Ferroli LEB 12.0-TS User And Installation Manual - 1. User Instructions

1. USER INSTRUCTIONS

1.1.

Introduction

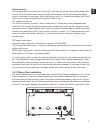

In order to follow the development trends in the field, Ferroli decided to launch the

LEB TS series direct heating electric units with capacities of 12kW, 15kW, 18kW,

21kW,24kW and 28kW This is a highly efficient heating boiler, which means that

the entire operation system is designed independently of the heating system. The

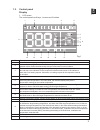

heating unit's use with its intended applications is easy, through the LCD screen

1.2.

Safety of goods and persons

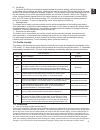

Make sure and check if the heating unit operates according to its intended purpose

by implementing the ISO9001 quality management system.

Use the heating unit in accordance with the requirements included in this manual

and in the manual's annexes. It is very important to ensure the proper operation of

the heating unit, avoiding unauthorized access of children, of persons under the

influence of drugs and alcohol, of all persons without discernment etc.

The supplier provides the products in compliance with the corresponding

regulations and standards, as well as the products from the series as per the

ISO9001 quality management system.

After you gained access to the contractual party's network, to which you agreed,

make sure you remain informed with regard to the products improvements (for

instance, those concerning mounting, commissioning, and when you use the

heating unit, those concerning the unit's adjustment and control, with a view to

local conditions, during and after the guarantee period).

1

EN

control panel.