- DL manuals

- Ferroli

- Heat Pump

- HXA

- Installation And Operation Manual

Ferroli HXA Installation And Operation Manual

Summary of HXA

Page 1

Hxa air - water heat pumps for outdoor installation installation and operation manual i migliori gradi centigradi r e fr ig er an t g a s e c o- friend l y .0 55.

Page 2

2 the manufacturer declines all the responsabilities regarding inaccuracies contained in this manual, if due to printing or typing mi- stakes. The manufacturer reserves the right to apply changes and improvements to the products at any time without notice. Dear customer, thank you for having purchas...

Page 3

3 table of contents general features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

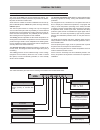

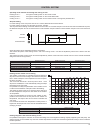

4 general features general instructions declaration of conformity unit dataplate the figure shows the fields reported on the unit dataplate : this manual and the wiring diagram supplied with the unit must be kept in a dry place for possible future consultation. The manual provides information on ins...

Page 5

5 ip 7 .1 vb ab 0 m 1 general features unit description this series of air-water heat pumps satisfies the heating, coo- ling and domestic hot water production requirements of residen- tial plants of small and medium size. All the units are suitable for outdoor installation and can be ap- plied to fa...

Page 6

6 general features external structure. Basement, supporting structure and lateral panels are made of galvanized and painted sheet-steel (colour ral 7035) to guarantee good resistance to atmospheric agents. Accessibility to internal parts is possible removing the frontal panel. For extraordinary mant...

Page 7

7 general features the microprocessor controller is able to manage not only the unit itself but also all that components of the plant which allow to realize a complete system. The main functions of the control system are : - room temperature control according to the outdoor temperatu- re (climatic c...

Page 8

8 general features options option “plant side flow rate management” pump (standard or high head or high efficiency) reversible heat pump (ip) without options option “integrative electrical heaters” plant side flow rate management standard pump allows the circulation of the water on the plant side. H...

Page 9

9 general features accessories rubber vibration dampers allow to reduce the transmission to the unit support plane of the mechanical vibrations generated by the compressor and by the fans in their normal operating mode. Coil protection grille protects the external surface of the finned coil. Remote ...

Page 10

10 technical data and performances technical data refrigerant type r410a - compressor type rotary scroll - quantity 1 n° power steps 0 - 100 % oil charge 0,35 0,50 1,13 1,13 1,20 1,80 1,80 1,80 kg plant side heat exchanger type stainless steel brazed plates - quantity 1 n° water volume 0.53 0,53 0.5...

Page 11

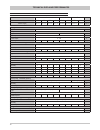

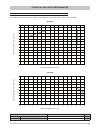

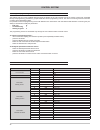

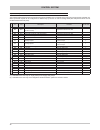

11 technical data and performances nominal performances - radiant plants nominal performances - standard plants data declared according to en 14511 . The values are referred to units without options or accessories. Data declared according to en 14511 . The values are referred to units without option...

Page 12

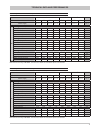

12 technical data and performances heating performances the graphs allow to get the corrective factors to be applied to the nominal performances in order to obtain the real performances in the selected operating conditions. The reference nominal condition is : a7w35 source : air in 7°c d.B. 6°c w.B....

Page 13

13 technical data and performances cooling performances the graphs allow to get the corrective factors to be applied to the nominal performances in order to obtain the real performances in the selected operating conditions. The reference nominal condition is : a35w7 source : air in 35°c d.B. Plant :...

Page 14

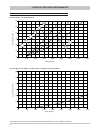

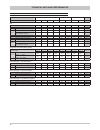

14 technical data and performances plant side hydraulic performances the graphs are referred to units operating with water at the temperature of 10°c (density 1000 kg/m 3 ). Flow rate [ l/h ] flow rate [ l/h ] pressure drops - unit without options pressure drops to be added - unit with option “integ...

Page 15

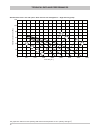

15 technical data and performances flow rate [ l/h ] flow rate [ l/h ] the graphs are referred to units operating with water at the temperature of 10°c (density 1000 kg/m 3 ). Available static head - unit with option “plant side flow rate management” : “standard pump” available static head - unit wi...

