- DL manuals

- Fer

- Boiler

- FALCON II

- Installation, servicing & user instructions

Fer FALCON II Installation, servicing & user instructions

Appr. nr. B99.06 A - CE 0461 AU 0447

3543544/0 - 01/01

INSTALLATION,

SERVICING AND

USER INSTRUCTIONS

G.C. NO: 47-267-24

C

OPPER

W

ALL

-M

OUNTED

C

OMBINATION

,

G

AS

F

IRED

B

OILER

FOR

C

ENTRAL

H

EATING

AND

D

OMESTIC

H

OT

W

ATER

P

RODUCTION

,

F

AN

A

SSISTED

, R

OOM

S

EALED

C

OMPARTMENT

,

E

LECTRONIC

F

LAME

I

GNITION

AND

C

ONTROL

FALCON II

Summary of FALCON II

Page 1

Appr. Nr. B99.06 a - ce 0461 au 0447 3543544/0 - 01/01 installation, servicing and user instructions g.C. No: 47-267-24 c opper w all -m ounted c ombination , g as f ired b oiler for c entral h eating and d omestic h ot w ater p roduction , f an a ssisted , r oom s ealed c ompartment , e lectronic f...

Page 2: Falcon Ii

Falcon ii 2 ce mark ce mark documents that the fer gas appliances comply with the requirement contained in european directives applicable to them. In particular, the appliances comply with the following cee directives and the technical specifications provided from them: • gas appliances directive 90...

Page 3: Falcon Ii

Falcon ii 3 1. Description 1.01 introduction the falcon ii is defined as a “room sealed” combination boiler, all air required for combustion is taken from outside the room in which it is installed. It is a new high performance gas fired heat generator for central heating and domestic hot water produ...

Page 4: Falcon Ii

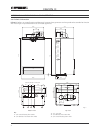

Falcon ii 4 fig. 1 2. Technical and dimensional characteristics 2.01 technical information falcon ii boilers are central heating and domestic hot water heat generators and are produced as standard to function with natural gas or liquid petrolium gas converted appliances. Key 1 - 3/4" central heating...

Page 5: Falcon Ii

Falcon ii 5 n.B. - the gas pressures at the burner and gas flows during the central heating phase given in the table refer to nominal boiler output . To reduce this output (where necessary), gas pressure must be reduced until the required output level is reached (see figures 4 and 5). During domesti...

Page 6: Falcon Ii

Falcon ii 6 2.03 boiler water flow diagram 2.02 boiler main components key 5 room sealed compartment 7 gas inlet 8 domestic hot water outlet 9 domestic hot water inlet 10 central heating flow outlet 11 central heating return inlet 14 safety valve 16 fan 19 combustion chamber 20 burner assembly 21 ma...

Page 7: Falcon Ii

Falcon ii 7 2.05 pump characteristics the pump head available for circulating the water is given in fig. 6. N.B. - the pump is factory set at position 3. The pump is a grundfos type 15-50 ups series. Grundfos pump performance graph note - minimum flow through boiler heat exchanger at any time should...

Page 8: Falcon Ii

Falcon ii 8 sizing of additional expansion vessels: deduct from the value given in the table the 10 litre vessel supplied. Note: 1. Fill c.H. Installation to min. 1.5 bar. 2. Expansion vessel must be fitted to central heating return pipe. 3. The standard 10 litre expansion vessel is charged to 1 bar...

Page 9: Falcon Ii

Falcon ii 9 3.0 installation details gas safety (installation & use) regulations: 1996 in the interest of safety, it is the law that all gas appliances are installed by a competent person in accordance with the above regulations, building regulations/building standards scotland, codes of practice, c...

Page 10: Falcon Ii

Falcon ii 10 central heating detailed recommendations are given in bs6798, bs5449, bs6700 and cp342 part 2. Pipework not forming part of the useful heating suface should be insulated to prevent any heat losses or possible freezing (i.E. In roof spaces or ventilated underfloor spaces). Drain taps sho...

Page 11: Falcon Ii

Falcon ii 11 terminal position position minimum spacing mm a directly below an openable window, air vent, or any other ventilation opening 300 b below gutters, soil pipes or drainpipes 75 c below eaves 100 d below a balcony 100 e from vertical drainpipes or soilpipes 75 f from internal or external c...

Page 12: Falcon Ii

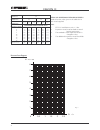

Falcon ii 12 3.01 drilling template (top flue application) select suitable mounting position for boiler, using the template mark flue outlet and boiler mounting points. Drill two 10mm holes 90mm deep to accept the wall plugs, fit wall plugs. Fit two special wall plugs on the wall as described in the...

Page 13: Falcon Ii

Falcon ii 13 3.02 restrictor for boiler operation, the restrictor supplied with the unit must be mounted following the instructions below. Determine the correct size of flue restrictor required. Before inserting the flue gas duct in the boiler, check that the restrictor fitted is correct and that it...

