- DL manuals

- Ferroli

- Boiler

- OPTIMAX 25 S

- Instructions for use, installation and maintenance

Ferroli OPTIMAX 25 S Instructions for use, installation and maintenance

Summary of OPTIMAX 25 S

Page 1

Optimax 25 s wall-mounting gas boiler, pre-mixed condensing system boiler instructions for use installation and maintenance cod. 3544696/4 - 08/2004 g c n° 41-267-22.

Page 2: Optimax 25 S

Optimax 25 s 2 important your “benchmark” installation, commissioning and service record log book will be enclosed in your customer information pack. “this record must be completed and left with the end user”. Ferroli is a member of the benchmark initiative and fully supports the aims of the program...

Page 3: Optimax 25 S

Optimax 25 s 3 1. Operating instructions..................................................................4 1.1 introduction.............................................................................................................4 1.2 control panel ..................................................

Page 4: Optimax 25 S

4 optimax 25 s 1. Operating instructions 1.1 introduction dear customer, thank you for choosing optimax 25 s, a ferroli wall-mounted boiler of the latest generation, featuring advanced design and cutting-edge technology. Optimax 25 s is a high-effi ciency condensing pre-mix appliance for heating wit...

Page 5: Optimax 25 S

5 optimax 25 s 1.2 control panel 2 3 4 1 fi g. 1 1 - system temperature adjustment / summer/winter selection this knob is used to adjust the system temperature and can switch over between summer / winter. To increase the system temperature, turn the knob clockwise; anticlockwise to decrease it. To s...

Page 6: Optimax 25 S

6 optimax 25 s 1.4 adjustments room temperature adjustment (with room thermostat on) using the room thermostat, set the temperature desired in the rooms. Controlled by the room thermo- stat, the boiler lights and heats the system water to the set system delivery setpoint temperature. The boiler turn...

Page 7: Optimax 25 S

7 optimax 25 s before calling the ferroli caresafe, check that the problem is not due to there being no gas or electricity. 1.5 maintenance it is strongly recommended that an annual maintenance of the boiler is carried out by a qualifi ed gas engineer. Please refer to the “maintenance” section in th...

Page 8: Optimax 25 S

Optimax 25 s 8 2. Installation 2.1 general instructions this device must only be used for the purpose for which it is specifi cally designed. This unit is designed to heat water to a temperature below boiling point and must be connected to a hea- ting system and/or a water supply system for domestic...

Page 9: Optimax 25 S

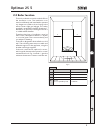

Optimax 25 s 9 2.2 boiler location the unit’s combustion circuit is sealed off from the installation room. The installation room must be suffi ciently well ventilated to prevent any dangerous conditions from forming in the event of even slight gas leakage. This safety standard is required by the eec...

Page 10: Optimax 25 S

Optimax 25 s 10 2.3 water connections the heating capacity of the unit should be previously established by calculating the building’s heat requirement according to current regulations. For good operation and long life of the boiler, the plum- bing system must be well proportioned and always complete...

Page 11: Optimax 25 S

Optimax 25 s 11 the connecting kits shown in fig. 4 are supplied as standard. Key a = nut b = compression olive d = 3/4 seal - green f = 1/2 gas seal - blue flow isolation valve gas isolation valve a b f a b d a b d return isolation valve fi g. 4 make up water provision must be made for replacing wa...

Page 12: Optimax 25 S

Optimax 25 s 12 water treatment if treatment is used ferroli limited recommanded only the use of fernox or sentinel water treatment products, which must be used in accordance with the manufactures instructions. For further information contact: fernox manufacturing co. Ltd. Sentinel division cookson ...

Page 13: Optimax 25 S

Optimax 25 s 13 central heating request the heat demand can be done by the room thermostat (terminal 4-5) or by a switch line 230 v phase (terminal 4). Standard systems for a general pipe layout and wiring diagram on the “s” and “y” plan systems please see fi g. 6a, 6b, and 7a, 7b. Optimax “s” plan ...

