- DL manuals

- Ferroli

- Boiler

- PEGASUS F3 N 2S

- Instructions For Use, Installation And Maintenance

Ferroli PEGASUS F3 N 2S Instructions For Use, Installation And Maintenance

Summary of PEGASUS F3 N 2S

Page 1

Pegasus f3 n 2s cod. 35443 1 0/3 - 04/2005 cast iron gas boiler for heating with electronic ignition and fl ame control instructions for use, installation and maintenance.

Page 2: Pegasus F3 N 2S

2 pegasus f3 n 2s this symbol indicates “caution” and is placed next to all safety warnings. Strictly follow these instructions in order to avoid danger and damage to persons, animals and things. This symbols calls attention to a note or important notice • carefully read the warnings in this instruc...

Page 3: Pegasus F3 N 2S

3 pegasus f3 n 2s 1. Operating instructions..................................................................4 1.1 introduction ............................................................................................................4 1.2 control panel ...............................................

Page 4: Pegasus F3 N 2S

4 pegasus f3 n 2s fig. 1 1. Operating instructions 1.1 introduction dear customer, thank you for choosing pegasus f3 n 2s, a ferroli floor-standing boiler featuring advanced design, cutting-edge technology, high reliability and quality construction. Please read this manual carefully and keep it for ...

Page 5: Pegasus F3 N 2S

5 pegasus f3 n 2s 1.3 turning on and off ignition • open the gas valve ahead of the boiler. • turn on or insert any switch or plug ahead of the boiler • turn the boiler switch “7” onto 1 (fig. 1). • turn knob “6” to the preselected temperature and any room thermostat to the desired temperature value...

Page 6: Pegasus F3 N 2S

6 pegasus f3 n 2s 1.5 maintenance the user must have the heating system serviced by qualified personnel at least once a year and combustion checked at least every two years. Consult chapter 3.3 of this manual for more information. The boiler casing, panel and aesthetic parts can be cleaned with a so...

Page 7: Pegasus F3 N 2S

7 pegasus f3 n 2s 2. Installation 2.1 general instructions this device must only be used for the purpose for which it is specially designed. This unit is designed to heat water to a temperature below boiling point at atmospheric pressure and must be connected to a heating system and/or a water suppl...

Page 8: Pegasus F3 N 2S

8 pegasus f3 n 2s it is advisable to install on-off valves between the boiler and heating system allowing the boiler to be isolated from the system if neces- sary. Make the boiler connection in such a way that its internal pipes are free of stress. Fig. 2 characteristics of the water system in the p...

Page 9: Pegasus F3 N 2S

9 pegasus f3 n 2s 2.5 electrical connections connection to the electrical grid the boiler must be connected to a single-phase, 230 volt-50 hz electric line. The unit’s electrical safety is only guaranteed when correctly connected to an efficient earthing system executed according to current safety s...

Page 10: Pegasus F3 N 2S

10 pegasus f3 n 2s 2.6 connection to the fl ue the diameter of the flue connection pipe must not be less than that of the connection on the anti-backflow device. Starting from the anti-backflow device it must have a vertical section at least 50 cm long. Current standards must be complied with regard...

Page 11: Pegasus F3 N 2S

11 pegasus f3 n 2s characteristics of the system water in the presence of water harder than 25° - 30° fr, we recommend the use of suitably conditioned water for the heating system in order to avoid possible scaling in the boiler, caused by hard water, or corrosion produced by aggressive water. It sh...

Page 12: Pegasus F3 N 2S

12 pegasus f3 n 2s 100 Ø Ø h ± 40 100 Ø 100 100 side view plan view 2 modules plan view 3 modules plan view 4 modules f l 100 Ø f 100 l l f hea t genera t ors with f acing modules comprehensive of fume ducting chamber st andard boiler pegasus f3 n 119 2s pegasus f3 n 136 2s pegasus f3 n 153 2s pegas...

Page 13: Pegasus F3 N 2S

13 pegasus f3 n 2s 2 modules 3 modules 4 module 238 272 306 340 374 442 510 578 262.0 298.0 336.0 374.0 412.0 486.0 560.0 628.0 1960 2140 2300 2480 2640 2980 3320 3660 1775 1800 1800 1850 1850 1850 1875 1875 300 350 350 450 450 450 500 500 lh Ø hea t genera t ors with modules in line comprehensive o...

