- DL manuals

- Ferris

- Lawn Mower

- FW35 Series

- Operator's Manual

Ferris FW35 Series Operator's Manual

Summary of FW35 Series

Page 1

Not for reproduction.

Page 2: Table Of Contents:

Not for reproduction table of contents: products covered by this manual......................................3 identification tag location...................................................3 product identification tag (stamped).................................3 operator safety..........................

Page 3

Not for reproduction thank you for purchasing this quality-built ferris commercial walk behind mower. We’re pleased that you’ve placed your confidence in the ferris brand. When operated and maintained according to the manuals, your ferris product will provide many years of dependable service. The ma...

Page 4: Operator Safety

Not for reproduction operator safety warning u.S.A. Models: the engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects, or other reproductive harm. Warning battery posts, terminals, and related accessories contain lead and lead compounds, ...

Page 5

Not for reproduction do not have adequate footing and unit traction (and control) can cause you to lose control and possibly slip and fall or roll the unit over. Always mow across slopes, not up and down (you could slip and fall.) also, note that the surface you are on can greatly impact your abilit...

Page 6

Not for reproduction • all operators and mechanics should be trained. The owner is responsible for training the users. • only allow responsible adults, who are familiar with the instructions, to operate the unit. • never let children or untrained people operate or service the equipment. Local regula...

Page 7

Not for reproduction • osha regulations may require the use of hearing protection when exposed to sound levels greater than 85 dba for an 8 hour time period. Caution this machine produces sound level in excess of 85 dba at the operator's ear and can cause hearing loss through extended periods of exp...

Page 8

Not for reproduction safe handling of gasoline danger fire and explosion hazard to avoid personal injury or property damage, use extreme care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive. • extinguish all cigarettes, cigars, pipes, and other sources of ignition....

Page 9

Not for reproduction pin holes or nozzles that eject hydraulic fluid under high pressure. Use paper or cardboard, and not hands, to search for leaks. Make sure all hydraulic fluid connections are tight and all hydraulic hoses and lines are in good condition before applying pressure to the system. If...

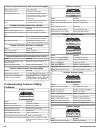

Page 10: Features And Controls

Not for reproduction safety icons hazard meaning callout alert a read the manual b go across slopes, not up and down c rollover hazard d fire hazard e amputation - hand in blade f amputation - foot in blade g thrown objects h safety interlock system this unit is equipped with safety interlock switch...

Page 11

Not for reproduction 3 instrument control panel: models equipped briggs & stratton efi engine briggs & stratton efi engines are available on models with either handle bar style. 4 control name callout operator presence handles a forward speed control lever b drive levers c hour meter d forward speed...

Page 12

Not for reproduction parking brake must be released before moving the forward speed control lever out of the neutral position or the engine will stop. S/n: 2016973574 & above: the forward speed control lever cannot be moved forward out of the neutral position if the parking brake lever is engaged. T...

Page 13: Operation

Not for reproduction control locations & functions - left side of mower 5 control name callout transmission oil fill a fuel tank cap b transmission release levers c fuel tank cap: to remove the cap, turn counter-clockwise. Transmission release levers: control name icon transmission release levers th...

Page 14

Not for reproduction checks before starting 6 • check that crankcase is filled to the full mark on the dipstick (a, figure 6). See the engine operator’s manual for engine oil dipstick location, oil fill instructions, and oil recommendations. • make sure all nuts, bolts, screws, and pins are in place...

Page 15

Not for reproduction 7 2. Once the unit is stopped, firmly depress the neutral return pedal (b) to place the transmission in neutral. 3. Disengage the pto by pushing down on the pto switch (c). 4. Engage the parking brake by pulling the parking brake lever (d) fully up and rearward towards the handl...

Page 16

Not for reproduction cutting height adjustment the cutting height indicator (a, figure 9) will help you identify the cutting height. 9 to raise the mower deck: turn the cutting height adjustment handle (b) clockwise. To lower the mower deck: turn the cutting height adjustment handle counter-clockwis...

Page 17

Not for reproduction 11 when and how often to mow the time of day and condition of the grass greatly affect the results you’ll get when mowing. For the best results, follow these guidelines: • mow when the grass is between three and five inches high. • mow with sharp blades. Short clippings of grass...

Page 18

Not for reproduction mulching consists of a mower deck which cuts and re-cuts clippings into tiny particles and which then blows them down into the lawn. These tiny particles decompose rapidly into by-products your lawn can use. Under proper conditions, your mulching mower will virtually eliminate n...

Page 19: Maintenance Schedule

Not for reproduction warning never store the unit, with gasoline in engine or fuel tank, in a heated shelter or in enclosed, poorly ventilated enclosures. Gasoline fumes may reach an open flame, spark or pilot light (such as a furnace, water heater, clothes dryer, etc.) and cause an explosion. Handl...

Page 20: Maintenance Procedures

Not for reproduction engine maintenance every 50 hours inspect / clean spark arrester.** every 100 hours check fuel filter. Refer to engine owner's manual service air filter. Change engine oil and filter. Check / replace spark plugs. * more often in hot (over 85° f; 30° c) weather or dusty operating...

Page 21

Not for reproduction change engine oil & filter this series of mower has three different engine options: briggs & stratton vanguard series (a, figure 15), briggs & stratton efi series (b), and kawasaki fx series (c). Please reference as the location of the components for this procedure may vary by s...

