- DL manuals

- Ferris

- Lawn Mower Accessories

- IS2000Z Diesel

- Operator's Manual

Ferris IS2000Z Diesel Operator's Manual

5101940

Rev H

Briggs & Stratton Power Products Group, LLC.

5375 North Main Street

Munnsville, NY 13409

800-933-6175

IS2000Z Series

Zero-Turn Riding Mower

OPERATOR’S

MANUAL

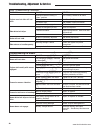

Model No.:

Description:

5900807

IS2000ZKAV3461SS

5900808

IS2000ZKAV2761

5900811

IS2000ZB3061SS

5900814

IS2000ZBV3061SS AUS/NZ

5900816

IS2000ZB3061SS CAL

5900840

IS2000ZKAV2552

5900879

IS2000ZKAV2661

5900945

IS2000ZKAV2652

5900939

IS2000ZKAV2652HT

5900968

IS2000ZB3061

5901025

IS2000ZKAV2661

5900587

IS2000ZB2852

5900536

IS2000ZB3061

5900586

IS2000ZB3261

5900563

IS2000ZKAV2652

Not

for

Reproduction

Summary of IS2000Z Diesel

Page 1

5101940 rev h briggs & stratton power products group, llc. 5375 north main street munnsville, ny 13409 800-933-6175 is2000z series zero-turn riding mower operator’s manual model no.: description: 5900807 is2000zkav3461ss 5900808 is2000zkav2761 5900811 is2000zb3061ss 5900814 is2000zbv3061ss aus/nz 59...

Page 2: Warning

Thank you for purchasing this quality-built ferris product. We’re pleased that you’ve placed your confidence in the ferris brand. When operated and maintained according to the instructions in this manual, your ferris product will provide many years of dependable service. This manual contains safety ...

Page 3: Table of Contents

1 table of contents operator safety .................................................. 2 safety decal locations .........................................11 safety interlock system ........................................12 features & controls ......................................... 13 identificati...

Page 4

2 operator safety operating safety congratulations on purchasing a superior-quality piece of lawn and garden equipment. Our products are designed and manufactured to meet or exceed all industry standards for safety. Do not operate this machine unless you have been trained. Reading and understanding ...

Page 5

3 operator safety slope operation operation on slopes can be dangerous. Using the unit on a slope that is too steep where you do not have adequate wheel traction (and control) can cause sliding, loss of steering, control, and possible rollover. You should not operate on a slope greater than a 5.4 fo...

Page 6

4 roll bar use keep the roll bar in the raised position and fasten the seat belt. There is no roll over protection when the roll bar is down! Do not jump off if the mower tips (it is safer to be secured by the seat belt with the roll bar raised.) lower the roll bar only when necessary (such as to te...

Page 7

5 operator safety enclosed areas only operate this unit outdoors and away from unventilated areas such as inside garages or enclosed trailers. The engine emits poisonous carbon monoxide gas and prolonged exposure in an enclosed area can result in serious injury or death. Fuel and maintenance always ...

Page 8

6 2. Mow only in the daylight or with good artificial light, keeping away from holes and hidden hazards. 3. Be sure all drives are in neutral and parking brake is engaged before starting engine. Only start engine from the operator’s position. Use seat belts if provided. 4. Be sure of your footing wh...

Page 9: Caution

7 operator safety 23. Use care when approaching blind corners, shrubs, trees or other objects that may obscure vision. 24. To reduce fire hazard, keep unit free of grass, leaves & excess oil. Do not stop or park over dry leaves, grass or combustible materials. 25. Osha regulations may require the us...

Page 10

8 operator safety emissions 1. Engine exhaust from this product contains chemicals known, in certain quantities, to cause cancer, birth defects, or other reproductive harm. 2. Look for the relevant emissions durability period and air index information on the engine emissions label. Ignition system (...

Page 11: Warning

9 operator safety roll bar instructions for models equipped with factory-installed roll over protection system (rops). Operational warnings • always use the seat belt when the roll bar is in the raised position. • never use the seat belt when the roll bar is in the down position. • remember there is...

Page 12: Warning

10 inspect buckle & latch inspect webbing operator safety warning failure to properly inspect and maintain the seat belt can cause serious injury or death. Inspection and maintenance of the roll bar seat belt • the seat belt like the roll bar, needs to be periodically inspected to verify that the in...

Page 13: Warning

11 operator safety safety decal locations before operating your unit, read the safety decals. The cautions and warnings are for your safety. To avoid a personal injury or damage to the unit, understand and follow all the safety decals. 1 2 3 4 6 5 7 8 9 11 10 12 13* 14* warning if any safety decals ...

Page 14: Warning

12 www.Ferrisindustries.Com operator safety safety interlock system this unit is equipped with safety interlock switches. These safety systems are present for your safety, do not attempt to bypass safety switches, and never tamper with safety devices. Check their operation regularly. Operational saf...

