- DL manuals

- Ferroli

- Boiler

- ROMA 55 FF

- Installation and servicing instructions

Ferroli ROMA 55 FF Installation and servicing instructions

These Instructions are to be left with the User or adjacent to the gas meter.

FERROLI

ROMA 55 FF

WALL MOUNTED,

FANNED FLUE BOILER

INSTALLATION

& SERVICING

INSTRUCTIONS

G.C. Appliance No. 4126705

Please read these Instructions

thoroughly before using

the appliance

FERROLI HELPINE

FOR SERVICE INFORMATION OR

HELP TELEPHONE: 08707 282 885

ALWAYS QUOTE SERIAL NUMBER

FOR IMMEDIATE ASSISTANCE

Phone numbers:

Installer ________________________

Service Engineer _________________

Serial N

°

________________________

Summary of ROMA 55 FF

Page 1

These instructions are to be left with the user or adjacent to the gas meter. Ferroli roma 55 ff wall mounted, fanned flue boiler installation & servicing instructions g.C. Appliance no. 4126705 please read these instructions thoroughly before using the appliance ferroli helpine for service informat...

Page 2: Roma 55 Ff

2 roma 55 ff.

Page 3: Roma 55 Ff

3 roma 55 ff list of contents 1 general description and information 2 technical data 3 boiler flow diagram 4 key boiler flow diagram 5 installation data 5.01 water systems 5.02 open (vented) systems 5.03 sealed systems 5.04 pump selection 5.05 drain points 5.06 hot storage vessel 5.07 quality of com...

Page 4: Roma 55 Ff

4 roma 55 ff 1. General description and information 1.1 information 1. Installation must be carried out by a competent person, and in accordance with the relevant requirements of the current issues of: a. Gas safety (installation & use) regulations. B. Building regulations. C. Building standards (sc...

Page 5: Roma 55 Ff

5 roma 55 ff 2. Technical data heat input 20 kw 68,200 btu/h 10 kw 34,100 btu/h heat output 16 kw 55,000 btu/h 7.3 kw 25,000 btu/h burner pressure 12 mbar 4.7 in wg 2.4 mbar 1.0 in wg gas rate - after 10 minutes 1.9 m 3 /h 66 ft 3 /h 0.95 m 3 /h 33 ft 3 /h gas connection size / position 1/2" bsp / l...

Page 6: Roma 55 Ff

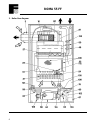

6 roma 55 ff 3. Boiler flow diagram.

Page 7: Roma 55 Ff

7 roma 55 ff 4. Key boiler flow diagram pos. G.C. No. Description q.Ty 3. Flue/air intake (side outlet) 1 16. Complete fan rl 85/0034a1 3025lh 422 1 21a. Main injector n.G. 1.25 9 21b. Main injector l.P.G. 0.72 9 23. Thermocouple 1 24. Complete spark electrode 1 25. Pilot 1 27. Copper heat exchanger...

Page 8: Roma 55 Ff

8 roma 55 ff 5. Installation data * h = maximum head developed by pump. 5.1 water system general 1. The roma 55 ff will supply central heating and, via an indirect cylinder, stored hot water. 2. All water systems must be in accordance with the bye-laws of the local water undertaking. 3. Only fully p...

Page 9: Roma 55 Ff

9 roma 55 ff 5.3 sealed system 1. Further guidance: bs 5449, bs 6798, bs 7074 part 1, british gas publications. 2. Two typical sealed systems are shown, above. 3. Components: a) expandion vessel. To bs 4814. Sized according to bs 5449 and/or bs 7074 part 1. Positioned on the inlet to the pump. B) sa...

Page 10: Roma 55 Ff

10 roma 55 ff boiler pressure loss 5.4 pump selection suitable pump should be fitted taking due account of the pressure loss across the boiler. Pump to comply with bs 1394. A minimum flow rate of 6 litres/min (1.3 gal/min) is required. 5.5 drain points must be provided to enable the system to be dra...

Page 11: Roma 55 Ff

11 roma 55 ff 5.9 flue system 1. Further guidance: bs 5440 part 1. 2. Flue types: fanned. Balanced, and hence appliance is room sealed. 3. Termination: outside. Horizontal. Vertical. 4. Direction: from boiler, to rear, either side and vertical (side & vertical required optional flue turret). 5. Maxi...

Page 12: Roma 55 Ff

12 roma 55 ff 6. Terminal position (outside) a quinnell barratt and quinnell guard (part. No. C2) should be screwed to the wall centrally over the terminal, when the distance is less than 2 m above a balcony, above ground or above a flat roof to which people have access. 6.01 terminal position minim...

Page 13: Roma 55 Ff

13 roma 55 ff 7. Terminal position horizontal, seduct, u duct standard se duct or u duct terminal position - the terminal must be situated relative to the seduct or u duct as shown. Horizontal only. Flue lengths - two lengths are available. Installation - the exposed wall face must be made good and ...