Page 14: Falcon Ii

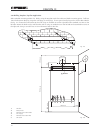

Falcon ii 14 a 90° bend (fig. 15) is supplied for the horizontal connection of air and flue gas pipes. This can be angled towards the chosen wall in degrees of 45°. 3.03 top outlet concentric flue connection 3.03.1 vertical concentric connection 1kwma31y d s l 125 70 50* 30 95 80 80 -3 mm/m Ø60 Ø80 ...

Page 15: Falcon Ii

Falcon ii 15 fig. 16 notes on concentric horizontal installation to locate the centre of the hole for passing the pipes through the wall, refer to fig. 12. Bear in mind that the two concentric pipes must slope downwards away from the boiler at a rate of about 3 mm/m to avoid rainwater entering the b...

Page 16: Falcon Ii

Falcon ii 16 fig. 18 Ø80 Ø80 air flue 1 2 3.04 top outlet: two pipe flue system 3.04.1 two pipe connection two separate ducts Ø80 for air intake and flue gas discharge can be directly connected to the boiler. Mount the separate outlet kit "1". Insert blanking plate 2 in remaining air intake connect ...

Page 17: Falcon Ii

Falcon ii 17 air flue ve rtical h or iz on ta l ve rtical h or iz on ta l description male-female flue/air pipe 1 m - Ø 80 female-female bend 45° Ø 80 m male-female bend 90° Ø 80 m dscription horizontal flue terminal Ø 80 mm air intake terminal Ø 80 mm outlet flue/air inlet for concentric system Ø 1...

Page 18: Falcon Ii

Falcon ii 18 for further accessories please refer to: "flue system manual for room sealed boiler" example of calculation for wall inlet/outlet with 2 pipe system maximum total flue length: 50 metres attention: remove the flue diaphragm. The flue + air pipes must have a 3% drop away from the boiler t...

Page 19: Falcon Ii

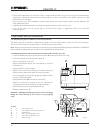

Falcon ii 19 3.05 connecting the central heating and domestic hot water circuits connect to the relevant connections as indicated in fig. 1. Connect the pressure relief valve discharge pipe (15mm) to the outside of the building, where possible over a drain. The discharge must be such that it will no...

Page 20: Falcon Ii

Falcon ii 20 all wiring must conform to current i.E.E. Regulations. Note : if the power supply cable has to be replaced, use “0.75mm (24/0.20) heat resisting cable only to bs6500 with a maximum external diameter of 8 mm. Note - when connecting a room thermostat or external timer, do not link the pow...

Page 21: Falcon Ii

Falcon ii 21 4. Commissioning and testing 4.01 checks to be carried out before starting up for the first time when starting the boiler up for the first time check: • that the gate valves between the boiler and central heating system are open; • that the central heating system is filled and vented; •...

Page 22: Falcon Ii

Falcon ii 22 5. Adjustment and gas conversion 5.01 adjusting the pressure and flow rate to the main burner this boiler operates on the flame modulation principle. It has two fixed pressure values, minimum and maximum, which must be as shown in the table (pages 5), whichever type of gas is used. Note...

Page 23: Falcon Ii

Falcon ii 23 5.04 adjusting maximum output for central heating system (fig. 22) this adjustment must be carried out electronically using the “p3” adjustment screw starting with a cold central heating system. Connect a pressure gauge to the pressure test point downstream of the gas valve. Rotate the ...

Page 24: Falcon Ii

Falcon ii 24 6. Maintenance and cleaning the following operations must be carried out by corgi registered engineers only. 6.01 annual servicing the following should be checked at least once a year: • water pressure in the central heating system when cold should be about 1 bar. If this is not the cas...

Page 25: Falcon Ii

Falcon ii 25 17. Re-assemble baffle, flue hood and fan assembly, secure with screws previously removed. 18. Refit burner assembly and burner rail. 19. Reconnect ignition and flame rectification leads. 20. Reconnect gas union and tighten. 21. Refit combustion chamber cover, secure with screws. 22. Ex...

Page 26: Falcon Ii

Falcon ii 26 7.0 replacement of parts 7.01 initial procedure a) the boiler is cold, electricity supply is isolated, and the gas supply is turned off at the inlet of the boiler b) for replacement of parts where water connections are broken, it will be necessary to isolate and drain either or both the...

Page 27: Falcon Ii

Falcon ii 27 7.06 air pressure switch (fig. 27) • isolate electricity • remove outer case (two screws bottom rear corners) • open room sealed department • remove the two screw "a" fixing air pressure switch • disconnect electrical leads "b" • remove pressure sensing tubes (white=d; red=c) • note rel...

Page 28: Falcon Ii

Falcon ii 28 7.10 removal of burner (fig. 29) • isolate gas and electricity supplies • remove outer case (two screws bottom rear corners) • remove room sealed cover • disconnect ignition and flame rectification leads "a" • undo gas rail union "b" • undo two screws securing the burner assembly to the...

