- DL manuals

- FFC

- Snow Blower

- V-Snow Blade

- Operator's Manual

FFC V-Snow Blade Operator's Manual

Summary of V-Snow Blade

Page 1

1 v-snow blade 800-456-7100 www.Paladinlcg.Com 2800 n. Zeeb rd., dexter, mi. 48130 united states of america model number_______________________ serial number___________________________ manual number: 51-4320 release date: december 2010 serial number 1052001 and up operator's & parts manual.

Page 2

2 notes.

Page 3: Table of Contents

3 table of contents preface .....................................................................................................................................................4 safety statements ..........................................................................................................

Page 4: Preface

4 general information this product was carefully designed and manufactured to give you many years of dependable service. Only minor maintenance (such as cleaning and lubricating) is required to keep it in top working condition. Be sure to observe all maintenance procedures and safety precautions in ...

Page 5: Safety Statements

5 danger! This signal word is used where serious injury or death will result if the instructions are not followed properly. Warning! This signal word is used where serious injury or death could result if the instructions are not followed properly. Caution! This signal word is used where minor injury...

Page 6: General Safety Precautions

6 warning! Lower or support raised equipment do not work under raised booms without supporting them. Do not use support material made of concrete blocks, logs, buckets, barrels or any other material that could suddenly collapse or shift positions. Make sure support material is solid, not decayed, wa...

Page 7: General Safety Precautions

7 general safety precautions warning! Safely maintain and repair equipment •do not wear loose clothing, or any accessories that can catch in moving parts. If you have long hair, cover or secure it so that it does not become entangled in the equipment. •work on a level surface in a well-lit area. •us...

Page 8

8 equipment safety precautions operating the v-snow blade: •do not exceed the lifting capacity of your prime mover. •operate only from the operator’s station. •when operating on slopes, drive up and down, not across. Avoid steep hillside operation which could cause the prime mover to over turn. •red...

Page 9: Safety Decals & Labels

9 safety decals & labels use part numbers to order replacements for lost or damaged decals. Be sure to read all decals before operating the attachment. They contain information you need to know for both safety and longevity. Placement or replacement of safety signs 1. Clean the area of application w...

Page 10: Installation

10 warning! Improper attachment of v-snow blade could result in injury or death. Do not operate this machine until you have positive indication that the attachment is securely mounted. 1. Position the blade on a level surface. 2. Enter the prime mover. 3. Fasten the safety restraints. 4. Start the e...

Page 11: Installation

11 installation removing the v-snow blade warning! Serious injury or death may result from disengaging the blade when the blade is in an unstable position. Place blade on a firm, level surface in a stable position before disengaging. Notice! Hoses for the blade must be removed before the quick attac...

Page 12: Operation

12 intended use: this blade is designed solely for the use in snow removal. This blade is not designed to move dirt, loose soil or gravel. Use in any other way is considered contrary to the intended use. Compliance with and strict adherence to operation, service and repair conditions as specified by...

Page 13: Operation

13 hydraulic sequencing model adjusting v-blade: 1. Start the prime mover at idle and raise the blade. 2. Adjust the blade to the desired angle (refer to “angling instructions”) and then lower to the ground. 3. Adjust blade until it is level to the ground ( refer to “leveling instructions”). 4. Incr...

Page 14: Operation

14 operation straight straight position: 1. If starting from the scoop position, reverse flow until right blade completely retracts. 2. While still reversing flow, retract left blade until it is in the straight position. 3. Use normal flow to extend right blade until it is parallel to left blade. V ...

Page 15: Operation

15 operation electro-hydraulic model adjusting v-blade: 1. Start the prime mover at idle and raise the blade. 2. Adjust the blade to the desired angle (refer to “angling instructions”) and then lower to the ground. 3. Adjust blade until it is level to the ground ( refer to “leveling instructions”). ...

Page 16: Operation

16 operation leveling instructions notice! A level unit should have no visible spaces between cutting edges and plowing surface. Scoop position if the front corners of the attachment are contacting the plowing surface and a gap is visible towards the center of the attachment (figure 2): 1. Lift atta...

Page 17: Operation

17 operation figure 2 figure 3 level scoop position shown.

Page 18: Operation

18 operation 1. Move prime mover to a level surface with the blade properly attached. 2. Place the prime mover in “park” and engage the parking brake. 3. Lower the blade onto the level surface. 4. Shut off prime mover engine, remove key and relieve all pressure from the hydraulic lines. 5. Check spr...

