- DL manuals

- Ferroli

- Boiler

- SYS 10-23

- Installation, Maintenance And User Instructions

Ferroli SYS 10-23 Installation, Maintenance And User Instructions

Summary of SYS 10-23

Page 1

Cod. 3544570/0 - 10/2003 wall-hung, gas-fired, system boiler, for central heating installation, maintenance and user instructions sys 10-23.

Page 2

2 this symbol indicates “warning” and is placed near all warnings regarding safety. Such provisions must be strictly adhered to so as to avoid danger and damage to persons and property. This symbol highlights a note or an important warning. • carefully read the warnings in this instruc- tion booklet...

Page 3

Sys 10-23 3 1. User/operating instructions....................................................................4 1.1 introduction.............................................................................................................4 1.2 control panel ..............................................

Page 4

4 sys 10-23 1. Operating/user instructions 1.1 introduction dear customer, thank you for having chosen the sys 10-23, an advanced-concept ferroli wall-hung boiler featuring cutting-edge technology, high reliability and constructional quality. Please carefully read this manual and leave it with the e...

Page 5

Sys 10-23 5 1.2 control panel to access the control panel, open the drop down cover. 1.3 ignition and shut-down ignition • open the gas cock of the boiler. • vent air present in the pipe upstream of the gas valve. • turn on the switch (if present) or plug upstream of the boiler. • turn on the boiler...

Page 6

6 sys 10-23 1.4 settings setting the ambient temperature (using the optional room thermostat) set, using the room thermostat, the temperature required inside the rooms. Based on the command from the room thermostat, the boiler is ignited and heats the system water to the set central heating outlet t...

Page 7

7 sys 10-23 2. Installation 2.1 general instructions this appliance must only be used for the purposes it has been specifically designed for. This appliance is used to heat water to below boiling temperature at atmospheric pressure and must be connected to a central heating and/or hot warm distribut...

Page 8

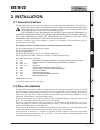

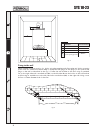

8 sys 10-23 fixing to the wall select suitable mounting position for boiler, using the template mark flue outlet and boiler mounting points. Drill two 10mm holes 90mm deep to accept the wall plugs, fit wall plugs. Fit two special wall plugs on the wall as described in the fig. 3. Fasten the wall bra...

Page 9

9 sys 10-23 2.3 water connections the heat capacity of the appliance should be established in advance by calculating the heating requirements of the building according to the standards in force. For correct operation and long-life of the boiler, the hydraulic system must be suitably proportioned and...

Page 10

10 sys 10-23 water treatment if water treatment is used ferroli ltd recommend only the use of fernox or sentinel water treatment products, which must be used in accordance with the manufacturers instructions. For further information contact: fernox manufacturing co. Ltd. Sentinel division tandern ho...

Page 11

11 sys 10-23 2.4 gas connection before making the connections, check that the appliance is configured for operation with the type of fuel available, and carefully clean all the gas pipes in the system, to remove any residues that may affect the correct operation of the boiler. The gas connections mu...

Page 12

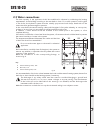

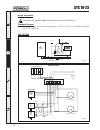

12 sys 10-23 room thermostat warning: the room thermostat must have 230v live contacts. Standard systems for a general pipe layout and wiring diagram on the “s” and “y” plan systems please see fig. 7a, 7b, and 8a, 8b. Sys “s” plan pipe layout wiring diagram sys ferroli boiler d.H.W. Zone valve a.A.V...

Page 13

13 sys 10-23 tempra 12/18 “y” plan pipe layout sys ferroli boiler auto air vent automatic bypass (mimimum flow of 6l/min.) wiring diagram 7 6 5 4 3 2 1 sys 10-23 junction box n l 1 2 3 4 5 6 7 8 9 10 programmer neutral live ch on dhw on dhw off blue white grey orange room thermostat cylinder thermos...

Page 14

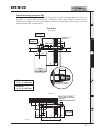

14 sys 10-23 Ø replacing the restrictor to install or change the restrictor, remove the fan unit, remove the flue gas connecting pipe 1 (as shown in fig. 9a) and insert the diaphragm 2 (as shown in fig. 9b). Type 60/100 length up to: 1 bend + 1 metre 1 bend + 3 metres 1 bend + 3 metres 1 bend + 4 me...

Page 15

15 sys 10-23 drill the wall 10, 20 mm greater than the diameter of the pipe slope downwards by 3 mm/m 70 d s 50* 125 110 50 l 115 160 240 * = between 10 and 60 mm bend 60/100 1kwmr81u d s l 125 70 Ø60 Ø100 70 min. Cut the internal pipe 70 mm longer than “l” 50* 50 115 115 80 -3 mm/m 192 208 Ø60/100 ...

Page 16

16 sys 10-23 sloped tile 1kwma82u concentric adapter 60/100 1kwmr52a max. 4m extension 60/100 1kwma56u 950 50 max. 4 mt roof terminal 1kwma83u 950 53 50 950 50 1000 125 10 vertical outlet for installation (top flue connection): 1. Define the position for the installation of the appliance 2. Drill th...

Page 17

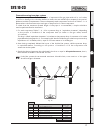

17 sys 10-23 ref. 1 2 3 4 5 6 n ° pieces 1 10 1 1 1 12 air bend Ø80 r/d = 0,75 horizontal air pipe air wall terminal air inlet closing flange flue bend 80 mm r/d = 0,75 horizontal flue description equivalente pressure drop 1,5 m 10,0 m 2,0 m included 2,5 m 24,0 m 45,0 m total table 6 7 1 air wall te...

