- DL manuals

- Fervi

- Power Tool

- 786

- Operation And Maintenance Manual

Fervi 786 Operation And Maintenance Manual

Summary of 786

Page 1

Operation and maintenance manual air impact wrench art. 0786 original instructions fervi.Com.

Page 2: Foreword

Hardware page 2 of 16 foreword read this manual before operating any machinery original instructions before starting any operation it is compulsory to read this instruction manual. The guarantee of smooth operation and full performance of the machine is highly dependent on the application of all the...

Page 3: Contents

Hardware page 3 of 16 contents 1 general safety instructions............................................................. 4 1.1 risks associated with the work area ............................................................................4 1.2 risks associated with the presence of rotating and/or ...

Page 4: Parts

Hardware page 4 of 16 1 general safety instructions 1. During use, maintain control of the tool. 2. The operators represent the most important aspect of safety. To best protect against the risk of injury, work cautiously and carefully. 3. The pneumatic tool should not be used and repaired by someone...

Page 5: 1.4 Technical Support

Hardware page 5 of 16 1.3 personal protective equipment when using the pneumatic tool, always wear the following: safety shoes work gloves hearing protection (cap, earplugs, etc.) protective goggles figure 1 – personal protective equipment. 1.4 technical support for any problems and/or concerns, ple...

Page 6: Intended Use

Hardware page 6 of 16 2 description of the air impact wrench and intended use the air impact wrench (art. 0786) is a portable pneumatic tool that is used to tighten and loosen nuts, bolts and threaded screws. The wrench is composed of: 1. The "gun" shaped shell, which contains the vane rotor and oth...

Page 7: 2.1

Hardware page 7 of 16 2.1 technical specifications quick release connector (square) 3/4” operating pressure (bar - psi) 6 / 90 torque (nm) 950 air intake (l/min - cfm) 240 / 8 rotation speed (rev/min) 4200 empty weight (just the wrench) (kg) 4.8 acoustic power level emitted into the environment (db(...

Page 8

Hardware page 8 of 16 3 improper use and contraindications it is strictly forbidden to!! allow the tool to be used by untrained personnel and those who have not read the instruction manual; use the tool for different purposes and uses other than those for which it was designed, i.E. Screw/unscre...

Page 9: 4 Commissioning

Hardware page 9 of 16 4 commissioning before it is possible to use the pneumatic gun art. 0786, put a few drops of lubricating oil (without resin acid) into the air inlet nozzle (figure 8 ref. C), remove the air inlet cap, then screw the nozzle supplied: 3/4" npt male quick-release coupling 1. Check...

Page 10: 4.1 General Warnings

Hardware page 10 of 16 4.1 general warnings air pressure to ensure proper operation and compliance with safety regulations, the operating pressure of the compressed air must not exceed 6 bar (90 psi). Higher pressures may cause damage and excessive wear of the tool. Information on the working pressu...

Page 11: 5 How To Use

Hardware page 11 of 16 5 how to use 5.1 mounting of sockets and extensions crushing and cutting before attaching and/or removing the sockets and extensions always remove the air supply hose. Protective gloves before attaching and/or removing the sockets and extensions wear suitable protective gloves...

Page 12: Workspace

Hardware page 12 of 16 workspace be familiar with the work area. Always check the work area before using the ratchet wrench. Keep the work area clean, uncluttered and well lit. After assembling the socket and connecting the flexible compressed air supply hose, grab the impact wrench by its "gun" han...

Page 13: Emergency

Hardware page 13 of 16 the impact wrench's start lever is a continuous hold lever, in the sense that the function controlled (i.E., the rotation of the accessory) is active as long as the lever itself is kept pressed. Therefore, release the lever to shut it down in an emergency. Figure 7 – starting ...

Page 14

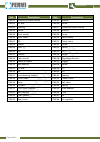

Hardware page 14 of 16 6 maintenance and cleaning the purpose of this chapter is to provide all the information on maintenance procedures and the frequency required for the air impact wrench. Intervention frequency daily weekly 1. General visual inspection x 2. General cleaning x 3. Clean the air ou...

Page 15

Hardware page 15 of 16 7 exploded view and spare parts fervi.Com.

Page 16

Hardware page 16 of 16 ref. Description ref. Description 0786/01 protective rubber device 0786/25 washer 0786/02 oil seal 0786/26 screw 0786/03 housing 0786/27 protective rubber device 0786/04 screw 0786/28 washer 0786/05 anvil socket 0786/29 screw 0786/06 anvil collar 0786/30 valve sleeve 0786/07 o...