Page 19: Operation

19 operation skid shoe set-up determine what type of surface is beneath the snow where your blade is being operated. If the surface is hard and smooth, like concrete or asphalt, the skid shoe placement as shipped from the factory is correct. (3 spacers on top, 16 on bottom) if the surface is soft or...

Page 20: Operation

20 caution ! Do not modify the v-snow blade in any way. Personal injury could result. If you have questions, contact your dealer or ffc. Repair or adjust the blade in a safe area, away from traffic and other hazards. Before adjusting or servicing, lower the blade to the ground, set parking brake, sh...

Page 21: Operation

21 operation general storage: notice! Do not store in direct sunlight. Materials will deteriorate prematurely if stored in direct sunlight. Do not store near intense heat. Storage: • clean the unit thoroughly, removing all mud, dirt and grease. • inspect for visible signs of wear, breakage or damage...

Page 22: Operation

22 lift points lifting points are identified by lifting decals where required. Lifting at other points is unsafe and can damage attachment. Do not attach lifting accessories around cylinders or in any way that may damage hoses or hydraulic components. See diagram: • attach lifting accessories to uni...

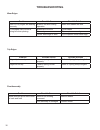

Page 23: Maintenance Schedule

23 maintenance schedule maintenance schedule procedure before each use after each use fittings/hoses, hydraulic - check for leaks/tighten check for damage fittings, zerk - grease (see lubrication points) oil, hydraulic - check level hardware - check for tightness oil cleanliness requirements notice!...

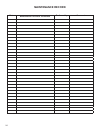

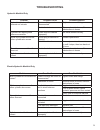

Page 24: Maintenance Record

24 maintenance record date maintenance procedure performed performed by comments.

Page 25: Maintenance

25 maintenance inverting front wear edges notice! All nuts and bolts must be installed using proper torque specifications (refer to bolt torque specifications). 1. Park prime mover on a firm, level surface with blade properly attached. 2. Lower the blades cutting edge onto a sturdy wood or metal blo...

Page 26: Maintenance

26 maintenance notice! All nuts and bolts must be installed using proper torque specifications (refer to bolt torque specifications). 1. Park prime mover on a firm, level surface with blade properly attached. 2. Place primer mover in “park” and engage parking brake. 3. Lower the blades cutting edge ...

Page 27: Maintenance

27 maintenance installing new polyurethane wear edges notice! All nuts and bolts must be installed using proper torque specifications (refer to bolt torque specifications). Notice! Improper installation of edges will result in damage to plowing surface and premature wearing of edges. 1. Park prime m...

Page 28: Maintenance

28 maintenance adjusting and inverting the polyurethane wear edges notice! The retaining plate between the polyurethane edge and the blade mounting has the holes closest to the ground while the front retaining plate has its holes near the top. Initial installation position holes are near the bottom ...

Page 29: Maintenance

29 maintenance installing center nylon and rubber wear edges 1. Remove all hardware and the original steel center edges and rubber center edge. Retain all for use with original steel wear edges. 2. Install new center rubber wear edge and nylon center edges. Notice! Use only 20 ft/lbs of torque on bu...

Page 30: Troubleshooting

30 problem possible cause possible solution hydraulic cylinder neither extends nor retracts hoses or fittings are loose or disconnected tighten hoses and fittings restriction in hoses remove bends in hoses, remove obstructions in hoses cylinders are fighting each others movements hoses may be instal...

Page 31: Troubleshooting

31 troubleshooting hydraulic manifold only problem possible cause possible solution hydraulic cylinder neither extends nor retracts hoses or fittings are loose or disconnected tighten hoses and fittings restriction in hoses remove bends in hoses, remove obstructions in hoses cylinders are fighting e...

Page 32: Hose Assembly

32 hose assembly item part qty description 1. 03-2092 2 elbow, 90º, 6mb-6mf 2. 03-2278 4 fitting, 6mf-8mb 3. 03-3515 2 fitting, 12mb-8mf 4. 03-3537 2 o-ring, #8 face seal 5. 03-4912 2 hose, .38 x 72, 8ff-8ff45, 100r2 6. 03-6074 2 plate, orifice, #8, o-ring face seal 7. 03-6244 4 hose, .38 x 24, 6ff-...

