- DL manuals

- Festool

- Power Tool

- Domino Machine

- User Manual

Festool Domino Machine User Manual

Summary of Domino Machine

Page 1

The perfect connection. The domino system user manual. D o m in o. T he p er fec t c on ne ct io n..

Page 3: The Perfect Connection.

The perfect connection. The domino system user manual. 2016_fes_domino_book_gb-en.Indb 1 03.03.16 12:13.

Page 4

There are numerous draft designs, cad drawings, parts lists and documentation for our domino connecting system. Yet the conversation and initial drawings where the idea was formed was on something a lot less imaginative: a napkin. But first things first. To be precise, it was initially only an infor...

Page 5

2016_fes_domino_book_gb-en.Indb 3 03.03.16 12:13.

Page 6

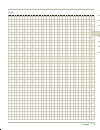

5 4 contents page 1 domino joining machine fundamentals 11 1.1 the domino pendulum router principle 12 1.2 the domino slot principle 13 1.3 the domino joining machines: an overview 14 1.4 performing basic settings for the domino joining machines switching on/off selecting hole width selecting domino...

Page 7

5 4 page 5 items included, specifications 85 6 accessories 87 6.1 cutters 88 6.2 stops 89 6.3 domino and connector domino and domino rod- beech domino exterior use- sipo domino corner and flat connector 90 92 94 95 7 supplementary system accessories 97 7.1 mobile dust extractors 98 7.2 mft 3 multifu...

Page 8

7 6 the domino joint. Simply perfect. Every timber joint has its advantages. The domino connecting system unites them all. In truth, there are numerous innovations which were developed on the basis of a spontaneous idea. Such as the domino connecting system. And yet it is also based just as much on ...

Page 9

7 6 2016_fes_domino_book_gb-en.Indb 7 03.03.16 12:13.

Page 10

9 8 the domino principle: fast. Easy. Versatile. 2016_fes_domino_book_gb-en.Indb 8 03.03.16 12:13.

Page 11

9 8 whether it is a small drawer or a large, solid timber door – domino is the solution. With the domino connecting system all the benefits of round dowels and biscuits have been united into one for the first time. Just as quickly and effortlessly. For board, frame and rack joints. For narrow or wid...

Page 12

11 10 1 2016_fes_domino_book_gb-en.Indb 10 03.03.16 12:13.

Page 13

11 10 1 domino joining machine fundamentals two routers – one principle. The domino joining machine is available in two sizes: the df 500 for domino sizes of 4 x 20 mm to 10 x 50 mm, perfectly suited for board and furniture making, as well as for lightweight frame or rack joints. Or the domino xl df...

Page 14

13 12 1 1.1 the domino pendulum router principle unique in its manual operation and patent by festool: the domino joining machine routing movement. The simultaneous rotating and pendulum movement of the cutter allows smooth working and holes without scorch marks. Thanks to the pendulum movement the ...

Page 15

13 12 1 1.2 the domino slot principle the first domino is positioned via an exact slot, the subsequent dominos inserted in wider slots with clearance – this allows the joint to be easily aligned. The result is a stable joint, rotation-resistant from the first domino. Room to move. The remaining slot...

Page 16

15 14 1 1.3 the domino joining machines: an overview 1 secondary handle 2 locking lever lock 3 domino hole depth locking lever 4 angle stop clamping lever 5 material thickness preselect slider 6 mains connection 7 spindle lock 8 extractor stub 9 motor unit/guide frame unlocking 10 routing height adj...

Page 17

15 14 1 1 handles 2 motor unit/guide frame unlocking 3 domino hole width a djustment lever 4 stop pin unlocking button 5 routing angle adjustment clamping lever 6 routing height adjustment preselect slider 7 routing depth adjustment marker 8 routing depth adjustment locking knob 9 routing depth adju...