Page 15: Features & Controls

13 features & controls features & controls identification number location sample sample identification tag control functions & locations the information below briefly describes the function of individual controls. Starting, stopping, driving, and mowing require the combined use of several controls a...

Page 16: Operation

14 www.Ferrisindustries.Com j ground speed control levers: these levers control the ground speed of the rider. The left lever controls the left rear drive wheel and the right lever controls the right rear drive wheel. Moving a lever forward increases the forward speed of the associated wheel, and pu...

Page 17: Warning

15 b a figure 1. Pre-start checks a. Fuel tank cap b. Fuel valve warning if you do not understand how a specific control functions, or have not yet thoroughly read the features & controls section, do so now. Do not attempt to operate the tractor without first becoming familiar with the location and ...

Page 18

16 www.Ferrisindustries.Com operation zero-turn driving practice the lever controls of the zero turn rider are responsive, and learning to gain a smooth and efficient control of the rider’s forward, reverse, and turning movements will take some practice. Spending some time going through the maneuver...

Page 19

17 advanced driving executing an end-of-row zero turn your zero turn rider’s unique ability to turn in place allows you to turn around at the end of a cutting row rather than having to stop and y-turn before starting a new row. For example, to execute a left end-of row zero turn: 1. Slow down at the...

Page 20

18 www.Ferrisindustries.Com mowing 1. Engage the parking brake. Make sure the pto switch is disengaged, the motion control levers are locked in the neutral position and the operator is on the seat. 2. Start the engine (see starting the engine). 3. Set the mower cutting height. 4. Set the throttle to...

Page 21

19 mowing methods proper broadcast mowing broadcasting, or side-discharging, disperses fine clippings evenly over the entire lawn. Many golf courses use this method. Your mower has a deep dish deck to allow freer circulation of clippings so they are broadcast evenly over the lawn. Engine speed & gro...

Page 22: Warning

20 www.Ferrisindustries.Com warning avoid serious injury or death from roll over: keep roll bar in the raised position and use seat belt. There is no roll over protection when the roll bar is down lower the roll bar only when necessary and never remove it. Do not use seat belt when the roll bar is d...

Page 23: Warning

21 operation storage temporary storage (30 days or less) remember, the fuel tank will still contain some gasoline, so never store the unit indoors or in any other area where fuel vapor could travel to any ignition source. Fuel vapor is also toxic if inhaled, so never store the unit in any structure ...

Page 24: Maintenance

22 www.Ferrisindustries.Com maintenance maintenance schedule the following schedule should be followed for normal care of your rider and mower. You will need to keep a record of your operating time. Determining operating time is easily accomplished by observing the elapsed time recorded by the hour ...

Page 25: Warning

23 regular maintenance warning replacement parts must be the same and installed in the same position as the original parts or fire could result. Inspect muffler and spark arrester inspect the muffler for cracks, corrosion, or other damage. Remove the spark arrester, if equipped, and inspect for dama...

Page 26: Warning

24 www.Ferrisindustries.Com regular maintenance figure 15. Battery compartment a. Positive (+) cable & terminal b. Negative (-) cable & terminal b a battery maintenance note: this unit is equipped with a maintenance-free bciu1 battery. Cleaning the battery and cables 1. Raise the seat plate to expos...

Page 27: Caution

25 servicing the mower blades removing the mower blade 1. To remove the mower blade, wedge a wooden block between the mower blade and the mower deck housing to keep the blade from turning and remove the mower blade mounting bolt with a 15/16” wrench (figure 21). Regular maintenance lubricating the f...

Page 28: Caution

26 www.Ferrisindustries.Com balancing the mower blades 1. Clean the mower blade to remove any dried grass or other debris. 2. See figure 25. Put the mower blade on a nail in a vise and turn the blade to the horizontal position. 3. Check the balance of the mower blade. If either end of the mower blad...

Page 29: Troubleshooting

27 troubleshooting while normal care and regular maintenance will extend the life of your equipment, prolonged or constant use may eventually require that service be performed to allow it to continue operating properly. The troubleshooting guide below lists the most common problems, their causes and...

Page 30

28 www.Ferrisindustries.Com troubleshooting, adjustment & service rider troubleshooting continued. Problem cause remedy engine runs but rider will not drive. Hydraulic release valve(s) in “open” position. Turn valve(s) clockwise to close. Belt is broken. See drive belt replacement drive belt slips. ...

Page 31

29 troubleshooting, adjustment & service troubleshooting common cutting problems problem cause remedy streaking blades are not sharp sharpen your blades. Blades are worn down too far. Replace your blades. Engine speed is too slow. Always mow at full throttle. Ground speed is too fast. Slow down. Dec...

Page 32

30 www.Ferrisindustries.Com troubleshooting, adjustment & service figure 27. Seat adjustment figure 29. Control lever adjustment a. Alignment hardware b. Placement hardware c. Ground speed control lever a b c seat adjustment see figure 27. The seat can be adjusted forward and back. Move the lever to...

