- DL manuals

- Ferris

- Lawn Mower

- IS5100Z Series

- Operator's Manual

Ferris IS5100Z Series Operator's Manual - Caution

Not for

Reproduction

41

Troubleshooting, Adjustment & Repair

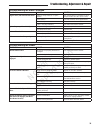

Parking Brake Adjustment

1. Disengage the PTO, stop the engine, block the

front wheels, remove the ignition key, and engage

the parking brake.

2. Locate the upper brake spring (A, Figure 37)

through the opening under the fuel tanks.

3. With the parking brake engaged, measure the

compressed spring length. The spring should be

2” - 2-1/8” (5,0 - 5,4cm) when compressed.

4. If adjustment is required, disengage the parking

brake and turn the adjustment nut (B).

5. Engage the parking brake and re-measure the

spring.

FRONT

Figure 37. Parking Brake Adjustment

A. Upper Brake Spring

B. Adjustment Nut

A

CAUTION

Do not adjust the spring to be shorter than

2” (5,0cm) when compressed. This may

damage the brake caliper.

2" - 2-1/8"

(5,0 - 5,4cm)

B

Summary of IS5100Z Series

Page 1

Not for reproduction this manual is available in spanish. For a copy, contact your ferris dealer or www.Ferrisindustries.Com. Este manual está disponible en español. Para obtener una copia, póngase en contacto con su distribuidor ferris o www.Ferrisindustries.Com. 5102954 rev d is5100z series zero-t...

Page 2: Warning

Not for reproduction thank you for purchasing this quality-built ferris product. We’re pleased that you’ve placed your confidence in the ferris brand. When operated and maintained according to the instructions in this manual, your ferris product will provide many years of dependable service. This ma...

Page 3

Not for reproduction 1 table of contents operator safety .................................................. 2 identification numbers ..........................................11 safety alert symbol & signal words ....................11 safety decals .....................................................

Page 4

Not for reproduction 2 operator safety operating safety congratulations on purchasing a superior-quality piece of lawn and garden equipment. Our products are designed and manufactured to meet or exceed all industry standards for safety. Do not operate this machine unless you have been trained. Readi...

Page 5

Not for reproduction 3 operator safety slope operation operation on slopes can be dangerous. Using the unit on a slope that is too steep where you do not have adequate wheel traction (and control) can cause sliding, loss of steering, control, and possible rollover. You should not operate on a slope ...

Page 6

Not for reproduction 4 roll bar use keep the roll bar in the raised position and fasten the seat belt. There is no roll over protection when the roll bar is down! Do not jump off if the mower tips (it is safer to be secured by the seat belt with the roll bar raised.) lower the roll bar only when nec...

Page 7

Not for reproduction 5 operator safety enclosed areas only operate this unit outdoors and away from unventilated areas such as inside garages or enclosed trailers. The engine emits poisonous carbon monoxide gas and prolonged exposure in an enclosed area can result in serious injury or death. Fuel an...

Page 8

Not for reproduction 6 2. Mow only in the daylight or with good artificial light, keeping away from holes and hidden hazards. 3. Be sure all drives are in neutral and parking brake is engaged before starting engine. Only start engine from the operator’s position. Use seat belts if provided. 4. Be su...

Page 9: Caution

Not for reproduction 7 operator safety 23. Use care when approaching blind corners, shrubs, trees or other objects that may obscure vision. 24. To reduce fire hazard, keep unit free of grass, leaves & excess oil. Do not stop or park over dry leaves, grass or combustible materials. 25. Osha regulatio...

Page 10

Not for reproduction 8 operator safety emissions 1. Engine exhaust from this product contains chemicals known, in certain quantities, to cause cancer, birth defects, or other reproductive harm. 2. Look for the relevant emissions durability period and air index information on the engine emissions lab...

Page 11: Warning

Not for reproduction 9 operator safety roll bar instructions for models equipped with factory-installed roll over protection system (rops). Operational warnings • always use the seat belt when the roll bar is in the raised position. • never use the seat belt when the roll bar is in the down position...

Page 12: Warning

Not for reproduction 10 inspect buckle & latch inspect webbing operator safety warning failure to properly inspect and maintain the seat belt can cause serious injury or death. Inspection and maintenance of the roll bar seat belt • the seat belt like the roll bar, needs to be periodically inspected ...

