- DL manuals

- FFEI

- Copier

- alinte4page

- Installation Manual

FFEI alinte4page Installation Manual

Summary of alinte4page

Page 2

P reliminaries important: ffei ltd products are so designed and constructed as to be safe without risk to health when properly used (in accordance with the supplied documentation) and when the safety precautions contained in this document are fully observed. This manual must not be copied without pr...

Page 3

A linte 4 page ctp electromagnetic compatibility notice - usa this equipment has been tested and found to be compliant with the limits for a class a digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmful interference when the ...

Page 4

P reliminaries about this manual this manual describes how to install one of the following alinte4page compu- ter-to-plate (ctp) systems after an on-site pre-installation check has been com- pleted. • alinte4page entry level: manual and semi-automatic . • alinte4page: manual, semi-automatic and full...

Page 5

A linte 4 page ctp t able of c ontents chapter 1 introducing the alinte4page the alinte4page ctp system .................................................................. 1-1 alinte4page entry level manual and semi-automatic ............... 1-2 alinte4page manual .......................................

Page 6

P reliminaries interlock warning labels .........................................................................2-11 safety devices ..............................................................................................2-14 unattended equipment ..................................................

Page 7

A linte 4 page ctp handling the equipment ......................................................................... 3-6 using a fork-lift ......................................................................................... 3-7 chapter 4 installing alinte4page equipment and software start the in...

Page 8

P reliminaries manual system .......................................................................................4-15 all variants ..............................................................................................4-16 install the autoloader ...............................................

Page 9

A linte 4 page ctp plate output alignment checks ...................................................... 4-57 clean engine drum ................................................................................... 4-59 install desktop applications and device driver ............................ 4-59 sys...

Page 10

P reliminaries check plate registration .....................................................................5-17 expose a 50% prediction test plate ................................................5-18 test image quality ..................................................................................

Page 11

A linte 4 page ctp chapter 6 demonstrating the alinte4page sys- tem demonstrate the platesetter .................................................................. 6-1 platesetter safety and interlocks ......................................................... 6-2 laser safety ...........................

Page 12

P reliminaries.

Page 13

I ntroducing the alinte 4 page 1.1 the alinte4page ctp system this installation manual explains how to install the following b2 family of platesetters fitted with violet laser optics and supplied options: alinte4page entry level manual and semi-automatic system : see “alinte4page entry level manual ...

Page 14

1-2 i ntroducing the alinte 4 page alinte4page multi-cassette autoloader (mal system : see “alinte4page multi-cassette (mal) autoloader” on page 1-7. Note: before starting an installation, the site should be assessed by a distributor representative for all site require- ments described in the alinte...

Page 15

Alinte 4 page i nstallation g uide 1-3 vacuum pump (external manufacturer supply). Rip/pci pc (supplied separately by the customer). Rip application software with the options of: celebrant gateway rampage. Pci (dashboard) application - see installation notes with pci software. 1.1.2 alinte4page manu...

Page 16

1-4 i ntroducing the alinte 4 page vacuum pump. Rip/pci pc (supplied separately by the customer). Rip application software with the options of: celebrant. Gateway. Rampage. Pci (dashboard) application - see installation notes with pci software. 1.1.3 alinte4page semi-automatic a typical alinte4page ...

Page 17

Alinte 4 page i nstallation g uide 1-5 pat air filter (external manufacturer supply). Vacuum pump. Processor (external manufacturer supply). Stacker (external manufacturer supply). Rip/pci pc server (supplied separately by the customer). Rip application software with options of: celebrant gateway ra...

Page 18

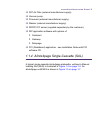

1-6 i ntroducing the alinte 4 page figure 1.4 alinte4page: single-cassette (without mls) a single-cassette comprises the following equipment and modules: engine. Autoloader with mls option. Trolley with cassette (one trolley supplied as standard with the option ofup to five). Pat air filter (externa...

Page 19

Alinte 4 page i nstallation g uide 1-7 . Figure 1.5 alinte4page: single-cassette (with mls) rip application software with options of: celebrant gateway rampage. Pci application (see installation notes with pci software cd). 1.1.5 alinte4page multi-cassette (mal) autoloader a typical multi-cassette a...

Page 20

1-8 i ntroducing the alinte 4 page figure 1.6 alinte4page: multi-cassette (mal) a multi comprises the following equipment and modules: engine. Autoloader. Autofeeder. Trolley and cassette (one trolley and two cassettes is supplied as standard with the option of up to seven cassettes). The standard t...

Page 21

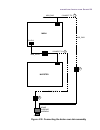

Alinte 4 page i nstallation g uide 1-9 1.2 network connections a typical networked system is shown in figure 1.7 on page 1-9 . Figure 1.7 networked configuration: semi-automatic network connections alinte4page platesetters are based on: 1. Ethernet (or any suitable network): from the rip pc to dtp s...

Page 22

1-10 i ntroducing the alinte 4 page server for downloading rip image data and controlling platesetter output. 3. Serial link (rs232): from the engine to the rip/pci server or any terminal with hyperterminal for accessing platesetter diagnostics. 4. Rs232 link: from the engine to the processor. Note:...

Page 23

S afety on the alinte 4 page 2.1 health and safety at work all personnel are advised to familiarize themselves with any local or national legislation relating to health and safety at work. Particular attention should be given to those sections covering personal respon- sibility regarding safe workin...

Page 24

2-2 s afety on the alinte 4 page 2.1.1 warnings and cautions there are two safety categories given in this manual: warnings are given for conditions which may endanger life. Warning: the instructions given in warnings must be followed pre- cisely. They are given to avoid injury or death. Cautions ar...