Page 22

Not for reproduction lubrication this unit is equipped with twenty four (24) different grease fittings that must be lubricated on this unit. They must be lubricated at the intervals as specified in the maintenance chart. Qty of fittings grease fitting location 1 forward speed control lever rod (a, f...

Page 23

Not for reproduction 19 20 lubricating the front casters interval: annually 1. Remove the 1/4-28 bolt (b, figure 21) screwed into the front caster and install a 1/4-28 grease fitting. 21 2. Grease the front caster. 3. Remove the 1/4-28 grease fitting and re-install the 1/4-28 bolt. 4. Repeat process...

Page 24

Not for reproduction inspecting the mower blades danger thrown objects hazard avoid injury: a worn or damaged mower blade can break and a piece of the blade could be thrown into the operator's area or bystander's area resulting in serious personal injury or death. • inspect the mower blade every 25 ...

Page 25

Not for reproduction 26 3. Check the balance of the mower blade. If either end of the mower blade moves downward is heavier than the other. Sharpen the heavy end until balance is achieved. See sharpening the mower blades for sharpening instructions. 4. Repeat the process until the mower blade remain...

Page 26

Not for reproduction 3. Apply a film of new oil to the gasket of the new replacement filter. After the oil has drained, thread the new filter onto the filter base until the gasket makes contact, then tighten 3/4 of a turn more. 4. Using a hex bit swivel socket or a modified allen wrench remove the t...

Page 27

Not for reproduction if machine veers to the left: 1. Loosen the jam nuts (a, figure 30) that are tightened against the ball joints (b). 2. Turn the left adjustment linkage rod 1/8 - 1/4 turn counter-clockwise. 3. Turn the right adjustment linkage rod 1/8 - 1/4 turn clockwise. 4. Re-tighten the jam ...

Page 28

Not for reproduction and record this measurement. This measurement should not be longer than 7-1/4" (18.4 cm). 5. Tighten the wing nut against the black adjustment knob. 6. Repeat this process for the other side of the unit. The measurements for both drive lever spring assemblies must be the same. D...

Page 29

Not for reproduction 5. Push the forward speed control lever forward (e) until the forward speed indicator is located in relation with the forward speed indicator icon that you identified as your preferred maximum forward speed. 6. Position the bolt so that it contacts the forward speed control leve...

Page 30

Not for reproduction 3. Turn the hex adjusters (d) on the front deck linkages so that the measurements from the bottom edge of the mower deck to the ground equals 1" (2.54 cm). 4. Turn the hex adjusters on the rear deck linkages so that the measurements from the bottom edge of the mower deck to the ...

Page 31

Not for reproduction the measurement as indicated in the chart. If the measurement does not equal the measurement as indicated in the chart, perform the adjusting the mower belt idler tensioner spring length procedure. 40 adjusting the mower belt idler tensioner spring length 1. Loosen the jam nut (...

Page 32

Not for reproduction jam nut a spring anchor eyebolt b adjustment nut c spring d transmission drive belt e transmission pulleys f front stationary pulley g crankshaft pulley h adjustable idler pulley i coil-to-coil spring measurement: 3-1/4" (8.3 cm) j 8. Loosen the adjustment nut (c) to release the...

Page 33

Not for reproduction 3. With the parking brake engaged, measure the compressed spring length (b) of the parking brake springs. The parking brake springs should measure 1-3/4" (4.4 cm) when compressed. If not, position the adjustment nut (c) until the compressed spring length measures 1-3/4" (4.4 cm)...

Page 34: Troubleshooting

Not for reproduction per hour. The battery is fully charged when the cells are gassing freely at low charging rate and less than 0.003 change in specific gravity occurs over a three hour period. Jump starting with auxiliary (booster) battery jump starting is not recommended. However, if it must be d...

Page 35

Not for reproduction this troubleshooting guide lists the most common problems, their causes and remedies. Refer to regular maintenance for instructions on how to perform most of these minor adjustments and service repairs yourself. If you prefer, all of these procedures can be performed for you by ...

Page 36

Not for reproduction problem: engine stalls easily with mower deck engaged. Set to full throttle. Engine speed too slow. Decrease ground speed. Ground speed to fast. Cut tall grass at maximum cutting height during first pass, and then at the desired cutting height for the second pass. Cutting height...

Page 37: Specifications

Not for reproduction problem: stingers replace your blades. Blades are worn down too far. Always mow at full throttle. Engine speed is too slow. Slow down. Ground speed is too fast. Clean out the mower. Deck is plugged with grass. Specifications note: specifications are correct at time of printing a...

Page 38: Warranty

Not for reproduction models with 48" mower deck 62.5" (158.8 cm) overall width (with discharge chute down) 41.5" (105.4 cm) height 809 lbs (367 kg) weight (aprox.) models with 52" mower deck 78.75" (200 cm) overall length 57" (145 cm) overall width (with discharge chute up) 67" (170 cm) overall widt...

Page 39

Not for reproduction improper maintenance or repair - this product must be maintained according to the procedures and schedules provided in the operator's manual, and serviced or repaired using genuine briggs & stratton parts or equivalent. Damage caused by lack of maintenance or use of non-original...

Page 40

Not for reproduction.