- DL manuals

- Ferroli

- Boiler

- DOMINA N 80 DGT

- Installation, service and user manual

Ferroli DOMINA N 80 DGT Installation, service and user manual

Appr

. nr

. B97.09 A - CE 0063 A

T

4967

DOMINA N 80 DGT

INSTALLATION, SERVICE AND USER

INSTRUCTIONS

G.C. NO: 47-267-23

Copper Wall-Mounted Combination,

Gas Fired Boiler for Central Heating

and Domestic Hot Water Production,

Fan Assisted, Room Sealed Compartment,

Electronic Flame Ignition and Control

3543832/1 - 07/2001

Summary of DOMINA N 80 DGT

Page 1

Appr . Nr . B97.09 a - ce 0063 a t 4967 domina n 80 dgt installation, service and user instructions g.C. No: 47-267-23 copper wall-mounted combination, gas fired boiler for central heating and domestic hot water production, fan assisted, room sealed compartment, electronic flame ignition and control...

Page 2

Domina n 80 dgt 2 ce mark ce mark documents that the ferroli gas appliances comply with the requirement contained in european directives applicable to them. In particular, the appliances comply with the following cee directives and the technical specifi cations provided from them: • gas appliances d...

Page 3

Domina n 80 dgt 3 1. Description 1.01 introduction the domina n 80 dgt is defi ned as a “room sealed” combination boiler, all air required for combustion is taken from outside the room in which it is installed. It is a new high performance gas fi red heat generator for central heating and domestic h...

Page 4

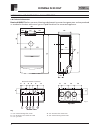

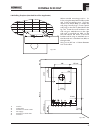

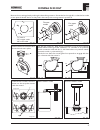

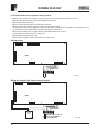

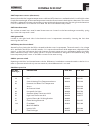

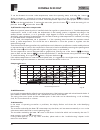

Domina n 80 dgt 4 fig. 1 top view distance between connections 178 190 270 272 760 249 98 60 95 36 60 95 bottom view 460 100 727 114 160 100 25 150 25 84 80 80 120 70 120 150 110 5 3 4 2 1 2. Technical and dimensional characteristics 2.01 technical information domina n 80 dgt boilers are central hea...

Page 5

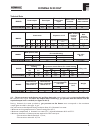

Domina n 80 dgt 5 n.B. - the gas pressures at the burner and gas fl ows during the central heating phase given in the table refer to nominal boiler output. To reduce this output (where necessary), gas pressure must be reduced until the required output level is reached (see fi gures 4 and 5). During ...

Page 6

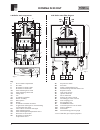

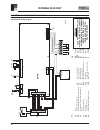

Domina n 80 dgt 6 2.03 boiler water fl ow diagram out i min air in air in flue out c.H. Out d.H.W. Out gas in d.H.W. In c.H. In fig. 3 2.02 boiler main components key 5 room sealed compartment 7 gas inlet 8 domestic hot water outlet 9 domestic hot water inlet 10 central heating fl ow outlet 11 centr...

Page 7

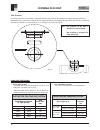

Domina n 80 dgt 7 2.04 central heating adjustment (not normally required) to adjust boiler heat input (thus also regulating heat output to the central heating water) simply adjust the main burner via the electronic control board (fi g. 4 and 5 and see paragraph 5.04 page 29). The diagrams indicate t...

Page 8

Domina n 80 dgt 8 fig. 8 pressure loss diagram sizing of additional ex pansion vessels: deduct from the value given in the table the 8 litre vessel supplied. Note: 1. Fill c.H. Installation to min. 1.5 bar. 2. Expansion vessel must be fi tted to central heating return pipe. 3. The standard 7 litre e...

Page 9

Domina n 80 dgt 9 3. Installation details gas safety (installation & use) regulations: 1996 in the interest of safety, it is the law that all gas appliances are installed by a competent person in accordance with the above regulations, building regulations/building standards scotland, codes of practi...

