- DL manuals

- Ferroli

- Water Heater

- MODENA S HE

- Instructions For Use, Installation And Maintenance

Ferroli MODENA S HE Instructions For Use, Installation And Maintenance

Summary of MODENA S HE

Page 1

& cod. 3 541 c3 64 — r ev. 00 - 12/20 12 modena s he instructions for use installation and maintenance.

Page 2

Modena s he 2 en cod. 3541c364 - rev. 00 - 12/2012 b • carefully read the warnings in this instruction book- let since they provide important information on safe installation, use and maintenance. • this instruction booklet is an integral part of the product and must be carefully kept by the user fo...

Page 3

Modena s he 3 & cod. 3541c364 - rev. 00 - 12/2012 1 instructions .............................................................................................................................. 4 1.1 introduction.............................................................................................

Page 4: 1. Instructions

Modena s he 4 en cod. 3541c364 - rev. 00 - 12/2012 1. Instructions 1.1 introduction thank you for choosing the modena s he, a ferroli wall-mounted boiler the latest generation appliance, featuring advanced design and cutting-edge technology. Modena s he is a high-efficiency condensing pre-mix applia...

Page 5

Modena s he 5 en cod. 3541c364 - rev. 00 - 12/2012 indication during boiler operation central heating mode the central heating heat demand (generated by the room thermostat or the clock) is indicated by the flashing of the hot air symbol over the radiator (part. 13 and 14 - fig. 1). The display indi...

Page 6

Modena s he 6 en cod. 3541c364 - rev. 00 - 12/2012 turning off press the on/off button (part. 7 - fig. 1) for 5 seconds. Fig. 6 - turning off when the boiler is turned off with this key, the p.C.B is still powered, heating operation is disabled and the display is off however the frost protection wil...

Page 7: 2. Installation

Modena s he 7 en cod. 3541c364 - rev. 00 - 12/2012 2. Installation 2.1 general instructions b this unit must only be used for its intended purpose. This unit is designed to heat water to a temperature below boiling point and must be connected to a heating system and/or a water supply system for dome...

Page 8

Modena s he 8 en cod. 3541c364 - rev. 00 - 12/2012 2.2 place of installation the combustion circuit is sealed with respect to the place of installation and therefore the unit can be in- stalled in any room. However, the place of installation must be sufficiently ventilated to prevent the creation of...

Page 9

Modena s he 9 en cod. 3541c364 - rev. 00 - 12/2012 shutoff valve kit the shutoff valves supplied (see fig. 10) must be installed between the boiler and heating system to allow the boiler to be isolated from the system if necessary. For installation, follow the instructions contained in the kit. Fig....

Page 10

Modena s he 10 en cod. 3541c364 - rev. 00 - 12/2012 water treatment if treatment of the water is necessary, ferroli recommends the exclusive use of specific products such as fernox or sentinel to be applied in compliance with the producer's instructions. For more information, please contact: a if th...

Page 11

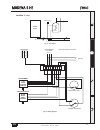

Modena s he 11 en cod. 3541c364 - rev. 00 - 12/2012 accessing electrical terminal block the electrical connections terminal block can be accessed after removing the casing. The layout of the terminals for the various connections is given in the wiring diagram in fig. 37. Fig. 12 - electrical termina...

Page 12

Modena s he 12 en cod. 3541c364 - rev. 00 - 12/2012 central heating demand the heat demand can be controlled by the room thermostat (terminal 3-4) or by a switch line 230 v (terminal 3). Standard system for a general pipe layout and wiring diagram on the “s” and “y” plan systems please see fig. 13, ...

Page 13

Modena s he 13 en cod. 3541c364 - rev. 00 - 12/2012 modena “y” plan fig. 15 - pipe layout fig. 16 - wiring diagram modena boiler auto air vent junction box 1 2 3 4 5 6 7 8 9 10 programmer neutral live ch on dhw on dhw off blue white grey orange room thermostat cylinder thermostat n e l honeywell v40...

Page 14

Modena s he 14 en cod. 3541c364 - rev. 00 - 12/2012 2.6 flue system this unit is a "c type" with sealed chamber and forced draught, with air inlet and flue exhaust to be connected to one of the following flue systems. Before installation, with the aid of the tables and calculation methods given, che...

Page 15

Modena s he 15 en cod. 3541c364 - rev. 00 - 12/2012 other coaxial connections fig. 18 - examples of connection with coaxial pipes ( = air / = fumes) for coaxial connection, fit the unit with one of the following starting accessories. For the wall hole dimensions, refer to section "4.1 dimensions and...

Page 16

Modena s he 16 en cod. 3541c364 - rev. 00 - 12/2012 connection with separate pipes fig. 20 - examples of connection with separate pipes ( = air / = fumes) for the connection of separate ducts, fit the unit with the following starting accessory: fig. 21 - starting accessory for separate ducts before ...

Page 17

Modena s he 17 en cod. 3541c364 - rev. 00 - 12/2012 position of terminals fig. 22 minimum dimensions of fume exhaust terminals a directly under an opening, air inlet, openable window, etc. 300 mm b above an opening, air inlet, openable window, etc. 300 mm c horizontally to an opening, air inlet, ope...

Page 18

Modena s he 18 en cod. 3541c364 - rev. 00 - 12/2012 connection to multiple flues or single flues with natural draught to connect the modena s he boiler to a multiple flue or a single flue with natural draught, the flue or chimney must be expressly designed by professionally qualified technical perso...