Page 25

Alinte 4 page i nstallation g uide 2-3 2.2 safety labels and indicators safety labels are fitted to the equipment to warn you of potential haz- ards. These labels must not be defaced or removed. Typical warning labels, fitted within the platesetter, are shown in figure 2.2 on page 2- 4 to figure 2.1...

Page 26

2-4 s afety on the alinte 4 page 2.2.2 drum and traverse warning labels figure 2.2 on page 2-4 illustrates the laser and spinner risks to the engineer on the user side after the cover is removed and the inter- locks are defeated. Figure 2.2 drum: moving parts and edge detect warning labels laser rad...

Page 27

Alinte 4 page i nstallation g uide 2-5 2.2.3 autoloader warning labels figure 2.3 on page 2-5 shows a moving parts label on the ptm feed head figure 2.3 plate feed moving parts 2.2.4 autofeeder warning labels figure 2.4 on page 2-6 to figure 2.7 on page 2-9 show the warning labels on the autofeeder..

Page 28

2-6 s afety on the alinte 4 page figure 2.4 autofeeder: elevator motor warning labels warning ensure mains supply disconnected before servicing.

Page 29

Alinte 4 page i nstallation g uide 2-7 figure 2.5 autofeeder: elevator warning label.

Page 30

2-8 s afety on the alinte 4 page figure 2.6 autofeeder elevator moving parts warning labels user side service side.

Page 31

Alinte 4 page i nstallation g uide 2-9 figure 2.7 autofeeder: earth wire safety label 2.2.5 optics warning labels figure 2.8 on page 2-10 shows the areas of risk for the engineer from exposed laser beams when the optics base lid is removed. Autofeeder.

Page 32

2-10 s afety on the alinte 4 page figure 2.8 optics base: laser warning labels 2.2.6 electrical warning labels figure 2.9 on page 2-11 shows the area of risk from high-tension volt- age inside the interlock box..

Page 33

Alinte 4 page i nstallation g uide 2-11 figure 2.9 interlock box: high-tension warning label 2.2.7 interlock warning labels figure 2.10 on page 2-12 (entry level) and figure 2.11 on page 2-13 shows the areas of laser beam risk to the engineer when the inter- locked covers are opened and the interloc...

Page 34

2-12 s afety on the alinte 4 page figure 2.10 interlock defeated warning labels: typical alinte4page entry level.

Page 35

Alinte 4 page i nstallation g uide 2-13 figure 2.11 interlock defeated warning labels: typical alinte4page manual.

Page 36

2-14 s afety on the alinte 4 page 2.2.8 safety devices read all warning labels. Make sure that all safety controls, such as those listed below, are present and working correctly: circuit breakers. Covers and doors. Guards. Panel indicators. Safety interlocks. Warning: unless essential for commission...

Page 37

Alinte 4 page i nstallation g uide 2-15 sette, or removing plates from the platesetter. 2.2.12 electrical safety regularly verify that mains supply cables are not worn or damaged. Make sure that water and other liquids do not come into contact with the equipment. Do not attempt to operate the equipm...

Page 38

2-16 s afety on the alinte 4 page d ) punch. The exact position of the cassette is always noted by the machine software during normal operation. If the position of the cassette is changed by hand then serious damage could result. Note the following caution: caution: after moving a cassette forward m...

Page 39

Alinte 4 page i nstallation g uide 2-17 2.3.1 interlocked covers figure 2.12 on page 2-17 , (alinte4page entry level) and figure 2.14 on page 2-19 (alinte4page sal) show the location of the interlocked covers. Warning: if the platesetter has to be run with a cover open and the interlocks over-ridden...

Page 40

2-18 s afety on the alinte 4 page figure 2.13 location of interlock covers: alinte4page sal 2 1.

Page 41

Alinte 4 page i nstallation g uide 2-19 figure 2.14 location of interlocked cassette door: alinte4page mal warning: all unqualified personnel must be prohibited from the area, while the machine is in the over-ridden state.The laser safety officer must be informed when the machine is in this state. 2...

Page 42

2-20 s afety on the alinte 4 page 2.3.3 interlock over-rides interlocks are defeated by inserting the approved engine actuator key into the interlock switch shown in figure 2.15 on page 2-20 (engine) and figure 2.16 on page 2-21 (autoloader). Operating an over-ridden system allows the platesetter to...

Page 43

Alinte 4 page i nstallation g uide 2-21 figure 2.16 fitting the interlock over-ride key: autoloader while the key is in the switch, it is impossible to shut the interlocked door and cover to prevent the engineer from leaving the machine with the interlocks defeated. 2.4 laser safety caution: use of ...

Page 44

2-22 s afety on the alinte 4 page maximum power output from this laser source is class iiib . Light from the edge detect laser is in the red spectrum at 635 nm for plate edge detection. Maximum power output is 0.8 mw . 2.4.1 laser precautions laser power is set at the factory from the nvram paramete...

Page 45

Alinte 4 page i nstallation g uide 2-23 figure 2.17 optic base shutter 2.4.3 laser safety warnings laser light, because of its special properties, poses safety hazards not associated with other light sources. The use of lasers requires that all service engineers and everybody near the laser system, ...

Page 46: 2.4.3.1 A Dla Room

2-24 s afety on the alinte 4 page laser beams can ignite volatile substances, such as alcohol or other solvents and damage light-sensitive elements in, for instance, photo- diodes. Reflected beams can also cause damage. Laser safety warnings must at all times comply with local and national regulatio...

Page 47

Alinte 4 page i nstallation g uide 2-25 figure 2.18 typical laser warning signs no entry to unauthorised personnel when warning light is on laser class 3b operations no entry to unauthorised personnel when warning light is on laser class iiib operations u.S.A. European.

