- DL manuals

- Fer

- Boiler

- HAWK II

- Installation Instructions Manual

Fer HAWK II Installation Instructions Manual

INDUSTRIE

INSTALLATION INSTRUCTIONS

WALL MOUNTED, FANNED,

ROOM SEALED, COMBINATION BOILER

SERVICE HELPLINE

FOR SERVICE OR TECHNICAL ASSISTANCE

PHONE: 08707 282 885

PLEASE QUOTE BOILER SERIAL NUMBER

Leave these instructions with the user

Important

:

Please read this book

before installing this appliance

INDUSTRIE

W.R.C. No. 9207076

01/01

Summary of HAWK II

Page 1

Industrie installation instructions wall mounted, fanned, room sealed, combination boiler service helpline for service or technical assistance phone: 08707 282 885 please quote boiler serial number leave these instructions with the user important : please read this book before installing this applia...

Page 2

Industrie 2 contents page index 3 introduction 4 technical data 5 appliance dimensions 6 boiler flow diagram 7 key of boiler flow diagram 8 installation details 9 location of boiler 9 air supply 10 flue system 10 gas supply 10 water system 11 temporarily filling loop 12 central heating pump 12 sizin...

Page 3

3 industrie introduction gas safety (installation and use) regulations 1994 (as amended) this appliance must be installed and serviced by a competent person, in accordance with the above regulations. Failure to install appliances correctly could lead to prosecution. It is in your own interest and th...

Page 4

Industrie 4 technical data g20 g31 nominal heat input d.H.W. & c.H. (gross) 28.6 kw 28.0 kw minimum heat input d.H.W. & c.H. (gross) 12.8 kw 12.5 kw nominal heat input d.H.W. & c.H. (net) 25.8 kw 25.8 kw minimum heat input d.H.W. & c.H. (net) 11.5 kw 11.5 kw nominal heat output d.H.W. & c.H. 23.3 kw...

Page 5

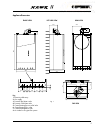

5 industrie appliance dimensions fig. 1 key 1. Electricity cable entry 2. Gas supply 3. Domestic hot water outlet 4. Domestic cold water inlet 5. Central heating pressure relief valve 6. Central heating flow outlet 7. Central heating return inlet 8. Air intake for two pipe flue systems front view le...

Page 6

Industrie 6 boiler flow diagram fig. 2.

Page 7

7 industrie key 1. Fixing point 5. Room sealed compartment 6. Control panel 7. Gas inlet 8. Domestic hot water outlet 9. Cold water inlet 10. Central heating flow outlet 11. Central heating return inlet 14. Central heating safety valve 16. Fan 18. Air distribution screen 19. Combustion - heat exchan...

Page 8

Industrie 8 installation details gas safety (installation & use) regulations: 1994 in the interest of safety, it is the law that all gas appliances are installed by a competent person in accordance with the above regulations, building regulations/building standards scotland, codes of practice, curre...

Page 9

9 industrie terminal position minimum clearance mm notes * access to the front of the boiler must be available for maintenance (min. 600 mm). Fig. 5 fig. 3.

Page 10

Industrie 10 flue system the boiler allows the flue outlet to be taken from the rear of the boiler or from either side. A standard flue length of 0.75 metres is provided. It is absolutely essential, to ensure that products of combustion discharging from the terminal cannot re-enter the building, or ...

Page 11

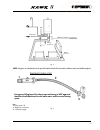

11 industrie fig. 7 note: a bypass must be fitted as far as possible from the boiler if thermostatic radiator valves are fitted throughout. Key 1. Filling point c.H. 2. Temporary connection 3. Cold water supply temporary filling loop a temporary filling loop of the above type conforming to wrc appro...

Page 12

Industrie 12 built-in central heating water circulating pump the pump head available for circulating the water is given in fig. 8. N.B. - the pump is factory set at position 3. The pump is a grundfos type 25-50 ups series. Note - minimum flow through boiler heat exchanger at any time should not fall...

Page 13

13 industrie note - to mount the boiler on the wall, a two person lift will be needed. 1.0 unpacking the appliance is delivered in three cartons. 1.1 the large carton contains the boiler, and the installation/servicing and users instructions. 1.2 the second carton contains the valves, fixing bolts a...

Page 14

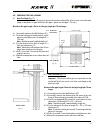

Industrie 14 * boiler fixing studs level with the bottom of the flue hole installation dimensions fig. 10 2 gas 22 mm 3 domestic hot water outlet 15 mm 5 outlet central heating safety valve 15 mm 4 domestic cold water inlet 15 mm 6 central heating flow outlet 22 mm 7 central heating return inlet 22 ...

Page 15

15 industrie 4.0 preparing the flue assembly 4.1 rear flue outlet (fig. 12) important - the aluminium flue pipe must protrude into the outside grill by 60 mm, never cut it to the same length as the plastic air pipe (aluminium flue pipe = plastic air inlet pipe + 70 mm !). Aluminium flue pipe length ...