Page 19

Modena s he 19 en cod. 3541c364 - rev. 00 - 12/2012 condensate drain if possible, the condensate should be conveyed inside the internal drainage system or pipe. For that purpose, use a pipe of at least 22 mm diameter and a trap with flexible connection supplied with the unit to facilitate connection...

Page 20: 3. Service and Maintenance

Modena s he 20 en cod. 3541c364 - rev. 00 - 12/2012 3. Service and maintenance all adjustment, conversion, startup and maintenance operations described below must only be carried out by qualified per- sonnel (meeting the professional technical requirements prescribed by current regulations). Ferroli...

Page 21

Modena s he 21 en cod. 3541c364 - rev. 00 - 12/2012 3.2 start-up b checks to be made at first lighting, and after all maintenance operations that involved disconnection from the systems or an operation on safety devices or parts of the boiler: before lighting the boiler • open any on-off valves betw...

Page 22

Modena s he 22 en cod. 3541c364 - rev. 00 - 12/2012 check the operational (working) gas inlet pressure set up the boiler to operate at maximum rate as de- scribed in section " test mode" pag. 21 of section 3.3. With the boiler operating in the maximum rate condi- tion check that the operational (wor...

Page 23

Modena s he 23 en cod. 3541c364 - rev. 00 - 12/2012 periodical check to keep the unit working properly over time, it is necessary to have qualified personnel make an annual check that in- cludes the following tests: • the control and safety devices (gas valve, flow meter, thermostats, etc.) must fun...

Page 24

Modena s he 24 en cod. 3541c364 - rev. 00 - 12/2012 combustion check connect the flue gas analyzer to the flue gas sampling point as shown in the fig. 30 and check combustion as described in table 4 and table 5. 1. Press the ch button for 5 seconds to place boiler into test mode 2. Wait for 10 minut...

Page 25

Modena s he 25 en cod. 3541c364 - rev. 00 - 12/2012 re-check the minimum rate turn off the boiler and then turn it back on and put in test mode at maximum for 1minute. Reduce to mini- mum and re-check the minimum rate output ensuring the co2 setting level has remained unchanged and confirm that the ...

Page 26

Modena s he 26 en cod. 3541c364 - rev. 00 - 12/2012 3.5 troubleshooting diagnostics the boiler is equipped with an advanced self-diagnosis system. In case of a boiler fault, the display will flash together with the fault symbol (detail 11 - fig. 1) indicating the fault code. Certain faults cause per...

Page 27

Modena s he 27 en cod. 3541c364 - rev. 00 - 12/2012 4. Technical data and characteristics 4.1 dimensions and connections fig. 32 - dimensions and connections 1 = heating system delivery 3 = gas inlet 5 = heating system return 120 120 80 11 0 400 600 320 1 3 5 150 35.5 130 131.5 157 105 35 103.

Page 28

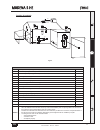

Modena s he 28 en cod. 3541c364 - rev. 00 - 12/2012 4.2 general view and main components fig. 33 - general view key 7 gas inlet 10 system delivery 11 system return 14 safety valve 32 heating circulating pump 36 automatic air vent 44 gas valve 56 expansion tank 81 ignition/ionization electrode 114 wa...

Page 29

Modena s he 29 en cod. 3541c364 - rev. 00 - 12/2012 4.3 water circuit fig. 34 - water circuit key 10 system delivery 11 system return 14 safety valve 32 heating circulating pump 36 automatic air vent 56 expansion tank 114 water pressure switch 154 condensate outlet pipe 186 return sensor 193 condens...

Page 30

Modena s he 30 en cod. 3541c364 - rev. 00 - 12/2012 4.4 technical data table data unit modena 18 s he modena 25 s he modena 32 s he ch max heat input kw 17.4 25.0 32.0 ch min heat input kw 4.0 5.8 6.7 ch max. Heat output (80/60°c) kw 17.0 24.5 31.4 ch min heat output (80/60°c) kw 3.9 5.7 6.6 ch max....

Page 31

Modena s he 31 en cod. 3541c364 - rev. 00 - 12/2012 4.5 diagrams head available for the system fig. 35 - pressure loss (modena 18 s he - modena 25 s he) a boiler pressure losses b circulating pump min. Speed c circulating pump max. Speed head available for the system fig. 36 - pressure loss (modena ...

Page 32

Modena s he 32 en cod. 3541c364 - rev. 00 - 12/2012 4.6 wiring diagram fig. 37 - wiring diagram a important: before connecting the room thermostat or the remote timer control, remove the jumper on the terminal block. 16 fan 32 heating circulating pump 44 gas valve 62 time clock (optional) 81 ignitio...

Page 34

Failure to install and commission according to the manufacturer’s instructions and complete this benchmark commissioning checklist will invalidate the warranty. This does not affect the customer’s statutory rights. If yes, and if required by the manufacturer, has a water scale reducer been fitted? Co...

Page 35

Service record it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service record below, please ensure you have carried out the service as described in the manufacturer’s in...

Page 36

Before contacting ferroli please have available the completed benchmark document (located in the back of this manual), boiler serial number and model detail. For technical assistance during the installation, call our technical helpline on 0843 479 0479. You will be required to provide your gas safe ...