Page 14: Optimax 25 S

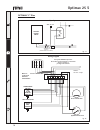

Optimax 25 s 14 optimax “y” plan pipe layout optimax ferroli boiler auto air vent automatic bypass (mimimum flow of 6l/min.) wiring diagram 4 3 2 1 junction box n l 1 2 3 4 5 6 7 8 9 10 programmer neutral live ch on dhw on dhw off blue white grey orange room thermostat cylinder thermostat n e l 240 ...

Page 15: Optimax 25 S

Optimax 25 s 15 room thermostat remove connections 4 - 5 if external control fitted. Warning: the room thermostat works at 230v. Fi g. 8 system external controls 5 4 3 2 1 switch line 230v l n fi g. 9 the user must never change the unit’s power cable. If the cable gets damaged, switch off the unit a...

Page 16: Optimax 25 S

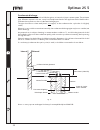

Optimax 25 s 16 * = between 10 e 60 mm * = between 10 e 60 mm 80 standard 1kwma53a flue kit 215 185 install level install level 50* 110 95 80 30 50* 30 95 s 50* p 110 l d s p 125 s 30 95 d s 50* l 30 95 215 185 175 185 215 175 install level install level connection with concentric fl ue system the u...

Page 17: Optimax 25 S

Optimax 25 s 17 angled roof tile 1kwma82u 1kwma56u 950 50 1kwma71w max. 6 metr es 60/100 roof end piece 1kwma83u 68 215 185 max. 16 metr es 80/125 950 50 50 950 50 1000 125 10 fi g. 10c reduction factors for bends 1 m 0,5 m 0,5 m 0,25 m table 2b maximum permissible duct length (horizontal) Ø mm 60/1...

Page 18: Optimax 25 S

Optimax 25 s 18 4 5 1kwma83w 1kwma82u 1kwma84u 1kwmr54a 2 ref. 2 4 5 23 23 1 vertical air pipe Ø80 vertical flue pipe Ø80 80 Ø vertical flue kit description equivalent loss 23,0 m 36,8 m 12,0 m 71,8 m total table 3 fi g. 11 fi g. 12 connection with 80 mm pipe system the unit can be connected to a sy...

Page 19: Optimax 25 S

Optimax 25 s 19 table of fl ue and accessory kwma86a kwma85a kwma84u air flue v e rtical horizontal v e rtical horizontal kwma65w kwma01w kwma83w • 1,00 m description pipe Ø 80 male-female bend 45 ° Ø 80 mm male - female bend 90 ° Ø 80 mm male - female description horozontial flue terminal horozonti...

Page 20: Optimax 25 S

Optimax 25 s 20 minimum dimensions of flue terminal positions directly below an opening, air brick, opening windows, etc. Above an opening, air brick, opening windows, etc. Horizontally to an opening, air brick, opening windows, etc. Below gutters, soil pipes or drain pipes below balconies or car po...

Page 21: Optimax 25 S

Optimax 25 s 21 connection to collective fl ues or single fl ues with natural draught if you are then going to connect the optimax 25 s boiler to a collective fl ue or a single fl ue with natural draught, the fl ue must be expressly designed by professionally qualifi ed technical personnel in confor...

Page 22: Optimax 25 S

Optimax 25 s 22 condensate discharge where possible the condensate should discharge into an internal soil pipe or waste system. The minimum pipe diameter required is 22 mm, a trap has already been fi tted to the appliance with a fl exible tail to facilitate the connection to the condensate discharge...

Page 23: Optimax 25 S

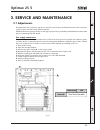

Optimax 25 s 23 3. Service and maintenance 3.1 adjustments all adjustment and conversion operations must be carried out by qualifi ed personnel such as the per- sonnel of the local after-sales technical service. Ferroli declines any responsibility for damage or physical injury caused by unqualifi ed...

Page 24: Optimax 25 S

Optimax 25 s 24 3.2 system start-up commissioning must be performed by qualifi ed personnel. Checks to be made at fi rst ignition, and after all maintenance operations that involved discon- necting from the systems or an intervention on safety devices or parts of the boiler: before lighting the boil...