Page 18

Df 500 df 700 17 16 1 1.4 performing basic settings for the domino joining machines the df 500 and df 700 domino joining machines are generally similar in handling and setting options. You should be aware of these in order to fully utilise the machines’ flexibility. All basic settings are explained ...

Page 19

Df 500 df 700 17 16 1 this is where the unique domino slot principle comes in. The first hole, known as the locating hole, is routed appropriate to the selected domino diameter. Owing to the domino in the locating hole, the joint aligns exactly with the front edge – the joint is correctly positioned...

Page 20

Df 500 1 2 3 4 19 18 1 after selecting the domino, use the appropriate cutter to make the hole. For example, if you would like to use an 8 mm diameter domino, you also use the 8 mm cutter. Always disconnect from the mains to change the cutter. Then raise the unlocking lever using an open ended spann...

Page 21

Df 500 1 2 3 4 19 18 1 the routing depth determines how deep the cutter cuts into the workpiece. The appropriate routing depth must be set for the different domino lengths; in most cases half of the domino length. The routing depth set on the joining machine corresponds to the depth of the domino ho...

Page 22

Df 700 df 700 21 20 1 df 700 press one or both locking switch to set the routing depth. Move the routing depth setting slider to the required routing depth. On the df 700, the possible routing depth is between 15 mm and 70 mm. Now release the locking switch– briefly check that the slider has locked ...

Page 23

Df 700 df 700 21 20 1 the routing height setting on both the domino df 500 and the df 700 is performed using the preselect slider, allowing predefined heights to be used. Alternatively, any individual dimension can be set using the scale. The routing height defines the distance from the workpiece to...

Page 24

Df 700 df 700 df 500 23 22 1 22 df 700 the routing height is adjusted on the df 700 equivalent to the df 500. The only difference to note: here, the preselect setting does not determine the board thickness, but instead the true distance from the top of the workpiece to the centre of the routed hole....

Page 25

Df 700 df 700 df 500 23 22 1 22 for mitred joints, the joining machine routing angle can be set using stages, predefined angles or any other degree between 0° and 90°. The precisely machined dominos optimally align the workpiece and prevent the mitre from slipping when being glued. 1.4.7 angle adjus...

Page 26

25 24 1 one of the greatest time advantages of working with domino joining machines is the result of working without the need for complex measuring or marking – the machine can be positioned quickly and accurately by using stop catches (df 500) or stop pins (df 700). Df 500 it is possible to define ...

Page 27

25 24 1 the df 700 possesses an innovative stop system, allowing even domino groups to be quickly and precisely positioned in relation to a reference edge using the integral stop pins. There are six stop pins on the stop side of the joining machine. Unnecessary stop pins can be pushed aside individu...

Page 28

A b c 1 2 3 3 2 1 27 26 1 the stop pins serve as distance pieces to the router centre and can be sepa- rately located. Pins ( 1 – 2 – 3 ) allow three separate distances to a reference edge. The pins allow two domino holes to be placed adjacent to each other at a defined distance to a reference edge ...

Page 29

A b c 1 2 3 3 2 1 27 26 1 additionally, it is possible to insert the pin in the previously routed domino hole and to use the edge of the domino hole as a stop. This means you can define domino holes over larger, uniform distances independent of the edge of the workpiece and without marking. (in the ...

Page 30

29 28 1 large amounts of timber chippings are created when working with the domino joining machines. To improve chip transfer out of the routed hole during the routing process, and to also protect your own health, we recommend you always work with dust extraction. However, please examine all domino ...

Page 31

29 28 1 the festool mobile dust extractors were especially developed for and coordinated with our tools, and are therefore also ideal in conjunction with the domino joining machines. Whether you choose a mobile dust extractor with a volume of 26, 32 or 48 litres and with or without automatic autocle...

Page 32

31 30 2 2016_fes_domino_book_gb-en.Indb 30 03.03.16 12:13.

Page 33

31 30 2 the domino 2016_fes_domino_book_gb-en.Indb 31 03.03.16 12:13.

