- DL manuals

- Ferroli

- Water Heater

- Divatop ST F 24

- Instructions For Use, Installation And Maintenance

Ferroli Divatop ST F 24 Instructions For Use, Installation And Maintenance

Summary of Divatop ST F 24

Page 1

( co d . 3 5 4 0 e8 2 1 — 1 1 /2 0 0 8 (r ev . 0 0 ) divatop f 24 instructions for use, installation and maintenance instructions d'utilisation, d'installation et d'entretien ȅǻǾīǴǼȈ ȋȇdzȈǾȈ, ǼīȀǹȉDZȈȉǹȈǾȈ Ȁǹǿ ȈȊȃȉdzȇǾȈǾȈ kullanma, kurulum ve bak øm talimatlarø.

Page 2: Declaration Of Conformity

Divatop f 24 2 en b declaration of conformity manufacturer: ferroli s.P.A. Address: via ritonda 78/a 37047 san bonifacio vr italy declares that this unit complies with the following eu directives: • gas appliance directive 90/396 • efficiency directive 92/42 • low voltage directive 73/23 (amended by...

Page 3

Divatop f 24 3 ( cod. 3540e821 - 11/2008 (rev. 00) 1 operating instructions ............................................................................................................ 4 1.1 introduction....................................................................................................

Page 4: 1. Operating Instructions

Divatop f 24 4 en cod. 3540e821 - 11/2008 (rev. 00) 1. Operating instructions 1.1 introduction dear customer thank you for choosing a wall-mounted boiler featuring ferroliadvanced design, cutting-edge technology, high re- liability and quality construction. Please read this manual carefully since it...

Page 5

Divatop f 24 5 en cod. 3540e821 - 11/2008 (rev. 00) indicator during operation heating the call for heating (generated by the room thermostat or remote timer control) is indicated by the hot air flashing above the radiator (part 24 and 25 - fig. 1). The graduated heating marks (part 26 - fig. 1) lig...

Page 6

Divatop f 24 6 en cod. 3540e821 - 11/2008 (rev. 00) 1.3 turning on and off boiler not electrically powered fig. 5 - boiler not powered b the antifreeze system does not work when the power and/or gas to the unit are turned off. To avoid damage caused by freezing during long idle periods in winter, it...

Page 7

Divatop f 24 7 en cod. 3540e821 - 11/2008 (rev. 00) when the boiler is turned off, the electronic board is still powered. Domestic hot water and heating operation are disabled. The antifreeze system remains activated. To re-light the boiler, press the button (detail 9 fig. 1) again for 1 second. Fig...

Page 8

Divatop f 24 8 en cod. 3540e821 - 11/2008 (rev. 00) domestic hot water temperature adjustment operate the dhw buttons (details 1 and 2 - fig. 1) to vary the temperature from a minimum of 40°c to a max- imum of 55°c. Fig. 11 room temperature adjustment (with optional room thermostat) using the room t...

Page 9

Divatop f 24 9 en cod. 3540e821 - 11/2008 (rev. 00) compensation curve and curve offset press the button (detail 10 - fig. 1) once to display the actual compensation curve (fig. 12), which can be modified with the dhw buttons (details 1 and 2 - fig. 1). Adjust the required curve from 1 to 10 accordi...

Page 10

Divatop f 24 10 en cod. 3540e821 - 11/2008 (rev. 00) if the room temperature is lower lower than the required value, it is advisable to set a higher order curve and vice versa. Proceed by increasing or decreasing in steps of one and check the result in the room. Fig. 14 - compensation curves fig. 15...

Page 11

Divatop f 24 11 en cod. 3540e821 - 11/2008 (rev. 00) water system pressure adjustment the filling pressure with system cold, read on the boiler water gauge, must be approx. 1.0 bar. If the system pressure falls to values below minimum, the boiler card will activate fault f37 (fig. 16). Fig. 16 - low...

Page 12: 2. Installation

Divatop f 24 12 en cod. 3540e821 - 11/2008 (rev. 00) 2. Installation 2.1 general instructions boiler installation must only be performed by qualified personnel, in accordance with all the instructions given in this technical manual, the provisions of current law, the pre- scriptions of national and ...

Page 13

Divatop f 24 13 en cod. 3540e821 - 11/2008 (rev. 00) system water charcteristics in the presence of water harder than 25° fr (1°f = 10ppm caco 3 ), the use of suitably treated water is advisable in order to avoid possible scaling in the boiler. The treatment must not in any case reduce the hardness ...

Page 14

Divatop f 24 14 en cod. 3540e821 - 11/2008 (rev. 00) accessing the electrical terminal block after removing the front panel of the boiler (see fig. 28), the terminal block can be accessed for connecting the external probe (detail 3 fig. 19) of the room thermostat (detail 1 fig. 19) or the remote tim...

Page 15

Divatop f 24 15 en cod. 3540e821 - 11/2008 (rev. 00) connection with coaxial pipes fig. 21 - examples of connection with coaxial pipes ( = air / = fumes) for coaxial connection, fit the unit with one of the following starting accessories. For the wall hole dimensions refer to sec. 4.1. Any horizonta...

Page 16

Divatop f 24 16 en cod. 3540e821 - 11/2008 (rev. 00) connection with separate pipes fig. 23 - examples of connection with separate pipes ( = air / = fumes) for connection of the separate ducts, fit the unit with the following starting accessory: fig. 24 - starting accessories for separate ducts befo...

