Fetco CBS-71A User Manual

FETCO

® and LUXUS® are trademarks or trade names of Food Equipment Technologies Company.

Part # P006 Revised December 15, 2003

FOOD EQUIPMENT TECHNOLOGIES COMPANY

640 Heathrow Drive

• Lincolnshire • IL • 60069 • USA

3

Phone: (800) 338-2699

• (847) 719-3000 • Fax: (847) 821-1178

Emergency Service Only: (800) 660-0035 (U.S. & Canada)

E-mail: techsupport@fetco.com

• Internet: http://www.fetco.com

User’s Guide

Installation - Operation - Service

Coffee

Brewing

CBS-71A/AC

Systems

CBS-72A/AC/AT/ATC

Table of Contents

Introduction..................................................................... 2

Product Description/Features ........................................ 2

Technical Data ............................................................... 2

Brewing Specifications ............................................... 2

Weights and Capacities.............................................. 2

Electrical Configuration and Brewing Efficiency ......... 3

Installation ...................................................................... 5

Keys To A Successful Installation .............................. 5

Brewer Installation ...................................................... 5

Steam Heated Brewers .............................................. 6

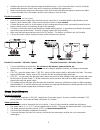

Transfer System (AT versions only) ........................... 7

Operating Procedures ....................................................8

Brewing System ..........................................................8

Transfer System..........................................................9

Service..........................................................................10

Warranty ...................................................................10

Principles of Operation .............................................10

Adjustments ..............................................................11

Maintenance/Cleaning ..............................................13

Replacement Parts List.............................................15