Page 34

33 32 2 2. The domino. The shape makes the difference. Not flat. Not round. Just domino. The difference is in the detail. More precisely: in the shape. Dominos unify all of the benefits of round dowels and biscuits. And are therefore as stable as mortise and tenon. They are available in 14 fixed siz...

Page 35

33 32 2 dominos not flat. Not round. Just domino. The special shape, in combination with swelling glue pockets and longitudinal grooves, gives the dominos a secure hold. For absolutely rotation-resistant connections and maximum stability. And with substantially faster working: the first domino hole ...

Page 36

35 34 2 dominos. 100 % rotation resistant from the very first domino, the joints are absolutely rotation resistant without additional workpiece alignment. Highest stability the unique shape of the domino in combination with swelling glue pockets and longitudinal grooves, gives the dominos a secure h...

Page 37

35 34 2 environmentally friendly all dominos originate from sustainable forest management. The beech dominos are certified by the pan european forest council (pefc). And now also flexible connect even faster. And release again if needed. The new corner and flat connectors for the domino xl df 700 gu...

Page 38

37 36 3 2016_fes_domino_book_gb-en.Indb 36 03.03.16 12:13.

Page 39

37 36 3 domino system accessories 2016_fes_domino_book_gb-en.Indb 37 03.03.16 12:13.

Page 40

39 38 3 3. Domino system accessories. For even greater application versatility. The festool system stands for application versa- tility and simplifies your work with accessories thought through to the finest detail: with a varie- ty of stops, compatible with both domino joining machines, even the mo...

Page 41

39 38 3 trim stop cross stop trims of 22 – 70 mm width can be quickly positioned and fixed centrally using the trim stop – ideal for rack joints. (for domino df 500 and domino xl df 700) repetitive hole centres of 100 – 205 mm can be easily transferred using the cross stop – without scribing the wor...

Page 42

Df 500 df 700 40 df 700 support surface extension df 500 additional stop the support surface extension provided with the df 700 allows the contact area to be extended for routing on the edge of the workpiece and the machine is thus more reliably guided. The additional stop provided with the df 500 i...

Page 43

41 4 practical application examples 2016_fes_domino_book_gb-en.Indb 41 03.03.16 12:13.

Page 44

43 42 4 4.1 overview: connections with domino joining machines the domino system is ideally suited for board, frame and rack joints, involving narrow or wide, delicate or solid workpieces with dominos ranging from 4 to 14 mm in diameter or flexible, separable corner and flat connectors. In short, th...

Page 45

43 42 4 domino joining machines df 500 df 700 very suitable suitable 2016_fes_domino_book_gb-en.Indb 43 03.03.16 12:13.

Page 46: 4.2 Frame Joints

1 2 3 4 5 45 44 4 4.2 frame joints in this example, we are processing 5 x 30 mm dominos. Set the routing depth to 15 mm for this. The applications of the domino connecting system are virtually unlimited, as well as uncomplicated. Just one domino is enough to connect a frame corner securely and ensur...

Page 47

1 2 3 4 5 45 44 4 for the second routed hole, either mark out the position or run the machine flush along the outside tip of the mitre. This routed hole can either be precisely routed like the first hole – which increases the stability of the joint but requires more precision – or it can be routed w...

Page 48

3 4 5 1 2 47 46 4 set the routing height to match the thickness of your workpiece. For the routing depth, select half the domino length. Route the holes by either using the right hole width for both for extreme precision fit or routing the second hole with clearance, if desired. The routed holes can...

Page 49

3 4 5 1 2 47 46 4 use this method to carry out routing for all four frame rails, whereby every second frame rail is routed into the workpiece lengthwise instead of into the front. Then glue the frame rail and brace with pads and clamps, if necessary. The second routed hole is set here using the stop...

