- DL manuals

- Ferroli

- Air Conditioner

- RFA

- Installation and operation manual

Ferroli RFA Installation and operation manual

Summary of RFA

Page 1

1 rfa packaged air conditioners and heat pumps roof top for outdoor installation installation and operation manual r e fr ig er an t g a s e c o- friend l y i migliori gradi centigradi.

Page 2

2 the manufacturer declines all the responsabilities regarding inaccuracies contained in this manual, if due to printing or typing mistakes. The manufacturer reserves the right to apply changes and improvements to the products at any time and without notice. Dear customer, thank you for having purch...

Page 3

3 table of contents general features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

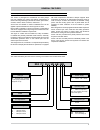

4 general features general instructions declaration of conformity unit dataplate the figure shows the fields reported on the unit dataplate : a - trademark b - model b1 - code c - serial number d - capacity in cooling e - capacity in heating (heat pump) f - power input in cooling g - power input in ...

Page 5

5 general features unit description this series of packaged air conditioners and heat pumps (roof top) satisfies the cooling and heating requirements of medium and large buildings (commercial centres, ipermarkets, cinemas, outlets, offices, canteens, restaurants ...) all the units are suitable for o...

Page 6

6 general features description of components external structure . Basement, supporting structure and lateral panels are made of galvanized and painted sheet- steel (colour ral 7035) to guarantee good resistance to atmospheric agents. The inspection panels are all easily removable by means of ¼ turn ...

Page 7

7 general features the internal side heat exchanger (user side) (2) is a finned coil realized with grooved copper pipes and aluminium fins with notched profile to increase the heat exchange coefficient. To avoid condensate drag, the frontal crossing air velocity don't exceed 2,7 m/s, also with the m...

Page 8

8 constructive configurations general features base version - vb each model can be supplied in different constructive configurations in order to satisfy the application requirements that can be necessary for the plants. The various versions, obtained adding to the base version some modules, are alwa...

Page 9

9 general features 2 dampers version - v2 the presence of two motorized dampers managed by the controller of the unit allows to operate with a minimum percentage of outdoor fresh air (adjustable through the user interface) and to perform thermal free cooling. The outdoor air inlet, equipped with a r...

Page 10

10 general features options constructive configuration vb - base version it only allows to operate with all return air. V1 - 1 damper version it allows to operate with a fixed percentage of outdoor fresh air, manually set. V2 - 2 dampers version it allows to operate with a variable percentage of out...

Page 11

11 general features accessories spring vibration dampers allow to reduce the transmission to the unit support plane of the mechanical vibrations generated by the com- pressor and by the fans in their normal operating mode. In order to keep the insulation degree higher than 90%, the number and the fe...

Page 12

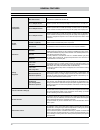

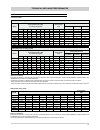

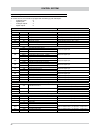

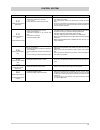

12 technical data and performances frame 1 2 3 model 35 .1 45 .1 55 .1 70 .2 90 .2 110 .2 140 .2 180 .2 220 .2 u.M. Powwer supply 400 - 3n - 50 400 - 3n - 50 400 - 3n - 50 v-ph-hz technical data refrigerant type r410a r410a r410a r410a r410a r410a r410a r410a r410a - compressor type scroll scroll sc...

Page 13

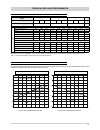

13 technical data and performances nominal performances pc cooling a35a27 ( source : air in 35°c d.B. / plant : air in 27°c d.B. 19°c w.B. ) total cooling capacity 35,5 46,3 57,7 71,0 92,3 113,0 142,0 184,0 226,0 kw rst* 0,70 0,70 0,70 0,70 0,70 0,70 0,70 0,70 0,70 - power input 10,9 14,0 17,7 22,5 ...

Page 14

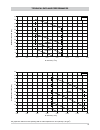

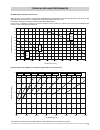

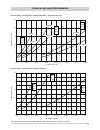

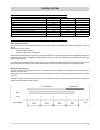

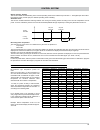

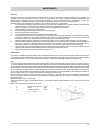

14 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0 15 20 25 30 35 40 45 50 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 15 20 25 30 35 40 45 50 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 15 20 25 30 35 40 45 50 technical data and performances cooling performances the graphs allow to get the corrective factors t...

