- DL manuals

- Ferris

- Lawn Mower

- F800X Series

- Dealer Service Manual

Ferris F800X Series Dealer Service Manual

Summary of F800X Series

Page 1

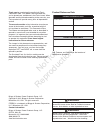

5102672 rev d f800x series zero-turn riding mower dealer service manual tractor model number description 5900911 f800xy30dce 5900940 f800xy30d ansi-exp mower deck 5900912 f800x/61ce 5900941 f800x/61 ansi-exp not for reproduction.

Page 2

Thank you for purchasing this quality-built ferris commerical zero turn mower. We’re pleased that you’ve placed your confidence in the ferris brand. When operated and maintained according to the manuals, your ferris product will provide many years of dependable service. The manuals contain safety in...

Page 3: Table of Contents

1 table of contents operator safety ...........................................................2 safety rules and information ..................................2 safety decals ........................................................11 safety icons .......................................................

Page 4

2 operator safety operating safety congratulations on purchasing a superior-quality piece of lawn and garden equipment. Our products are designed and manufactured to meet or exceed all industry standards for safety. Do not operate this machine unless you have been trained. Reading and understanding ...

Page 5

3 operator safety slope operation operation on slopes can be dangerous. Using the unit on a slope that is too steep where you do not have adequate wheel traction (and control) can cause sliding, loss of steering, control, and possible rollover. You should not operate on a slope greater than a 5.4 fo...

Page 6

4 roll bar use keep the roll bar in the raised position and fasten the seat belt. There is no roll over protection when the roll bar is down! Do not jump off if the mower tips (it is safer to be secured by the seat belt with the roll bar raised.) lower the roll bar only when necessary (such as to te...

Page 7

5 operator safety enclosed areas only operate this unit outdoors and away from unventilated areas such as inside garages or enclosed trailers. The engine emits poisonous carbon monoxide gas and prolonged exposure in an enclosed area can result in serious injury or death. Fuel and maintenance always ...

Page 8

6 2. Mow only in the daylight or with good artificial light, keeping away from holes and hidden hazards. 3. Be sure all drives are in neutral and parking brake is engaged before starting engine. Only start engine from the operator’s position. Use seat belts if provided. 4. Be sure of your footing wh...

Page 9: Caution

7 operator safety 23. Use care when approaching blind corners, shrubs, trees or other objects that may obscure vision. 24. To reduce fire hazard, keep unit free of grass, leaves & excess oil. Do not stop or park over dry leaves, grass or combustible materials. 25. Osha regulations may require the us...

Page 10

8 operator safety emissions 1. Engine exhaust from this product contains chemicals known, in certain quantities, to cause cancer, birth defects, or other reproductive harm. 2. Look for the relevant emissions durability period and air index information on the engine emissions label. Ignition system (...

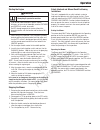

Page 11: Warning

9 operator safety roll bar instructions for models equipped with factory-installed roll over protection system (rops). Operational warnings • always use the seat belt when the roll bar is in the raised position. • never use the seat belt when the roll bar is in the down position. • remember there is...

Page 12: Warning

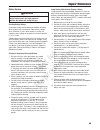

10 inspect buckle & latch inspect webbing operator safety warning failure to properly inspect and maintain the seat belt can cause serious injury or death. Inspection and maintenance of the roll bar seat belt • the seat belt like the roll bar, needs to be periodically inspected to verify that the in...

Page 13

11 operator safety safety decals before operating your unit, read the safety decals. The cautions and warning are for your safety. To avoid a personal injury or damage to the unit, understand and follow all the safety decals. This decal is installed on the battery for ce models only. Warning if any ...

Page 14

12 www.Ferrisindustries.Com operator safety 1. Warning: read and understand the operator’s manual before using this machine. Know the location and function of all controls. Do not operate this machine unless you are trained. 2. Warning: consult technical literature before performing technical repair...

Page 15

13 operator safety danger: machine rollover. Do not operate on any slopes when wet or slippery. Do not operate near drop-offs or near water. Danger: dismemberment. This machine can crush and cut. Keep hands away from deck lift rod. Warning: avoid serious injury or death from roll over do not jump of...

Page 16

14 www.Ferrisindustries.Com operator safety safety interlock system this unit is equipped with safety interlock switches. These safety systems are present for your safety, do not attempt to bypass safety switches, and never tamper with safety devices. Check their operation regularly. Operational saf...

