- DL manuals

- Ferroli

- Boiler

- OPTIMAX HE 25 S

- Instructions For Use Manual

Ferroli OPTIMAX HE 25 S Instructions For Use Manual

Summary of OPTIMAX HE 25 S

Page 1

Instructions for use installation and maintenance for the united kingdom and eire optimax he 31 s wall-mounted gas fired, pre-mix condensing system boiler cod. 3540f441 - 04/2007 (rev. 01) g.C. No 41-267-26.

Page 2

Optimax he 31 s 2 cod. 3540f441 - 03/2007 (rev. 01) • read the warnings given in this manual thoroughly. They provide important information for safe instal- lation, use and maintenance • by law the instruction manual must be left with the end user. • if the appliance is sold or transferred to anothe...

Page 3

Optimax he 31 s 3 cod. 3540f441 - 03/2007 (rev. 01) 1. Operating instructions .................................................................4 1.1 introduction ............................................................................................................4 1.2 control panel .............

Page 4

Optimax he 31 s 4 cod. 3540f441 - 03/2007 (rev. 01) 1. Operating instructions 1.1 introduction dear customer, thank you for choosing the optimax he 31 s, a ferroli wall-mounted boiler of the latest generation, featuring advanced design and cutting-edge technology. Optimax he 31 s is a high-efficienc...

Page 5

Optimax he 31 s 5 cod. 3540f441 - 03/2007 (rev. 01) 1.2 control panel eco comfort reset 8 15 13 14 12 11 2 1 4 3 6 7 5 fig. 1 1 = domestic hot water temperature setpoint decreasing push button (not used) 2 = domestic hot water temperature setpoint increasing push button (not used) 3 = central heatin...

Page 6

Optimax he 31 s 6 cod. 3540f441 - 03/2007 (rev. 01) 1.3 turning on and off without main power supply to avoid damage caused by freezing during long shutdowns in winter, it is advisable to drain all water from the system. Ignition ensure the power is on to the appliance. For the first 120 seconds, th...

Page 7

Optimax he 31 s 7 cod. 3540f441 - 03/2007 (rev. 01) when the boiler is turned off with this key, the p.C.B is still powered, heating operation is disabled and the display is off however the frost protection will still be active. To totally isolate close the gas cock ahead of the boiler and disconnec...

Page 8

1.5 maintenance it is strongly recommended to carry out annual maintenance of the boiler and heating system. Please refer to the “maintenance” section in this manual. The casing, the control panel and the aesthetic parts of the boiler can be cleaned using a soft and damp cloth, do not use abrasives ...

Page 9

Optimax he 31 s 9 cod. 3540f441 - 03/2007 (rev. 01) 2. Installation 2.1 general instructions this device must only be used for the purpose for which it is specially designed. This unit is designed to heat water to a temperature below boiling point and must be connected to a heat- ing system and/or a...

Page 10

Optimax he 31 s 10 cod. 3540f441 - 03/2007 (rev. 01) minimum a b d 2,5 cm 20 cm 60 cm (via an openable panel) c 30 cm table 1 fig. 9 a a b d c 2.2 boiler location the unit’s combustion chamber is sealed off from the installation room and therefore requi- res no compartment ventilation. The installat...

Page 11

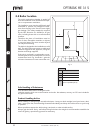

Optimax he 31 s 11 cod. 3540f441 - 03/2007 (rev. 01) fig. 10 1 3 5 7 6 97 145,5 134 73,5 187 187 247 2.3 boiler water connections the heating capacity of the unit should be previously established by calculating the building’s heat requi- rement according to current regulations. For good operation an...

Page 12

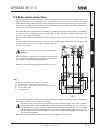

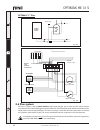

Optimax he 31 s 12 cod. 3540f441 - 03/2007 (rev. 01) fig. 11 fig. 12 3 2 1 4 key a = nut b = compression olive d = 3/4 seal (green) f = 1/2 gas seal (blue) g = filter h = cap flow isolation valve gas isolation valve return isolation valve 22 22 22 a a a b b b d d f g h red yellow blue the isolatio...

Page 13

Optimax he 31 s 13 cod. 3540f441 - 03/2007 (rev. 01) 2.5 electrical connections the unit must be installed in conformity with current national and local regulations. Connection to the electrical supply the boiler must be connected to a single-phase, 230 volt-50 hz electric supply. The unit’s electri...