Page 10

Domina n 80 dgt 10 note: a bypass that will ensure a minimum fl ow rate of 6 l/min. At all all time must be fi tted as far as possible from the boiler if thermostatic radiator valves are fi tted thoughout. Fig. 9 central heating detailed recommendations are given in bs6798, bs5449, bs6700 and cp342 ...

Page 11

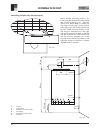

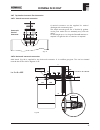

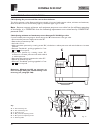

Domina n 80 dgt 11 clearances: * 600mm minimum clearance for servicing access top clearance only applies to 100Ø concentric fl ue system 460 5 min. 5 min. 100 min. 900 200 min. 272 50 mm 600* min. 760 fig. 11 terminal position fig. 12 p d, e q q l b c a g f l j h h k n n m m q directly below an open...

Page 12

Domina n 80 dgt 12 3.01 boiler mounting plate 149 178 131 fig. 13.

Page 13

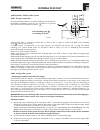

Domina n 80 dgt 13 3.02 drilling template (standard rear flue application) select suitable mounting position for boiler, using the template mark fl ue outlet and boiler mounting points. Drill two 10mm holes 90mm deep to accept the wall plugs, fi t wall plugs. Fit two special wall plugs on the wall a...

Page 14

Domina n 80 dgt 14 3.03 drilling template (top flue application) select suitable mounting position for boiler, using the template mark fl ue outlet and boiler mounting points. Drill two 10mm holes 90mm deep to accept the wall plugs, fi t wall plugs. Fit two special wall plugs on the wall as describe...

Page 15

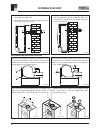

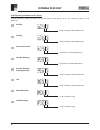

Domina n 80 dgt 15 3.04 back fl ue outlet (diagram 1-9) fig. 16a fig. 16b fig. 16c 1. Core drill 127mm hole (5"). 2. Push through the outer fl ue. 3. Gently pull back until wall seal is fl ush with the wall. Fig. 16d 4. Place wall plate on outer fl ue ensuring it is level. Mark and drill four holes,...

Page 16

Domina n 80 dgt 16 fig. 17c fig. 17d fig. 17e remove fan by pulling off electrical connections. Pull off air pressure switch tubes from the air pressure switch remove 2 screws b. Rotate the fan upward to disengage it from the securing pin a. Fig. 17a fig. 17b 3.05 domina top outlet fl ue conversion ...

Page 17

Domina n 80 dgt 17 fig. 17f fig. 17g fig. 17h remove fan mounting plate by undoing the three fi xing screws c. Rotate the fan through 90° so that the fan nozzle points upward. Secure the fan to the plate in the new position using screws in position d. C d c d d - c common for rear outlet for upper o...

Page 18

Domina n 80 dgt 18 3.06 restrictor for boiler operation, the restrictor supplied with the unit must be mounted following the instructions below. Determine the correct size of fl ue restrictor required. Before inserting the fl ue gas duct in the boiler, check that the restrictor fi tted is correct an...

Page 19

Domina n 80 dgt 19 3.07 top outlet concentric flue connection 3.07.1 vertical concentric connection fig. 20 a vertical connector can be supplied for vertical discharge with concentric pipes. The simple mounting and use of double lip gaskets at the joints makes this an extremely easy and safe option....

Page 20

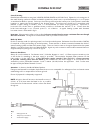

Domina n 80 dgt 20 fig. 21 notes on concentric horizontal installation to locate the centre of the hole for passing the pipes through the wall, refer to fi g. 15. Bear in mind that the two concentric pipes must slope downwards away from the boiler at a rate of about 3 mm/m to avoid rainwater enterin...