Page 17

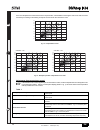

Divatop f 24 17 en cod. 3540e821 - 11/2008 (rev. 00) table. 4 - accessories losses in m eq air inlet fume exhaust vertical horizontal Ø 80 pipe 0.5 m m/f 1kwma38a 0.5 0.5 1.0 1 m m/f 1kwma83a 1.0 1.0 2.0 2 m m/f 1kwma06k 2.0 2.0 4.0 bend 45° f/f 1kwma01k 1.2 2.2 45° m/f 1kwma65a 1.2 2.2 90° f/f 1kwm...

Page 18

Divatop f 24 18 en cod. 3540e821 - 11/2008 (rev. 00) connection to collective flues fig. 25 - examples of connection to flues ( = air / = fumes) if you are then going to connect the divatop f 24 boiler to a collective flue or a single flue with natural draught, the flue must be expressly designed by...

Page 19

Divatop f 24 19 en cod. 3540e821 - 11/2008 (rev. 00) 3. Service and maintenance all adjustment, conversion, system start-up and maintenance operations described hereunder must be carried out solely by qualified personnel (with the professional technical requirements prescribed by current regulations...

Page 20

Divatop f 24 20 en cod. 3540e821 - 11/2008 (rev. 00) adjustment of pressure at burner since this unit has flame modulation, there are two fixed pressure values: minimum and maximum, which must be those given in the technical data table according to the type of gas. • connect a suitable pressure gaug...

Page 21

Divatop f 24 21 en cod. 3540e821 - 11/2008 (rev. 00) heating power adjustment to adjust the heating power, set the boiler on test operation (see sec. 3.1). Press the heating buttons (part 3 and 4 - fig. 1) to increase or decrease the power (minimum = 00 - maximum = 100). Press the reset button withi...

Page 22

Divatop f 24 22 en cod. 3540e821 - 11/2008 (rev. 00) 3.3 maintenance periodical check to ensure proper operation of the unit over time, have qualified personnel carry out a yearly check, providing for the following: • the control and safety devices (gas valve, flowmeter, thermostats, etc.) must func...

Page 23

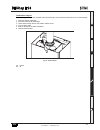

Divatop f 24 23 en cod. 3540e821 - 11/2008 (rev. 00) combustion analysis two sampling points have been included at the top of the boiler, one for fumes and the other for air. To take samples: 1. Open the air/fume outlet plug; 2. Insert the probes as far as the stop; 3. Check that the safety valve is...

Page 24

Divatop f 24 24 en cod. 3540e821 - 11/2008 (rev. 00) 3.4 troubleshooting diagnostics the boiler is equipped with an advanced self-diagnosis system. In case of a boiler fault, the display will flash together with the fault symbol (detail 22 - fig. 1) indicating the fault code. There are faults that c...

Page 25

Divatop f 24 25 en cod. 3540e821 - 11/2008 (rev. 00) f40 incorrect system water pres- sure pressure too high check the system check the safety valve check the expansion tank a41 sensor positioning delivery sensor disconnected from the pipe check the correct positioning and operation of the heating s...

Page 26

Divatop f 24 26 en cod. 3540e821 - 11/2008 (rev. 00) 4. Technical data and characteristics 4.1 dimensions and connections fig. 30 - dimensions and connections 1 = heating system delivery 2 = tap water outlet 3 = gas inlet 4 = tap water inlet 5 = heating system return 6 = safety valve drain 266 330 4...

Page 27

Divatop f 24 27 en cod. 3540e821 - 11/2008 (rev. 00) 4.2 general view and main components fig. 31 - general view 5 sealed chamber 7 gas inlet 8 domestic hot water outlet 9 cold water inlet 10 system delivery 11 system return 14 safety valve 16 modulating fan 19 combustion chamber 20 burner assembly ...

Page 28

Divatop f 24 28 en cod. 3540e821 - 11/2008 (rev. 00) 4.3 plumbing circuit fig. 32 - plumbing circuit 5 sealed chamber 7 gas inlet 8 domestic hot water outlet 9 cold water inlet 10 system delivery 11 system return 14 safety valve 16 modulating fan 20 burner assembly 27 copper exchanger for heating an...

Page 29

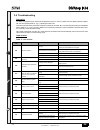

Divatop f 24 29 en cod. 3540e821 - 11/2008 (rev. 00) 4.4 technical data table the column on the right gives the abbreviation used on the technical data plate. Data unit value max. Heating capacity kw 25.8 (q) min. Heating capacity kw 8.3 (q) max. Heat output in heating kw 24.0 (p) min. Heat output i...

Page 30

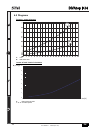

Divatop f 24 30 en cod. 3540e821 - 11/2008 (rev. 00) 4.5 diagrams pressure - power diagrams a lpg b natural gas losses of load / head of circulators a boiler losses of head 1 - 2 - 3 circulator speed b a 0 1 2 3 4 5 6 7 0 500 1.000 1.500 2.000 q [l/h] h [m h 2 o] a 3 2 1.

Page 31

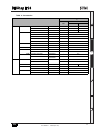

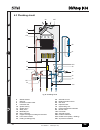

Divatop f 24 31 en cod. 3540e821 - 11/2008 (rev. 00) 4.6 wiring diagram fig. 33 - wiring diagram a important: before connecting the room thermostat or the remote timer control, remove the jumper on the terminal block. Key 16 modulating fan 32 heating circulating pump 42 dhw temperature sensor 44 gas...