Page 17: Features and Controls

15 features and controls features and controls identification numbers when contacting your authorized dealer for replacement parts, service, or information you must have these numbers. Record your model / serial number and engine serial numbers on the space provided on the inside front cover for eas...

Page 18: Features and Controls

16 www.Ferrisindustries.Com features and controls cutting height adjustment pin with the actuator fully extended move the cutting height adjustment pin to the desired cutting height. Retract the actuator until it makes contact with the cutting height adjustment pin to set the cutting height. Control...

Page 19

17 features and controls mower deck lift actuator switch pulling back on the switch will lower the mower deck. Pushing forward on the switch will raise the deck. The ground speed controls levers must be in the neutral positon to raise or lower the mower deck. Driving the mower: the mower deck must e...

Page 20: Operation

18 www.Ferrisindustries.Com features & controls operation general operating safety before first time operation: • be sure to read all information in the safety and operation sections before attempting to operate this unit. • become familiar with all of the controls and how to stop the unit. • drive ...

Page 21

19 operation figure 1. Pre-start checks a. Engine oil dipstick b. Fuel tank cap c. Hydraulic oil fill a seat adjustment (suspension seat) s/n: 2014648787 & below: in addition to the forward and backward seat adjustment, models equipped with a suspension seat can be adjusted for lumbar support, suspe...

Page 22

20 www.Ferrisindustries.Com 20 operation figure 3. Checking tire pressure check tire pressures tire pressure should be checked periodically, and maintained at the levels shown in the chart. Note that these pressures may differ slightly from the “max inflation” stamped on the side-wall of the tires. ...

Page 23

21 operation priming the fuel system priming the fuel system removes any air bubbles from the fuel system. The fuel system would only need to be primed under the following conditions: • before starting the engine for the first time. • after running the machine out of fuel and fresh fuel has been add...

Page 24

22 www.Ferrisindustries.Com operation check engine coolant level the engine coolant level and quality should be checked before each use, when the engine is cool and off. The cooling system is a closed type. Never open the radiator cap unless you are flushing the system. Opening the radiator cap may ...

Page 25

23 23 operation starting the engine 1. While sitting in the operator’s seat, engage the parking brake by pulling the parking brake lever up, make sure that the pto switch is disengaged (pressed fully down) and the ground speed control levers are locked in the neutral position. 2. Set the engine thro...

Page 26

24 www.Ferrisindustries.Com 24 operation zero-turn driving practice the lever controls of the zero turn rider are responsive, and learning to gain a smooth and efficient control of the rider’s forward, reverse, and turning movements will take some practice. Spending some time going through the maneu...

Page 27

25 25 operation advanced driving executing an end-of-row zero turn your zero turn rider’s unique ability to turn in place allows you to turn around at the end of a cutting row rather than having to stop and y-turn before starting a new row. For example, to execute a left end-of row zero turn: 1. Slo...

Page 28

26 www.Ferrisindustries.Com 26 proper cutting height incremental cutting cut here on first pass cut here on second pass operation mowing recommendations several factors can affect how well your machine cuts grass, following proper mowing recommendations can improve the performance and life of your m...

Page 29

27 27 operation when and how often to mow the time of day and condition of the grass greatly affect the results you’ll get when mowing. For the best results, follow these guidelines: 1. Mow when the grass is between three and five inches high. 2. Mow with sharp blades. Short clippings of grass one i...

Page 30

28 www.Ferrisindustries.Com pushing the rider by hand 1. Disengage the pto, engage the parking brake, turn the ignition off, and remove the key. 2. Locate the hydraulic release valves ( a, figure 13 ) on the bottom side of the hydraulic pumps. 3. To disengage the pumps (free-wheel position), turn th...

Page 31

29 raise and lower the roll bar to lower the roll bar: 1. Pull the hair pin clips ( a, figure 14 ) out of the retainer pins ( b ). 2. Push or pull the top of the roll bar ( c ) forward against the rubber stops ( d ) and remove the retainer pins ( b ). 3. Lower the roll bar and reinstall the retainer...

Page 32

30 www.Ferrisindustries.Com attachment removal and installation procedure positioning the mower deck for service 1. Park the machine on a smooth, level surface such as a concrete floor. Engage the parking brake, disengage the pto, and turn off the ignition key. 2. Turn the ignition key to the run po...