Page 16

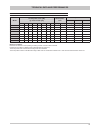

16 technical data and performances available static head - unit with option “plant side flow rate management” : “high efficiency pump” flow rate [ l/h ] available static head [ kpa ] the graphs are referred to units operating with water at the temperature of 10°c (density 1000 kg/m 3 ). 0 20 40 60 8...

Page 17

17 technical data and performances operating limits temperature difference between unit inlet and outlet plant side d t max maximum value 11 °c d t min minimum value 3 °c heating inlet air temperature d.B. [°c] outlet temperature - plant side [°c] the graphs reported below show the operating area in...

Page 18

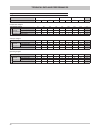

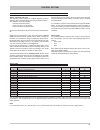

18 technical data and performances electrical data unit plant side pump - standard (option) plant side pump - high head (option) plant side pump - high efficiency (option) integrative electrical heaters (option) power supply 230-1-50 230-1-50 230-1-50 230-1-50 230-1-50 230-1-50 - - v-ph-hz f.L.A. Ma...

Page 19

19 technical data and performances noise levels reference conditions performances referred to units operating in heating mode at nominal conditions a7w35. Unit placed in free field on reflecting surface (directional factor equal to 2). The sound power level is measured according to iso 3744 standard...

Page 20

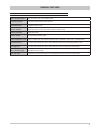

20 technical data and performances weights unit without options 76 80 88 95 107 125 141 150 kg options plant side flow rate management standard pump 6 6 6 6 6 6 13 13 kg high head pump 8 8 8 8 13 13 14 14 kg high efficiency pump 6 6 6 6 7 7 7 7 kg integrative electrical heaters 4 4 4 4 4 4 4 4 kg un...

Page 21

21 technical data and performances overall dimensions 1 plant return 2 plant return with option "plant side water flow management" : "standard pump" or "high head pump" 3 plant flow 4 plant flow with option "integrative electrical heaters" frame 1 frame 2 frame 3 pompa standard pompa alta prevalenza...

Page 22

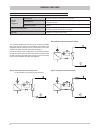

22 connections hydraulic connections to design properly the hydraulic system respect the local safety regulations in force. It is always necessary to guarantee an appropriate water flow through the plate heat exchanger of the unit even if is installed, as standard, a differential pressure switch tha...

Page 23

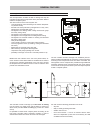

23 connections electrical connections the electrical wirings must be carried out by qualified personnel according to the regulations in force at the installation time in the country of installation. Before starting any work on the electrical circuit make sure that the unit power supply line is disco...

Page 24

24 receiving and positioning receiving check on receiving as soon as the unit is received verify accurately the correspon- dance of the load to what was ordered to make sure that all the material has been delivered. Check carefully that the load has not been damaged. In case of goods with visible da...

Page 25

25 start up start up the following operations must be carried out only by properly trained personnel. To make the contractual warranty effective, start up must be carried out by authorized service centres. Before calling the service centre it is advisable to make sure that all the installation steps...

Page 26

26 control system control system configuration the control system can be configured in different ways in order to adapt itself to the user needs and to the kind of plant managed by the heat pump. The simpler configuration consists of unit controller (a) and ou- tdoor air temperature sensor (b). Such...

Page 27

27 control system heating and cooling circuits the controller of the heat pump is able to manage up to two zones : - zone 1 : heating and cooling - zone 2 : only heating the management of further zones, possibile by means of additional zone controllers, is not treated in this manual. For each zone c...

Page 28

28 control system min. 10 cm control system devices installation remote thermostat and remote control ( wired or wireless ) they should be located in the main room of the zone they manage taking into account the following criteria : - the place of installation should be chosen so that the sensor can...

Page 29

29 control system a b c a led b button a led b button c connector x60 a led b button outdoor air sensor the device must be installed outside the building. The sensor is con- nected to the controller of the unit or to the wireless adaptor through a two wire cable ( the wires are interchangeable ). Wi...

Page 30

30 control system wireless devices connection wireless remote controller wireless adaptor for outdoor temperature sensor wireless repeater the wireless devices should be located in such a way that the transmission is as interference free as possible. The following criteria must be observed : - do no...