Page 21

Domina n 80 dgt 21 fig. 23 Ø80 Ø80 air flue 1 2 3.08 top outlet: two pipe flue system 3.08.1 two pipe connection two separate ducts Ø80 for air intake and fl ue gas discharge can be directly connected to the boiler. For converson to top outlet (see 3.05) mount the separate outlet kit 1 insert blanki...

Page 22

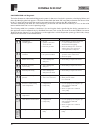

Domina n 80 dgt 22 air flue v ertical horizontal v ertical horizontal description male-female flue Ø80 female-female bend 45 ° Ø80 female-female bend 90 ° Ø80 male-female bend 90 ° Ø80 pipe fitting m/m/f Ø80 with inspecting plug+trap for condensate drainage system description air terminal of inlet p...

Page 23

Domina n 80 dgt 23 for further accessories please refer to: "flue system manual for room sealed boiler" attention: resistance of fl ue restrictor (if req.) is included (see table on page 18) remove the fl ue restrictor. The fl ue and air pipes must have an inclination downward equal to 3% from boile...

Page 24

Domina n 80 dgt 24 3.09 connecting the central heating and domestic hot water circuits connect to the relevant connections as indicated in fi g. 1. Connect the pressure relief valve discharge pipe (15mm) to the outside of the building, where possible over a drain. The discharge must be such that it ...

Page 25

Domina n 80 dgt 25 note: if the power supply cable has to be replaced, use “0.75mm (24/0.20) heat resisting cable only to bs6500 with a maximum external diameter of 8 mm. Note - when connecting a room thermostat or external timer, do not link the power supply of these devices to the switching contac...

Page 26

Domina n 80 dgt 26 fig. 29 existing wiring - remove outer case by removing two securing screws from the rear bottom corners and lift off. - remove screw securing facia panel and swing facia panel down. - remove rear cover from facia. - remove clock blanking plate from the boiler facia panel. - mount...

Page 27

Domina n 80 dgt 27 4. Commissioning and testing 4.01 checks to be carried out before starting up for the fi rst time when starting the boiler up for the fi rst time check: • that the gate valves between the boiler and central heating systems are open; • that the central heating system is fi lled and...

Page 28

Domina n 80 dgt 28 in out c f e b a d fig. 31 5. Adjustment and gas conversion 5.01 adjusting the pressure and fl ow rate to the main burner this boiler operates on the fl ame modulation principle. It has two fi xed pressure values, minimum and maximum, which must be as shown in the table (pages 5),...

Page 29

Domina n 80 dgt 29 5.03 adjusting room temperature (when a room thermostat is fi tted) room temperature is controlled by positioning the room thermostat knob to the required value. The thermostat automatically controls the boiler, temporarily interrupting the electrical supply subject to the room he...

Page 30

Domina n 80 dgt 30 6. Maintenance and cleaning the following operations must be carried out by corgi registered engineers only. 6.01 annual servicing the following should be checked at least once a year: • water pressure in the central heating system when cold should be about 1 bar. If this is not t...

Page 31

Domina n 80 dgt 31 flue air fig. 33 21. Refi t combustion chamber cover, secure with screws. 22. Examine seals on room sealed cover refi t cover and secure with screws. 23. Turn on gas and electricity. 24. Fire boiler and check all gas joints for soundess. 25. Check fl ame picture and all controls f...

Page 32

Domina n 80 dgt 32 7. Replacement of parts 7.01 initial procedure a) the boiler is cold, electricity supply is isolated, and the gas supply is turned off at the inlet of the boiler b) for replacement of parts where water connections are broken, it will be necessary to isolate and drain either or bot...

Page 33

Domina n 80 dgt 33 fig. 36 7.05 gas valve (fi g. 36) • isolate gas and electricity supplies • remove outer case (two screws bottom rear corners) • remove the two securing screws and lower control panel • disconnect electrical connections from valve ("a") • disconnect plastic tube "c" • loosen the co...