Page 14: Pegasus F3 N 2S

14 pegasus f3 n 2s electrical connection of module generators each generator comprising the modular assembly is supplied pre-wired for both the adjustments and the safety devices. It can therefore operate on its own (see wiring diagrams of paragraph 4.5). Connect each generator to a single-phase ele...

Page 15: Pegasus F3 N 2S

15 pegasus f3 n 2s application systems the 2 application systems are described here. System 1: 4 modular generators with no hot water production application direct delivery heating with at most 4 modular generators. Key: c1 - c2 - c3 - c4 = modular generators v1 - v2 - v3 - v4 = 3-way valves t5 = de...

Page 16: Pegasus F3 N 2S

16 pegasus f3 n 2s system 2: 4 modular generators with hot water production application direct delivery heating with at most 4 modular generators with hot water production via diverter valve. Key: c1 - c2 - c3 - c4 = modular generators v1 - v2 - v3 - v4 = 3-way valves b = boiler vd = diverter valve ...

Page 17: Pegasus F3 N 2S

17 pegasus f3 n 2s control and check panel for module generators in sequence (supplied on request) in order to make the electric connection between the four-stage sequence governor w6050c, the module generators pegasus f3 n 2s and the various system components more straightforward and functional, we...

Page 18: Pegasus F3 N 2S

18 pegasus f3 n 2s 3. Service and maintenance 3.1 adjustments all adjustment and conversion operations must be carried out by qualified personnel. The manufacturer declines any responsibility for damage or physical injury caused by unqualified and unauthorized persons tampering with the device. Adju...

Page 19: Pegasus F3 N 2S

19 pegasus f3 n 2s from natural to liquid gas 1 replace the nozzles at the main burner and pilot light, inserting the nozzles specified in the technical data table in chap. 4.3. 2 remove the small plug 3 (fig. 14) from the gas valve, screw the ignition “step” regulator 2, contained in the conversion...

Page 20: Pegasus F3 N 2S

20 pegasus f3 n 2s to measure the burner gas pressure, use the pressure point on the gas manifold pipe of the burner assembly (see part 14 in fig. 24) main components key 1 pressure point upstream from the valve 2 ignition “step” regulator for liquid gas 3 plug 4 safety cap 5 pressure adjustment scr...

Page 21: Pegasus F3 N 2S

21 pegasus f3 n 2s 3.2 system start-up system start-up must be carried out by qualified personnel. The following operations and checks are to be made at the first ignition, and after all maintenance work that involved disconnecting from the systems or work on safety devices or parts of the boiler. B...

Page 22: Pegasus F3 N 2S

22 pegasus f3 n 2s turning off to temporarily turn the boiler off, just turn the boiler switch 7 (fig. 1) onto 0. To turn the boiler off for an extended period: • turn the knob of the boiler switch 7 (fig. 1) onto 0; • close the gas cock ahead of the boiler; • disconnect the electrical power to the ...

Page 23: Pegasus F3 N 2S

23 pegasus f3 n 2s combustion analysis a point for sampling fumes has been included inside the boiler in the upper part of the anti-backflow device (see fig. 16). To take the sample: 1) remove the top panel of the boiler (see fig. 4). 2) remove the insulation on the anti-backflow device. 3) open the...

Page 24: Pegasus F3 N 2S

24 pegasus f3 n 2s fig. 17 fig. 18 disassembly and cleaning the burner unit to remove the burner unit: • disconnect the electrical power supply and turn off the gas ahead of the boiler. • unscrew the two screws securing the electronic flame controller to the gas valve (fig. 17) and extract it from t...

Page 25: Pegasus F3 N 2S

25 pegasus f3 n 2s key 1 combustion chamber door 2 inspection door 3 pilot burner 4 ignition electrode 5 detection electrode 6 pilot nozzle 7 gas supply pipe fig. 21 pilot light unit 3 3 ÷ 4 mm 5 7 4 cleaning the boiler and fl ue to clean the boiler properly (fig. 22): • turn off the gas ahead of th...

Page 26: Pegasus F3 N 2S

26 pegasus f3 n 2s 3.4 troubleshooting fault cause and cure. After a few attempts at ignition, the electronic controller shuts down the boiler. Pilot light nozzle dirty - clean with compressed air. Check the regular gas flow to the boiler and the air has been eliminated from the pipes. Check that th...