Page 33

31 figure 17. Actuator a. Actuator b. Pin with lanyard a b installing the attachment 1. Remove the pins with lanyards ( b, figure 15 ) from the rear holes of the attachment latches ( d ). 2. Drive the tractor into the mower deck. 3. Push the deck attachment lever ( e ) forward and down. Make sure th...

Page 34: Regular Maintenance

32 www.Ferrisindustries.Com maintenance maintenance schedule the following schedule should be followed for normal care of your rider and mower. You will need to keep a record of your operating time. Determining operating time is easily accomplished by observing the elapsed time recorded by the hour ...

Page 35

33 maintenance warning fuel and its vapors are extremely flammable and explosive. Fire or explosion can cause severe burns or death. • diesel fuel is highly flammable and must be handled with care. Never fill the tank when the engine is still hot from recent operation. Do not allow open flame, smoki...

Page 36

34 www.Ferrisindustries.Com maintenance fuel filter this unit is equipped with two fuel filters. One is a water seperator ( a, figure 14 ) and the other is a fuel filter ( c ). Both filters are located in the engine compartment on the right side of the engine. The water separator should be drained e...

Page 37

35 maintenance figure 22. Changing engine oil & filter a. Engine oil dipstick b. Oil drain cap c. Engine oil filter d. Engine oil fill a check / add engine oil level refer to figure 22 for dipstick and oil fill locations. Refer to the engine owners manual for specific engine oil check and fill proce...

Page 38

36 www.Ferrisindustries.Com maintenance figure 24. Front caster & wheel a. 1/4-28 bolt a lubrication lubricate the unit at the location shown in figures 23 through 29 as well as the following lubrication points: grease: • front caster wheel axles & yokes • drive shaft pillow blocks • deck lift pivot...

Page 39

37 maintenance figure 25. Control handle pivots & seat plate pivot a b figure 26. Idler arms a. Pto clutch drive belt idler arm b. Hydraulic pump drive belt idler arm figure 28. Attachment lift arms & actuator figure 29. Deck lift rods figure 27. Mower deck lubrication points not for reproduction.

Page 40

38 www.Ferrisindustries.Com servicing the mower blades removing the mower blade 1. To remove the mower blade, use a 1” wrench on the flats of the spindle shaft and remove the mower blade mounting bolt with a 15/16” wrench ( figure 30 ). 2. If there are no flats on the spindle shaft, wedge a wooden b...

Page 41

39 maintenance sharpening the mower blade 1. Sharpen the mower blades with grinder, hand file, or electric blade sharpener. 2. Sharpen the mower blade by removing an equal amount of material from each end of the mower blade. 3. Keep the original bevel ( a, figure 33 ) when grinding. Do not change th...

Page 42

40 www.Ferrisindustries.Com maintenance figure 36. Checking hydraulic oil level a. Hydraulic oil reservoir b. Reservoir cap b figure 37. Changing the hydraulic oil filter a. Hydraulic oil filter a check hydraulic oil level note: do not open the hydraulic reservoir unless oil is being added. 1. Raise...

Page 43

41 figure 38. Top speed adjustment a. Top speed adjustment bolt b. Handle placement hardware c. Alignment hardware d. Ground speed control lever mount bolts e. Control lever base maintenance a a b c d e warning do not adjust the tractor for a faster overall speed forward or reverse than it was desig...

Page 44

42 www.Ferrisindustries.Com neutral adjustment if the tractor “creeps” while the ground speed control levers are locked in neutral, then it may be necessary to adjust the linkage rod. 1. Park the machine on a hard, level surface such as a concrete floor. Disengage the pto, engage the parking brake, ...

Page 45

43 figure 40. Return-to-neutral adjustment a. Return spring b. Set collar a b b a figure 42. Parking brake adjustment a. Brake spring b. Adjustment nut 2-1/4” (5,72 cm) figure 41. Remove the kick plate a. Kick plate a b a maintenance return-to-neutral adjustment checking the adjustment: to determine...

Page 46

44 www.Ferrisindustries.Com figure 43. Checking the deck lift rod timing these edges of the rod pivots should be straight up and down. Figure 44. 2 x 4 locations maintenance deck lift rod timing adjustment 1. Park the machine on a flat, level surface. Disengage the pto, engage the parking brake, tur...

Page 47

45 figure 47. Hanger chain adjustment a. Adjustment point maintenance a a deck leveling adjustment note: before adjusting the deck level, the deck lift rod timing must be checked and/or adjusted. Coarse adjustment procedure when adjusting the deck level, the coarse adjustment procedure should be use...

