- DL manuals

- Ferroli

- Heat Pump

- HSW 11.1

- Installation And Operation Manual

Ferroli HSW 11.1 Installation And Operation Manual

Summary of HSW 11.1

Page 1

Hsw water - water and brine - water heat pumps for indoor installation r410a installation and operation manual.

Page 2

Dear customer, thank you for having purchased a ferroli product. It is the result of many years of experiences and of particular research studies and has been made with top quality materials and advanced technologies. The ce mark guaran- tees that the products satisfy all the applicable european dir...

Page 3

3 table of contents general features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 general instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

General features this manual and the wiring diagram supplied with the unit must be kept in a dry place for possible future consultations . The manual provides information on installation and correct use and maintenance of the unit. Before carrying out installation, please carefully read all the info...

Page 5

5 unit description general features unit identification code this series of water-water heat pumps satisfies the heating, cooling and domestic hot water production requirements of residential plants of small and medium size. All the units are suitable for indoor installation and can be applied to fa...

Page 6

General features description of components external structure. Basement, lateral panels and frontal panel, are completely thermally and acoustically insulated in order to minimize thermal losses and noise emissions in the surroundings. Accessibility to internal parts is possible remo- ving the front...

Page 7

7 general features control system the microprocessor controller is able to manage not only the unit itself but also all that components of the plant which allow to realize a complete system. The main functions of the control system are : - room temperature control according to the outdoor tempe- rat...

Page 8

General features options source side flow rate management pump allows the circulation of the water on the source side. 2 way valve modulates the water flow rate on the source side when the water circulation is assured by an external pump. Domestic hot water production 3 way valve allow to divert the...

Page 9

9 general features fs fs 5 6 2 1 4 3 fs fs 5 6 2 1 4 3 fs fs fs 5 6 2 1 4 3 option “domestic hot water production” 3 way valve 3 way valve with primary heat exchanger 3 way valve with secondary heat exchanger 4 3 4 3 4 3 in this configuration the heat pump can be coupled to a domestic hot water tank...

Page 10

General features accessories remote thermostat allows operating mode selection and set point adjustment. The on board temperature sensor can be used in order to realize a climatic control. Remote control (wired or wireless) replicates all the control and visualization functionalities of the controll...

Page 11

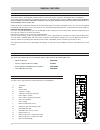

11 technical data and performances technical data frame 1 model 3.1 5.1 7.1 9.1 11.1 u.M. Power supply 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 v-ph-hz refrigerant type r410a r410a r410a r410a r410a - compressor type rotary rotary rotary rotary rotary - quantity 1 1 1 1 1 n° ...

Page 12

Technical data and performances ih heating w10w35 ( source : water in 10°c out 7°c / plant : water in 30°c out 35°c ) heating capacity 3,37 5,11 6,85 9,31 11,8 kw power input 0,59 0,90 1,24 1,69 2,18 kw cop 5,71 5,68 5,52 5,51 5,41 - water flow rate plant side 578 874 1171 1591 2023 l/h available st...

Page 13

13 technical data and performances ih heating w10w45 ( source : water in 10°c out 7°c / plant : water in 40°c out 45°c ) heating capacity 3,10 4,70 6,30 8,56 10,9 kw power input 0,71 1,08 1,48 2,01 2,58 kw cop 4,37 4,35 4,26 4,26 4,22 - water flow rate plant side 529 801 1072 1458 1861 l/h available...

Page 14

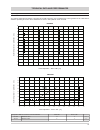

The graphs allow to get the corrective factors to be applied to the nominal performances in order to obtain the real perfor- mances in the selected operating conditions. The reference nominal conditions are : - water-water units : w10w35 (source : water in 10°c out 7°c / plant : water in 30°c out 35...

Page 15

15 technical data and performances cooling performances 0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8 -10 -5 0 5 10 15 20 25 30 35 40 45 cooling capacity ( brine and water ) inlet temperature - source side [°c] 0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8 -10 -5 0 5 10 1...

Page 16

Technical data and performances plant side hydraulic performances 0 10 20 30 40 50 60 70 80 0 500 1000 1500 2000 2500 3000 3500 flow rate [ l/h ] 3.1 7.1 9.1 5.1 11.1 the graphs are referred to units operating with water at the temperature of 10°c (density 1000 kg/m 3 ). Available static head - unit...