Page 15

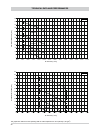

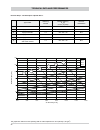

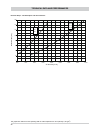

15 technical data and performances 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0 -15 -10 -5 0 5 10 15 20 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 -15 -10 -5 0 5 10 15 20 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 -15 -10 -5 0 5 10 15 20 heating performances heating capacity inlet air temperature w.B. [°c]...

Page 16

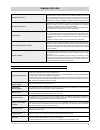

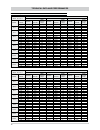

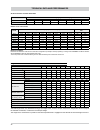

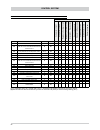

16 technical data and performances hot water coil performances 2 rows water : 60 - 40 °c air flow rate minimum standard maximum model t inlet air capacity water flow rate water pressure drops capacity water flow rate water pressure drops capacity water flow rate water pressure drops [°c] [kw] [l/h] ...

Page 17

17 technical data and performances 3 rows water : 80 - 60 °c air flow rate minimum standard maximum model t inlet air capacity water flow rate water pressure drops capacity water flow rate water pressure drops capacity water flow rate water pressure drops [°c] [kw] [l/h] [kpa] [kw] [l/h] [kpa] [kw] ...

Page 18

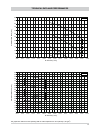

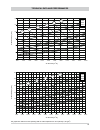

18 0 50 100 150 200 250 300 350 400 450 500 550 600 5000 6000 7000 8000 9000 10000 11000 12000 technical data and performances plant side aeraulic performances available static head - unit without options the graphs are referred to units operating with air at the temperature of 20°c (density 1,20 kg...

Page 19

19 0 50 100 150 200 250 300 350 400 450 500 550 600 5000 6000 7000 8000 9000 10000 11000 12000 technical data and performances air flow rate [ m 3 /h ] available static head [ pa ] upsized 55 .1 standard reduced the graphs are referred to units operating with air at the temperature of 20°c (density ...

Page 20

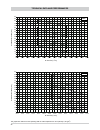

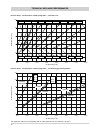

20 0 50 100 150 200 250 300 350 400 450 500 550 600 8000 9000 10000 11000 12000 13000 14000 15000 16000 17000 18000 19000 20000 21000 air flow rate [ m 3 /h ] available static head [ pa ] upsized 70 .2 standard reduced 0 50 100 150 200 250 300 350 400 450 500 550 600 8000 9000 10000 11000 12000 1300...

Page 21

21 0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 16000 18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000 40000 42000 technical data and performances air flow rate [ m 3 /h ] available static head [ pa ] upsized 140 .2 standard reduced the graphs are referre...

Page 22

22 0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 16000 18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000 40000 42000 air flow rate [ m 3 /h ] available static head [ pa ] upsized 180 .2 standard reduced 0 50 100 150 200 250 300 350 400 450 500 550 600 650 7...

Page 23

23 technical data and performances the graphs are referred to units operating with air at the temperature of 20°c (density 1,20 kg/m 3 ). Available static head of the return air fan when the return air fan is present, verify that the available head, corresponding to an air flow rate equal to the 70%...

Page 24

24 0 30 60 90 120 150 180 5000 6000 7000 8000 9000 10000 11000 12000 pressure drops - unit with option “special filters” air flow rate [ m 3 /h ] pressure drops [ pa ] technical data and performances 4 5 3 2 1 0 35.1 45.1 55.1 the graphs are referred to units operating with air at the temperature of...

Page 25

25 technical data and performances the graphs are referred to units operating with air at the temperature of 20°c (density 1,20 kg/m 3 ). 0 30 60 90 120 150 180 18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000 40000 42000 air flow rate [ m 3 /h ] pressure drops [ pa ] 4 5 3 2 1 0 14...

Page 26

26 technical data and performances 0 20 40 60 80 100 5000 10000 15000 20000 25000 30000 35000 40000 pressure drops - unit with option “heating integration” : "hot water coil" air flow rate [ m 3 /h ] pressure drops [ pa ] 0 20 40 60 80 100 120 5000 10000 15000 20000 25000 30000 35000 40000 pressure ...

Page 27

27 technical data and performances 0 5 10 15 20 25 5000 10000 15000 20000 25000 30000 35000 40000 pressure drops - unit with option “heating integration” : "electricl heater coil" air flow rate [ m 3 /h ] pressure drops [ pa ] 0 10 20 30 40 50 5000 10000 15000 20000 25000 30000 35000 40000 pressure ...