Page 48

2-26 s afety on the alinte 4 page.

Page 49: 3.1.1 Consignment Check

U npacking and h andling 3.1 unpacking the equipment 3.1.1 consignment check the local engineer or agent must ascertain, from a ffei-compiled list or the shipper's consignment note, that the consignment is correct. Any deficiencies must be reported immediately. Depending on the ordered alinte4page c...

Page 50

3-2 u npacking and h andling stacker (if ordered) processor (semi- and fully-automatic) pat air filter (all variants) installation pack (all variants) - see table 3.1 on page 3-5 . Dimensions and weights of the packed modules for all variants is given in the alinte4page ctp pre-installation guide. N...

Page 51: Tip-N-Tell

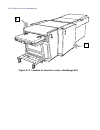

Alinte 4 page i nstallation g uide 3-3 figure 3.1 mishandling indicators 3.1.3 unpacking the modules caution: two people are required to manoeuvre the engine while it is supported by castors. The module is very heavy and includes delicate items of equipment. Caution: modules should be left for a 24 ...

Page 52

3-4 u npacking and h andling check for signs of moisture inside the module. Make a note of any defects in the installation report . 6. Carefully cut away the vacuum seal wrapping and remove any bubble-wrap. 7. Remove the front block of the wooden frame to the palette, see figure 3.2 on page 3-4 , be...

Page 53

Alinte 4 page i nstallation g uide 3-5 8. Remove any foam inserts around the palette. 9. Use the fork-lift truck to remove the module from the palette, see also section (crossrefformat> “using a fork-lift” on page 3-7 . A limit block at the rear of the plinth locates the position of each fork before...

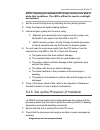

Page 54

3-6 u npacking and h andling note: the vacuum pump and pat are supplied as part of a sep- arate country pack, depending on what needs to be installed for the local voltage range. 3.1.4 unpacking the processor caution: four people will be required to lift the processor and one to remove the palette. ...

Page 55

Alinte 4 page i nstallation g uide 3-7 castors are fitted to allow modules to be moved short distances and for manoeuvring it into its working position. Check that the floor of the intended route is suitable and avoids jolts, bumps and vibration. Caution: ensure the operating area is clean and free ...

Page 56

3-8 u npacking and h andling.

Page 57

I nstalling alinte 4 page e quipment and s oftware 4.1 start the installation 4.1.1 special tools required as well as the basic service toolset, you will need additional tools for installing the system: 4 this chapter shows how to install and connect the alinte4page plateset- ter equipment for a man...

Page 58

4-2 i nstalling alinte 4 page e quipment and s oftware socket set up to 12 mm (metric) 600 mm spirit level adjustable spanner up to 30 mm jaw space. 4.1.2 pre-install checks before installing the platesetter make sure the pre-install checks in the pre-installation guide have been completed. If there...

Page 59

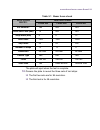

Alinte 4 page i nstallation g uide 4-3 e ) repeat steps b ) and c ) for the other two directions. F ) total the readings for each direction separately. G ) if the gradient total is less than 30 mm ( 1.18 in) for all three directions then proceed with the installation. Figure 4.1 checking floor gradi...

Page 60

4-4 i nstalling alinte 4 page e quipment and s oftware figure 4.2 removing covers and doors: alinte4page covers and doors should be completely removed from modules dur- ing the installation in order to access assemblies. Where possible, refit them to protect the interior from dust contamination. Not...

Page 61: Ual)

Alinte 4 page i nstallation g uide 4-5 screws located underneath the door. Interlocked ( i ) covers include a sensor to detect if they are open or closed. Before powering on the system ensure that all interlocked covers are closed, or the interlocks are overridden using the keys shown in section 2.3...

Page 62: Auto)

4-6 i nstalling alinte 4 page e quipment and s oftware 2. Lift the cover towards the back of the machine to release it from below the load platen. 4.1.3.3 remove entry level engine top cover (semi- auto) the top cover on the entry level semi-automatic engine, shown in figure 4.4 on page 4-6 , is rem...

Page 63

Alinte 4 page i nstallation g uide 4-7 position the vacuum pump. Caution: obtain assistance before lifting or manoeuvring any large modules. 4.1.5 installation sequence 4.1.5.1 semi-automatic (alinte4page entry level) install a semi-automatic system in the the following module order figure 4.5 on pa...

Page 64: 4.1.5.3 Alinte4Page Sal

4-8 i nstalling alinte 4 page e quipment and s oftware figure 4.6 install sequence: alinte4page semi-automatic 4.1.5.3 alinte4page sal one sal only : install a fully-automatic system in the the module order shown in figure 4.7 on page 4-8 . Two or more sals : install the first system as shown in fig...

Page 65: 4.1.5.4 Alinte4Page Mal

Alinte 4 page i nstallation g uide 4-9 4.1.5.4 alinte4page mal install a multi-cassette system in the the following module order figure 4.8 on page 4-9 . Figure 4.8 install sequence: alinte4page mal 4.2 install the processor caution: lifting this unit is a five-man operation. Using the supplied inst...

Page 66

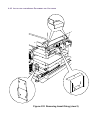

4-10 i nstalling alinte 4 page e quipment and s oftware remove the following transit fixings: a ) traverse carriage - see “traverse carriage transit fixing” on page 4-10 b ) platen - see “platen transit fixings (entry level only)” on page 4-12 . C ) mmi console cover. 4.3.1.1 traverse carriage trans...

Page 67

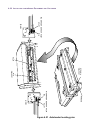

Alinte 4 page i nstallation g uide 4-11 figure 4.9 removing the traverse transit bolt transit bracket screw fixing points screw fixing point orange transit screw.