Page 14: Roma 55 Ff

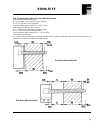

14 roma 55 ff 8. Location 1. Further guidance: bs 6798. 2. Not suitable for external installation. 3. Must be mounted on a suitable load bearing flat wall. 4. Combustable walls are not suitable. 5. Dimensions of the boiler. Weight empty 30 kg 66 lb weight full 30.5 kg 67 lb height 655 mm 26.8 in wid...

Page 15: Roma 55 Ff

15 roma 55 ff 8.1 boiler location dimensions (mm) minimum clearances (mm).

Page 16: Roma 55 Ff

16 roma 55 ff 9. Boiler connections gas, water and electrical front view. All connections at rear. Side view. (with optional side flue turret) a. Air pipe for flue system 4" (100 mm) plastic g. Gas service cock connection 1/2" bsp female f. Flow 22 mm compression r. Return 22 mm compression 9.1 gas ...

Page 17: Roma 55 Ff

17 roma 55 ff 10. Electricity supply and connections all electrical installation work must be carried out by a qualified electrician, and all work shall be in accordance with the current issue of the iee wiring regulations. Supplied for use on 230 v ~ 50 hz supply, protected by a 3 amp fuse. The boi...

Page 18: Roma 55 Ff

18 roma 55 ff 11. Boiler flow diagram key 16. Fan 23. Thermocouple 24. Spark electrode 32. Pump (not fitted) 43. Air pressure switch 46. Solenoid gas valve 49. Overheat cut-off thermostat 50. Heat exchanger limit thermostat 63. C.H. Boiler thermostat 66. Microswitch combination gas valve 67. Ignitio...

Page 19: Roma 55 Ff

19 roma 55 ff 12. Electrical functional drawing key 16. Fan 23. Thermocouple 24. Spark electrode 32. Pump (not fitted) 43. Air pressure switch 46. Solenoid gas valve 49. Overheat cut-off thermostat 50. Heat exchanger limit thermostat 63. C.H. Boiler thermostat 66. Microswitch combination gas valve 6...

Page 20: Roma 55 Ff

20 roma 55 ff 13. Illustrated wiring diagram key 16. Fan 24. Spark electrode 43. Air pressure switch 44. Combination gas valve 46. Solenoid gas valve 49. Overheat cut-off thermostat 50. Heat exchanger limit thermostat 63. C.H. Boiler thermostat 66. Microswitch combination gas valve 67. Ignition tran...

Page 21: Roma 55 Ff

21 roma 55 ff 14. Installation procedure in most cases it will be easy and desireable to install the boiler with only the front section of the outer case and the lower cover removed. However, if it is wished to install the flue system without the boiler on the wall, the upper rear frame is easily de...

Page 22: Roma 55 Ff

22 roma 55 ff 14.3 prepare the wall 1. Using the template provided decide upon the position of the boiler. 2. Mark and drill four holes 10 mm diameter 60 mm deep. 3. Insert wall plugs provided and screw in the hexagon headed screws provided into the upper holes to within about 5 mm of the wall face....

Page 23: Roma 55 Ff

23 roma 55 ff 14.4 prepare the flue and air pipes rear and side flue outlet 1. Measure the wall thickness, w. 2. For rear flues; cut the plastic air pipes to length: w + 125 + 100 mm including terminal; cut the metal flue pipe to length: w + 120 + 60 mm. This allows for expansion. Go to step 4. 3. F...

Page 24: Roma 55 Ff

24 roma 55 ff 14.5 vertical flue 1. Fit the side vertical flue turret bend (facing upwards) to the upper frame, using the fibre gasket and four self tapping screws provided. Discard the rear flue socket. 2. Measure the length for the plastic air pipe vertically from the appliance turret inner stop t...

Page 25: Roma 55 Ff

25 roma 55 ff 14.6 mounting the boiler / completing the flue system note - if access is restricted, then pre-plumb the boiler flow and return connections at this stage. 1. Lift the boiler or upper frame only if removed, and locate the upper key hole slots in the back panel over the upper mounting sc...

Page 26: Roma 55 Ff

26 roma 55 ff the pump is connected as follows (3 wire electrical lead). Brown - live blue - neutral green/yellow - earth if external controls are not required remove tha supplied 5 core electrical lead and replace with a 3 core lead to supply the permanent 230 v live supply to the appliance. Link o...

Page 27: Roma 55 Ff

27 roma 55 ff 15. Commissioning carry out preliminary electrical system checks i.E. Earth continuity, resistance to earth, short circuit and polarity using a suitable test meter. 1. Remove the outer case and lower cover (17.2.1 & 3). 2. Test for gas soundness up to the boiler service cock - bs 6891....