Page 28

28 technical data and performances 0 20 40 60 80 100 120 140 160 5000 7000 9000 11000 13000 15000 17000 19000 21000 pressure drops - unit with option “air flow silencers” air flow rate [ m 3 /h ] pressure drops [ pa ] the graphs are referred to units operating with air at the temperature of 20°c (de...

Page 29

29 technical data and performances operating limits the graphs reported below show the operating area inside which the correct working of the unit is guaranteed. 10 15 20 25 30 35 40 5 10 15 20 25 30 35 40 45 50 55 cooling inlet air temperature d.B - source side [°c] inlet air temperature d.B. - pla...

Page 30

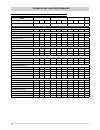

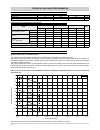

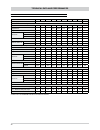

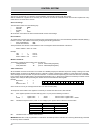

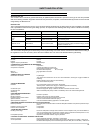

30 technical data and performances electrical data model 35 .1 45 .1 55 .1 70 .2 90 .2 110 .2 140 .2 180 .2 220 .2 u .M . Power supply 400v - 3ph+n - 50hz v-ph-hz f .L .A . - maximum current input compressor 1 23,0 28,0 37,0 23,0 28,0 37,0 45,0 60,0 76,0 a compressor 2 - - - 23,0 28,0 37,0 45,0 60,0...

Page 31

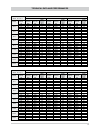

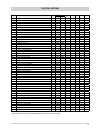

31 technical data and performances noise levels base acoustic setting up (ab) model sound power levels [db] by octave bands [hz] sound power level sound pressure level at 1 metre at 5 metres at 10 metres 63 125 250 500 1000 2000 4000 8000 [db] [db(a)] [db(a)] [db(a)] [db(a)] 35 .1 83,6 82,7 84,7 79,...

Page 32

32 technical data and performances weights model 35 .1 45 .1 55 .1 70 .2 90 .2 110 .2 140 .2 180 .2 220 .2 u .M . Constructive configuration base version vb 724 807 874 1052 1220 1345 1820 1940 2010 kg 1 damper version v1 916 999 1066 1316 1484 1609 2148 2268 2338 kg 2 dampers version v2 927 1010 10...

Page 33

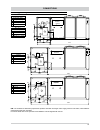

33 d 6 7 10 6 55 51 150 22 51 q.E. 5 4 3 245 285 9 8 11 a2 q.E. 245 5 4 3 13 11 6 7 10 9 8 e 55 51 22 51 d m 150 h a4 n 6 106 b 106 39 39 5 53 a1 53 6 6 c 1 2 5 2 1 c 39 39 1 53 a1 53 106 b 106 6 6 35.1 45.1 55.1 70.2 90.2 110.2 vb vb con modulo termico a gas legend pos. Description 1 refrigerant ci...

Page 34

34 q.E. 3 14 13 4 7 10 6 9 8 12 12 5 22 51 55 51 245 a4 i o d m 800 468 q.E. D 4 3 5 245 a2 7 10 9 8 6 6 14 55 51 22 51 12 12 f 800 468 1085 q.E. 3 15 13 4 7 10 6 9 8 12 12 5 22 51 245 a5 1190 l 6 55 51 d m 1600 468 q.E. D 4 3 5 245 7 10 9 8 6 15 22 51 12 12 a3 1190 1600 468 g 6 55 51 6 v3 con modul...

Page 35

35 6 10 6 8 3 3 11 2 1 1 6 6 5 9 5 7 4 4 212, 5 2345 2132, 5 2200 55 a1 55 39 39 106 b 106 2132 2345 365 a2 285 d 150 e 2298 34 101 1923 176 180, 5 1923 10 5 vista assonometrica 6 10 8 3 3 11 9 5 7 6 13 13 4 4 2132 365 2345 a4 n d m 150 h vb con modulo termico a gas 6 10 8 3 3 9 5 7 6 13 13 6 10 8 3...

Page 36

36 8 17 16 1 2 9 3 5 10 11 7 4 b c a b a c 8 17 16 1 2 9 3 10 11 7 4 5 1 the choice of the location of the unit is very important in order to guarantee the unit to work properly. Air flow obstructions, air circulation difficulties, leaves or other foreign materials that can clog the coils, winds tha...

Page 37

37 connections hydraulic connections internal coil condensate discharge connection (compulsory) it is very important that this operation be performed with particular care by specialized personnel. For the sequence follow these instructions: • . Connect the condensate discharge tube. • . Use a siphon...