Page 25: Optimax 25 S

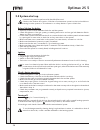

Optimax 25 s 25 3.3 maintenance the following operations are strictly reserved for qualifi ed personnel, such as corgi registered engineers or ferroli personeer. Seasonal inspection of the boiler and fl ue it is advisable to carry out the following checks at least once a year: • the control and safe...

Page 26: Optimax 25 S

Optimax 25 s 26 cleaning the boiler and burner the body and burner must not be cleaned with chemical products or wire brushes. Special care must be taken over all the sealing systems pertaining to the sealed chamber (gaskets, cable clamps, etc.). In addition, it is necessary to pay attention after p...

Page 27: Optimax 25 S

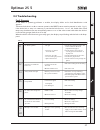

Optimax 25 s 27 3.4 troubleshooting fault diagnosis in the event of operating problems or trouble, the display blinks and a fault identifi cation code appears. There are faults that in order to restore operation the reset button must be pressed or (ref.2 - fi g. 1); if the boiler fails to start, it ...

Page 28: Optimax 25 S

Optimax 25 s 28 incorrect system water pressure • pressure too low • sensor damaged • fill the system • check the sensor fault possible cause cure software fault • software operating fault • cut off and restore the electricity supply. If the trouble remains, check and/or change the main cvbc deliver...

Page 29: Optimax 25 S

Optimax 25 s 29 4 technical characteristics and data 4.1 dimensions and connections fi g. 19 top view bottom view 1 4 3 2 720 196,5 135,5 135,5 175 120 120 65 95 11 11 11 11 400 378 50,5 185,5 124 40 370 key 1 ch fl ow 2 gas inlet 3 ch return 4 condense outlet.

Page 30: Optimax 25 S

Optimax 25 s 30 4.2 general view and main components fi g. 20 145 246 196 161 22 10 7 11 154 49 34 16 35 36 14 32 44 186 19 5 21 29 flue sensor 56 201 83 82 188 175 200 key 5 airtight chamber 7 gas inlet 10 ch fl ow 11 ch return 14 safety valve 16 premix fan 19 combustion chamber 21 gas injector 22 ...

Page 31: Optimax 25 S

Optimax 25 s 31 11 10 7 154 200 36 35 34 49 145 246 14 32 44 56 186 161 201 16 4.3 hydraulic diagram fi g. 21 key 7 gas inlet 10 ch fl ow 11 ch return 14 heating safety valve 16 premix fan assembly 32 heating pump 34 flow temperature sensor 35 air separator 36 automatic air vent 44 gas valve 49 safe...

Page 32: Optimax 25 S

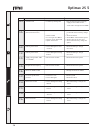

Optimax 25 s 32 4.4 technical data table heating heating temperature adjustment range °c maximum working pressure in heating bar minimum working pressure in heating bar expansion tank capacity litres expansion tank pre-filling pressure bar total boiler water content litres dimensions, weights connec...

Page 33: Optimax 25 S

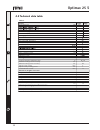

Optimax 25 s 33 4.5 diagrams head available for the system key 1 - 2 - 3 = pump selector positions a = boiler losses of head fi g. 22 0 1 2 3 4 5 6 7 0 500 1.000 1.500 2.000 q [l/h] h [m h 2 o] a 3 2 1.

Page 34: Optimax 25 S

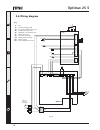

Optimax 25 s 34 1 4 2 5 3 6 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 16 1 6 2 7 3 8 4 9 5 10 v1 v2 t l n 1 2 3 4 5 6 1 2 3 4 5 6 n l 230 v 44 81 82 f2a tr 32 34 49 24 v. 186 191 x1 x12 x11 114 s4965v1018 dc f02.1 dsp49a1100 cpd5.1 remove if external controls fitted x3 x6 x1 x7 x5 x2 1 2 3 4 5 6 7 8 9 10 ...

Page 36

Phone numbers: installer service engineer because of our constant endeavour for improvement details may vary slightly from those quoted in these instructions. Lichfi eld road, branston industrial estate, burton upon trent, staffordshire de14 3hd tel. 08707 282 885 - fax 08707 282 886 all specificati...