Page 50

1 2 3 4 49 48 4 use the domino df 700 for stable frame joints such as for doors, where larger dominos can be processed for even greater stability. In this example, a panel door is created with a pinned internal rebate and additional tenon. The domino joining machines are unique in that you can set t...

Page 51

1 2 3 4 49 48 4 in the lengthwise rail, set the routed holes with a 70 mm routing depth as well, but route the first hole with precision and the second as a slot with clearance. Proceed likewise for the additional lengthwise and crosswise rails. Then drive the dominos all the way into the routed hol...

Page 52

1 2 3 4 51 50 4 4.3 rack joints and secure spindle positioning making rack joints with the domino joining machine saves an incredible amount of time. Especially when relatively narrow spindles are being processed, working with the trim stop (available as an accessory or included in the df 500 set) i...

Page 53

1 2 3 4 51 50 4 set the width of the trim stop to the thickness of your spindle by adjusting the guide in the parallel side fence to the correct dimension using the scale and the green rotary wheels. In this example, we are working with 30 x 30 mm rectangular spindles. Using the spindle as a guide, ...

Page 54

7 5 8 9 6 53 52 4 note you can naturally use the df 700 to apply this method with a domino diameter of 8 mm or greater. Caution especially with handrails, it is often not possible to position the joining machine securely on the side of the workpiece due to the handrail design; the round shape preven...

Page 55

7 5 8 9 6 53 52 4 route the holes in the handrail, positioning the joining machine on the second marking. Applying a sufficient amount of glue, insert the dominos into the routed holes and join the handrail to the spindles. Then set the trim stop to the width of the handrail. 2016_fes_domino_book_gb...

Page 56

55 54 4 set the routing height to the centre of the workpiece. Mark out the axis distance of the spindles on the top side of the workpiece. In this case (when simply using markings) bring the scale in the viewing window of the domino over the scribe mark and set the routed holes. A second scribe mar...

Page 57

55 54 4 notes 2016_fes_domino_book_gb-en.Indb 55 03.03.16 12:13.

Page 58: 4.4 Round Profile Joints

2 1 3 4 5 57 56 4 4.4 round profile joints when connecting round timber profiles, such as those used for handrails, the handrail fence is available as an accessory to ensure a secure workpiece hold. This part fits both the df 500 and the df 700 for diameters from 35–60 mm. The following example desc...

Page 59

2 1 3 4 5 57 56 4 the handrail fence holds the workpiece securely and centres it automatically thanks to the prism-shaped contact surfaces. Set the routing angle on the joining machine according to your sawing angle on the workpiece. In our example, the handrail was sawed at 15°, which means the rou...

Page 60

C b a c b a 59 58 4 the separable corner connectors provide even more flexibility, especially with large, solid workpieces like tables or beds. These connectors allow for quick and easy assem- bly and disassembly of furniture pieces, making transport a breeze. In terms of how they are processed, the...

Page 61

C b a c b a 59 58 4 per corner connector: 1 x anchor bolt including domino connector cover 1 x transverse anchor including stud 1 x expansion bolt optional: 1 x cover cap in silver, light brown or dark brown the corner and flat connectors are always processed with the 14 mm router on the df 700. For...

Page 62

1 2 3 4 5 6 7 61 60 4 it is a good idea to work with the stop pins in this case. Select the pins depending on the desired hole distance. Ensure that the routing for the corner connector has a minimum distance of 37 mm from the edge of the workpiece. If you work with the stop pins, use the centre pin...

Page 63

1 2 3 4 5 6 7 61 60 4 then set the routing depth to 25 mm for routing the transverse hole. (this dimension depends on the workpiece; see dimen- sional drawing. What is important to note is that the transverse hole should overlap the longitudinal hole by 3 mm in depth.) change the routing depth to 50...

Page 64

8 9 10 11 12 13 14 15 63 62 4 it is important to ensure that the expansion bolt is flush with the workpiece surface. Then screw the anchor bolt all the way into the expansion bolt. This expands the expansion bolt, pulling it another approx. 1 mm into the workpiece thanks to the self-drawing property...