Page 38

38 connections important • . If the unit is supported by anti-vibration mounts, take particular note that also the water connections must have anti-vibration joints installed . • . It is obligatory to mount a metal mesh filter with a mesh of no more than 1 mm on the water inlet tube, at the risk of ...

Page 39

39 connections aeraulic connections all the units, in their various configurations, are equipped with an intake that is always frontal, and an outlet that can be frontal or downward. The edges of the outlet and inlet openings are designed in such a manner as to permit the proper attachment of the du...

Page 40

40 q.E. Mb mb 43 3 16 2 43 3 54 285 54 44 1 15 35 1 42 11 32 1 1900 q.E. 60 1 1900 393 q.E. 518 mb 60 1 1940 q.E. Mb mb 64 400 54 1940 75 2 47 4 18 3 47 4 80 1 65 1 49 61 05 1 mb mb mb mb 442 569 429 569 191 2610 569 569 106, 5 2610 q.E. Mb mb 43 3 16 2 43 3 54 285 54 44 1 15 35 1 42 11 32 1 1900 q....

Page 41

41 q.E. Mb mb 43 3 16 2 43 3 54 285 54 44 1 15 35 1 42 11 32 1 1900 q.E. 60 1 1900 393 q.E. 518 mb 60 1 1940 q.E. Mb mb 64 400 54 1940 75 2 47 4 18 3 47 4 80 1 65 1 49 61 05 1 mb mb mb mb 442 569 429 569 191 2610 569 569 106, 5 2610 models 140 .2 - 180 .2 - 220 .2 expulsion air damper position 150 6...

Page 42

42 general standards the electric wiring must be installed by qualified personnel according to the standards that are in force at the time of installation in the destination country. Before beginning any work on the electrical system, first make sure that the unit's power supply line is isolated at ...

Page 43

43 q.E. 2 1 3 4 5 245 57 1 43 6 06 446 195 2735 930 465 465 163 51 5 q.E. 2 1 3 4 5 47 4 268 2900 1200 334 600 600 46 1 00 7 74 627 193 35.1 - 45.1 - 55.1 standard maggiorato q.E. 4 2 1 3 5 2900 1200 600 600 350 289 85 2 34 1 78 7 99 503 347 70.2 - 90.2 - 110.2 standard 70.2 - 90.2 - 110.2 maggiorat...

Page 44

44 q.E. 2 1 3 4 5 245 57 1 43 6 06 446 195 2735 930 465 465 163 51 5 q.E. 2 1 3 4 5 47 4 268 2900 1200 334 600 600 46 1 00 7 74 627 193 35.1 - 45.1 - 55.1 standard maggiorato q.E. 4 2 1 3 5 2900 1200 600 600 350 289 85 2 34 1 78 7 99 503 347 70.2 - 90.2 - 110.2 standard 70.2 - 90.2 - 110.2 maggiorat...

Page 45

45 receiving on receiving the unit, make sure the shipment is complete by carefully checking its agreement with that ordered. Carefully check the load for any damage. In case of goods with visible damage, promptly report it to the carrier, writing "collection with reserve due to clearly visible dama...

Page 46

46 positioning all series units are designed for outside installation. To ensure correct installation: • . Make sure the support surface is perfectly level and that it can take the weight of the unit. It is advisable to create a base of suitable size for the unit. This precaution is indispensable wh...

Page 47

47 start up start up the operations described below must only be carried out by adequately trained personnel. For the contractual warranty to be valid, commissioning must be carried out by an authorised assistance centre. Before calling, it is advisable to ensure that all the installation steps have...

Page 48

48 checks and settings after switching on refrigerant circuit for each refrigerant circuit, make sure : • there are no gas leaks (all the caps of the pressure points must be fitted and secured) • the saturation temperature (dew point) corresponding to the condensation pressure is approx. 10-15°c hig...

Page 49

49 control system control system the unit is managed by a controller with microprocessor consisting of a card, inside the electrical panel, to which all the loads and control devices are connected and a user interface accessed by removing the electrical panel protection panel. A further interface ca...

Page 50

50 control system led step 1 : compressor circuit 1 on : compressor circuit 1 on off : compressor circuit 1 off flashing at a frequency of 1 hz (1 per second) : timing in progress flashing at low frequency ( : defrost in progress on circuit 1 led step 3 : compressor circuit 2 on : compressor circuit...

Page 51

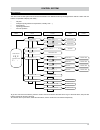

51 control system main structure the menu of the control system has a tree structure based on four different levels. By scrolling the menu with the “mode” and “set” buttons it is possible to display and modify : • set point • analogue inputs (probes for temperature, humidity, co2 …) • active alarms ...