Page 13: Sample

Not for reproduction 11 operator safety north american models sample sample when contacting your authorized dealer for replacement parts, service, or information you must have these numbers. Record your model/serial number and engine serial numbers on the space provided for easy access. These number...

Page 14: Warning

Not for reproduction 12 www.Ferrisindustries.Com operator safety a b c d e f g safety decals before operating your unit, read the safety decals. The cautions and warnings are for your safety. To avoid a personal injury or damage to the unit, understand and follow all safety decals. Warning if any sa...

Page 15: Warning

Not for reproduction 13 operator safety safety icons a b c d e f g h i j k l m n o p callout description a alert b read the manual c amputation - rotating parts d pinch point e fire hazard f amputation - hand in blade g amputation - foot in blade h thrown objects i maximum slope angle for safe opera...

Page 16: Features and Controls

Not for reproduction 14 www.Ferrisindustries.Com features & controls features and controls a b d c e h i g j f control functions and locations the information below briefly describes the function of the individual controls. Starting, stopping, driving, and mowing require the combined use of several ...

Page 17

Not for reproduction 15 features & controls b. Glow plug indicator: lamp that indicates that the glow plugs are heating. Hold the ignition key in the “heat” position until indicator lamp turns off, then turn the key to start. C. Pto (power take off) switch: the pto switch engages and disengages the ...

Page 18: Operation

Not for reproduction 16 www.Ferrisindustries.Com operation operation general operating safety before first time operation: • be sure to read all information in the safety and operation sections before attempting to operate this tractor and mower. • become familiar with all of the controls and how to...

Page 19: Warning

Not for reproduction 17 operation priming the fuel system priming the fuel system fills the fuel filters and removes any air bubbles from the fuel system. This must be performed before the first use, after any fuel filter maintenance or if the fuel system is run dry. To prime the fuel system: on the...

Page 20: Warning

Not for reproduction 18 www.Ferrisindustries.Com operation starting the engine 1. While sitting in the operators seat, engage the parking brake and make sure the pto switch is disengaged and the ground speed control levers are locked in the neutral position. 2. Set the throttle to middle position (s...

Page 21: Basic Driving

Not for reproduction 19 operation zero-turn driving practice the lever controls of the zero turn rider are responsive, and learning to gain a smooth and efficient control of the rider’s forward, reverse, and turning movements will take some practice. Spending some time going through the maneuvers sh...

Page 22: Advanced Driving

Not for reproduction 20 www.Ferrisindustries.Com operation advanced driving executing an end-of-row zero turn your zero turn rider’s unique ability to turn in place allows you to turn around at the end of a cutting row rather than having to stop and y-turn before starting a new row. For example, to ...

Page 23

Not for reproduction 21 operation mowing 1. Engage the parking brake. Make sure the pto switch is disengaged, the motion control levers are locked in the neutral position and the operator is on the seat. 2. Start the engine (see starting the engine). 3. Set the mower cutting height. 4. Set the throt...

Page 24

Not for reproduction 22 www.Ferrisindustries.Com operation when and how often to mow the time of day and condition of the grass greatly affect the results you’ll get when mowing. For the best results, follow these guidelines: 1. Mow when the grass is between three and five inches high. 2. Mow with s...

Page 25

Not for reproduction 23 operation proper mulching mulching consists of a mower deck which cuts and recuts clippings into tiny particles and which then blows them down into the lawn. These tiny particles decompose rapidly into by-products your lawn can use. Under proper conditions, your mulching mowe...

Page 26

Not for reproduction 24 www.Ferrisindustries.Com operation attaching a trailer the maximum weight of a towed trailer should be less than 300 lbs (138kg). Secure the trailer with a appropriately sized clevis pin (a, figure 9) and clip (b). Excessive towed loads can cause loss of traction and loss of ...

Page 27: Warning

Not for reproduction 25 operation warning avoid serious injury or death from roll over: keep roll bar in the raised position and use seat belt. There is no roll over protection when the roll bar is down lower the roll bar only when necessary and never remove it. Do not use seat belt when the roll ba...

Page 28: Warning

Not for reproduction 26 www.Ferrisindustries.Com operation warning never store the unit, with diesel fuel in engine or fuel tank, in a heated shelter or in enclosed, poorly ventilated enclosures. Diesel fumes may reach an open flame, spark or pilot light (such as a furnace, water heater, clothes dry...