Page 33: Hose Assembly

33 hose assembly item part qty description 1. 03-10111 2 hose, .38 x 78, 6ff-8mb, 100r2 2. 03-2092 4 elbow, 90º, 6mb-6mf 3. 03-3573 2 o-ring, face seal, 3/8, sae #6 4. 03-3689 2 elbow, 90º, 6ff-6mf 5. 03-4704 2 hose, .38 x 27, 6ff-6ff, 3k 6. 03-5236 2 hose, .38 x 42, 6ff-6ff90, 3k 7. 03-5903 1 manif...

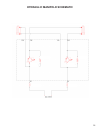

Page 34

34 hydraulic/electric manifold schematic.

Page 35: Hydraulic Manifold Schematic

35 hydraulic manifold schematic.

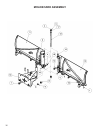

Page 36: Moldboard Assembly

36 moldboard assembly.

Page 37: Moldboard Assembly

37 moldboard assembly item part qty description 1. 07-0206 6 pin, cotter, gr2, 3/16 x 2 (5 ft) 07-0206 8 pin, cotter, gr2, 3/16 x 2 (6,7,8,9,10 ft) 2. 07-0223 2 fitting, zerk, 1/8npt 3. 07-3268 2 snap ring 4. 07-3674 2 screw, hhc, gr8, 1/2-13 x 2 3/4 5. 07-4090 6 washer, 1 1/2 x 1 x .075 (5 ft) 07-4...

Page 38: Trip Edge Assembly

38 trip edge assembly item part qty description 1. Laf6405 4 trip spring, .393 x 14 x (26.25) 2. 13-17406-60 1 weld, left, trip edge (5 ft) 13-17406-72 1 weld, left, trip edge (6 ft) 13-17406-84 1 weld, left, trip edge (7 ft) 13-17406-96 1 weld, left, trip edge (8 ft) 13-17406-108 1 weld, left, trip...

Page 39: Steel Wear Edge Assembly

39 steel wear edge assembly item part qty description 1. Rhw2663 4 bolt, plow, .63-11 x 1.75, gr8 (5 ft) rhw2663 6 bolt, plow, .63-11 x 1.75, gr8 (6,7 ft) rhw2663 8 bolt, plow, .63-11 x 1.75, gr8 (8,9 ft) rhw2663 10 bolt, plow, .63-11 x 1.75, gr8 (10 ft) 2. 13-17488 2 plate, 3/8 x 3.5 x 6.36 3. 13-1...

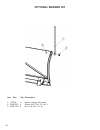

Page 40: Optional Marker Kit

40 optional marker kit item part qty description 1. 103006 2 marker, orange, 28 inches 2. Rhw1105 4 screw, hhc, gr5, .31-18 x 1 3. Rhw7103 4 nut, lock, gr5, .31-18.

Page 41: Notes

41 notes.

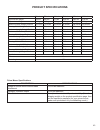

Page 42: Product Specifications

42 specifications and model views product specifications “v” position straight position scoop position angle position.

Page 43: Product Specifications

43 description specifications weight of primer mover without blade attachment 13,230 lbs maximum hydraulic pressure output 3,500 psi maximum rear ballast as required to maintain full product stability. (note the shipping weight on the product specification page, then see the operator’s manual(s) for...

Page 44: Bolt Torque Specifications

44 bolt torque specifications note - nylock nuts are utilized when greater resistance to vibrating loose is required, and greater operating temperatures are not a factor. In addition, like lock nuts, nylock nuts have a safety feature that if the bolt does vibrate loose, the nut will remain on the sc...

Page 45

45 face seal: assembly, tube to fitting notice - face seal fittings have the most reliable sealing method and therefore, should be used whenever possible. Installation 1. Make sure threads and sealing surfaces are free of burrs, nicks, scratches, or foreign materials. 2. Install proper sae o-ring to...

Page 46

46 hydraulic torque specifications straight thread o-ring fitting: assembly, fitting to port note - straight thread o-ring fittings are utilized to adapt hydraulic systems to motors, pumps, cylinders, and valves. Installation (adjustable fitting) 1. Make sure threads and sealing surfaces are free of...

Page 47: Warranty

47 warranty limited warranty except for the excluded products as described below, all new products are warranted to be free from defects in material and/or workmanship during the warranty period, in accordance with and subject to the terms and conditions of this limited warranty. 1. Excluded product...