Page 27: Pegasus F3 N 2S

27 pegasus f3 n 2s burner explosion. Delay on ignition. Check that the gas pressure is sufficient and the boiler casing is not dirty. The adjustment thermostat switches back on with too great a temperature difference. Check that the thermostat bulb is properly inserted in the sheath. Check the 2-sta...

Page 28: Pegasus F3 N 2S

28 pegasus f3 n 2s 4 technical characteristics and data 4.1 dimensions and connections fig. 23 side view front view rear view pegasus f3 n 119 2s pegasus f3 n 136 2s pegasus f3 n 153 2s pegasus f3 n 170 2s pegasus f3 n 187 2s pegasus f3 n 221 2s pegasus f3 n 255 2s pegasus f3 n 289 2s 930 1020 1100 ...

Page 29: Pegasus F3 N 2S

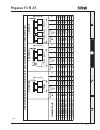

29 pegasus f3 n 2s fig. 24 4.2 general view and main components key 1 “0 - 1 - test” switch 2 2-stage adjustment thermostat 3 electronic controller reset button 4 plug 5 thermometer water gauge 6 plug 7 safety thermostat 8 arrangement for fitting an electronic controller 9 fume outlet on fume chambe...

Page 30: Pegasus F3 N 2S

30 pegasus f3 n 2s 4.3 technical data table gas supply pmax pmin heating power (net heat v alue - hi) useful heating power powers pmax pmin kw 119 71 kw 131 77 dimensions, weights connections depth mm 1050 width mm 930 height mm 1050 boiler water content litr es 38 no. Burner trains 7 minimum workin...

Page 31: Pegasus F3 N 2S

31 pegasus f3 n 2s 4.4 diagrams loss of head fig. 25 40 3 4 5 6 7 8 9 10 20 30 6 5 2 3 4 0.6 0.7 0.8 0.9 1 221 289 11 9 136 255 0.2 0.3 0.4 0.5 153 170 187 delivery m /h losses of head m column h o 2 3.

Page 32: Pegasus F3 N 2S

32 pegasus f3 n 2s wiring laid out by the installer key 24 ignition electrode 32 heating circulator (not supplied) 44 gas valve 49 safety thermostat 72 room thermostat (not supplied) 82 detection electrode 83 electronic controller 98 switch 114 water pressure switch 116 gas pressure switch 129 reset...

Page 33: Pegasus F3 N 2S

33 pegasus f3 n 2s wiring laid out by the installer key 24 ignition electrode 32 heating circulator (not supplied) 44 gas valve 49 safety thermostat 72 room thermostat (not supplied) 82 detection electrode 83 electronic controller 98 switch 114 water pressure switch 116 gas pressure switch 129 reset...

Page 34: Pegasus F3 N 2S

34 pegasus f3 n 2s key 24 ignition electrode 32 heating circulator (not supplied) 44 gas valve 49 safety thermostat 72 room thermostat (not supplied) 82 detection electrode 83 electronic controller 98 switch 114 water pressure switch 116 gas pressure switch 129 reset button with indicator lamp 159 t...

Page 35: Pegasus F3 N 2S

35 pegasus f3 n 2s key 24 ignition electrode 32 heating circulator (not supplied) 44 gas valve 49 safety thermostat 72 room thermostat (not supplied) 82 detection electrode 83 electronic controller 98 switch 114 water pressure switch 116 gas pressure switch 129 reset button with indicator lamp 159 t...

Page 36

Benchmark controls to comply with the building regulations, each section must have a tick in one or other of the boxes time & temperature control to heating room t/stat & programmer/timer programmable roomstat time & temperature control to hot water cylinder t/stat & programmer/timer combi boiler he...

Page 37: Service Interval Record

Service interval record it is recommended that your heating system is serviced regularly and that you complete the appropriate service interval record below. Service provider. Before completing the appropriate service interval record below, please ensure you have carried out the service as described...

Page 40

Phone numbers: installer service engineer because of our constant endeavour for improvement details may vary slightly from those quoted in these instructions. Lichfi eld road, branston industrial estate, burton upon trent, staffordshire de14 3hd tel. 08707 282 885 - fax 08707 282 886 all specificati...