Page 52

52 control system inputs and outputs to monitor the unit, the controller is equipped with the following inputs and outputs : • analogue inputs : 8 • digital inputs : 11 • analogue outputs : 3 • digital outputs : 8 description characteristics analogue inputs ai1 str ts.B. Probe inlet air ntc temperat...

Page 53

53 control system controller technical data description typical minimum maximum power supply voltage * 12, 0 v~ 10,8 v~ 13, 2 v~ power supply frequency 50 hz / 60 hz - - power 11 va - - insulation class 1 - - protection degree frontal ip0 - - ambient operating temperature 25 °c -10 °c 60 °c ambient ...

Page 54

54 control system loads blocked compressor circuit 1 compressor circuit 2 reverse cycle valve circuit 1 reverse cycle valve circuit 2 internal fan - return air fan electrical heater coil gas heating module hot water coil 3 way valve external fans circuit 1 external fans circuit 2 outdoor air damper ...

Page 55

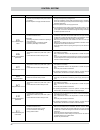

55 control system alarm diagnostics intervention of a safety device indicates an operation fault. Before resetting the alarm it is necessary to carry out a check and eliminate the cause of the alarm. Given below is a list of possible problems and causes, as a troubleshooting guide for some faults th...

Page 56

56 control system alarm cause possible action or check 8. External fans faulty (in heating). 9. External fan speed adjustment system inefficient (in heating). 10. Phase sequence at supply terminals incorrect. 8. Check for any obstructions on the fan blades. Check the electrical windings and replace ...

Page 57

57 control system alarm cause possible action or check e42 outside air temperature probe fault 1. Probe shorted or disconnected. 2. Temperature outside the probe limits (-30°c ÷ 90°c). 3. Probe electrical connection faulty or loose. 1. Check the probe as described in the section “probe characteristi...

Page 58

58 control system functions available for the user set point the set point value in cooling and in heating can be set. These values must come within a predetermined max. And min. Value. The task of the controller is to keep the inlet air temperature as close as possible to the set value by activatin...

Page 59

59 control system remote cooling - heating this function allows remote switching of the machine operating mode and is enabled only if pa h49 = 1. The digital input used is id11. If the input is active (contact open) the selected operating mode is heating. Automatic mode this function enables automat...

Page 60

60 serial communication the unit can communicate on a serial line using the modbus communication protocol with rtu coding. With the “modbus kit”, supplied as an accessory, the unit can be connected to an rs485 network and meet the requirements of any master device connected to the network serial lin...

Page 61

61 control system label description rw register address bit num- ber lsb cpl exp um dec hex - cooling set point rw 2049 0801 16 0 y -1 °c - heating set point rw 2050 0802 16 0 y -1 °c h10 enable heat pump rw 2060 080c 16 0 n 0 - h49 operating mode selection configuration rw 2099 0833 16 0 n 0 - h67 ...

Page 62

62 maintenance maintenace important. Before carrying out any cleaning or maintenance operations on the unit make sure the power is disconnected. Any routine or extraordinary maintenance operations given below must be carried out by specialised and authorised personnel in order to ensure compliance w...

Page 63

63 maintenance air filters checking the filters is considered routine maintenance to be carried out according to the place where the unit is installed. It is advisable to carry out this operation weekly in particularly dusty places. All the units are fitted standard with pleated filter cells (g4 fil...

Page 64

64 maintenance pulleys avoid the conditions listed below, which could cause early wear of the pulleys (fixed or expanding). • lack of alignment, lack of parallelism, breakage, high wear and lack of eccentricity • dust, grease, dirt and also a high level of humidity which would cause the formation of...

Page 65

65 safety and pollution accessing the unit the access to the unit must be granted exclusively to qualified personnel trained to operate on this type of units and provided with the necessary protection equipment. Moreover such personnel, to operate, must be authorized by the owner of the unit and rec...

Page 66

66 safety and pollution the manufacturer declines all the responsabilities regarding inaccuracies contained in this manual, if due to printing or typing mistakes. The manufacturer reserves the right to apply changes and improvements to the products at any time and without notice. Respiratory tract p...

Page 67

67.

Page 68

68 i migliori gradi centigradi ferroli spa ¬ 37047 san bonifacio (verona) italy ¬ via ritonda 78/a tel. +39.045.6139411 ¬ fax +39.045.6100933 ¬ www.Ferroli.It cod. 3qe22363.