- DL manuals

- Ferris

- Lawn Mower

- Evolution Series

- Operator's Manual

Ferris Evolution Series Operator's Manual

Summary of Evolution Series

Page 1

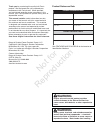

5102168 revision c evolution series compact zero-turn riding mower operator’s manual model number description 5900858 evkav2652 5900930 evkav2252 not for reproduction.

Page 2: Warning

Briggs & stratton power products group, llc. Copyright © 2012 briggs & stratton corporation milwaukee, wi, usa. All rights reserved. Ferris is a trademark of briggs & stratton corporation milwaukee, wi, usa. Contact information: briggs & stratton power products group, llc. 5375 n. Main st. Munnsvill...

Page 3: Table of Contents

1 table of contents operator safety .................................................. 2 safety decals ..........................................................8 safety interlock system ..........................................9 safety icons ...........................................................

Page 4

2 operator safety operating safety congratulations on purchasing a superior-quality piece of lawn and garden equipment. Our products are designed and manufactured to meet or exceed all industry standards for safety. Do not operate this machine unless you have been trained. Reading and understanding ...

Page 5

3 operator safety slope operation operation on slopes can be dangerous. Using the unit on a slope that is too steep where you do not have adequate wheel traction (and control) can cause sliding, loss of steering, control, and possible rollover. You should not operate on a slope greater than a 5.4 fo...

Page 6

4 operator safety enclosed areas only operate this unit outdoors and away from unventilated areas such as inside garages or enclosed trailers. The engine emits poisonous carbon monoxide gas and prolonged exposure in an enclosed area can result in serious injury or death. Fuel and maintenance always ...

Page 7

5 operator safety 3. Be sure all drives are in neutral and parking brake is engaged before starting engine. Only start engine from the operator’s position. Use seat belts if provided. 4. Be sure of your footing while using pedestrian controlled equipment, especially when backing up. Walk, don’t run....

Page 8: Warning

6 operator safety 25. Osha regulations may require the use of hearing protection when exposed to sound levels greater than 85 dba for an 8 hour time period. Slope operation slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death. All sl...

Page 9

7 operator safety service and maintenance to avoid personal injury or property damage, use extreme care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive. Safe handling of gasoline 1. Extinguish all cigarettes, cigars, pipes, and other sources of ignition. 2. Use onl...

Page 10

8 www.Ferrisindustries.Com operator safety safety decals this unit has been designed and manufactured to provide you with the safety and reliability you would expect from an industry leader in outdoor power equipment manufacturing. Although reading this manual and the safety instructions it contains...

Page 11: Warning

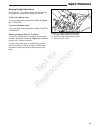

9 safety interlock system this unit is equipped with safety interlock switches. These safety systems are present for your safety, do not attempt to bypass safety switches, and never tamper with safety devices. Check their operation regularly. Operational safety checks test 1 — engine should not cran...

Page 12: Sample

10 www.Ferrisindustries.Com identification tag features and controls sample sample when contacting your authorized dealer for replacement parts, service, or information you must have these numbers. Record your part number, serial number and engine serial numbers in the space provided for easy access...

Page 13

11 control functions the information below briefly describes the function of individual controls. Starting, stopping, driving, and mowing require the combined use of several controls applied in specific sequences. To learn what combination and sequence of controls to use for various tasks see the op...

Page 14

12 www.Ferrisindustries.Com ignition switch the ignition switch starts and stops the engine, it has three positions: off stops the engine and shuts off the electrical system. Run allows the engine to run and powers the electrical system. Start cranks the engine for starting. Note: never leave the ig...

Page 15: Operation

13 operation general operating safety before first time operation: • be sure to read all information in the safety and operation sections before attempting to operate this tractor and mower. • become familiar with all of the controls and how to stop the unit. • drive in an open area without mowing t...

Page 16: Warning

14 www.Ferrisindustries.Com warning if you do not understand how a specific control functions, or have not yet thoroughly read the features & controls section, do so now. Do not attempt to operate the tractor without first becoming familiar with the location and function of all controls. Starting th...

Page 17

15 operation zero turn driving practice the lever controls of the zero turn rider are responsive, and learning to gain a smooth and efficient control of the rider’s forward, reverse, and turning movements will take some practice. Spending some time going through the maneuvers shown and becoming fami...

Page 18

16 www.Ferrisindustries.Com advanced driving executing an end-of-row zero turn your zero turn rider’s unique ability to turn in place allows you to turn around at the end of a cutting row rather than having to stop and y-turn before starting a new row. For example, to execute a left end-of row zero ...

Page 19

17 mowing 1. Engage the parking brake. Make sure the pto switch is disengaged, the ground speed control levers are in the neutral position and the operator is on the seat. 2. Set the mower cutting height. 3. Start the engine (see starting the engine). 4. Set the throttle to full. 5. Engage the pto b...

Page 20

18 www.Ferrisindustries.Com when and how often to mow the time of day and condition of the grass greatly affect the results you’ll get when mowing. For the best results, follow these guidelines: 1. Mow when the grass is between three and five inches high. 2. Mow with sharp blades. Short clippings of...