Page 17

17 0 5 10 15 20 25 30 35 40 0 500 1000 1500 2000 2500 3000 3500 technical data and performances source side hydraulic performances flow rate [ l/h ] pressure drop s [ kpa ] 7.1 9.1 5.1 11.1 3.1 0 10 20 30 40 50 60 70 80 0 500 1000 1500 2000 2500 3000 3500 flow rate [ l/h ] available st atic head [ k...

Page 18

Technical data and performances domestic hot water side hydraulic performances the graphs are referred to units operating with water at the temperature of 10°c (density 1000 kg/m 3 ). 0 10 20 30 40 50 60 70 80 0 500 1000 1500 2000 2500 3000 3500 flow rate [ l/h ] a b a = unit with option “domestic h...

Page 19

19 -5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50 technical data and performances the graphs reported below show the operating area inside which the correct working of the unit is guaranteed. The dotted lines show the operating area when brine solutions in the s...

Page 20

Technical data and performances electrical data unit power supply 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 v-ph-hz f.L.A. Maximum total current input 5,9 7,7 10,1 13,3 17,0 a f.L.I. Maximum total power input 1,3 1,7 2,2 2,9 3,7 kw m.I.C. Maximum total start current 36 45 52 8...

Page 21

21 technical data and performances weights unit unit without options 130 134 136 145 148 kg options source side flow rate management pump 3 3 3 3 3 kg 2 way valve 2 2 2 2 2 kg domestic hot water production 3 way valve 3 3 3 3 3 kg 3 way valve with pri- mary heat exchanger 9 9 9 9 9 kg 3 way valve wi...

Page 22

22 technical data and performances overall dimensions rispect the free area around the unit as shown in figure in order to guarantee a good accessibility and facilitate maintenance and control operations. 8 5 2 8 5 53 600 600 90 80 80 80 90 90 90 a b a 600 mm b 300 mm minimum operating area a b 600 ...

Page 23

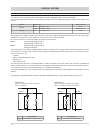

Connections 23 hydraulic connections to design properly the hydraulic system respect the local safety regulations in force. It is always necessary to guarantee an appropriate water flow through the plate heat exchangers of the unit even if on both the hydraulic circuits (source side and plant side) ...

Page 24

Connections 24 electrical connections the electrical wirings must be carried out by qualified person- nel according to the regulations in force at the installation time in the country of installation. Before starting any work on the electrical circuit make sure that the unit power supply line is dis...

Page 25

Receiving and positioning 25 receiving positioning check on receiving as soon as the unit is received verify accurately the corre- spondance of the load to what was ordered to make sure that all the material has been delivered. Check carefully that the load has not been damaged. In case of goods wit...

Page 26

Start up 26 start up the following operations must be carried out only by properly trained personnel. To make the contractual warranty effective, start up must be carried out by authorized service centres. Before calling the service centre it is advisable to make sure that all the installation steps...

Page 27

Control system 27 control system configuration the control system can be configured in different ways in order to adapt itself to the user needs and to the kind of plant mana- ged by the heat pump. The simpler configuration consists of unit controller (a), outdoor air temperature sensor (b) and user...

Page 28

Control system 28 heating and cooling circuits the controller of the heat pump is able to manage two circuits in heating and one circuit in cooling. The management of further heating or cooling circuits, possible by means of additional expansion modules, is not treated in this manual. Function circu...

Page 29

Control system 29 remote control 1 remote thermostat 1 remote control 2 remote thermostat 2 zone 1 zone 2 hc1/cc1 hcp remote control 1 remote thermostat 1 zone 1 zone 2 hc1/cc1 hcp remote control 1 zone 1 hc1/cc1 hcp remote control 1 remote thermostat 1 zone 1 zone 2 hc1/cc1 hcp configuration 3 zone...

Page 30

Control system 30 control system devices installation they should be located in the main room of the zone they manage taking into account the following criteria : - the place of installation should be chosen so that the sensor can measure the room temperature as accurately as possible without being ...

Page 31

Control system the device must be installed outside the building. The sensor is connected to the controller of the unit or to the wireless adaptor through a two wire cable ( the wires are interchangeable ). Outdoor air sensor the device must be installed inside the building. The device is powered by...