Page 33: Warning

31 troubleshooting, adjustment & service figure 31. Neutral adjustment (rh side shown) a. Adjustment linkage rod b. Nuts a b neutral adjustment if the tractor “creeps” while the ground speed control levers are locked in neutral, then it may be necessary to adjust the linkage rod. Note: perform this ...

Page 34: Caution

32 www.Ferrisindustries.Com figure 33. Parking brake adjustment a. Brake spring b. Adjustment nut a b parking brake adjustment 1. Disengage the pto, engage the parking brake, stop the engine and remove the ignition key. 2. Raise the seat plate. 3. Locate the brake spring (a, figure 33). 4. With the ...

Page 35: Warning

33 troubleshooting, adjustment & service warning use two hands when adjusting the shock springs. This will prevent the wrench from slipping while pressure is being applied. To adjust the upper mounting position: 1. Park machine on a flat, level surface. Disengage the pto, stop the engine and engage ...

Page 36

34 www.Ferrisindustries.Com c figure 35. Mowing height adjustment a. Cutting height adjustment pin b. Deck lift foot pedal c. Deck lift lock lever b a a b c figure 36. Foot pedal adjustment a. Deck lift foot pedal b. Pedal mount tab c. Pedal mount hardware mowing height adjustment the cutting height...

Page 37

35 measure 1st measure 2nd measure 1st measure 2nd troubleshooting, adjustment & service figure 38. Deck lift pedal & pin position inner rod outer rod inner rod outer rod adjust here figure 37. Measure the inner & outer lift rods figure 39. Adjust the inner & outer lift rods adjust here deck lift ro...

Page 38: Caution

36 www.Ferrisindustries.Com figure 40. 2 x 4 locations figure 41. Hanger chain adjustment troubleshooting, adjustment & service deck leveling adjustment note: before adjusting the deck level, the deck lift rod timing must be checked and/or adjusted. 1. Park machine on a flat, level surface. Disengag...

Page 39

37 figure 43. Deck lift spring location a. Deck lift spring deck lift spring the deck lift springs (a, figure 43) are factory set to provide optimal lifting performance. Although it is fastened with a multi-position anchor, this is not an adjustment point. Do not attempt to adjust the spring length ...

Page 40: Warning

38 www.Ferrisindustries.Com mower belt replacement 1. Park the tractor on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Using a 1/2” breaker bar, place the square end in the square hole located in t...

Page 41

39 figure 46. Mower pto belt routing a. Spindle pulley b. Pto drive belt c. Spring-loaded idler pulley d. Stationary idler pulley c b d a a a d d c b d a a a d 52” deck 61” deck troubleshooting, adjustment & service figure 47. Mower belt idler spring length a. Mower belt tensioner spring b. Anchor e...

Page 42: Warning

40 www.Ferrisindustries.Com battery service checking battery voltage a voltmeter can be used to determine condition of battery. When engine is off, the voltmeter shows battery voltage, which should be 12 volts. When engine is running, the voltmeter shows voltage of charging circuit which normally is...

Page 43: Warning

41 to starter switch starting vehicle battery to ground to starter switch discharged vehicle battery engine block this hook-up for negative ground vehicles make certain vehicles do not touch jumper cable jumper cable warning any procedure other than the preceding could result in: (1) personal injury...

Page 44: Specifications

42 www.Ferrisindustries.Com specifications displacement 49.43 cu. In (810 cc) electrical system 12 volt, 16 amp. Alternator; battery: 340 cca oil capacity 2.1 us qt. (2.0 l) w/ filter 30 gross hp* briggs & stratton commercial turf (product model: 5900536) make briggs & stratton model 49m977-0114-g5 ...

Page 45

43 specifications †power ratings: all power levels are stated gross horsepower per sae j2723 as rated by kawasaki and tested per the sae j1995 test standard. The gross power curves and more information can be viewed at www.Kawasaki-criticalpower.Com. *power ratings: the gross power rating for indivi...

Page 46

44 www.Ferrisindustries.Com this is a 15 degree slope instr uctions 1. Fold this pa g e along the dotted line indicated abo ve . 2. Align the left edg e of this guide with a ver tical tree , a po wer line pole , a f ence post, or an y ver tical structure . 3. Compare the angle of the f old with the ...

Page 47

Thank you for purchasing ferris commercial mowing equipment. Please take a few minutes to read this limited warranty information. It contains all the information you will need to have your ferris mower repaired in the unlikely event that a breakdown covered by this limited warranty should occur. Own...

Page 48: Is2000Z Series

Is2000z series zero-turn riding mower operator’s manual briggs & stratton power products group, llc. 5375 north main street munnsville, ny 13409 800-933-6175 www.Ferrisindustries.Com not for reproduction.