Page 65

8 9 10 11 12 13 14 15 63 62 4 press the transverse anchor all the way into the routed hole using the spanner. Then insert the threaded screw. Tighten it only so that the screw stays in place, but the opening remains open for the anchor bolt. Clip the two domino connector covers around the anchor bol...

Page 66

16 17 18 19 65 64 4 tip it is usually a good idea to fit flexible connectors to one of the sides and securely glue dominos into the other side. Then join the frame to the post by pushing the connector and dominos into their respective holes. 2016_fes_domino_book_gb-en.Indb 64 03.03.16 12:13.

Page 67

16 17 18 19 65 64 4 optionally, you can cover the routing with a cover cap, available in one of three colours depending on the material: silver, light brown or dark brown. Tighten the connection using a 4 mm hexagonal socket. This is a quick way to create a stable joint that can be quickly disassemb...

Page 68

C c* a c* c* a a 67 66 4 4.6 stable, separable flat joints the domino flat connector is ideal for creating stable flat joints that are separable. You can connect plates, kitchen worktops or other surfaces, quickly and flexibly. This application example demonstrates how to connect a kitchen worktop. ...

Page 69

C c* a c* c* a a 67 66 4 for flat joints, you need the following components from the domino corner and flat connector system: only suitable for joining timber or timber-like materials in furniture construction (no lightweight building materials!) the domino connector is only a connecting element, no...

Page 70

1 4 5 2 3 69 68 4 mark out the connector position on the surface of the worktop at the desired point. Also mark the positions for additional dominos (used to ensure a flush connection). For this connection, you need at least two flat connectors and the following components from the domino corner and...

Page 71

1 4 5 2 3 69 68 4 set the routing height: the distance from the flip stop to the centre of the router should be half the worktop thickness. With a worktop thickness of 38 mm, for example, set the routing height to 20 mm. Then set the routing depth to 50 mm and set the markers to 50 mm and 30 mm. Ins...

Page 72

8 7 11 12 9 6 10 71 70 4 then set a routing depth of 30 mm – this dimension depends on the material. What is important to note is that the transverse hole should overlap the longitudinal hole by 5 mm in depth. If using the transverse anchors without enlarging clips, an overlap of 3 mm suffices. The ...

Page 73

8 7 11 12 9 6 10 71 70 4 insert the transverse anchors into the routed holes. If you have decided to use additional dominos in order to ensure a flush connection and extra transverse load transmission, insert these into the other routed holes. Tighten the studs in the transverse anchor only so that ...

Page 74

16 17 14 13 15 73 72 4 clip the domino clips around the double-headed bolt. Tip the double-headed bolt can be fitted with one or two domino clips. With one domino clip, the clip sits flush and neatly between both workpieces. With two domino clips, the double-headed bolt has some clearance later for ...

Page 75

16 17 14 13 15 73 72 4 push both workpieces together ... ... And clamp the connectors by tightening the stud on the second workpiece side. Tip in general, these connections are located on the bottom of tabletops and kitchen worktops, i.E. Outside of visible area. Nevertheless it is possible, of cour...

Page 76: 4.7 Mitred Joints

2 1 3 4 75 74 4 4.7 mitred joints mitred joints are not just possible for smaller workpieces and frames – naturally they can also be used for stabler connections of solid workpieces thanks to the df 700. The following example uses a bench to show how these types of joints are quickly and easily crea...

Page 77

2 1 3 4 75 74 4 after routing the first hole (the pin is positioned at the edge of the workpiece in this case), the pin goes into the routed hole, thus setting the next stop. Route the first hole with precision, and all other holes as slots with clearance. Then join the workpiece parts together, glu...