Page 68

4-12 i nstalling alinte 4 page e quipment and s oftware figure 4.10 fitting the ball cage 5. From the service side : from the right hand side of the carriage, support the carriage by hand and unscrew the orange transit fixing screw fully-anti-clockwise. It is not possible to remove it completely unt...

Page 69

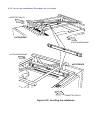

Alinte 4 page i nstallation g uide 4-13 4.3.2 integrate the processor and engine 4.3.2.1 set the processor height using the supplied oem installation manual, install the processor and its chiller unit. See figure 4.11 on page 4-15 . 1. Locate the processor in its correct working position. 2. Remove ...

Page 70: 10.

4-14 i nstalling alinte 4 page e quipment and s oftware 6. Adjust the engine height until the underside of the steel rule is approximately 2 mm above the lower input roller. Check from each end. If the floor is outside the recommended minimum specification, set the anchor feet to their lowest settin...

Page 71: 4.3.3.1 Manual System

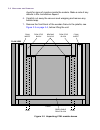

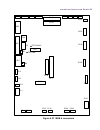

Alinte 4 page i nstallation g uide 4-15 figure 4.11 levelling the engine and processor 4.3.3 level the engine 4.3.3.1 manual system see figure 4.12 on page 4-16 . 1. Locate the engine in its working position. 2. Set the height as shown in figure 4.11 on page 4-15 . Ruler plastic input rollers rubber...

Page 72: 4.3.3.2 All Variants

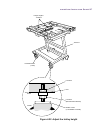

4-16 i nstalling alinte 4 page e quipment and s oftware figure 4.12 adjusting the engine castors and feet 4.3.3.2 all variants 1. Service to user direction : place a 600 mm spirit level on the traverse motor drive rail, avoiding the encoder scale, see figure 4.13 on page 4-17 . Anchor foot castor 12...

Page 73

Alinte 4 page i nstallation g uide 4-17 ensure that the horizontal level between the two ends is less than 0.5 mm. 2. Input to output direction: using a 600 mm spirit level, check along the top of the engine skin. 3. Make sure the full weight of the machine is evenly on all four anchor feet and ther...

Page 74

4-18 i nstalling alinte 4 page e quipment and s oftware figure 4.14 remove the diverter transit fixings 1. Remove the top interlocked cover from the autoloader. 2. Remove the nudger lift and diverter transit fixings (2-off m4). 3. Remove the cassette lid and lift out the two polystyrene blocks. 4. R...

Page 75

Alinte 4 page i nstallation g uide 4-19 figure 4.15 remove the nudger transit fixings 4.4.1.1 remove the mls transit fixings remove the following (see figure 4.16 on page 4-20 ): a ) tape holding the door closed. B ) transit screw on the m-roller assembly. Nudger lift transit fixing (right) nudger l...

Page 76

4-20 i nstalling alinte 4 page e quipment and s oftware figure 4.16 mls transit screw transit screw m-roller assembly mls cover tape (both ends) nudger frame nudger transit fixing nudger arm.

Page 77

Alinte 4 page i nstallation g uide 4-21 4.4.2 mate the autoloader and engine the autoloader and engine are mated as follows: 1. Move the autoloader close to the engine and route the following cables between the two units: 1. V6a_ilock : from the autoloader interlock switch to the free end of v6_iloc...

Page 78

4-22 i nstalling alinte 4 page e quipment and s oftware 3. Mate the autoloader to the engine adaptor assembly as follows: a ) locate the two adaptor plate pins inside the two autoloader keyholes. B ) raise the autoloader feet gradually (using a 8 mm spanner) so that the two adaptor assembly pins are...

Page 79

Alinte 4 page i nstallation g uide 4-23 figure 4.19 locate the adaptor pins and keyhole slots m5 screw (5-off) adaptor assembly (fitted to engine) autoloader adaptor plate pin (2-off) keyhole (2-off) autoloader adaptor assembly keyhole pin in slot contacting lower lip.

Page 80

4-24 i nstalling alinte 4 page e quipment and s oftware 4.4.3 level the trolley and cassette note: it is very important that the cassette lid is closed cor- rectly after loading plates, and that both latches are holding the lid in place. Failure to do this will result in plate loading or paper handl...

Page 81

Alinte 4 page i nstallation g uide 4-25 4. Pull out the cassette and tighten all four castor locknuts. 5. Push the cassette back into the bay and make sure that the locating pins locate smoothly into the cassette, and you can hear the cassette latch ‘snap’ to engage correctly. Check that the latch i...

Page 82

4-26 i nstalling alinte 4 page e quipment and s oftware figure 4.21 autoloader locating pins loca ting pin la tch bumper lo c ating p in hole la tch pin la tch hooked around pin la tch pin la tch hooked around pin view 1 view 2.

Page 83

Alinte 4 page i nstallation g uide 4-27 figure 4.22 adjust the trolley height locknut locknut (below pad position) pad wheel hood (clockwise to raise) wheel trolley castor wheel (4-off) trolley base 1 2 check levels 1 and 2.

Page 84

4-28 i nstalling alinte 4 page e quipment and s oftware 4.4.4 set the second trolley height if the installation has two or more autoloaders then the height adjust- ment for each machine should allow the transfer of trolleys between autoloaders. To set the trolley heights follow the procedure set out...

Page 85

Alinte 4 page i nstallation g uide 4-29 do not remove the mls transit bolt. Connect the diagnostic cable between the rip pc or laptop and msb 4 (pl16), see figure 4.27 on page 4-35 . If you need to manually raise or lower the shelves then use the procedure in “remove transit fixings using the brake ...