Page 29: Maintenance

Not for reproduction 27 regular maintenance figure 11. Checking tire pressure check tire pressures tire pressure should be checked periodically, and maintained at the levels shown in the chart. Note that these pressures may differ slightly from the “max inflation” stamped on the side-wall of the tir...

Page 30: Warning

Not for reproduction 28 www.Ferrisindustries.Com regular maintenance checking / adding fuel to add fuel: 1. Remove the fuel cap (a, figure 12). 2. Fill the tank to the bottom of the fill tube. This will leave room in the tank for fuel expansion. Refer to your engine manual for specific fuel recommen...

Page 31

Not for reproduction 29 regular maintenance check / add engine oil refer to figure 14 for dipstick and oil fill locations. Refer to the engine owners manual for specific engine oil check and fill procedures. Also refer to the engine owners manual for specific engine oil and filter change procedures....

Page 32: Warning

Not for reproduction 30 www.Ferrisindustries.Com regular maintenance check engine coolant level the engine coolant level and quality should be checked before each use, when the engine is cool and off. 1. Remove the radiator pressure cap (a, figure 17) to check the fluid level. 2. Coolant level shoul...

Page 33

Not for reproduction 31 regular maintenance lubrication lubricate the unit at the locations shown in figure 19 through 23. Grease: use grease fittings when present. Disassemble parts to apply grease to moving parts when grease fittings are not installed. Not all greases are compatible. Red grease (p...

Page 34: Warning

Not for reproduction 32 www.Ferrisindustries.Com regular maintenance cleaning the battery and cables (note: the tractor equipped with a maintenance-free bci58 battery) 1. Disconnect the cables from the battery, negative cable first (b, figure 24). 2. Remove the battery and clean the compartment with...

Page 35: Warning

Not for reproduction 33 regular maintenance servicing the mower blades 1. Blades should be sharp and free of nicks and dents. If not, sharpen blades as described in following steps. 2. To remove blade for sharpening, use a 1” wrench on the flats of the spindle shaft while removing the blade mounting...

Page 36: Troubleshooting

Not for reproduction 34 www.Ferrisindustries.Com troubleshooting, adjustment & repair troubleshooting while normal care and regular maintenance will extend the life of your equipment, prolonged or constant use may eventually require that service be performed to allow it to continue operating properl...

Page 37

Not for reproduction 35 troubleshooting, adjustment & repair troubleshooting the rider continued problem cause remedy engine runs, but rider will not drive. Hydraulic dump valve(s) in “open” position. Turn dump valve(s) clockwise to close. Torque to 80-120 in.Lbs. (9-13.5 nm) belt is broken. See bel...

Page 38

Not for reproduction 36 www.Ferrisindustries.Com troubleshooting, adjustment & repair troubleshooting common cutting problems problem cause remedy streaking blades are not sharp. Sharpen your blades. Blades are worn down to far. Replace your blades. Engine speed is too slow. Always mow at full throt...

Page 39

Not for reproduction 37 troubleshooting, adjustment & repair hood latch operation this unit is equipped with a hood latch that must be released prior to opening the hood. 1. Pull the hood latch (a, figure 28) towards the rear of the machine to release the hood latch. 2. Open the hood. Floor pan remo...

Page 40

Not for reproduction 38 www.Ferrisindustries.Com troubleshooting, adjustment & repair mowing height adjustment the cutting height adjustment pin (a, figure 31) controls the mower cutting height. The cutting height is adjustable between 1-1/2” (3,8 cm) and 6” (15,2 cm) in 1/4” (0,64 cm) increments. 1...

Page 41: Warning

Not for reproduction 39 troubleshooting, adjustment & repair ground speed control lever adjustment the control levers can be adjusted in three ways. The alignment of the control levers, the placement of the levers (how close the ends are to one another) and the height of the levers can be adjusted. ...

Page 42

Not for reproduction 40 www.Ferrisindustries.Com troubleshooting, adjustment & repair neutral adjustment if the tractor “creeps” while the ground speed control levers are locked in neutral, then it may be necessary to adjust the control linkage. Note: perform this adjustment on a hard, level surface...

Page 43: Caution

Not for reproduction 41 troubleshooting, adjustment & repair parking brake adjustment 1. Disengage the pto, stop the engine, block the front wheels, remove the ignition key, and engage the parking brake. 2. Locate the upper brake spring (a, figure 37) through the opening under the fuel tanks. 3. Wit...