Page 78: 4.8 Drawer Connections

1 2 3 4 77 76 4 4.8 drawer connections even thin cross-sections from 12 mm can be joined perfectly with the df 500, using the small 4 x 20 mm dominos and the appropriate 4 mm router. The 4 x 20 mm domino is suitable for right-angle connections in thin workpieces or mitred joints from a 15 mm thickne...

Page 79

1 2 3 4 77 76 4 set the additional stop on the domino df 500. This uses the additional stop pins to reduce the lateral distance to the centre of the domino router from 37 mm to 20 mm. Set the routing depth to 20 mm, the routing height to the minimum and the routing angle to 45°. Flip the additional ...

Page 80

5 6 79 78 4 ... And join the workpiece together. Note of course, butted joints are also possible using the smallest domino. Proceed as described above and route the domino holes on the front side using the additional stop. The additional stop also provides a secure support surface when clamped verti...

Page 81: 4.9 Butted Panel Joint

5 6 79 78 4 4.9 butted panel joint panel joints like those for cupboard or shelving units can be ideally created with the domino joining machines. The following example shows how to create a unit with the df 500. 2016_fes_domino_book_gb-en.Indb 79 03.03.16 12:13.

Page 82

1 5 2 6 3 7 4 8 81 80 4 to fit the cross stop on the machine in question, turn the clamp jaw on the stop pin so that it is set to the df 500 or df 700 position (each machine is marked accordingly on the front of the pin). Mount the cross stop onto the joining machine according to the operating instr...

Page 83

1 5 2 6 3 7 4 8 81 80 4 use the same process to create the routed holes for the side wall of the cabinet. Set the first hole with the stop pin of the domino joining machine ... ... And create the others using the cross stop pins. Using the additional stop, along with the cross stop – is beneficial h...

Page 84

9 13 10 14 11 12 83 82 4 in our example, the centre shelf and side part are flush at the front and are clamped accordingly. Adjust the angle of the joining machine to 0° and the routing depth to 15 mm. Then route the first domino hole with the narrow hole width with the stop pin in the horizontal si...

Page 85

9 13 10 14 11 12 83 82 4 proceed likewise for the second side part. Then insert the domino in the routed holes and join your workpiece together, applying glue to the joint. Set the other holes using the scale in the viewing window, which you align with the scribe marks. Set all holes here in the pan...

Page 86

85 84 5 2016_fes_domino_book_gb-en.Indb 84 03.03.16 12:13.

Page 87

85 84 5 items included, specifications 2016_fes_domino_book_gb-en.Indb 85 03.03.16 12:13.

Page 88

87 86 6 5. Items included, specifications domino df 500 items included specifications domino df 700 items included df 500 q-plus gb 240v 574327 domino d 5 router, support bracket, accessory tool set, in a sys 2 t-loc systainer df 700 eq-plus gb 240v 574420 domino d 12 router, support bracket, 2x dom...

Page 89

87 86 6 accessories 2016_fes_domino_book_gb-en.Indb 87 03.03.16 12:13.

Page 90: 6. Accessories

89 88 6 cutters for domino df 500 joining machine cutters for domino xl df 700 joining machine 1 d 4-nl 11 hw-df 500 router d 4 mm, nl 11 mm, in self-service display pack 495663 2 d 5-nl 20 hw-df 500 router d 5 mm, nl 20 mm, in self-service display pack 493490 3 d 6-nl 28 hw-df 500 router d 6 mm, nl...

Page 91: 6.2 Stops

89 88 6 stops for domino df 500 joining machine and domino xl df 700 qa-df 500/700 cross stop for df 500 and df 700, items included: a left and a right cross stop, for repeated hole centres of 100 – 205 mm, for exact positioning of routing with edge distances of 100 – 205 mm, in self-service display...

Page 92: 6.3 Dominos and Connectors

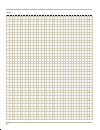

91 90 6 6.3 dominos and connectors domino length (mm) (mm) 2016_fes_domino_book_gb-en.Indb 90 03.03.16 12:13.