Page 86

4-30 i nstalling alinte 4 page e quipment and s oftware figure 4.23 locating the top adaptor plate 3. Locate the autofeeder in its working position next to the autoloader and adjust the four jacking feet to get the two modules approximately level. 4. From the service end first, lift off the wooden t...

Page 87

Alinte 4 page i nstallation g uide 4-31 7. Adjust the level of the autofeeder so the adaptor plate extensions are level with the two opposing cassette support ledges. Slide a small metal rule along the two surfaces and check that it moves smoothly across in both directions, see figure 4.25 on page 4...

Page 88

4-32 i nstalling alinte 4 page e quipment and s oftware figure 4.24 levelling the autofeeder cassette/trolley cassette/trolley autoloader/engine autoloader/engine autofeeder autofeeder.

Page 89

Alinte 4 page i nstallation g uide 4-33 figure 4.25 ledges and extensions are level 4.5.2 connect the autofeeder cables attach the following cables betwwen the autoloader and the auto- feeder: v6af_mains_feed (99700688): this is routed to avoid signal cables. Fit the iec connector at the rear of the...

Page 90

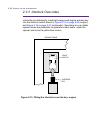

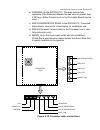

4-34 i nstalling alinte 4 page e quipment and s oftware page 4-34 . Figure 4.26 interlock box to mains connection msb_power (99700690): connect the free end from the interlock box ilock msb3 connector to msb 4 (pl31). Route the cable through the top access hole in the autofeeder. Mains output to aut...

Page 91

Alinte 4 page i nstallation g uide 4-35 figure 4.27 msb 4 connectors pl8 pl10 pl25 pl24 pl23 pl7 pl9 pl12 pl14 pl21 pl26 pl18 pl19 sk3 sk2 pl6 pl5 sk1 pl4 pl3 pl2 pl1 pl15 pl16 pl20 pl22 pl31 pl17 pl27 pl28 pl29 pl30 pl11 pl13 lk1 lk2 pl33 tp3 can 5v tp1 gnd.

Page 92

4-36 i nstalling alinte 4 page e quipment and s oftware figure 4.28 fit the earth wire v6af_earth (99700684): this cable is attached between the earth fixing points on the autoloader and autofeeder, see figure 4.28 on page 4-36 . Route the cable through the bottom access hole on the autofeeder. Warn...

Page 93

Alinte 4 page i nstallation g uide 4-37 figure 4.29 routing of autofeeder cables 4.5.3 remove transit fixings using the brake override warning: keep away from moving parts on or near the scissor-jack elevator while using this procedure. Safety features on the autofeeder are overridden. Use the brake...

Page 94

4-38 i nstalling alinte 4 page e quipment and s oftware item required : brake override switch assembly (7a10980). This assembly routes +24 vdc directly to the two safety solenoids and the brake relay to release the solenoids and the motor brake. 4.5.3.1 set up the brake override 1. Switch off the en...

Page 95

Alinte 4 page i nstallation g uide 4-39 figure 4.30 connecting the brake over-ride assembly msb4 inverter pl31 pl1/pl2 msb_pwr msb_door door_lock brake override assembly switch a b a b msb_pwr connect to connect to.

Page 96: 4.5.3.2 Lower The Elevator

4-40 i nstalling alinte 4 page e quipment and s oftware 4.5.3.2 lower the elevator 1. Depress the override switch and turn the elevator motor spindle anti- clockwise to tension the chain. 2. Depress the switch briefly in short steps to release the brake and allow the shelves to lower under their own...

Page 97

Alinte 4 page i nstallation g uide 4-41 b ) elevator side : remove the 2-off elevator side brackets (4-off screws) on each side. C ) cassette rear : remove the 1-off (2 screws) cassette rear bracket during the cassette change procedure. Figure 4.31 removing transit fixing (view 1) elevator side tran...

Page 98

4-42 i nstalling alinte 4 page e quipment and s oftware figure 4.32 removing transit fixing (view 2).

Page 99

Alinte 4 page i nstallation g uide 4-43 4. With the system switched on and the desktop application loaded, use the change cassette procedure (see the alinte4page user’s guide ) to open the cassette door. Caution: do not select the top shelf during a change cassette before removing the wooden transit...

Page 100

4-44 i nstalling alinte 4 page e quipment and s oftware figure 4.33 checking autofeeder-autoloader alignment 3. Push the cassette into the two location pins and note if the cassette front end has to ‘nudge’ in either horizontal direction to reach the correct mount position. Caution: always push the ...

Page 101

Alinte 4 page i nstallation g uide 4-45 note: unlatch the cassette from the autoloader by pulling back the latch arm under the cassette base. 4. If there is slight movement then: raise the autofeeder feet move the autofeeder slightly in the same ‘nudge’ direction to re-align with the location pins l...

Page 102

4-46 i nstalling alinte 4 page e quipment and s oftware figure 4.34 securing the autofeeder and autoloader 4.5.6 levelling the trolley 1. Use cassette change to remove a cassette on to the trolley. 2. Load the cassette with plates. 3. Adjust the trolley feet so that the side bumpers are level with t...

Page 103

Alinte 4 page i nstallation g uide 4-47 6. Two man lift : fit the top autofeeder pod and secure into position at each corner (4-off screws in support pack). 7. Refit all the covers..

Page 104

4-48 i nstalling alinte 4 page e quipment and s oftware figure 4.35 levelling the trolley bumper guide cassette bumper cassette bumper bumper guide.

Page 105

Alinte 4 page i nstallation g uide 4-49 4.6 set up the system 4.6.1 align carriage and ball cage both the traverse carriage and ball cage are setup manually so that they always move back and forward as aligned assemblies. The pro- cedure below is carried out at the user end of the engine. 1. Hold th...