Page 34

Domina n 80 dgt 34 7.08 removal of burner (fi g. 39) • isolate gas and electricity supplies • remove outer case (two screws bottom rear corners) • remove room sealed cover • disconnect ignition and fl ame rectifi cation leads "a" • undo gas rail union "b" • undo two screws securing the burner assemb...

Page 35

Domina n 80 dgt 35 7.12 spark or fl ame detect electrode (fi g. 41) • isolate gas and electricity supply • remove outer case (two screws bottom rear corners) • open room sealed compartment and combustion chamber • identify electrode from fi g. 41 • unplug electrical connection "a" from sensing elect...

Page 36

Domina n 80 dgt 36 7.14 pump (fi g. 43) replacement of pump head • isolate electricity and fl ow and return pipes • remove casing (two screws bottom rear corners). • remove the two securing screws and lower control panel • release pressure from boiler via pressure relief valve • unplug the pump lead...

Page 37

Domina n 80 dgt 37 8. Fault finding before beginning any fault fi nding ensure that gas, water and electricity are available. 8.01 operating sequence with the power established the boiler is in its stand-by mode i. E. Power on but no demand. The operational sequence for c.H. And d.H.W. Are as follow...

Page 38

Domina n 80 dgt 38 fault possible cause microprocessor faulty • microprocessor operation faulty failed burner assembly ignition • no gas • ignition or detection electrode fault • defective gas valve insufficient water system pressure • system empty • sensor not connected excessive central heating ou...

Page 39

Domina n 80 dgt 39 8.04 temperature sensors (thermistors) identical, but individual, negative temperature co-effi cient (ntc) thermistors are fi tted in the c.H. And d.H.W. Outlets from the heat exchanger. As the water temperature increases the resistance in the thermistor decreases. This causes the...

Page 40

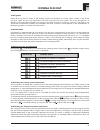

Domina n 80 dgt 40 key 16 fan 32 ce n tr a l he ati n g pump 3 4 ce n tr al he ati n g fl ow temper atur e s e n so r 4 2 d o me sti c h o t w ater fl ow temper atur e se n so r 4 3 a ir pr e ss ur e sw it ch 44 g a s va lv e 4 9 s a fet y therm os ta t 50 ce n tr al he ati n g limit therm os ta t f...

Page 41

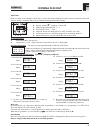

Domina n 80 dgt 41 fig. 45 10. User instructions the operation of the appliance is mostly automatic. The heat rate for the heating function is regulated automatically by the control system according to the characteristics of the internal and external environment (with optional external probe install...

Page 42

Domina n 80 dgt 42 10.01 operating indications on the display during operation, without pressint any of the buttons the display shows the operating status of the appliance: central heating outlet temperature heating central heating outlet temperature standby following domestic hot water temperature ...

Page 43

Domina n 80 dgt 43 10.02 ignition check than any shut-off valves in the heating system and domestic hot water circuit outside of the boiler are open. Open the gas cock upstream from boiler and press the main switch. The boiler will perform an self-test cycle lasting approximately one minute, at the ...

Page 44

Domina n 80 dgt 44 20 30 40 50 60 70 80 90 20 10 0 -10 -20 external temperature ° c c.H. Outlet temperatur e c ° 1 2 3 4 5 6 7 8 9 10 to set the domestic hot water outlet temperature, access the operating menu, and using the button display parameter 2 – domestic hot water temperature. On pressing on...

Page 45

Domina n 80 dgt 45 time clock a 24 hour time clock is fi tted to the boiler to control the central heating, this will come into operation when the selector switch is turned to the position marked “heating timed and hot water”. Auto a b e r d p f to set time of day 1. Slide switch (a) to left positio...

Page 48

Phone numbers: installer service engineer because of our constant endeavour for improvement details may vary slightly from those quoted in these instructions. Lichfi eld road, branston industrial estate, burton upon trent, staffordshire de14 3hd tel. 08707 282 885 - fax 08707 282 886 all specificati...