Page 48

46 www.Ferrisindustries.Com maintenance pto clutch belt replacement 1. Park the tractor on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Raise the hood to gain access to the pto clutch belts ( a, fi...

Page 49

47 maintenance hydraulic pump drive belt replacement 1. Park the tractor on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Raise the hood to gain access to the hydraulic pump drive belts ( a, figure ...

Page 50

48 www.Ferrisindustries.Com maintenance mower belt replacement 1. Park the tractor on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Lower the mower deck to its lowest cutting position and remove the...

Page 51

49 maintenance figure 53. Gearbox oil level a. Oil fill plug b. Drain plug gearbox maintenance check the gearbox oil level 1. Park the machine on a flat, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine. 2. Raise the mower deck to the service p...

Page 52

50 www.Ferrisindustries.Com 50 regular maintenance fuse locations the fuse blocks are located on the side of the instrument control panel installed in the right hand fuel tank. Refer to figure 54 for the location and amperage of the fuses used in this machine. A. Charge circuit : 20 amp fuse b. Actu...

Page 53

51 fault diagnosis lamps this unit is equipped with a attachment module that features three fault diagnosis lamps labelled a, l and c. Checking the attachement module can help you in quickly identify certain problems with the machine. 1. Park the machine on a flat, level surface such as a concrete f...

Page 54

52 www.Ferrisindustries.Com cleaning the battery and cables note: this unit is equipped with a maintenance-free bciu1 battery. 1. Disconnect the cables from the battery, negative (black) cable first ( b, figure 56 ). 2. Clean the battery terminals and cable ends with a wire brush until shiny. 3. Rei...

Page 55

53 53 regular maintenance battery service checking battery voltage a voltmeter can be used to determine condition of battery. When engine is off, the voltmeter shows battery voltage, which should be 12 volts. When engine is running, the voltmeter shows voltage of charging circuit which normally is 1...

Page 56

54 www.Ferrisindustries.Com regular maintenance to starter switch starting vehicle battery to ground to starter switch discharged vehicle battery engine block this hook-up for negative ground vehicles make certain vehicles do not touch jumper cable jumper cable figure 57. Jump starting warning any p...

Page 57

55 regular maintenance storage temporary storage (30 days or less) remember, the fuel tank will still contain some fuel, so never store the unit indoors or in any other area where fuel vapor could travel to any ignition source. Fuel vapor is also toxic if inhaled, so never store the unit in any stru...

Page 58: Troubleshooting

56 www.Ferrisindustries.Com troubleshooting troubleshooting troubleshooting chart while normal care and regular maintenance will extend the life of your equipment, prolonged or constant use may eventually require that service be performed to allow it to continue operating properly. The troubleshooti...

Page 59

57 troubleshooting troubleshooting the rider continued problem cause remedy engine runs, but rider will not drive. 1. Hydraulic release valve(s) in “open” position. 2. Belt is broken. 3. Drive belt slips. 4. Brake is not fully released. 1. Turn hydraulic release valve(s) clockwise to close. 2. See d...

Page 60

58 www.Ferrisindustries.Com troubleshooting troubleshooting common cutting problems problem cause remedy streaking 1. Blades are not sharp. 2. Blades are worn down too far. 3. Engine speed is too slow. 4. Ground speed is too fast. 5. Deck is plugged with grass. 6. Not overlapping cutting rows enough...

Page 61: Specifications

59 specifications specifications note: specifications are correct at time of printing and are subject to change without notice. Engine 30 gross hp¹ yanmar make yanmar model 3tnv82a-bdfs displacement 81.22 cu. In (1331 cc) electrical system 12 volt, 40 amp. Alternator, battery 500 cca oil capacity 5....

Page 62

60 www.Ferrisindustries.Com this is a 15 degree slope instr uctions 1. Fold this pa g e along the dotted line indicated abo ve . 2. Align the left edg e of this guide with a ver tical tree , a po wer line pole , a f ence post, or an y ver tical structure . 3. Compare the angle of the f old with the ...

Page 63

Thank you for purchasing ferris commercial mowing equipment. Please take a few minutes to read this limited warranty information. It contains all the information you will need to have your ferris mower repaired in the unlikely event that a breakdown covered by this limited warranty should occur. Own...

Page 64: F800X Series

F800x series zero-turn riding mower dealer service manual not for reproduction.