Page 31

31 control system control system use the remote control (wired or wireless) allows the complete con- trol of the system permitting to visualize and modify all the ope- rating parameters of the unit and is equipped with a temperatu- re sensor to measure the room temperature of the zone that it manage...

Page 32: Xxxxxxxxxxxxxxxxxxxxxxxxxxx

32 control system operating mode button allows to select the active heating mode (indicated by a bar under the corresponding symbol). Heating mode automatic - room temperature controlled according to the set time table (switching between comfort and reduced set point) - protective functions active -...

Page 33

33 control system dhw button allows to select the domestic hot water heating mode (indicated by a bar under the corresponding symbol). Domestic hot water heating mode on - domestic hot water temperature controlled according to the set time table - protective functions active domestic hot water heati...

Page 34

34 control system control system programming menu structure the settings that can not be modified directly through the buttons of the user interface and of the remote controls are accessible through the programming parameters, grouped inside the various programming menus. The menus concerning functi...

Page 35

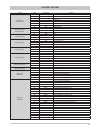

35 control system menu level parameter function time table 5 cooling circuit 1 e 600 preselection e 601 phase 1 on e 602 phase 1 off e 603 phase 2 on e 604 phase 2 off e 605 phase 3 on e 606 phase 3 off e 616 default values holidays program heating circuit 1 e 642 start e 643 end e 648 operating lev...

Page 36

36 control system remote thermostat programming remote control (wired o wireless) programming functions available for the user the configuration parameters of the remote thermo- stat must be set on the device itself. A long press (longer than 3 seconds) on the oc- cupancy button allows to enter the ...

Page 37

37 control system comfort reduced frost protection operating mode selection for heating and cooling circuits heating circuit 1 : through the heating button on the remote control heating circuit p : through the heating button on the remote thermostat cooling circuit 1 : through the cooling button on ...

Page 38

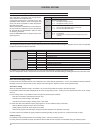

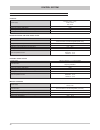

38 control system inputs and outputs the following table shows the list of the inputs and outputs available on the controller of the heat pump along with the expected use. Some inputs and outputs can be configured in a different way by the user in order to manage other plant components which are not...

Page 39

39 control system alarms alarms table alarms activation and reset the controller is able to perform a complete diagnosis of the unit detecting all the operating faults and notifying different alarms. The activation of an alarm implies : - involved consumers locked - alarm icon shown on the display -...

Page 40

40 control system controller technical data power supply 230 vac (+10% / -15%) 50 hz / 60 hz max 11 va safety class (en 60730) ii degree of protection (en 60529) ip 00 operating room temperature (not condensing) -20°c ... 50°c storing room temperature -20°c ... 65°c power supply bus bsb communicatio...

Page 41

41 control system power supply 230 vac (+10% / -15%) 50 hz (+6% / -6%) max 0,5 va communication wireless bsb bus frequency 868 mhz safety class (en 60730) iii degree of protection (en 60529) ip 20 operating room temperature (not condensing) 0°c ... 50°c storing room temperature -20°c ... 65°c power ...

Page 42

42 maintenance important. Make sure the unit is not electrically powered before carrying out any cleaning or main- tenance operation. All ordinary and extraordinary maintenance operations must be carried out by specialized and authorized personnel, in order to ensure compliance with the current safe...

Page 43

43 safety and pollution general considerations pollution the unit contains refrigerant gas and lubricating oil. During discarding such fluids must be recovered and eliminated according to the regulations in force in the country where the unit is installed. The unit must not be abandoned during disca...

Page 44

44 safety and pollution respiratory tract protection for rescue and for maintenance works in tanks, use self-contained breathing apparatus. The vapours are heavier than air and can cause suffocation, reducing the oxygen available for breathing. Eye protection total protection glasses. Hand protectio...

Page 45

45.

Page 46

46 the manufacturer declines all responsibility for any inaccuracies in this manual due to printing or typing errors. The reserves the right to modify the products contents in this catalogue without previous notice..

Page 47

47.

Page 48

Ferroli spa ¬ 37047 san bonifacio (verona) italy ¬ via ritonda 78/a tel. +39.045.6139411 ¬ fax +39.045.6100933 ¬ www.Ferroli.It cod. 3qe26614.