Page 18

18 sys 10-23 pipes and fittings reduction table air flue v e rtical horizontal v e rtical horizontal description male -fem ale flue Ø80 female -fem ale bend 45 ° Ø80 female -fem ale bend 90 ° Ø80 male -fem ale bend 90 ° Ø80 pipe fitting m/m/f Ø80 with inspecting plug+trap for condensate drainage sys...

Page 19

19 sys 10-23 p d, e q q l b c a g f l j h h k n n m m q flue terminal positions fig. 13 minimum dimensions of flue terminal positions directly below an opening, air brick, opening windows, etc. Above an opening, air brick, opening windows, etc. Horizontally to an opening, air brick, opening windows,...

Page 20

20 sys 10-23 3. Service and maintenance 3.1 settings all the adjustment and conversion operations must be performed by qualified personnel, such as personnel from the local customer service centre. Ferroli ltd. Declines all liability for damage to persons and/or things deriving from tampering with t...

Page 21

21 sys 10-23 3.2 commissioning the appliance must only be commissioned for use by qualified personnel, before igniting the boiler: • open any on-off valves between the boiler and systems. • check the gas system for soundness, proceeding with care and using a leak detection water solution to find any...

Page 22

22 sys 10-23 if, after correctly having performed the ignition operations, the burners do not ignite and the shut-down warning light is on, wait around 15 seconds and then turn knob “a” (fig. 1) to the reset position and release it. The control unit will be reset and will repeat the ignition cycle. ...

Page 23

23 sys 10-23 opening the casing to open the boiler casing: 1 using a screwdriver, completely remove the 2 screws, “a” 2 open the control panel “b” by pulling down 3 unscrew the 2 screws “c” 4 remove the casing “d”. C d b fi g. 15 a d air flue gases cleaning the boiler and the burner the body and the...

Page 24

24 sys 10-23 remove and re-presurising of c.H. Expansion vessel • refer to 7.01 a, b • isolate electricity and water supplies • remove outer case (two screws bottom rear corners) • loosen the "a" connections to expansion vessel • remove "b" screw • remove the expansion vessel • re-assemble in revers...

Page 25

25 sys 10-23 a b c d gas valve (fig. 19) • isolate gas and electricity supplies • remove outer case (two screws bottom rear corners) • remove the two securing screws and lower control panel • disconnect electrical connections from valve ("a") • disconnect plastic tube "c" • loosen the connection "d"...

Page 26

26 sys 10-23 removal of burner (fig. 22) • isolate gas and electricity supplies • remove outer case (two screws bottom rear corners) • remove room sealed cover • disconnect ignition and flame rectification leads "a" • undo gas rail union "b" • undo two screws securing the burner assembly to the boil...

Page 27

27 sys 10-23 spark a flame detect spark or flame detect electrode (fig. 24) • isolate gas and electricity supply • remove outer case (two screws bottom rear corners) • open room sealed compartment and combustion chamber • identify electrode from fig. 24 • unplug electrical connection "a" from sensin...

Page 28

28 sys 10-23 1 2 3 4. Characteristics and technical specifications 4.1 dimensions and fittings fi g. 25 key 1 central heating flow 2 gas supply 3 central heating return.

Page 29

29 sys 10-23 4.2 overall view and main components fi g. 26 11 7 44 14 10 20 21 22 82 81 49 28 5 29 187 43 56 16 27 50 19 26 36 32 63 129 145 188 51 133 key 5 room sealed compartment 7 gas inlet 10 central heating flow 11 central heating return 14 safety valve 16 fan 19 combustion chamber 20 burner a...

Page 30

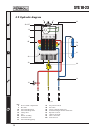

30 sys 10-23 fi g. 27 4.3 hydraulic diagram + - 43 49 50 56 81 44 32 20 82 5 29-187 16 10 7 11 14 key 5 room sealed compartment 7 gas inlet 10 central heating flow 11 central heating return 14 safety valve 16 fan 20 burner assembly 29 internal flue exit 32 central heating pump 43 air pressure switch...

Page 31

31 sys 10-23 4.4 technical data table gas supply pmax pmin nominal heat input (net) nominal heat output output pmax pmin kw 23,3 9,7 kw 25,8 11,2 dimensions, weights, fittings depth mm 370 width mm 400 height mm 720 hot water capacity litres 1,5 expansion vessel pre-fill pressure bar 1 expansion ves...

Page 32

32 sys 10-23 4.5 diagrams pressure - output diagrams legenda 1 - 2 - 3 = pump switch positions a = boiler pressure drop discharge head available to system fi g. 29 0 1 2 3 4 5 6 7 0 500 1.000 1.500 2.000 q [l/h] h [m h 2 o] a 3 2 1 fi g. 28 kw kcal/h x 1000 m b ar 18 19 20 21 22 23 5 10 15 20 25 30 ...

Page 33

33 sys 10-23 4.6 internal electrical diagrams fi g. 30a.

Page 34

34 sys 10-23 fi g. 30b.

Page 36

Phone numbers: installer service engineer because of our constant endeavour for improvement details may vary slightly from those quoted in these instructions. Lichfi eld road, branston industrial estate, burton upon trent, staffordshire de14 3hd tel. 08707 282 885 - fax 08707 282 886 all specificatio...