Page 106

4-50 i nstalling alinte 4 page e quipment and s oftware 4.6.2 connect power and equipment see figure 4.37 on page 4-50 below. 1. Connect the following cables from the rear of the engine to the mains outlet and linked equipment: a ) external alert (to a remote light or buzzer supplied and fitted by t...

Page 107

Alinte 4 page i nstallation g uide 4-51 b ) firewire (to the rip/gui pc). This may include hub repeaters if the distance between the two units is greater than 4,500 mm. Either firewire port on the formatter board can be used. C ) rs232 diagnostics rs232 to the rip/gui pc, if required. Alternatively,...

Page 108

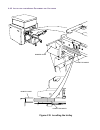

4-52 i nstalling alinte 4 page e quipment and s oftware 4.6.3 attach the pat air filtering system see figure 4.39 on page 4-52 below. The pat air filter (506id) reduces dust contamination inside the drum and optics module by generating clean filtered air. Use the supplied manufacturer’s installation...

Page 109

Alinte 4 page i nstallation g uide 4-53 1. Unpack the pat unit and move it to the recommended location of for the type of platesetter to ensure purity of air supply. Fully-automatic : next to the autoloader service door manual and semi-automatic : between the platen and the engine service door. See ...

Page 110

4-54 i nstalling alinte 4 page e quipment and s oftware note: make sure all tubes are fully seated to ensure a tight seal. You can moisten the tube end with water but do not use an oil- based lubricant. 2. Power/control cable : connect to the power outlet at the rear of the engine, see figure 4.37 o...

Page 111

Alinte 4 page i nstallation g uide 4-55 6. Feed the cable end, marked ‘g&j’ through the cable entry hole at the back of the box. 7. Fit the cable to the earth stud shown in figure 4.41 on page 4-56 (b). 8. Replace the processor cover. Figure 4.41 fitting the processor earth to the engine base earth ...

Page 112

4-56 i nstalling alinte 4 page e quipment and s oftware 4.6.5.2 heights (inca) earth cable fitting from the engine end: 1. Switch off the engine and isolate from mains supply. 2. Obtain the v6_processor_earth (99700651) from the support pack and pass one end through the cable entry slot (see figure ...

Page 113

Alinte 4 page i nstallation g uide 4-57 no punch machines : check that the alignment holes on the output plate and the drum output guide are aligned within 1 mm, see figure 4.42 on page 4-58 . Figure 4.42 no punch output alignment punch machines : check that the punch output platen is flush with the...

Page 114

4-58 i nstalling alinte 4 page e quipment and s oftware figure 4.43 punch output alignment 4.6.8 clean engine drum 1. If the engine doors have been opened for a lengthy period then vacuum the drum or clean it with a lintless cloth to remove dust. 2. Close all covers to prevent any more dust from ent...

Page 115

Alinte 4 page i nstallation g uide 4-59 4.7 install desktop applications and device driver the engine firmware is factory-installed from a set of cds supplied with the system. Note: the server installation guide and release notes, shipped on the server software media, provide the latest information ...

Page 116

4-60 i nstalling alinte 4 page e quipment and s oftware the server application must be running before the engine and pci functions correctly. The software on the supplied alinte4page ctp disk 1 cd is loaded using an installshield wizard. Note the following: 1. Install the pci software before the rip...

Page 117

Alinte 4 page i nstallation g uide 4-61 the product options (hardware and software) should be installed at this stage before plates are tested with customer jobs. To obtain the licence key for the ordered option(s), navigate to the ffei sio site (http://touchbase.Ffei.Co.Uk) and open the online inst...

Page 118

4-62 i nstalling alinte 4 page e quipment and s oftware 5. Switch on the engine. 6. Make sure the customer is aware of their keys by supplying a text file copy. Once the product is ready for shipping, you can obtain its licence key(s) from sio in advance of the installation start date. Other section...

Page 119

C ommissioning the alinte 4 page s ystem 5.1 start to commission the platesetter system commissioning is divided into stages: 1. Initial machine and software checks and setups : diagnostics menu and engine clock power supply interlock doors and covers traverse level check plate feed 5 this chapter d...

Page 120

5-2 c ommissioning the alinte 4 page s ystem processor setup. 2. Optics setups : the optics system is fully tested at the factory but needs to be configured for the installation. 3. Platesetter plate handling : plates are transported through the system and adjustments are made to handling mechanisms...

Page 121

Alinte 4 page i nstallation g uide 5-3 3. Set the properties options for the platesetter comms link to the terminal as follows: connect : com1 or 2. Settings : autodetect. Configuration : 9600 bits per sec; 8 data bits; no parity; 1 stop bit; no flow control. 32-bit display. 4. If you need to transf...

Page 122

5-4 c ommissioning the alinte 4 page s ystem 5.2.3 check cover interlocks see the alinte4page service guide . 1. Engine and autoloader : while the system is switched on, check the operation of the engine and autoloader interlocks. With the engine user door and autoloader top cover closed, enter: ser...

Page 123

Alinte 4 page i nstallation g uide 5-5 579 : autoloader top cover removed error code 577 indicates that the interlock system has failed. Run the following utility to check for the cause: service/sensors/environ 5.2.4 check engine traverse level note: check the level after the installation and again ...

Page 124: 10.

5-6 c ommissioning the alinte 4 page s ystem figure 5.1 check traverse level 7. Release the traverse servo-drive by entering: diagnostics/service/traverse/halt 8. Align and measure as in steps 3. And 4. Above. 9. If the difference between the measurements is greater than 0.5 mm, then an engine level...