Page 16

Industrie 16 5.0 connecting the boiler 5.1 place the boiler on its back. 5.2 remove the boiler base plate, four screws (fig. 16). Remove the plugs fitted to the boiler water connections. Remove the bag of sealing washers from the boiler pipework. Remove the front panel by gripping on both sides, sli...

Page 17

17 industrie external controls: room stat or remote time clock in the place of loop terminals 4 and 5. Please note 24 v only, use only voltage free contacts. Important if 230 v is connected to terminals 4 or 5, damage will be caused to the p.C.B. Fixing screw front screw blue brown fig. 19 fig. 18 2...

Page 18

Industrie 18 8.0 commissioning and testing 8.1 filling the central heating system fig. 20 burner pressure test point automatic air vent vent cap heat exchanger vent pump c.H. Pressure relief valve d.H.W. Expansion vessel (optional) gas inlet pressure test point d.H.W. Drain point pressure gauge remo...

Page 19

19 industrie 8.5 to light the boiler (fig. 21) 1. Before lighting check central heating system pressure is at 1 bar. (4). 2. Ensure electric, gas and water mains are on valves on the boiler are open. 3. Set any room thermostat/external controls to "on" position. 4. Set boiler thermostat (3) to maxim...

Page 20

Industrie 20 burner pressure c.H. And d.H.W. 8.6 to range rate the boiler c.H.(not required on standard installations) the boiler can be range rated for an output from 9.7 kw up to 23.3 kw. When the boiler is supplied it is factory set at the maximum output 23,3 kw. Procedure a.␣ release the control...

Page 21

21 industrie honeywell vr 4600 n 4002 valve (code 3680252/0) with v7335a4014 modureg (code 3680254/0) gas pressure adjustment 1 - with the burner lit: 2 - connect suitable pressure gauge to burner test point "b", and then: 3 - disconnect air pressure compensation tube "h"; 4 - disconnect the wires f...

Page 22

Industrie 22 1.1 use buttons + and - to set 1st on time eg. 6:00 display 2.1 use buttons + and - to set off time, eg. 9:00 display 3.1 use button + and - to set 2nd on time, eg. 12:30 display 4.1 use button + and - to set 2nd off time eg. 14:00 display 5.1 use button + and - to set 3rd on time, eg. ...

Page 23

23 industrie over ride by pressing the over ride button (e) the timer programme is over ridden ie, if programme is in off time it will come on and if in on time will go off. The timer will revert back to it set programme on reaching the next on or off time. When the programme is on over ride the sig...

Page 24

Industrie 24 8.7 d.H.W. Burner pressure the domestic hot water burner pressure is not range rateable and not adjustable but the maximum and minimum burner pressure should be checked as follows: a.␣ check electricity supply is still off. B.␣ open a d.H.W. Tap at high flow until the water runs cool an...

Page 25

25 industrie fig. 46 blue black black 1 2 black dl 1e brown blue 3 3 1 1 2 kromschroder huba 605 2 1 3 brown blue 3 brown kromschroder huba 602 1 2 2 3 huba 605 huba 602 2 3 1 brown - common black = n.C. Blue = n.O. 11.0 air pressure switch.

Page 26

Industrie 26 spare parts list item no. G.C. Part no.Makers part no no. Off description 14 386816 800130 1 c.H. Safety valve 16 - 803860 1 complete fan 21 372176 815850 4 main injector (natural gas) 21 - 800920 4 main injector (l.P.G.) 23 390210 801170 1 thermocouple 24 - 801090 1 spark electrode 25 ...

Page 27

27 industrie domestic hot water performance fig. 1 - d.H.W. Pressure drop vs. Flow a␣ =␣ standard with col water flow restricter b␣ =␣ cold water flow restricter removed fig. 1 fig. 2 - d.H.W. Temperature vs. Flow a␣ =␣ cold water 15 ° c b␣ =␣ cold water 5 ° c fig. 2.

Page 28

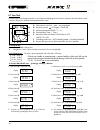

Industrie 28 jp1 - jp4 jumper links on p.C.B. Jp1 is not required jp4 must be fitted p1 = c.H. Max. Output p2 = d.H.W. Temperature (factory set) 12 1 tr1 x4 x6 2 3 4 x2 ry1 x1 2at 230v 50hz 1 11 10 7 2 6 3 5 12 9 10 1 2 p1 x3 6 5 3 4 1 f1 9 8 7 6 5 4 3 2 1 x8 1 2 3 4 5 6 7 8 9 x5 1 2 x7 jp4 13 l7 ry...

Page 29

29 industrie general notes *the pilot light should only be ignited after the fan (16) has run for at least 20 seconds on full speed. *the central heating pump (32) will run to disperse heat if the temperature at the heat exchanger limit thermostat (50) is too high *fuse on p.C.B.: 2 amp. Led n ° sig...

Page 32

Industrie all specifications subject to change po box 3774 sutton coldfield west midlands b76 8bh tel.: 08707 282 885 cod. 3540258/3 - 01/01.