Page 28: Roma 55 Ff

28 roma 55 ff 15. Pilot adjustment screw clockwise to decrease 17. Adjustment screw burner pressure clockwise to increase 18. Burner pressuretest point 18. After 10 minutes, adjust the heat input to the required value. (anticlockwise to decrease). Replace the cap. 19. Note - if the required pressure...

Page 29: Roma 55 Ff

29 roma 55 ff.

Page 30: Roma 55 Ff

30 roma 55 ff start does pilot light? Il pilot lifting off? Is 230 v at terminals l and n? Replace spark igniter purge air from gas supply and check for blocked pilot injector clean if necessary. Check inlet gas pressure light pilot replace thermocouple does pilot now stay alight? Replace gas valve ...

Page 31: Roma 55 Ff

31 roma 55 ff 16.1 fault finding rectify are connections at air pressure switch correct? Replace air pressure switch is fan operating at full speed? Ie 230 v at pcb terminals 17 and 18? Are sensing tubes connected/connected correctly to air pressure switch? Are sensing tubes damaged replace tubes ha...

Page 32: Roma 55 Ff

32 roma 55 ff 16.2 fault finding is fan running at low speed? Replace fan replace relay replace pcb fuse check electrical connections to fan is fan jammed or seized? Has pcb fuse blown? Is there 230 v at terminals l and n? Is voltage at fan approx. 85v? (pcb terminals 18 and 17) is voltage at fan 23...

Page 33: Roma 55 Ff

33 roma 55 ff 17. Replacement of parts 17.1 general procedures and notes 1. Replacement of parts must be out by a competent person. 2. Isolate the electrical supply and turn off the gas supply (gas service cock). 3. Upon completion always: • check for gas soundness of joints broken • afeter water dr...

Page 34: Roma 55 Ff

34 roma 55 ff 17.3 fan 1. Refer to 17.1, then remove the outer and inner cases (17.2, 1 & 2). 2. Disconnect the pressure sensing tube. 3. Withdraw fan complete with collector hood then remove 4 screws. 4. Disconnect 3 electrical leads. Replacement: • ensure that gaskets a. And b. Are transferred and...

Page 35: Roma 55 Ff

35 roma 55 ff 17.4 pilot burner assembly 1. Refer to 17.1, then remove the outer and inner cases, the lower cover, and the combustion chamber front cover (17.2.1 to 4). 2. Disconnect the thermocouple and withdraw. 3. Unscrew the pilot pipe at both ends, and withdraw the pipe from the burner (the inj...

Page 36: Roma 55 Ff

36 roma 55 ff 17.5 electrode 1. Refer to 17.1, then remove the outer and inner cases, and the combustion chamber front cover. (17.2.1, 2 & 4). 2. Disconnect the electrode lead at the pcb and remove the bush from control box. Unscrew the electrode and withdraw the lead (item 5). Replacement: check th...

Page 37: Roma 55 Ff

37 roma 55 ff 17.8 main burner / injectors 1. Refer to 17.1, then remove the outer and inner cases, the lower cover, the combustion chamber front cover, and the control box (17.2.1 to 5). 2. Remove the pilot burner assembly (17.4.2 to 4). 3. Remove the burner from the chamber side panels, 2 screws. ...

Page 38: Roma 55 Ff

38 roma 55 ff 17.12 pressure switch note - any of 3 alternative pressure switches can be used (fig. Section 10). 1. Refer to 17.1, then remove the outer case and lower cover (17.2.1 & 3). 2. Remove the switch complete with bracket, 1 screw. 3. Disconnect 3 electrical leads and 2 pressure tubes. Repl...

Page 39: Roma 55 Ff

39 roma 55 ff 17.15 control box components 1. Refer to 17.1, then remove the outer case, the lower cover and the control box (17.2.1, 3 & 5). A. Capacitor 2. Remove nut and washer. 3. Disconnect 2 leads. Replacement: polarity is immaterial. B. Fuse 2. Pull from holder. Replacement: a spare is provid...

Page 40: Roma 55 Ff

40 roma 55 ff 18. Routine servicing 18.1 general to ensure the continued, safe operation of the boiler, it is recommended that it is checked and serviced as necessary at regular intervals. Frequency will depend upon particular installation conditions and usage, but in general once a year should be a...

Page 41: Roma 55 Ff

41 roma 55 ff.

Page 42: Roma 55 Ff

42 roma 55 ff 20. Parts list pos. G.C. No. Description q.Ty makers part no. 3. Flue/air intake hood side vertical outlet (opt) 1 3980220 16. 372368 complete fan rl 85/0034a1 3025lh 422 1 3980224 21a. 386174 main injector n.G. 1.25 9 3980146 21b. 386175 main injector l.P.G. 0.72 9 3980148 23. 372369 ...

Page 43: Roma 55 Ff

43 roma 55 ff.

Page 44

Because of our constant endeavour for improvement details may vary slightly from those quoted in these instructions. Phone numbers: installer _________________________ service engineer __________________ all specifications subject to change lichfield road, branston industrial estate, burton upon tre...