Page 14

Optimax he 31 s 14 cod. 3540f441 - 03/2007 (rev. 01) fig. 13 the user must never change the unit’s power cable. If the cable gets damaged, switch off the unit and have it changed only by professionally qualified personnel. If changing the electric power cable, use only “har h05 vv-f” 3x0.75 mm 2 cab...

Page 15

Optimax he 31 s 15 cod. 3540f441 - 03/2007 (rev. 01) central heating demand the heat demand can be controlled by the room thermostat (terminal 5-6) or by a switch line 230 v (terminal 5). Standard systems for a general pipe layout and wiring diagram on the “s” and “y” plan systems please see fig. 15...

Page 16

Optimax he 31 s 16 cod. 3540f441 - 03/2007 (rev. 01) optimax “y” plan fig. 16a fig. 16b optimax ferroli boiler auto air vent wiring diagram 4 3 2 1 junction box n l 1 2 3 4 5 6 7 8 9 10 programmer neutral live ch on dhw on dhw off blue white grey orange room thermostat cylinder thermostat n e l 240 ...

Page 17

Optimax he 31 s 17 cod. 3540f441 - 03/2007 (rev. 01) * = between 10 e 60 mm * = between 10 e 60 mm 80 95 95 50* 80 95 30 50* standard 1kwma53a flue kit 232 218 30 p 125 s d s 50* l 30 95 s 50* p 95 l d s 232 218 156 drill the wall 10÷20 mm more than the pipe diameter 218 232 156 drill the wall 10÷20...

Page 18

Optimax he 31 s 18 cod. 3540f441 - 03/2007 (rev. 01) pitch roof slate 1kwma82u 1kwma56u 950 50 1kwma71w max. 6 mt 60/100 max. 16 mt 80/125 vertical terminal 1kwma83u 68 950 50 50 950 50 1000 125 10 eco comfort reset 1 2 3 4 0 bar vertical outlet fig. 17c reduction factors for bends 1 m 0,5 m 0,5 m 0...

Page 19

Optimax he 31 s 19 cod. 3540f441 - 03/2007 (rev. 01) ref. 2 4 5 18 15 1 vertical air pipe Ø80 vertical flue pipe Ø80 80 Ø vertical flue kit description equivalent loss 18 m 24 m 12 m 54 m total table 3 fig. 18 fig. 19 connection with 80 mm pipe system the unit can be connected to a system of separat...

Page 20

Optimax he 31 s 20 cod. 3540f441 - 03/2007 (rev. 01) 1kwma86a 1kwma85a 1kwma84u air flue vertical horizont al vertical horizont al 1kwma65w 1kwma01w 1kwma83w 1,00 m description pipe Ø 80 male-female bend 45° Ø 80 mm male - female bend 90° Ø 80 mm male - female description horizontal flue terminal ...

Page 21

Optimax he 31 s 21 cod. 3540f441 - 03/2007 (rev. 01) minimum dimensions of flue terminal positions directly below an opening, air brick, opening windows, etc. Above an opening, air brick, opening windows, etc. Horizontally to an opening, air brick, opening windows, etc. Below gutters, soil pipes or ...

Page 22

Optimax he 31 s 22 cod. 3540f441 - 03/2007 (rev. 01) b connection to collective flues or single flues with natural draught if you are then going to connect the optimax he 31 s boiler to a collective flue or a single flue with natural draught, the flue must be expressly designed by professionally qua...

Page 23

Optimax he 31 s 23 cod. 3540f441 - 03/2007 (rev. 01) external 32/40mm solvent weld pipework cement seal 100mm dia tube bottom sealed lime stone chippings ground level (either/or) hole depth 400mm 25mm 2 rows of 3x12 mm holes internal -300mm fig. 22 condensate discharge where possible the condensate ...

Page 24

Optimax he 31 s 24 cod. 3540f441 - 03/2007 (rev. 01) fig. 23 injector Ø natural gas lpg see technical data table 3. Service and maintenance 3.1 adjustments all adjustment and conversion operations must be carried out by qualified personnel such as ferroli technical service. Ferroli declines any resp...

Page 25

Optimax he 31 s 25 cod. 3540f441 - 03/2007 (rev. 01) 3.2 system start-up commissioning must be performed by qualified personnel. Checks to be made at first ignition, and after all maintenance operations that involved discon- necting from the systems or an intervention of a safety device. Before ligh...