Page 125

Alinte 4 page i nstallation g uide 5-7 note: checking the readhead led is best carried out in dark or white light conditions. The led is difficult to read in a safelight environment. 1. Set the correct trolley level by adjusting the four jacking screws. 2. Clean the engine and plate loading platform...

Page 126: 5.3.1 Check Beam Focus

5-8 c ommissioning the alinte 4 page s ystem 3. Set the processor plate thickness: medproc/thickness [value] where the [value] is the plate thickness (in μm) as: 0.15 = 150 0.20 = 200 0.24 = 240 0.30 = 300. 4. Check in the processor display that the processor pre-heat temperature zones change as pla...

Page 127

Alinte 4 page i nstallation g uide 5-9 figure 5.2 rip exposure settings: 48 resolution 3. In diagnostics find and record the rip exposure nd settings for 96 resolution shown in figure 5.3 on page 5-9 : nvram>dnv nd_res96_rip_expose figure 5.3 rip exposure settings: 96 resolution 4. Navigate to the v...

Page 128

5-10 c ommissioning the alinte 4 page s ystem figure 5.5 final values screen 5. In the final values table, set the 48 resolution nd value to the 48 resolution value recorded in step 1. 6. In the final values table, set the 96 resolution nd value to the 96 resolution value recorded in step 2. 7. Save...

Page 129: 10.

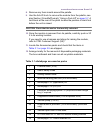

Alinte 4 page i nstallation g uide 5-11 the plate will eject when the test is complete. 10. Process the plate to reveal the three sets of test strips: the first two sets are for 96 resolution. The third set is for 48 resolution. Table 5.1 beam focus check auto focus macro: run test strips focus 96v ...

Page 130

5-12 c ommissioning the alinte 4 page s ystem 5.3.2 calculating values for 96 resolution test strips figure 5.6 96 resolution test strips note: figure 5.6 on page 5-12 shows the focus 96v and focus 96h test strips. Each set consists of 13 strips 8 mm wide. The focus setting for each strip is shown h...

Page 131

Alinte 4 page i nstallation g uide 5-13 4. Repeat steps one to three for the second set of focus 96h test strips. All six recorded values (first and second test strips) should be within 150 of each other, if not, check the plate again to confirm your recorded figures. 5. Calculate the average of all...

Page 132

5-14 c ommissioning the alinte 4 page s ystem enter the 96 resolution values into the 96, 100, 144, 2400 and 3600 bcf positions in the final values table. 5.3.3 calculating values for 48 resolution test strips figure 5.7 48 resolution test strips note: figure 5.7 on page 5-14 shows the focus 48h tes...

Page 133: 5.3.4.1 Mmi Menus

Alinte 4 page i nstallation g uide 5-15 4. Calculate the average of all three values recorded so far. The resulting average is the focus setting for 48 resolution for all plate thicknesses. 5. Enter the resulting resolution value into the 48, 50 and 1200 bcf positions in the final values table for a...

Page 134

5-16 c ommissioning the alinte 4 page s ystem figure 5.8 exposure calibration screen: mmi 2. Make a note of the current nd values in the exposure information screen 3. Press start calibration to measure the exposure level at the drum and calculate the nd settings of the filter wheel for all resoluti...

Page 135

Alinte 4 page i nstallation g uide 5-17 figure 5.9 nd values screen: mmi note: the nd settings for exposing rip images are stored directly on the engine and are not supplied by the rip. When exposure calibration has been performed, linearise the per- centage dots at the required resolutions and scre...

Page 136

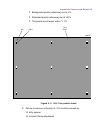

5-18 c ommissioning the alinte 4 page s ystem 1. Expose and process a grid image from the pci diagnostics (stock images folder) menu which gives vertical and horizontal lines. Use the largest possible plate size for this procedure, for example, 765 x 686 mm. Figure 5.10 plate registration check 2. C...

Page 137

Alinte 4 page i nstallation g uide 5-19 background points (reference) are at 0 %. Saturated points (reference) are at 100 %. Tint points are all equal within + /- 1%. Figure 5.11 50% tint predict check 3. Failure to achieve uniformity of ±1% could be caused by: dirty spinner incorrect focus adjustme...

Page 138

5-20 c ommissioning the alinte 4 page s ystem poor mechanical/vacuum conformance gum on plate increases dot% by 3% – 4% poor processor conditions for: a ) pre-heat b ) developer ph reading should be 12 ± 0.25 (11.75 to 12.25) c ) process time d ) developer scrub pressure. Consult ffei customer suppo...

Page 139

Alinte 4 page i nstallation g uide 5-21 3. Check that the led on the edge detect pcb is off when the beam is on the plate and on when the beam is on the drum. 4. Press ctrl-c to exit medirq. 5. Reboot the engine. 5.4 checking plate output (without a punch) see the user’s guide and service guide . Th...

Page 140

5-22 c ommissioning the alinte 4 page s ystem figure 5.12 image skew check 5.4.2 check image base and edge accuracy 1. Expose a tint on a 765 mm x 686 mm plate, or the largest plate available on-site. 2. Check that the distance between the image base and edge start positions as shown in figure 5.13 ...

Page 141

Alinte 4 page i nstallation g uide 5-23 6. If required, move the image edge offset direction using the procedure in “set image edge offset” on page 5-24 . Figure 5.13 image edge detect accuracy 5.4.3 set image base offset note: the image traverse centre position is factory-set and should not need to...

Page 142

5-24 c ommissioning the alinte 4 page s ystem to move the image nearer the registration pins, reduce the value. To move the image away from the pins, increase the value. Figure 5.14 setting the image base offset 5.4.4 set image edge offset 1. Open the optics_mmi setup screen from: optics> mmi 2. Run...