Page 93: New

91 90 6 corner connectors flat connectors * * flat connectors – here with the optional enlarging clips around the transverse anchor. New 2016_fes_domino_book_gb-en.Indb 91 03.03.16 12:13.

Page 94

93 92 6 6.3.1 dominos and dominos beech domino, beech d 4 x 20/450 bu dimensions 4 x 20 mm, qty. In pack 450 pcs, in self-service display pack 495661 domino, beech d 5 x 30/300 bu dimensions 5 x 30 mm, qty. In pack 300 pcs, in self-service display pack 494938 domino, beech d 5 x 30/1800 bu dimension...

Page 95

93 92 6 domino rod, beech d 8 x 750/36 bu dimensions 10 x 750 mm, qty. In pack 36 pcs, in carton 498686 domino rod, beech d 10 x 750/28 bu dimensions 10 x 750 mm, qty. In pack 28 pcs, in carton 498687 domino rod, beech d 12 x 750/22 bu dimensions 12 x 750 mm, qty. In pack 22 pcs, in carton 498688 do...

Page 96

95 94 6 6.3.2 domino and domino rods sipo domino, sipo d 5 x 30/300 mau dimensions 5 x 30 mm, qty. In pack 300 pcs, in self-service display pack 494869 domino, sipo d 5 x 30/900 mau dimensions 5 x 30 mm, qty. In pack 900 pcs, in carton 494859 domino, sipo d 6 x 40/190 mau dimensions 6 x 40 mm, qty. ...

Page 97

95 94 6 6.3.3 domino corner and flat connectors c or ne r co nne ct or s fl at c on ne ct or s anchor bolt sv-ab d14/32 32 anchor bolts for corner connections, including 64 domino connector covers for transferring transverse loads. 201350 expansion bolt sv-sa d14/32 32 expansion bolts for secure loc...

Page 98

97 96 7 6.3.3 domino corner and flat connectors domino, birch, domino d 14 x 75/104 bu 104 domino, birch d 14 x 75, exactly matched to the dimensions of the corner connectors. Serves to transfer loads – in addition to the connectors. 201499 cover cap sv-ak d14 slr/32 32 cover caps, silver. For cover...

Page 99

97 96 7 supplementary system accessories 2016_fes_domino_book_gb-en.Indb 97 03.03.16 12:13.

Page 101

99 98 7 7.2 mft 3 multifunction table mft 3 accessories mft 3 multifunction table table with perforated top and foldaway legs, swivel unit, support unit, angle stop, adjustable stop, fs 1080/2 guide rail, fs-aw deflector, additional clamp, in carton 495315 x extreme precision – with aluminium profil...

Page 102

100 vac sys set se 1 gb 240v vac sys vp vacuum pump in the sys 3 systainer, vac sys se 1 vacuum clamping unit with vac sys vt d 215 mm vacuum pad, vacuum hose and foot valve in sys 4 systainer 712257 vac sys se 2 vac sys vt 275 x 100 mm vacuum pad, connecting piece, vacuum hose, in sys 4 systainer 5...

Page 103: Your Work.

100 concentrate on what’s most important: your work. Every day, we consider how we can make life easier for you. With highly sophisticated tools – and services which are tailored to the demands of your work. You want to and need to avoid downtime, unnecessary expenses and additional costs as much as...

Page 104

103 102 notes 2016_fes_domino_book_gb-en.Indb 102 03.03.16 12:13.

Page 105

103 102 notes 2016_fes_domino_book_gb-en.Indb 103 03.03.16 12:13.

Page 106

2016_fes_domino_book_fr_be_ch-fr.Indb 104 08.03.16 14:23.

Page 108

Subject to changes and errors. All images are non-binding. Produced for festool gmbh, 73240 wendlingen, germany, 01/2016 vibration levels and emission values can be found in the operating instructions at www.Festool.Co.Uk/vibration www.Festool.Co.Uk festool domino system user manual order no. 65483 ...