Page 44

Not for reproduction 42 www.Ferrisindustries.Com troubleshooting, adjustment & repair rear tire camber adjustment the rubber bushings in the cast a-arms may stretch and wear with time and adversely affect the angle that the rear tire runs against the ground. To evaluate if the rear tire camber shoul...

Page 45: Warning

Not for reproduction 43 troubleshooting, adjustment & repair warning use two hands when adjusting the shock springs. This will prevent the wrench from slipping while pressure is being applied. Suspension adjustment the shock assembly can be adjusted to vary the amount of pre-load applied to the spri...

Page 46

Not for reproduction 44 www.Ferrisindustries.Com troubleshooting, adjustment & repair deck lift rod timing adjustment 1. Park machine on a flat, level surface. Disengage the pto, stop the engine and engage the parking brake. Rear tires must be inflated to 18 psi (1,24 bar); front tires to 25 psi (1,...

Page 47: Caution

Not for reproduction 45 troubleshooting, adjustment & repair deck leveling adjustment note: before adjusting the deck level, the deck lift rod timing must be checked and/or adjusted. 1. Park machine on a flat, level surface. Disengage the pto, stop the engine and engage the parking brake. Rear tires...

Page 48: Warning

Not for reproduction 46 www.Ferrisindustries.Com troubleshooting, adjustment & repair belt removal & replacement mower drive belt removal & replacement 1. Park the tractor on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remov...

Page 49

Not for reproduction 47 troubleshooting, adjustment & repair 9. Reinstall the mower deck guards and tighten the 5/16” hardware to secure in place. 10. Run the mower under no-load condition for approximately 5 minutes to break in the belt. Check the mower belt tensioner spring length 1. Lower the mow...

Page 50: Warning

Not for reproduction 48 www.Ferrisindustries.Com troubleshooting, adjustment & repair figure 51. Clutch belt removal & replacement a. Idler arm b. Clutch belt idler spring c. Clutch anchor hardware d. Gearbox drive pulley e. Gearbox e c a b d clutch belt removal 1. Park the tractor on a smooth, leve...

Page 51: Warning

Not for reproduction 49 troubleshooting, adjustment & repair pump drive belt removal 1. Park the tractor on a smooth, level surface such as a concrete floor. Disengage the pto, engage the parking brake, turn off the engine, and remove the ignition key. 2. Remove the pto drive belt from the clutch (s...

Page 52

Not for reproduction 50 www.Ferrisindustries.Com troubleshooting, adjustment & repair top front figure 53. Gearbox oil level a. Fill plug b. Drain plug a b gearbox maintenance check gearbox oil level 1. Remove fill plug (a, figure 53) on gearbox. 2. Once plug is removed, oil should seep out of fill ...

Page 53

Not for reproduction 51 troubleshooting, adjustment & repair deck shut down module this unit is equipped with a deck shut down module that will automatically shut down the mower deck if the engine looses oil pressure or begins to overheat. What to do if the deck shuts down during operation: • immedi...

Page 54: Warning

Not for reproduction 52 www.Ferrisindustries.Com troubleshooting, adjustment & repair battery service checking battery voltage a voltmeter can be used to determine condition of battery. When engine is off, the voltmeter shows battery voltage, which should be 12 volts. When engine is running, the vol...

Page 55: Warning

Not for reproduction 53 troubleshooting, adjustment & repair a c b d d a e f this hook-up is for negative grounded vehicles. Callout description a to starter switch b starting vehicle battery c to ground d jumper cable e discharged vehicle battery f engine block make sure vehicles do not touch. Figu...

Page 56: Specifications

Not for reproduction 54 www.Ferrisindustries.Com specifications specifications note: specifications are correct at time of printing and are subject to change without notice. Engine: 33 gross hp¹ caterpillar make caterpillar model 3013e displacement 91.54 cu. In (1500 cc) electrical system 12 volt, 1...

Page 57

Not for reproduction notes.

Page 58

Not for reproduction briggs & stratton products warranty policy september 2012 limited warranty briggs & stratton warrants that, during the warranty period specified below, it will repair or replace, free of charge, any part that is defective in material or workmanship or both. Transportation charge...

Page 59

Not for reproduction california, u.S. Epa, and briggs & stratton corporation emissions control warranty statement your warranty rights and obligations september 2012 the california air resources board, u.S. Epa, and briggs & stratton (b&s) are pleased to explain the emissions control system warranty...

Page 60: Is5100Z Series

Not for reproduction is5100z series zero-turn riding mower operator’s manual.