Page 143

Alinte 4 page i nstallation g uide 5-25 6. Repeat these steps until the edge of the plate to the image start position is 2 mm. 5.5 checking plate output (with a punch) these procedures apply to platesetters with a punch and check for: punch configuration : see “punch configuration check” on page 5-2...

Page 144

5-26 c ommissioning the alinte 4 page s ystem figure 5.15 alinte4page punch option configurations 8 mm punch a 6.35 mm x 9.525 punch b 12.68 mm x 10 punch c 12 mm x 14.68 mm heidelberg + bacher 425 mm 393 mm 220 mm a a b c b b 11 mm a = bacher b = heidelberg c = heidelberg ds400 400 mm a b 8 mm punc...

Page 145

Alinte 4 page i nstallation g uide 5-27 5.5.2 check image to top of plate accuracy note: this check only needs to be made if image skew is noticeable. C heck image to top of plate accuracy as follows: 1. Expose 4 plates with a 50% tint stock image. 2. Move the image (usually set at 2 mm ) as close a...

Page 146

5-28 c ommissioning the alinte 4 page s ystem 4. Calculate the skew over the full plate width as follows: skew = (a-b) x plate width in mm reg pin distance in mm (259, 305 or 470) 5. Skew should be less than 50 microns on each plate. 6. Possible skew errors could be caused by poor pull bar alignment...

Page 147

Alinte 4 page i nstallation g uide 5-29 3. Skew error differences between the measurements a and b should be less than 100 microns for each plate. 4. Possible skew errors could be caused by poor pull bar alignment - see the alignment procedure in the service guide . 5.5.4 check image base position i...

Page 148

5-30 c ommissioning the alinte 4 page s ystem 5.6 installing the remote alert forwarding the alinte4page alert forwarding system operates as an option within the desktop software (1.2 and later). Once enabled, it runs as a pc background utility to detect and report errors from the output engine. Ale...

Page 149

Alinte 4 page i nstallation g uide 5-31 figure 5.19 remote alert menu bar 5. The remote alert system is enabled for use by selecting: remote alert > enabled this global enable option allows the operator to switch the alert sys- tem on/off to start or stop alerts. Leave this selection disabled when c...

Page 150: 5.6.2.1 Local Mail Server:

5-32 c ommissioning the alinte 4 page s ystem emails are always sent via an smtp mail host. Even if using pop authentication you must still define the smtp host. Figure 5.20 mail configuration window 5.6.2.1 local mail server: 1. Obtain the mail server url from the site it administrator. 2. Enter th...

Page 151: 5.6.2.5 Pop Authentication

Alinte 4 page i nstallation g uide 5-33 2. Tick the smtp authentication check box, see figure 5.21 on page 5- 33 . 3. Enter the supplied id in the user id field below. 4. Enter the password in the password field. 5.6.2.4 web-based mail host 1. Use the user id and password for the mail account. 2. Ti...

Page 152

5-34 c ommissioning the alinte 4 page s ystem figure 5.22 pop authentication 2. Obtain the pop mail server url from the site it administrator. 3. Enter this address in the pop mailhost field. 4. Enter the pop tcp/ip port number supplied by the site it administrator. For a local mail host this will n...

Page 153

Alinte 4 page i nstallation g uide 5-35 3. Enter the password in the password field. 5.6.3 configure the alert system 1. Select view > destinations window to set the destination of the operator receiving the alert. 2. Click on create to open a window when the destination is a mobile: 3. Enter the fo...

Page 154

5-36 c ommissioning the alinte 4 page s ystem alerts then also add their destination details. Operators can be enabled and disabled depending on their work shifts. Select edit or remove to alter or remove the name details from the destinations window. 5. Select view > errors to open the errors windo...

Page 155

Alinte 4 page i nstallation g uide 5-37 6. Select the errors requiring an alert and click on enabled check box. For instance, to check for an error message, select 572 (user open.

Page 156: 10.

5-38 c ommissioning the alinte 4 page s ystem door error) and open and engine door. The system will beep and then send the error report. 7. Save and close the window. 8. Click on test and open the test destination window to check if the alert forwarding system is correctly configured. 9. Click on se...

Page 157

D emonstrating the alinte 4 page s ystem 6.1 demonstrate the platesetter as a final task, the installation engineer (or a qualified representative) needs to give the customer a brief description of the platesetter's main features. The aim is to ensure that the customer understands how to: operate th...

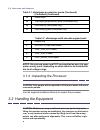

Page 158: 6.2.1 Laser Safety

6-2 d emonstrating the alinte 4 page s ystem recover from an error condition. 6.2 platesetter safety and interlocks 6.2.1 laser safety the customer should be aware of the main safety interlocks and their function in preventing the laser beam from damaging eyesight. They should also understand that u...

Page 159

Alinte 4 page i nstallation g uide 6-3 6.3 using the mmi (if fitted) and pci show the customer how they can navigate the mmi/pci menus between the two modes of operation: run and pause. Explain the options available for each mode. 6.4 platesetter maintenance take the operator through the maintenance...

Page 160

6-4 d emonstrating the alinte 4 page s ystem 6.4.5 vacuum clean the platesetter show the customer how and when to vacuum clean the interior of the platesetter and cassettes. Areas for particular attention are: drum interior - using a vacuum cleaner or lint-free cloth cassette recesses - emphasise th...

Page 161

Alinte 4 page i nstallation g uide 6-5 6.5.1.1 recovery from system errors system faults (electrical, optical, etc) are usually interpreted by error codes that appear on the mmi/pci. Customers should be advised to note the code number and call the local distributor customer support. 6.6 loading cass...

Page 162

6-6 d emonstrating the alinte 4 page s ystem 6.7.3 ordering new options explain how the customer can order new options from the list dis- played from the pci option..