode! • "stand-by" mode: the base station is switched on and the receive...

Page 139

Fig. 109 ° switch on from stand-by mode press on/off key (a) for about a second ° switch on from off mode press reset button (i). 7.17.7 set the base station channel on the tractor procedure 1. Press soft key (b) 2. Follow on-screen instructions fig. 110 3. Connect cable on the base station (communi...

Page 140

4. Connect cable to tractor at x4219 top-right c-pillar serial interface (use null modem db9 m-m adapter) fig. 112 5. Confirm connection fig. 113 6. Transmission of base station configuration to the tractor 7. Close window using fig. 114 7. Start-up 140 varioguide 438.020.070.012.

Page 141

7.17.8 operate base station with external battery procedure connect cables (2,3,4) to the battery fig. 115 (1) base station (2) current supply cable for base station (3) sae connecting cable - current supply to base station (4) sae connecting cable - alligator clips (5) battery 7. Start-up varioguid...

Page 142

7. Start-up 142 varioguide 438.020.070.012.

Page 143: 8. Faults and Remedy

8. Faults and remedy 8.1 fault diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145 8.1.1 problems and possible remedial action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145 table of contents var...

Page 144

Table of contents 144 varioguide 438.020.070.012.

Page 145: 8.1 Fault Diagnostics

8.1 fault diagnostics 8.1.1 problems and possible remedial action fault possible cause: indication remedy the following appears: automatic way-line guidance is not possible or has been terminated. The steering wheel has been turned by the operator. Electrohydraulic steering (ehl) has not been pre- a...

Page 146

Fault possible cause: indication remedy the front axle suspension/bearing has play. Contact your fendt dealer. The middle position of the steering angle sensor has not been calibrated precisely. Calibrate steering angle sensor (2401), see chapter 6.1.1 calibrate steering angle sensor and steering va...

Page 147

Fault possible cause: indication remedy overlapping or underlapping. Implement offset is set incorrectly in the terminal. Overlapping between the first two runs. Underlapping between the next two runs. Adjust implement offset in the terminal. Gnss signal strength insufficient to operate automatic wa...

Page 148

Fault possible cause: indication remedy more are displayed on the flat. No omnistar correction signal is present in the operating region of the tractor. A red cross appears in field (b) of system info, see chapter 7.13.1 check system info/system status, page 125. Inform omnistar of the tractor's ope...

Page 149: 9. Appendix

9. Appendix 9.1 glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151 9.1.1 glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151 table of...

Page 150

Table of contents 150 varioguide 438.020.070.012.

Page 151: 9.1 Glossary

9.1 glossary 9.1.1 glossary designation description activated status the status in which automatic steering is switched on and controls the steering movements of the tractor. The status display is green when automatic steering is in activated status. Pass-to-pass accuracy the relative accuracy from ...

Page 152

Designation description ehl electrohydraulic steering. Field defined working area of the tractor. Field boundary the edge of the field. Firmware a computer program that is permanently embedded in the hardware of a device. Area marker mapping the processed area. Accuracy the level of concordance betw...

Page 153

Designation description l1 frequency/signal the first l band frequency is used by gps satellites that are centered at 1575.42 mhz. L2 frequency/signal the second l band frequency is used by gps satellites that are centered at 1227.6 mhz. Lag latency time the age of the correction used for the gps so...

Page 154

Designation description real time kinematics (rtk) a relative positioning procedure where carrier phase measurements (or corrections) are sent in real time from a reference or base station to a known location or to one or more vehicles equipped with a gnss receiver. Reference station a gnss receiver...

Page 155

Designation description roll when one side of the tractor lifts or lowers relative to the other side due to changes in the terrain. Waypoint one of the two reference points in the field used to define a virtual straight line: the wayline. Xtrack the right-angled distance between the current tractor ...

Page 156

9. Appendix 156 varioguide 438.020.070.012.

Page 158

© agco corporation, 2015. All rights reserved. 438.020.070.012 (english) november 2015.