Page 29: Falcon Ii

Falcon ii 29 7.14 spark or flame detection electrode (fig. 31) • isolate gas and electricity supply • remove outer case (two screws bottom rear corners) • open room sealed compartment and combustion chamber • identify electrode from fig. 31 • unplug electrical connection "a" from sensing electrode •...

Page 30: Falcon Ii

Falcon ii 30 7.16 pump (fig. 33) replacement of pump head • isolate electricity and flow and return pipes • remove casing (two screws bottom rear corners). • remove the two securing screws and lower control panel • release pressure from boiler via pressure relief valve • unplug the pump lead "a" fro...

Page 31: Falcon Ii

Falcon ii 31 8.0 fault finding before beginning any fault finding ensure that gas, water and electricity are available. Warning : do not link any terminals on block x10 or x11 as this will damage the pcb beyond repair. 8.01 operating sequence with the power established the boiler is in its stand-by ...

Page 32: Falcon Ii

Falcon ii 32 in order, the five lights indicate: 1 boiler on indicate 2 boiler shut down warning 3 domestic hot water circuit on 4 central heating standby (flashing light) central heating circuit on (permanent light) 5 insufficient pressure in central heating system (flashing light) electric power s...

Page 33: Falcon Ii

Falcon ii 33 8.04 temperature sensors (thermistors) identical, but individual, negative temperature co-efficient (ntc) thermistors are fitted in the c.H. And d.H.W. Outlets from the heat exchanger. As the water temperature increases the resistance in the thermistor decreases. This causes the pcb to ...

Page 34: Falcon Ii

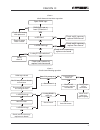

Falcon ii 34 8.10 general test and fault finding chart 1 check electrical supply - c.H. Water pressure and frost protection is led5 on? Put main switch to on ch selector to summer “ ” position d.H.W. Taps closed is 230v present across terminals x1-1 x1-2? Check and if necessary replace 2a fuse yes i...

Page 35: Falcon Ii

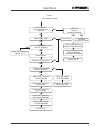

Falcon ii 35 chart 2 check domestic hot water operation wait 2 minutes dhw taps closed put ch temperature selector to maximum ensure external controls are calling for heat is led4 flashing? Does c.H. Pump run? Yes yes go to chart 4 is relay ry101 switch on check and if necessary replace main board n...

Page 36: Falcon Ii

Falcon ii 36 chart 4 check fan/flue gas system does fan run? Is relay ry100 switch on? No go to charts 2-3 no is 230v present across fan terminals? Yes check air pressure switch wiring connection in n.O. No check and if necessary replace air pressure switch no check and if necessary replace fan yes ...

Page 37: Falcon Ii

Falcon ii 37 chart 6 check ignition system is led1 light on? Does sparking start at burner? Does burner light? Yes is led2 on after 10 seconds? No yes go to chart 5 reset lockout yes does burner light now? Is flame present before lockout condition? No yes no check and if necessary replace safety the...

Page 38: Falcon Ii

Falcon ii 38 jp01 on = delay between shutdown and re-ignition disabled jp01 off = delay between shutdown and re-ignition enabled jp02: jumper on for natural gas jumper on for lpg jp03 on = max temperature d.H.W. 62°c jp03 off = max temperature d.H.W. 55°c (standard) potentiometer adjustment p1 = cen...

Page 39: Falcon Ii

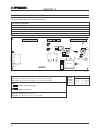

Falcon ii 39 key 16 fan 32 central heating pump 34 central heating flow temperature sensor 42 domestic hot water flow temperature sensor 43 air pressure switch 44 gas valve 49 safety thermostat 50 central heating limit thermostat 62 time clock 72 room thermostat fig. 35 key br brown blue blue bl bla...

Page 40: Falcon Ii

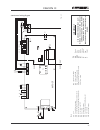

Falcon ii 40 fig. 36 10. User instructions the boiler is designed for use with two types of gas: natural gas ng or propane (lpg). The type of gas can be selected when purchasing the boiler or the appliance can be converted later on site by a competent person. It operates with technologically advance...

Page 41: Falcon Ii

Falcon ii 41 frost protection in cold weather the boiler may appear to run when there is no demand for heating (i.E. Clocks or room thermostats turned off). This is due to the central heating sensor going into frost protection mode. Once the boiler has reached 14°c or more it will close down until e...

Page 42: Falcon Ii

Falcon ii 42 time clock a 24 hour time clock is fitted to the boiler to control the central heating, this will come into operation when the selector switch is turned to the position marked “heating timed and hot water”. Auto + - r over ride x x 4 a b e r d p auto p o i f p to set time of day 1. Slid...

Page 44: 08707 282 885

Phone numbers: installer service engineer because of our constant endeavour for improvement details may vary slightly from those quoted in these instructions. Should you require help with any difficulties call our technical service helpline on 08707 282 885 po box 3774, sutton coldfield, west midlan...