Page 21

19 proper mulching mulching consists of a mower deck which cuts and recuts clippings into tiny particles and which then blows them down into the lawn. These tiny particles decompose rapidly into by-products your lawn can use. Under proper conditions, your mulching mower will virtually eliminate noti...

Page 22: Warning

20 www.Ferrisindustries.Com warning fuel and its vapors are extremely flammable and explosive. Fire or explosion can cause severe burns or death. Never store the unit, with gasoline in the engine or fuel tank, in a heated shelter or in enclosed, poorly ventilated enclosures. Gasoline fumes may reach...

Page 23: Maintenance

21 maintenance maintenance schedule the following schedule should be followed for normal care of your rider and mower. You will need to keep a record of your operating time. Determining operating time is easily accomplished by observing the elapsed time recorded by the hour meter. * refer to engine ...

Page 24: Warning

22 www.Ferrisindustries.Com regular maintenance checking / adding fuel to add fuel: 1. Remove the fuel cap (see figure 1). 2. Fill the tank to the bottom of the filler neck. This will allow for fuel expansion. Note: do not overfill. Refer to your engine manual for specific fuel recommendations. 3. I...

Page 25

23 regular maintenance change oil & filter 1. Warm engine by running for a few minutes. (refer to the engine operator’s manual for oil & filter replacement instructions.) 2. Route the oil drain hose ( a, figure 13 ) over the side of the engine deck and underneath the fuel tank. 3. Place a small pan ...

Page 26

24 www.Ferrisindustries.Com servicing the hydraulic system removing the tank the right hand tank ( a, figure 14 ) must be removed prior to checking and/or changing the hydraulic oil. 1. Unscrew the three (3) wing bolts ( b ) that secure the tank to the unit. 2. Remove the tank from the unit. Check h...

Page 27

25 lubrication lubricate the unit at the locations shown in figures 16 through 20 as well as the following lubrication points. Grease: • front caster wheel axles & yokes • deck lift pivot blocks • mower deck & pump drive idler arm • operator compartment front pivots use grease fi ttings when present...

Page 28: Caution

26 www.Ferrisindustries.Com regular maintenance servicing the mower blades removing the mower blade 1. To remove the mower blade, wedge a wooden block between the mower blade and the mower deck housing to keep the blade from turning and remove the mower blade mounting bolt with a 15/16” wrench ( fig...

Page 29: Caution

27 figure 26. Tightening the mower blade for installation a. Mower blade mounting bolt b. Flat washer c. Mower blade air lift (points up for installation) d. 4 x 4 wooden block d a b a b figure 24. Sharpening the mower blade a. Mower blade bevel b. Mower blade cutting edge figure 25. Balancing the m...

Page 30: Caution

28 www.Ferrisindustries.Com regular maintenance seat adjustment the height of the seat ( a, figure 27 ) can be adjusted either up or down and the position of the seat can be adjusted forward or back to accomidate the operator’s comfort level. 1. Remove the seat height adjustment hardware ( b ). 2. P...

Page 31: Warning

29 speed balancing adjustment if the unit veers to the right or left when the ground speed control levers are in either the maximum forward or reverse position, the top speed of the ground speed control levers can be adjusted. Only adjust the speed of the wheel that is travelling faster. To reduce t...

Page 32

30 www.Ferrisindustries.Com regular maintenance figure 32. Adjusting the range selector plate a. Range selector hardware b. Range selector pivot hardware c. Range selector plate d. Brake hub 1 4 3 2 a c b d parking brake adjustment the parking brake system consists of two range selector plates and t...

Page 33

31 adjusting the parking brake spring 1. Locate the two (2) brake springs ( a, figure 33 ). 2. With the parking brake engaged, measure the compressed spring length. The spring should be 2-3/8” (6 cm) when compressed. 3. If the spring length does not equal the measurement, the spring length will need...

Page 34: Warning

32 www.Ferrisindustries.Com suspension adjustment the front shock assemblies ( a, figure 34 ) and the operator compartment shock assembly ( b ) can be adjusted to vary the amount of pre-load applied to the springs. This allows the operator to maintain the ride height. Use less pre-load for light wei...

Page 35

33 regular maintenance mowing height adjustment see figure 35. The mowing height can be adjusted by turning the cutting height adjustment handle. To raise the mower deck: turn the cutting height adjustment handle ( a, figure 35 ) clockwise. To lower the mower deck: turn the cutting height adjustment...

Page 36

34 www.Ferrisindustries.Com deck lift rod timing adjustment 1. Park the machine on a flat, level surface. Disengage the pto, stop the engine, and engage the parking brake. Rear tires must be inflated to 18 psi (1,24 bar). 2. Measure and record the distance between the lift pivots and the rod pivots....

Page 37: Caution

35 deck leveling adjustment note: before adjusting the deck level, the deck lift rod timing must be checked and/or adjusted. 1. Park the machine on a flat, level surface. Disengage the pto, stop the engine and engage the parking brake. Rear tires must be inflated to 18 psi (1,24 bar). 2. Adjust the ...