Page 26

Optimax he 31 s 26 cod. 3540f441 - 03/2007 (rev. 01) 3.3 maintenance the following operations are strictly reserved for qualified personnel, such as corgi registered engineers or ferroli engineers. Seasonal inspection of the boiler and flue it is advisable to carry out the following checks at least ...

Page 27

Optimax he 31 s 27 cod. 3540f441 - 03/2007 (rev. 01) fig. 24 b a c a eco com fort reset 1 2 3 4 0 bar eco com fort res et 1 2 3 4 0 bar air flue gas air flue gas fig. 25 opening the casing to open the boiler casing, you need to follow the sequence given below and the instructions of fig. 24. 1 using...

Page 28

Optimax he 31 s 28 cod. 3540f441 - 03/2007 (rev. 01) 3.4 troubleshooting fault diagnosis in the event of operating problems or trouble, the display will flash and a fault identification code appears. There are faults that in order to restore operation the reset button must be pressed (ref.6 - fig. 1...

Page 29

Optimax he 31 s 29 cod. 3540f441 - 03/2007 (rev. 01) fault possible cause cure f13 flue sensor fault sensor damaged or wiring shorted check the wiring or change the sensor sensor damaged or wiring broken check the wiring or change the sensor f14 flow sensor fault sensor damaged or short circuited ch...

Page 30

Optimax he 31 s 30 cod. 3540f441 - 03/2007 (rev. 01) 4. Technical characteristics and data 4.1 dimensions and connections 6 pressure relief valve 7 condense outlet key 1 system flow (22 mm with isolation valve fitted) 3 gas inlet (22 mm with isolation valve fitted) 5 system return - 22 mm with isola...

Page 31

Optimax he 31 s 31 cod. 3540f441 - 03/2007 (rev. 01) 4.2 general view and main components fig. 27 5 room sealed compartment 7 gas inlet 10 ch flow 11 ch return 14 heating safety valve 16 premix fan assembly 19 combustion compartment 21 main injector 22 main burner 29 flue collar 32 pump 36 automatic...

Page 32

Optimax he 31 s 32 cod. 3540f441 - 03/2007 (rev. 01) 4.3 hydraulic diagram fig. 28 56 44 14 32 11 10 7 241 246 36 186 161 201 278 193 154 16 key 7 gas inlet 10 ch flow 11 ch return 14 pressure relief valve 16 premix fan assembly 32 pump 36 automatic air vent 44 gas valve 56 expansion vessel 154 cond...

Page 33

Optimax he 31 s 33 cod. 3540f441 - 03/2007 (rev. 01) 4.4 technical data table heating heating temperature adjustment range °c maximum working temperature in heating °c heating circuit pms safety valve ( preset ) bar minimum working pressure in heating bar expansion vessel capacity litres expansion v...

Page 34

Optimax he 31 s 34 cod. 3540f441 - 03/2007 (rev. 01) 4.5 diagrams head available for the system fig. 29 0 1 2 3 4 5 6 7 0 500 1.000 1.500 2.000 q [l/h] h [m h 2 o] a 3 1 2 key 1 - 2 - 3 = pump selector positions a = boiler losses of head.

Page 35

Optimax he 31 s 35 cod. 3540f441 - 03/2007 (rev. 01) key 16 fan 32 central heating pump 44 combination gas valve 62 time clock (optional) 81 spark electrode 82 ionisation electrode 101 main p.C.B. 103 relay 104 fuse 186 return temperature sensor 191 exhaust temperature sensor 202 transformer 230v-24...

Page 37

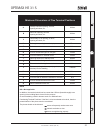

Benchmark controls to comply with the building regulations, each section must have a tick in one or other of the boxes time & temperature control to heating room t/stat & programmer/timer programmable roomstat time & temperature control to hot water cylinder t/stat & programmer/timer combi boiler he...

Page 38: Service Interval Record

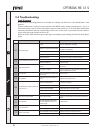

Service interval record it is recommended that your heating system is serviced regularly and that you complete the appropriate service interval record below. Service provider. Before completing the appropriate service interval record below, please ensure you have carried out the service as described...

Page 39

Phone numbers: installer service engineer because of our constant endeavour for improvement details may vary slightly from those quoted in these instructions. All specifications subject to change please note - to avoid incurring unnecessary expense, in the event of a boiler shut down, check this is ...