Page 32

Control system 32 the wireless devices should be located in such a way that the transmission is as interference free as possible. The following criteria must be observed : - do not place the devices in the vicinity of electrical cables, strong magnetic fields or equipments as pc, televisions, micro ...

Page 33

Control system control system using the user interface, placed on the frontal panel, allows the complete control of the system permitting to visualize and modify all the operating parameters of the unit. The remote control (wired or wireless) replicates all the func- tions available through the user...

Page 34: Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Control system 34 xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx heating : comfort set point heating : reduced set point heating : frost protection set point cooling : comfort set point wait change batteries holiday function active reference to heating circuit al...

Page 35

Control system knob allows to modify the comfort set point (in heating or in cooling according to the active operating mode). Press the ok button to confirm. Allows moreover to select the different parameters inside the menu and to select the values of each parameter. Info button pressing the info b...

Page 36

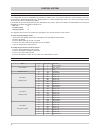

Control system 36 control system programming the settings that can not be modified directly through the buttons of the user interface and of the remote controls are accessi- ble through the programming parameters, grouped inside the various programming menus. The menus concerning functions which are...

Page 37

Control system menu level parameter function time table 5 cooling circuit 1 e 600 preselection e 601 phase 1 on e 602 phase 1 off e 603 phase 2 on e 604 phase 2 off e 605 phase 3 on e 606 phase 3 off e 616 default values holidays program heating circuit 1 e 642 start e 643 end e 648 operating level ...

Page 38

Control system 38 remote thermostat programming the configuration parameters of the remote ther- mostat must be set on the device itself. A long press (longer than 3 seconds) on the occupancy button allows to enter the programming menu from which is possible to modify the parameters listed in the ta...

Page 39

39 control system operating mode selection for heating and cooling circuits heating circuit 1 : through the heating button heating circuit p : through the heating button (if the management of the heating circuit 1 and p is in common) or through the parameter 1300 (if the management is independent) c...

Page 40

40 control system inputs and outputs id use description features available for the user input s b9 b9 outdoor air temperature temperature sensor ntc 1k b91 b91 source heat exchanger inlet temperature temperature sensor ntc 10k b92 b92 source heat exchanger outlet temperature temperature sensor ntc 1...

Page 41

Control system 41 alarms activation and reset the controller is able to perform a complete diagnosis of the unit detecting all the operating faults and notifying different alarms. The activation of an alarm implies : - involved consumers locked - alarm icon shown on the display - event recorded in t...

Page 42

Control system power supply 230 vac (+10% / -15%) 50 hz / 60 hz max 11 va safety class (en 60730) ii degree of protection (en 60529) ip 00 operating room temperature (not condensing) -20°c ... 50°c storing room temperature -20°c ... 65°c controller technical data controller power supply bsb bus comm...

Page 43

Control system temperature [°c] resistance [kΩ] resistance [kΩ] -20 7,578 96,360 -15 5,861 75,502 -10 4,574 55,047 -5 3,600 42,158 0 2,857 32,555 5 2,284 25,339 10 1,840 19,873 15 1,492 15,699 20 1,218 12,488 25 1,000 10,000 30 0,827 8,059 35 0,687 6,535 40 0,575 5,330 45 0,483 4,372 50 0,407 3,605 ...

Page 44

Maintenance maintenance important before carrying out maintenance or cleaning operations make sure the unit power supply is dis- connected. Any ordinary or extraordinary maintenance operation must be carried out by specia- lized and authorized personnel in order to ensure compliance with the safety ...

Page 45

Safety and pollution refrigerant safety card 1 supplier company and product identification card no frig 8 product r-410a supplier company identification rivoira spa 2 composition / informations on ingredients substance / prepared prepared components / impurities contains the following components : d...

Page 46

Safety and pollution 8 control of exposure / personal protection personal protection ensure adequate ventilation, especially in closed areas. Control parameters difluoromethane (r32): recommended exposure limits: ael (8h and 12h twa) = 1000 ml/m3 pentafluoroethane (r125): recommended exposure limits...

Page 47

47.

Page 48

3qe24781 ferroli spa ¬ 37047 san bonifacio (verona) italy ¬ via ritonda 78/a tel. +39.045.6139411 ¬ fax +39.045.6100933 ¬ www.Ferroli.It.