Page 38: Warning

36 www.Ferrisindustries.Com pto drive belt replacement 1. Park the unit on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Remove the mower deck guard. 3. Position the mower deck in the transport posi...

Page 39: Warning

37 regular maintenance mower deck drive belt replacement 1. Park the unit on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Remove the mower deck guard. 3. Remove the pto drive belt (see pto drive be...

Page 40

38 www.Ferrisindustries.Com regular maintenance hydraulic pump drive belt replacement 1. Park the unit on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Remove the pto drive belt (see pto drive belt ...

Page 41

39 7” (17,8 cm) a e b figure 50. Pump drive belt routing a. Nut b. Spring anchor eyebolt c. Pump drive pulleys d. Crankshaft pulleys e. Anchor tab f. Spring g. Idler arm regular maintenance c d g c f fuse locations the fuse block is located underneath the left instrument control panel. Refer to figu...

Page 42

40 www.Ferrisindustries.Com regular maintenance removing the mower deck it may be necessary to remove the mower deck to facilitate servicing the mower deck. The following procedure details how to remove the mower deck from the unit. 1. Park the machine on a flat, level surface such as a concrete flo...

Page 43

41 a b f e d c figure 55. Pusher rollers a. 1/2”-13 x 3-1/2” bolt b. Deck guide c. Sleeve bushing d. Roller e. 1/2 uss washer f. 1/2-13 hex nylock flange nut removing the operator compartment assembly it may be necessary to remove the operator compartment assembly to facilitate servicing the unit. T...

Page 44

42 www.Ferrisindustries.Com regular maintenance figure 58. Disconnect the cable plate a. Allen head screw b. Choke and throttle cable plate a a b 4. Loosen and remove the four (4) allen head screws ( a, figure 58 ) that secure the choke and throttle cable plate ( b ) to the dash panel assembly. 5. L...

Page 45

43 8. Locate the wire harness disconnect points under the right instrument control panel. Disconnect the wire harnesses by squeezing the quick release tabs and pulling the main unit wire harness connector ( b, figure 61 ) from the instrument panel wire harness connector ( b ). 9. There are two (2) 1...

Page 46

44 www.Ferrisindustries.Com regular maintenance installing the operator compartment assembly 1. Park the machine on a flat, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Place the operator compartment assembl...

Page 47: Warning

45 battery maintenance note: this unit is equipped with a maintenance-free bciu1 battery. Removing the tank the right hand tank ( a, figure 65 ) must be removed prior to performing maintenance on the battery. 1. Unscrew the three (3) wing bolts ( b ) that secure the tank to the unit. 2. Remove the t...

Page 48: Warning

46 www.Ferrisindustries.Com regular maintenance battery service checking battery voltage a voltmeter can be used to determine condition of battery. When engine is off, the voltmeter shows battery voltage, which should be 12 volts. When engine is running, the voltmeter shows voltage of charging circu...

Page 49: Warning

47 to starter switch starting vehicle battery to ground to starter switch discharged vehicle battery engine block this hook-up for negative ground vehicles make certain vehicles do not touch jumper cable jumper cable figure 67. Jump starting warning any procedure other than the proceeding could resu...

Page 50: Troubleshooting

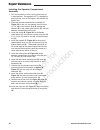

48 www.Ferrisindustries.Com troubleshooting troubleshooting troubleshooting chart while normal care and regular maintenance will extend the life of your equipment, prolonged or constant use may eventually require that service be performed to allow it to continue operating properly. The troubleshooti...

Page 51

49 troubleshooting the rider continued problem cause remedy engine runs, but rider will not drive. 1. Hydraulic release valve(s) in “open” position. 2. Belt is broken. 3. Drive belt slips. 4. Brake is not fully released. 1. Turn hydraulic release valve(s) clockwise to close. 2. See drive belt replac...

Page 52

50 www.Ferrisindustries.Com troubleshooting troubleshooting common cutting problems problem cause remedy streaking 1. Blades are not sharp. 2. Blades are worn down too far. 3. Engine speed is too slow. 4. Ground speed is too fast. 5. Deck is plugged with grass. 6. Not overlapping cutting rows enough...

Page 53: Specifications

51 specifications note: specifications are correct at time of printing and are subject to change without notice. Engine 22 gross hp† kawasaki make kawasaki model fx651v-as00-s displacement 44.3 cu. In. (726 cc) electrical system 12 volt, 15 amp. Alternator, battery: 330 cca oil capacity 2.2 qt. ( 2....

Page 54

52 www.Ferrisindustries.Com this is a 15 degree slope instr uctions 1. Fold this pa g e along the dotted line indicated abo ve . 2. Align the left edg e of this guide with a ver tical tree , a po wer line pole , a f ence post, or an y ver tical structure . 3. Compare the angle of the f old with the ...

Page 55

Thank you for purchasing ferris commercial mowing equipment. Please take a few minutes to read this limited warranty information. It contains all the information you will need to have your ferris mower repaired in the unlikely event that a breakdown covered by this limited warranty should occur. Own...

Page 56: Evolution Series

Evolution series compact zero-turn riding mower operator’s manual not for reproduction.